Pull-out type glass kiln flue gas dust removal device and application

A glass kiln and dust removal device technology, which is applied in gas treatment, transportation and packaging, and dispersed particle filtration, etc. It can solve the problems of large solid particles sticking to the chimney and achieve the effects of simple structure, enhanced purification effect, and reduced solid particles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

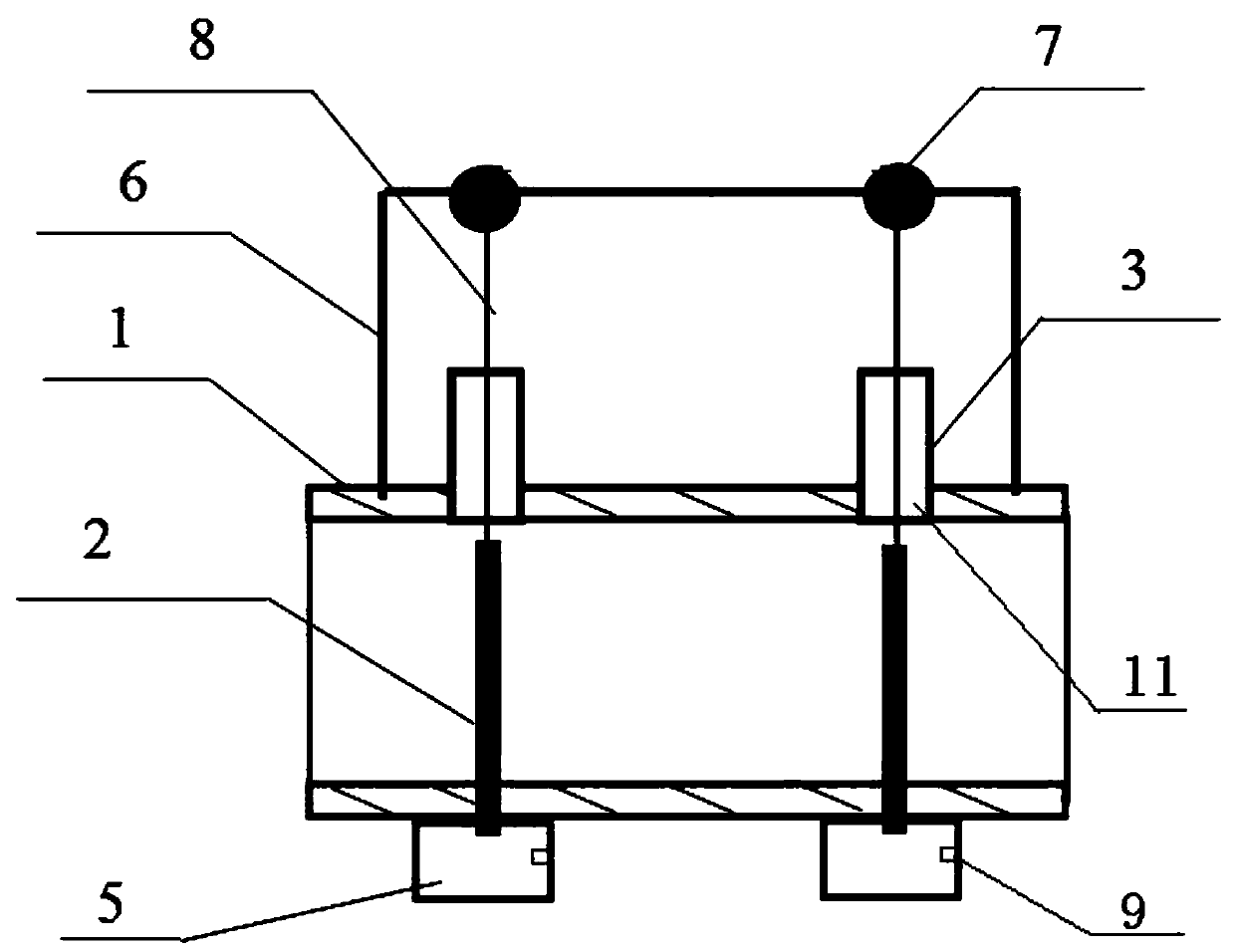

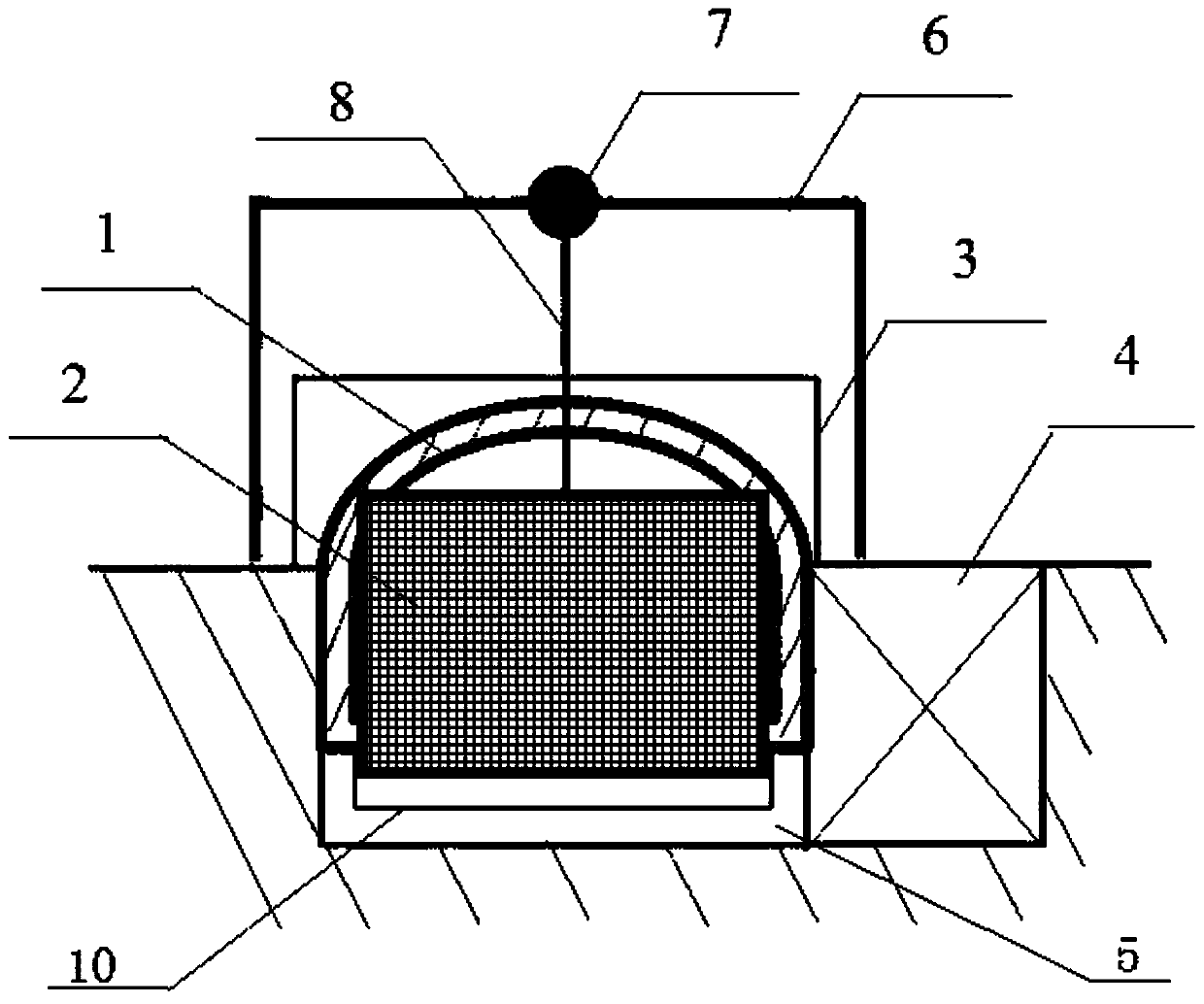

[0036] Such as Figure 1-2 As shown, the present embodiment provides a pull-type glass kiln flue gas dust removal device, including a flue 1, a grid 2, a transmission frame 6, a transmission wheel 7, a transmission chain 8 and a motor, and the flue 1 is Set the commutator and the general gate, between the commutator and the general gate, set the opening 11 above the flue 1 at a distance of 0.5m from the commutator, set slots on both sides of the flue opening 11, and grid 2 Insert the flue through the opening 11 and the slot, dig a corresponding rectangular ash collection pit 5 in the bottom of the flue 1 on the lower side of the grid 2, and set the ash pit 4 on one side of the flue 1, and the ash pit 4 is connected with the ash collection. The pit 5 is connected, and the transmission frame 6 is installed above the flue 1. The transmission frame 6 is a rectangular parallelepiped frame. A plurality of beams are arranged on the upper side of the transmission frame 6. A motor is i...

Embodiment 2

[0038] A pull-out glass kiln flue gas dust removal device, the structure is as described in Example 1, the difference is that between the commutator and the main gate, above the flue 1 at a distance of 1m from the commutator The opening 11 is set, and the sealing cover 3 is set on the upper side of the opening 11 of the flue 1. The sealing cover 3 is a cuboid as a whole, and the lower side of the sealing cover 3 fits the flue. The split-type airtight door is opened to both sides during the grille, and closed after the replacement is completed, and the airtight cover acts as a seal.

Embodiment 3

[0040] A pull-type glass kiln flue gas dust removal device, the structure is as described in Embodiment 1, the difference is that the grid hole diameter of the grid 2 is 10mm, and the grid 2 is made of alumina ceramic material. The double-layer structure strengthens the purification effect of flue gas, and alumina ceramics can withstand the high temperature of 600°C, ensuring that the grid will not be affected by the high temperature of flue gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com