Double-screw pump without bearing

A technology of screw shaft and main screw, which is applied in the direction of pumps, rotary piston pumps, rotary piston machines, etc., can solve the problems of complex structure, poor material suction and long axial dimension of twin-screw pumps, and achieve compact structure, Effects of improved suction performance and reduced axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

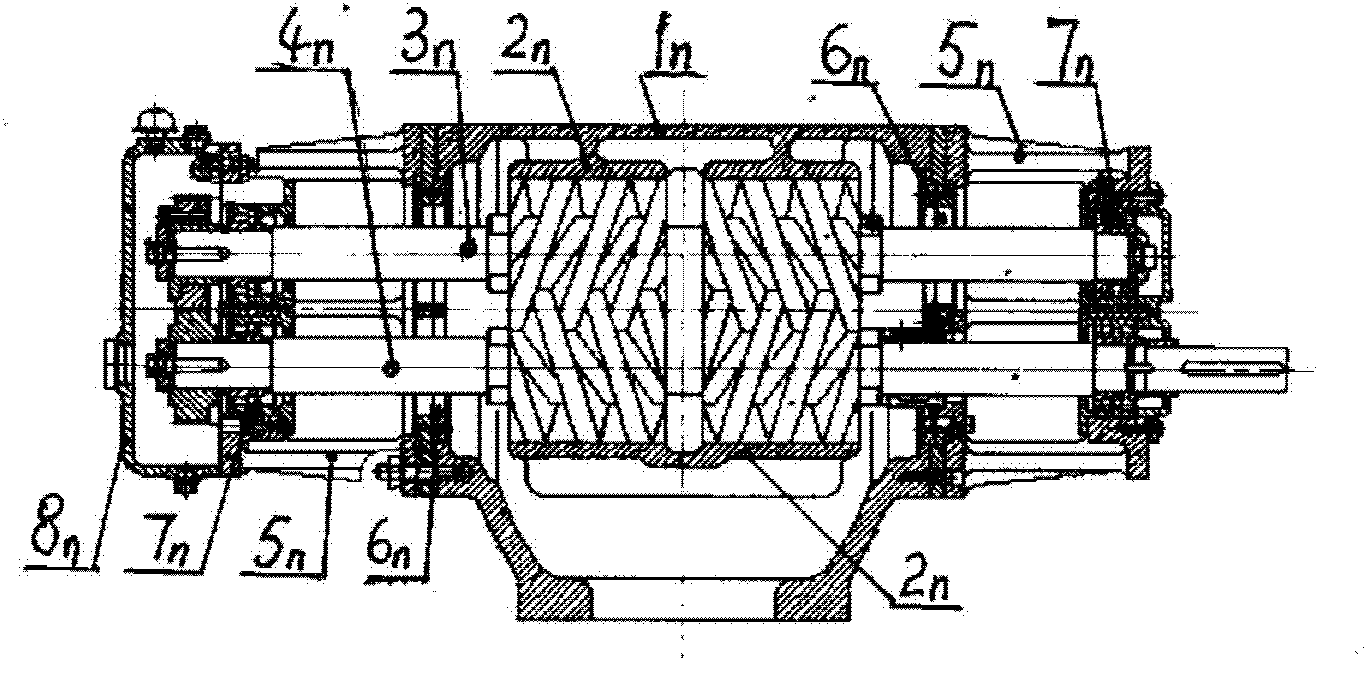

[0015] Example 1: see image 3 , Figure 4 , Figure 5 .

[0016] Bearingless twin-screw pump construction with removable split housing 1A.

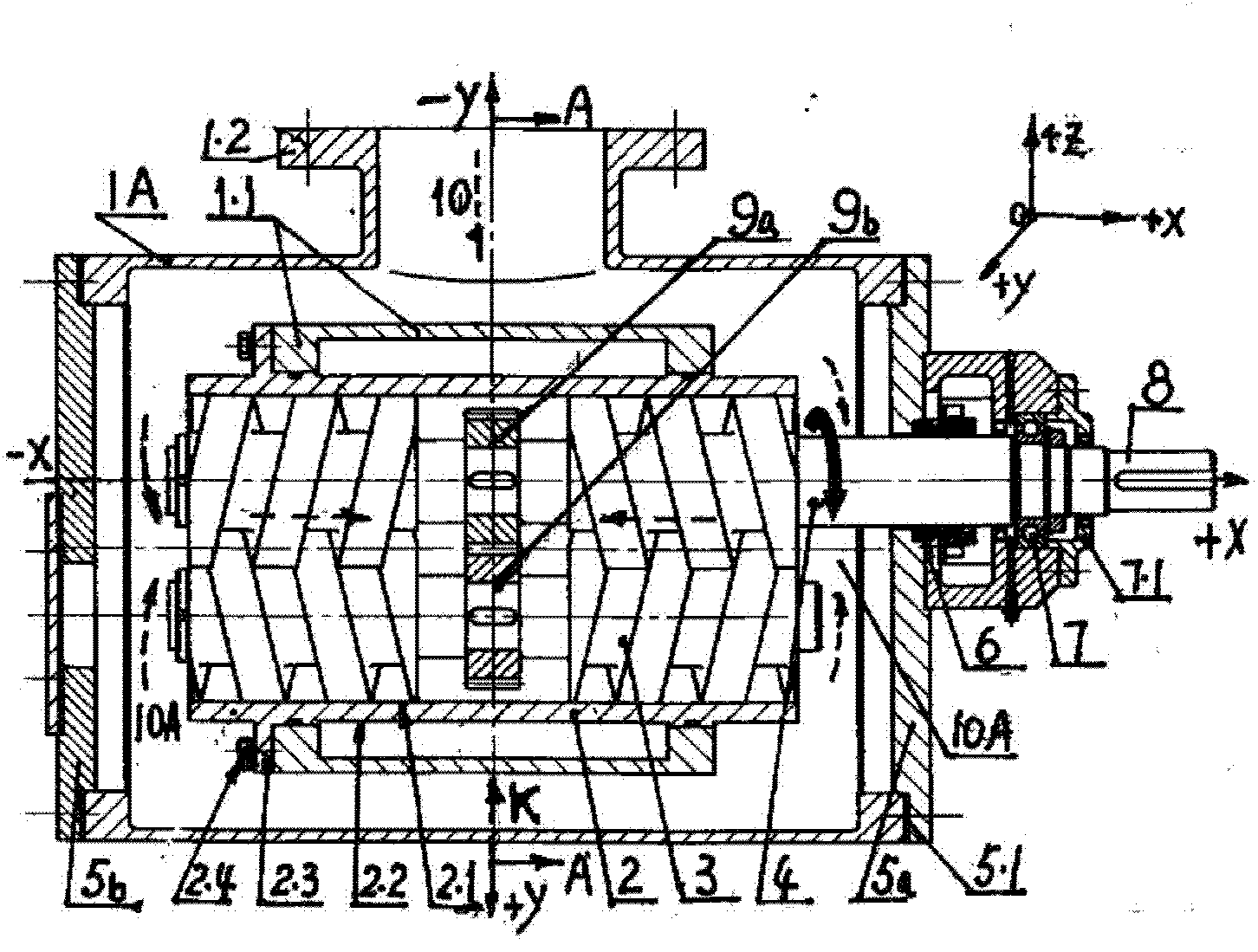

[0017] See image 3 , a bearingless twin-screw pump, with a detachable split casing 1A, inside the casing 1A is a working rotor formed by a main screw shaft 4 and an auxiliary screw shaft 3 arranged horizontally along the longitudinal direction Y. See Figure 4 , between the outer surface of the rotating main screw shaft 4 and the auxiliary screw shaft 3 and the inner surface of the stationary casing bushing 2 is a closely fitted 8-shaped mating surface 2.1, which is the main bearing surface 2.1 of the working rotor. See image 3 and Figure 4 , the outer surface 2.2 of the housing bushing 2 is placed in the housing seat 1.1, and the housing seat 1.1 is connected and fixed with the housing rib 1.3. See image 3 and Figure 5 , the rear end of the outer surface of the shell bushing 2 is fixed with a connecting plate 2.3, and the...

Embodiment 2

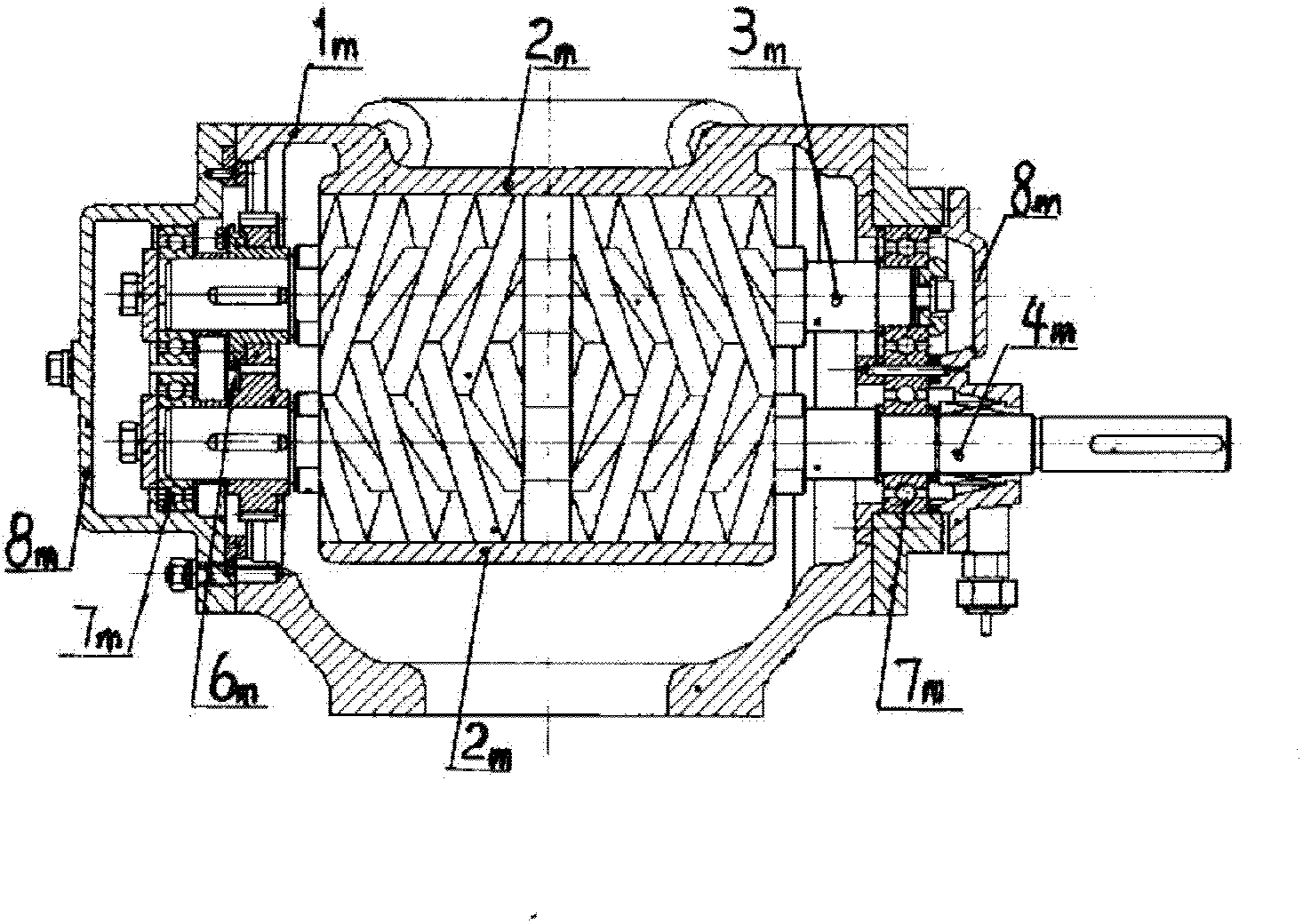

[0022] See Figure 6 , the integral shell 1 in which the shell bushing 2a and the shell 1 are fixed as one is adopted. with Example 1 image 3 Compare, Figure 6 There is no housing base 1.1 connected with bolts 2.4 outside the middle housing bushing 2a, and the housing bushing 2a is directly fixed to the housing 1 as a whole through the ribs below the vertical Z in the housing. Embodiment 2 is identical to Embodiment 1 except that the housing is integral, and will not be described again here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com