Turning clamp and turning method of polycrystalline rod material

A polycrystalline bar material and turning technology, which is applied in the direction of manufacturing tools, fine working devices, and working accessories, can solve problems such as irregular geometric shapes and failure to meet process requirements, and achieve high safety, stable clamping, and The effect of small radial runout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

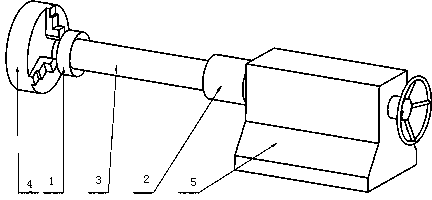

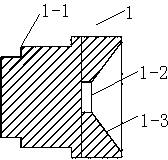

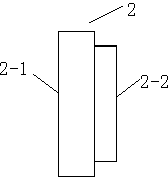

[0014] Such as figure 2 , 3 As shown, a polycrystalline bar turning fixture, the fixture includes a left end fixed plate 1, a right end fixed plate 2, the left end fixed plate 1 is a cylinder, one end of which is stepped 1-1, and the bottom end of the hole at the other end is a blind hole 1-2, the upper end in the hole is an inner cone surface 1-3, and the fixed disk 2 at the right end is a cylinder, one end of which is a plane 2-1, and the other end is a circular convex surface 2-2.

[0015] Such as figure 1 Shown, a kind of turning method step of polycrystalline bar stock is as follows:

[0016] Grind the left end of the polycrystalline rod 3 into a certain taper according to the size, cut the right end of the polycrystalline rod 3 into a plane, and the perpendicularity between the end surface and the center line of the polycrystalline rod 3 is less than 0.2mm, and then cut the polycrystalline rod 3 The right end face of the right end is glued together with the plane 2-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com