High-lift pump impeller for electric automobile

A water pump impeller, electric vehicle technology, applied to parts, pumps, pump components, etc. of pumping devices used for elastic fluids, can solve the problems of high power, narrow rated working area, large water inlet and outlet of water pumps, etc., to reduce input Power, avoid cavitation, reduce the effect of water inlet and outlet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

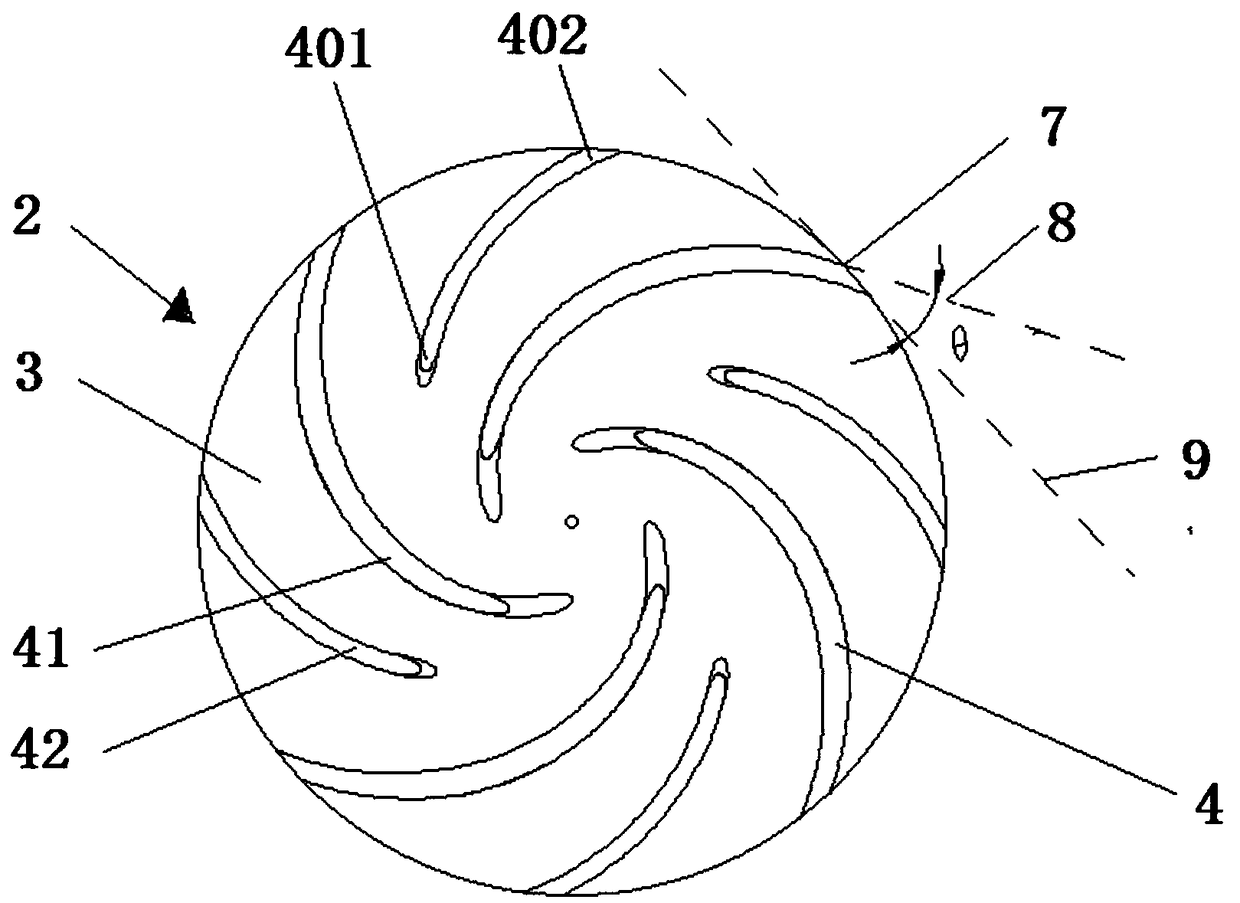

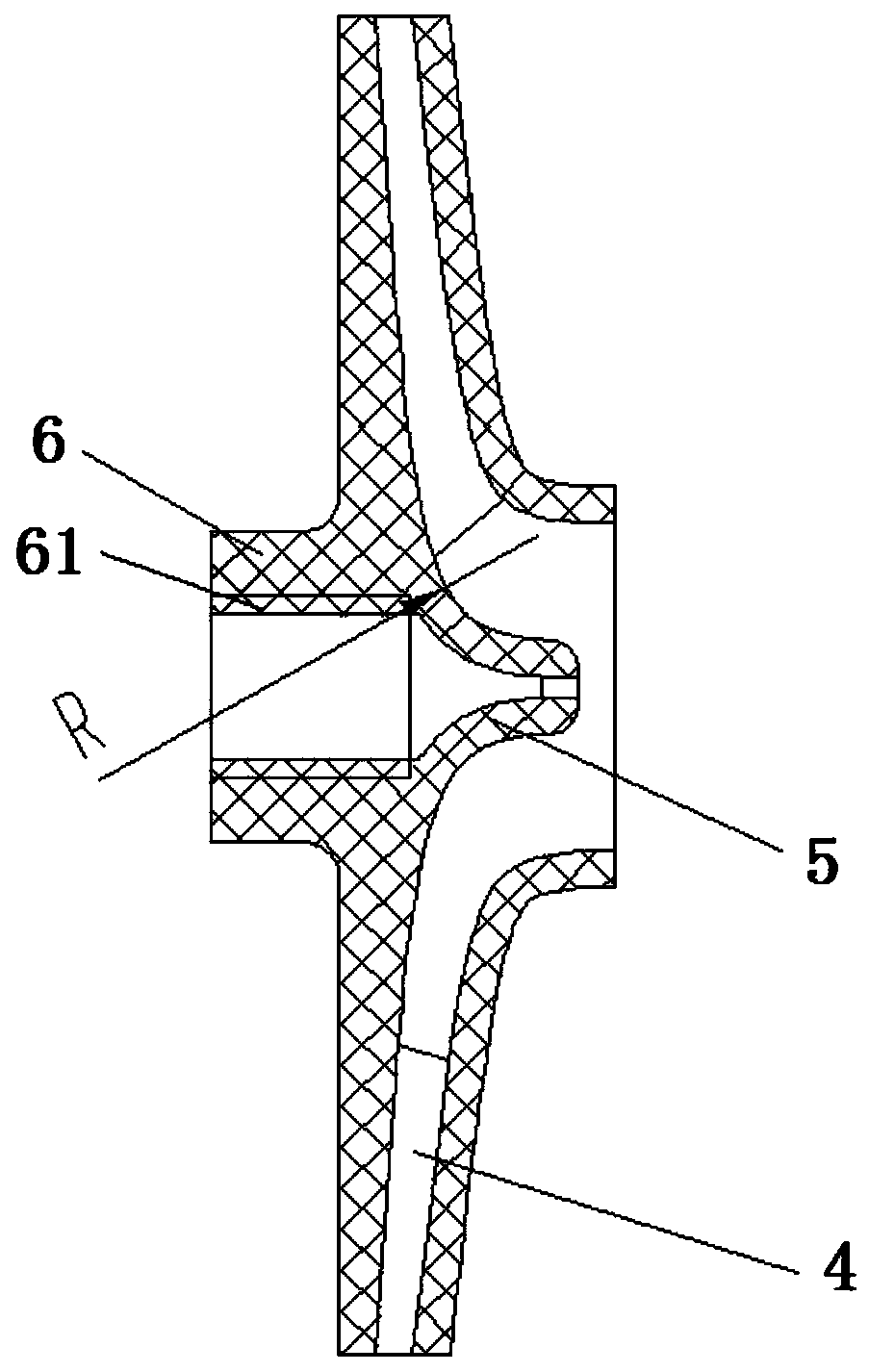

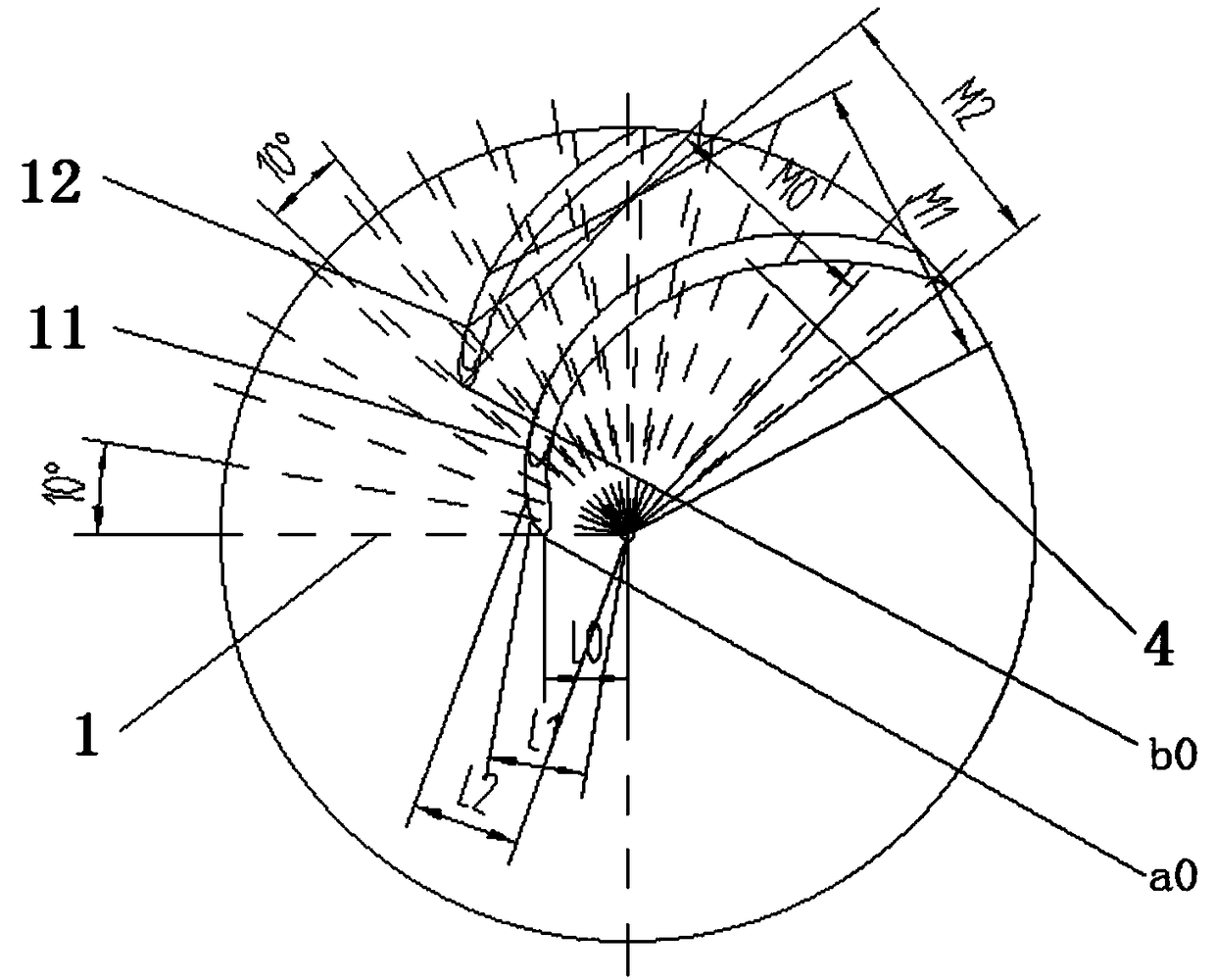

[0023] A high-lift water pump impeller for electric vehicles, as shown in the figure, includes an impeller 2 installed in the pump body, the impeller 2 includes a panel 3 and a blade 4 installed on the panel 3, and the blade 4 includes a main blade 41 and an auxiliary blade 42 , the main blade 41 and the auxiliary blade 42 are arranged around the center axis of the panel 3 , and the length of the main blade 41 is longer than that of the auxiliary blade 42 .

[0024] The blades 4 are all arc-shaped pieces vertically placed on the surface of the panel 3, the main blade 41 and the auxiliary blade 42 are arranged at intervals, the end of the blade 4 close to the central axis of the panel 3 is the starting end 401, and the other end of the blade 4 is the tail end 402.

[0025] The end 402 of the main blade 41 and the end 402 of the auxiliary blade 42 all extend to the edge of the panel 3, and the distance from the end 402 of the main blade 41 and the end 402 of the auxiliary blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com