Novel mixing equipment for interior decoration material production

A technology for interior decoration and mixing equipment, which is applied in mixers, transportation and packaging, and dispersed particle filtration, etc. It can solve the problems of blending, insufficient mixing, low mixing efficiency, and affecting adsorption capacity, so as to avoid insufficient mixing , Improve accuracy and speed up efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

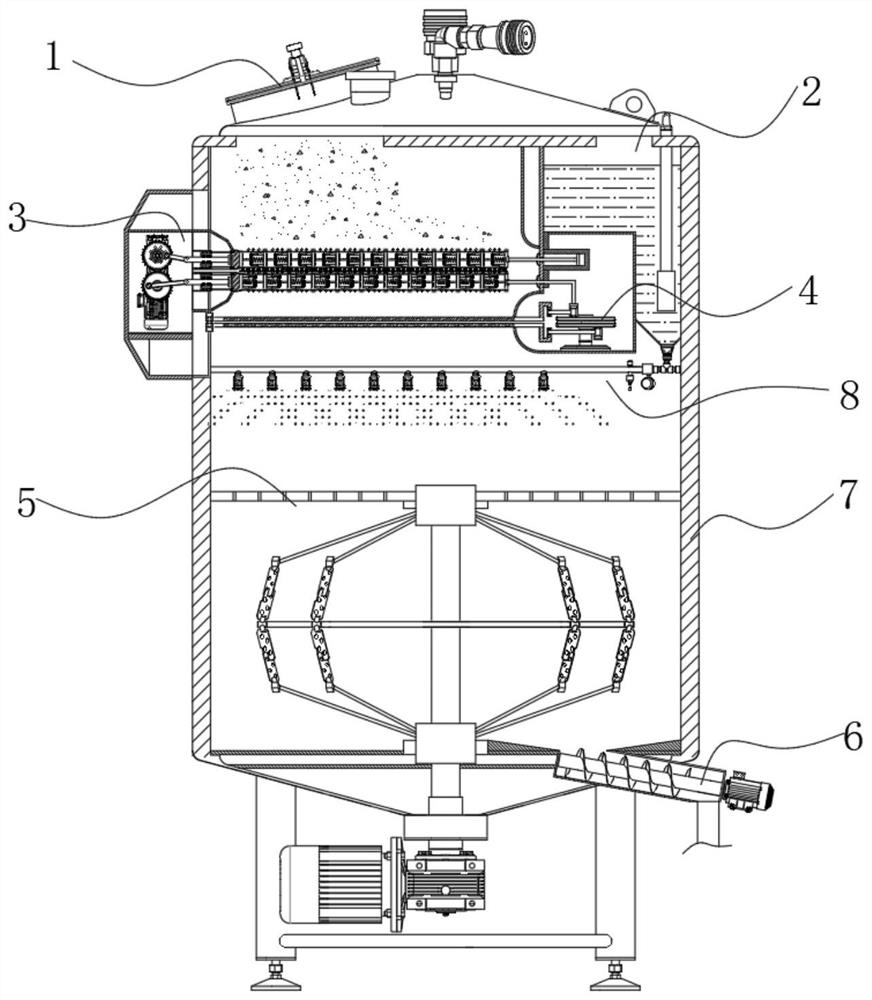

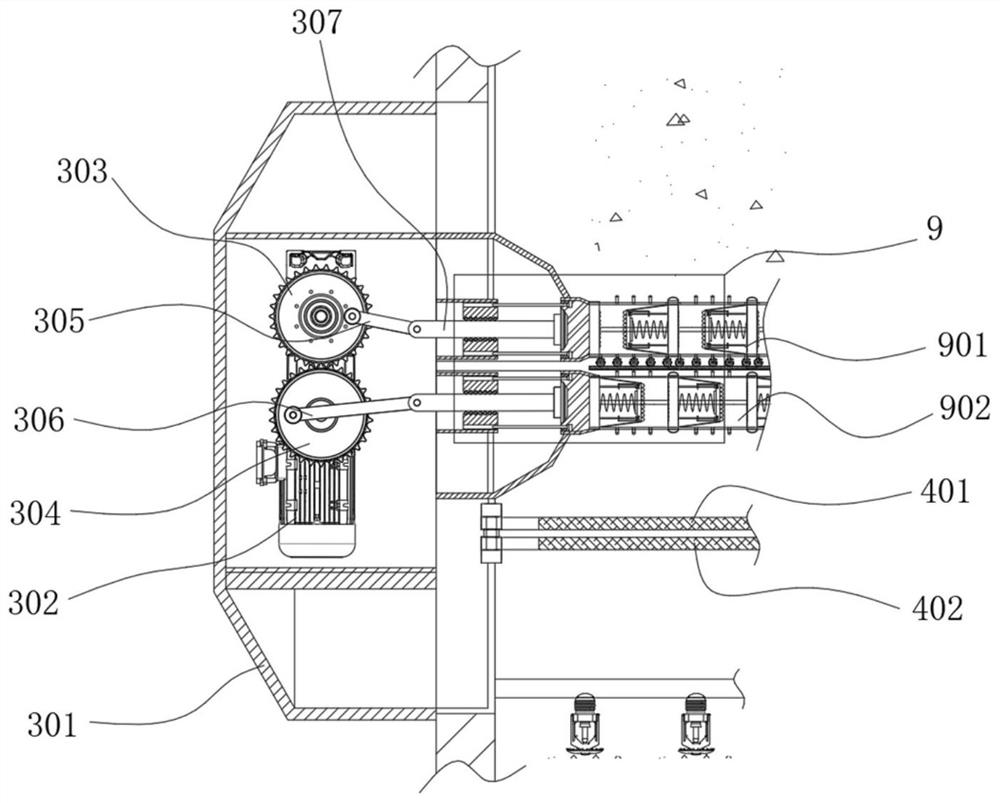

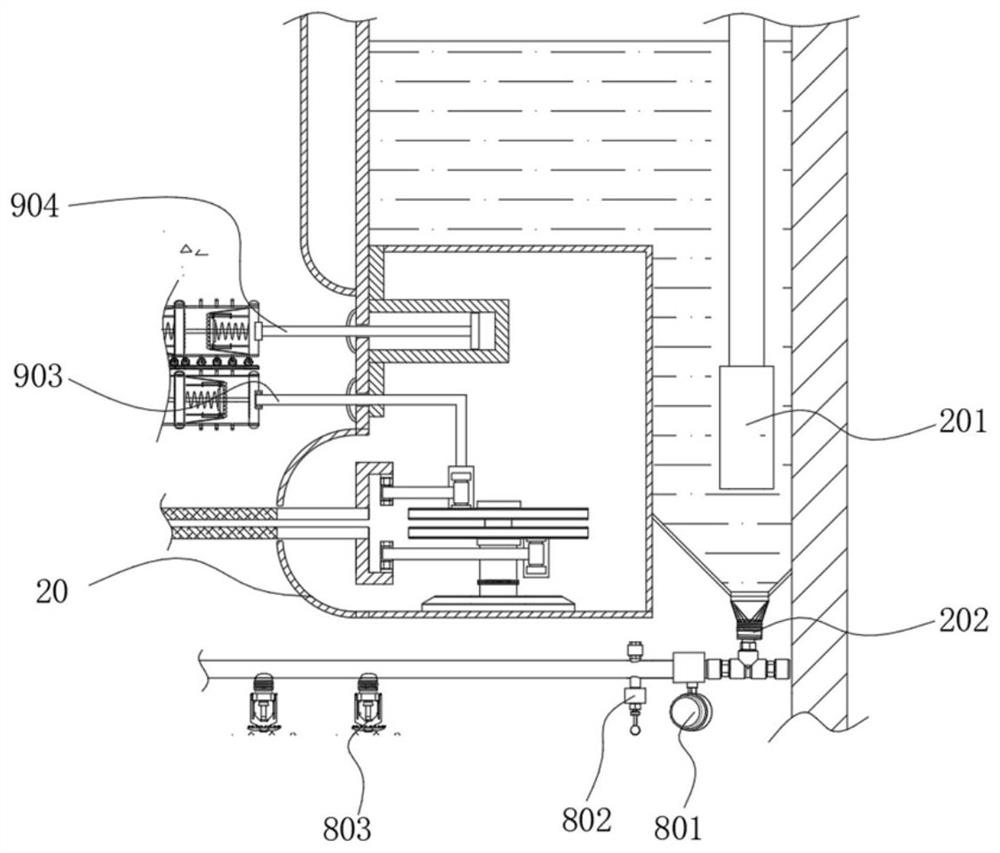

[0037] refer to figure 1, the present invention provides a technical solution: a new type of mixing equipment for the production of interior decoration materials, which includes a stirring tank 7, a feed port 1, an elastic milling assembly 3, a stirring device 5, and a discharge box 6, wherein the The elastic grinding assembly 3 is fixedly connected to the side wall of the upper end of the mixing tank 7 in the transverse direction, so that the upper space of the elastic grinding assembly 3 occupies a quarter of the inside of the mixing tank 7, and the elastic grinding assembly 3 is also equipped with a Dislocation diffusion assembly 4, the height of the gap between the elastic grinding assembly 3 and the dislocation diffusion assembly 4 is consistent with the height of the elastic grinding assembly 3, and the elastic grinding assembly 3 drives the dislocation diffusion assembly 4, by The elastic grinding component 3 grinds the crystal particles of the raw material of the devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com