Grain processing rice milling device

A grain and equipment technology, applied in the field of grain processing and rice milling equipment, can solve the problems of reducing the rice yield, incomplete rice grains, insufficient rice peeling, etc., and achieve the effect of simplifying the structure and simplifying the process of bran and rice production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

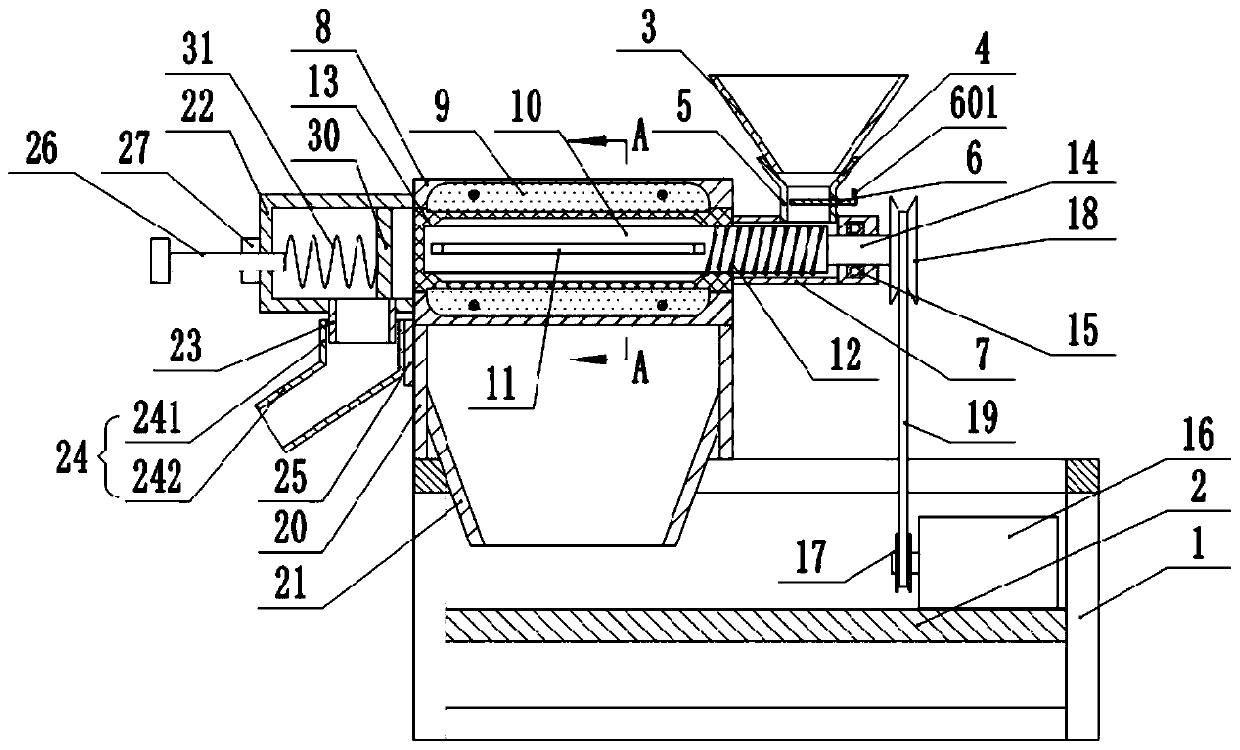

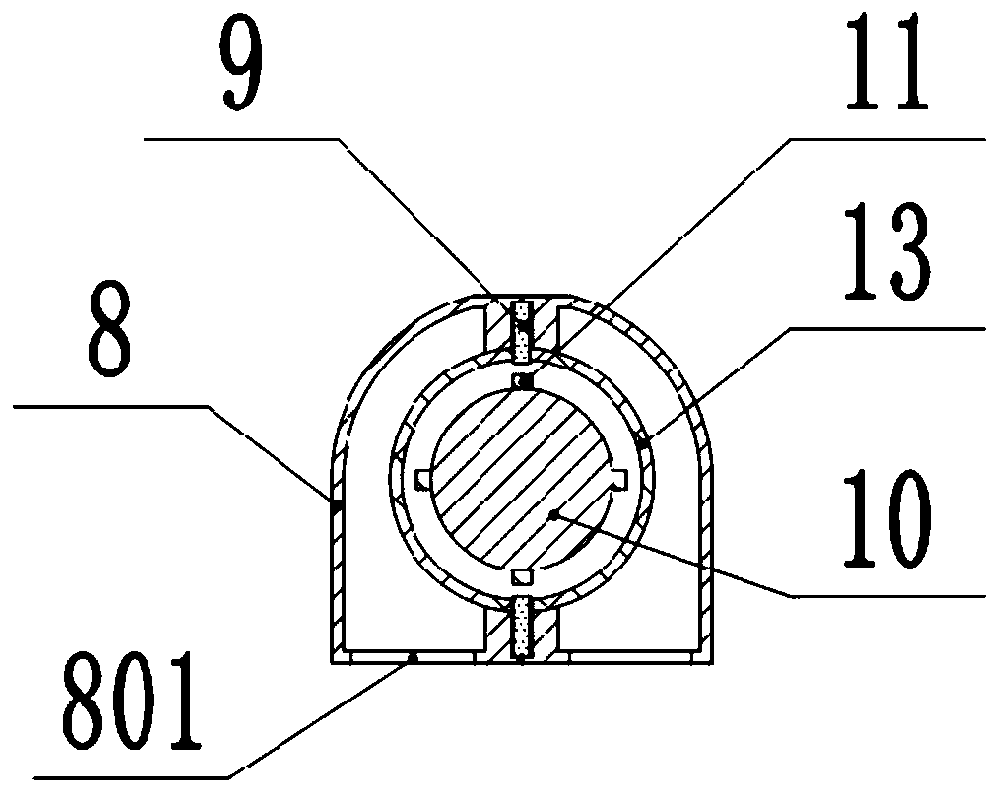

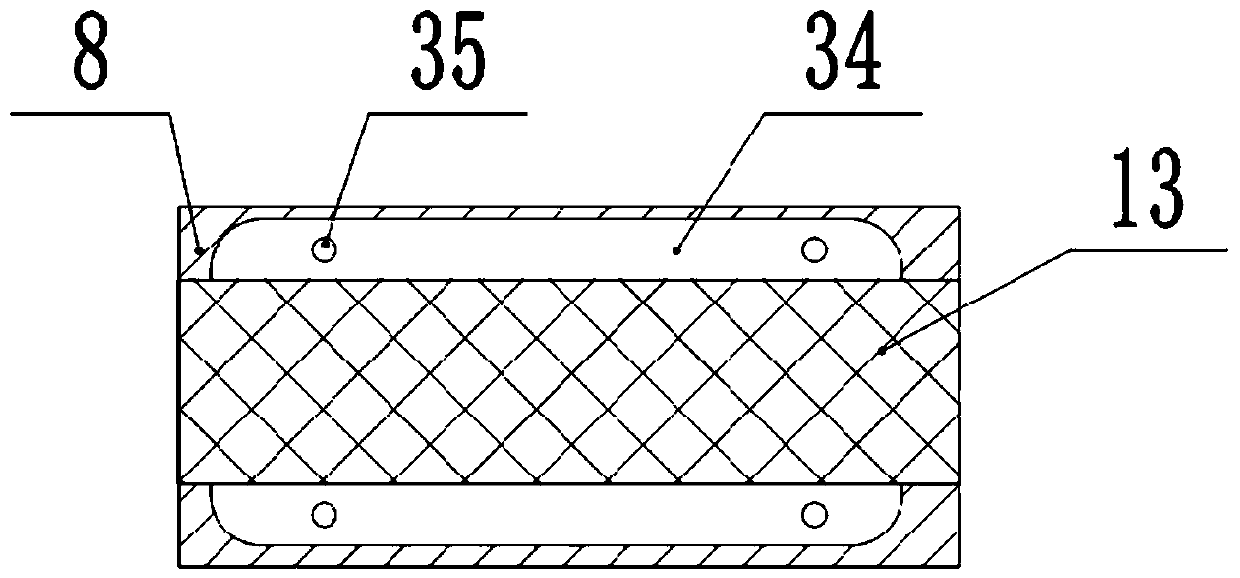

[0043] The embodiment is basically as attached figure 1 Shown: Rice milling equipment for grain processing, including the transmission mechanism, feeding mechanism, rice milling mechanism, and rice discharging mechanism arranged in sequence from right to left, and the bran discharging mechanism is arranged below the rice milling mechanism.

[0044] The feeding mechanism includes a feeding box 7 and a feeding hopper. In this embodiment, the feeding box 7 is cylindrical, and the inside of the feeding box 7 is hollow, and the feeding hopper communicates with the feeding box 7. In this embodiment, the feeding The bucket includes a first feed hopper 3 and a second feed hopper 4, and the upper side of the feed box 7 is connected with a feed pipe 5, and one end of the feed pipe 5 is fixedly connected with the feed box 7 by bolts, and the feed pipe 5 The other end of the second feed hopper 4 is connected, and the feed pipe 5 is integrally formed with the second feed hopper 4. In this ...

Embodiment 2

[0060] like Figure 4As shown, the difference between the grain processing rice milling equipment and the first embodiment is that the adjusting screw 26 in the present embodiment is provided with a through hole along its axial direction, and a pull rod 28 is coaxially slid in the through hole, and the diameter of the pull rod 28 is smaller than The through-hole diameter of adjustment screw 26, the right end of pull bar 28 is vertically fixedly connected with material stopper 30 by screw, and the left end of pull bar 28 is welded and fixed with auxiliary rod 29 in the present embodiment, and auxiliary rod 29 and pull rod 28 are vertically arranged. When the discharge port 23 is stuck, and the discharge port 23 cannot discharge rice grains normally, at this time, by pulling the pull rod 28 outside, the material baffle plate 30 can be moved, and the discharge port 23 can be loosened. To make the rice grains be discharged smoothly, the setting of the pull rod 28 in this embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com