Patents

Literature

45results about How to "Reduce temperature requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid and high temperature resistant cement composites

InactiveUS20140047999A1Increase resistanceReduce resistanceSolid waste managementCement productionHigh resistanceSilicon dioxide

Process for production of acid and high temperature resistant cement composites, where the matrix is alkali activated F fly ash alone, F Fly ash combined with ground slag or ground slag alone. F-fly ash produces lower quality alkali activated cement systems. On the other hand the lack of calcium oxide results in very high resistance to medium and highly concentrated inorganic or organic acids. The high strength and low permeability of pure F-fly ash cement systems is achieved by using in the composition un-densified silica fume, the amorphous silicone dioxide obtained as by products in production of ferro-silicones. Precipitated nano-particle silica made from soluble silicates and nano-particle silica fume produced by burning silicon tetra chloride in the hydrogen stream.

Owner:RAZL IVAN

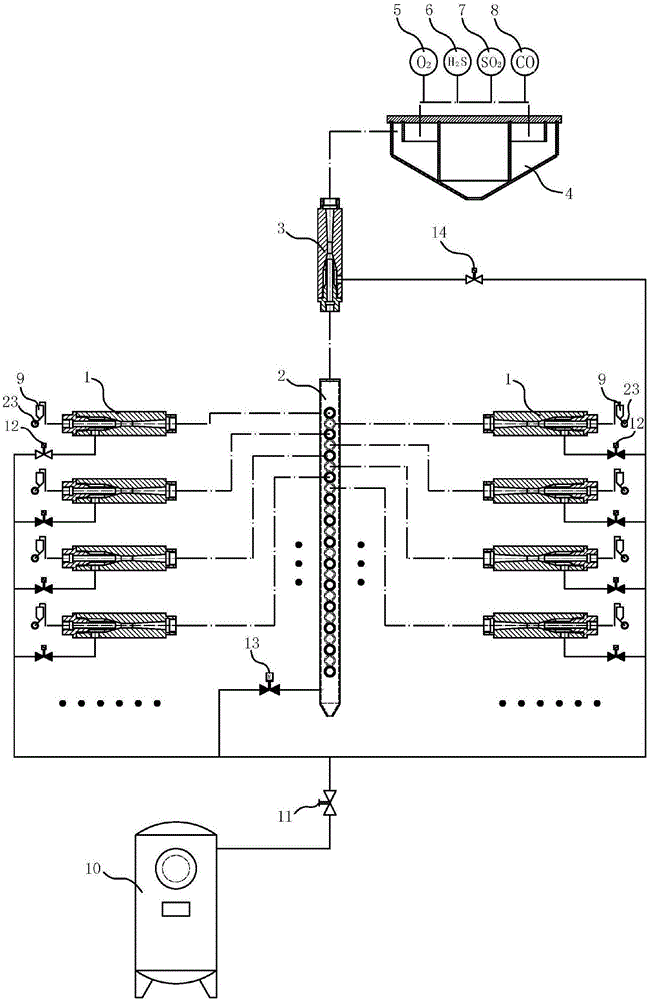

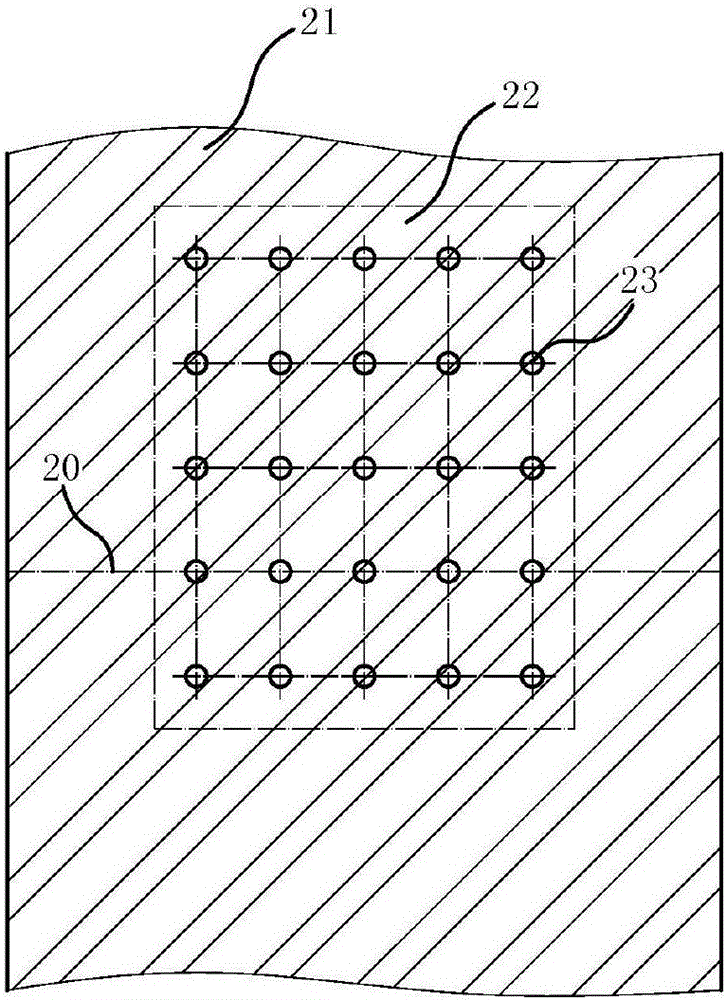

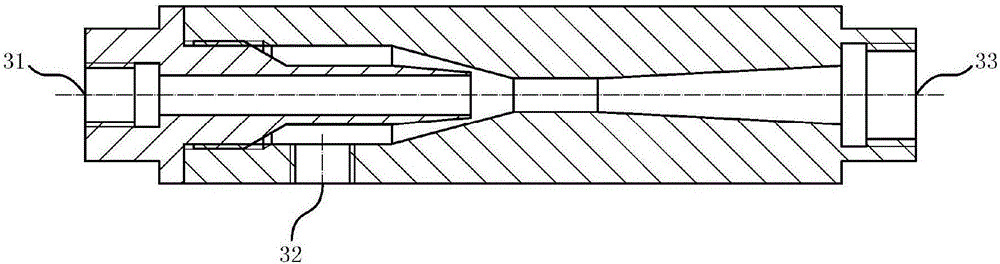

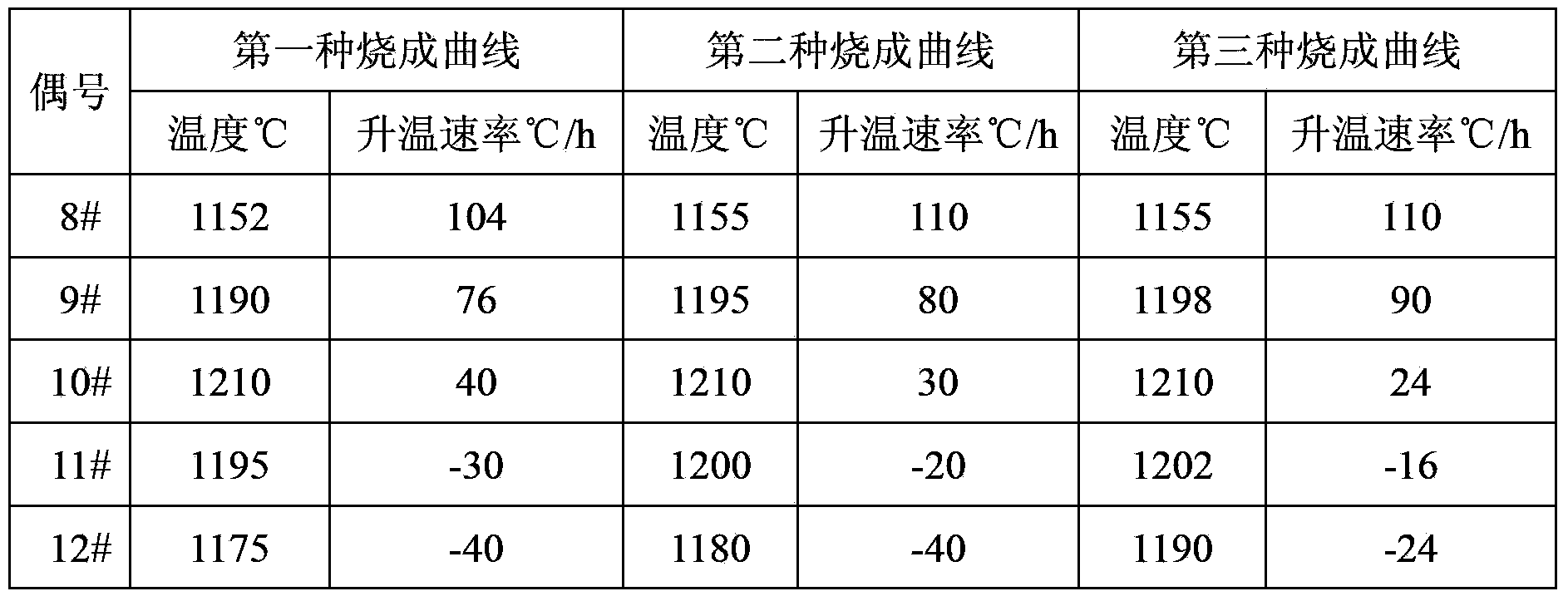

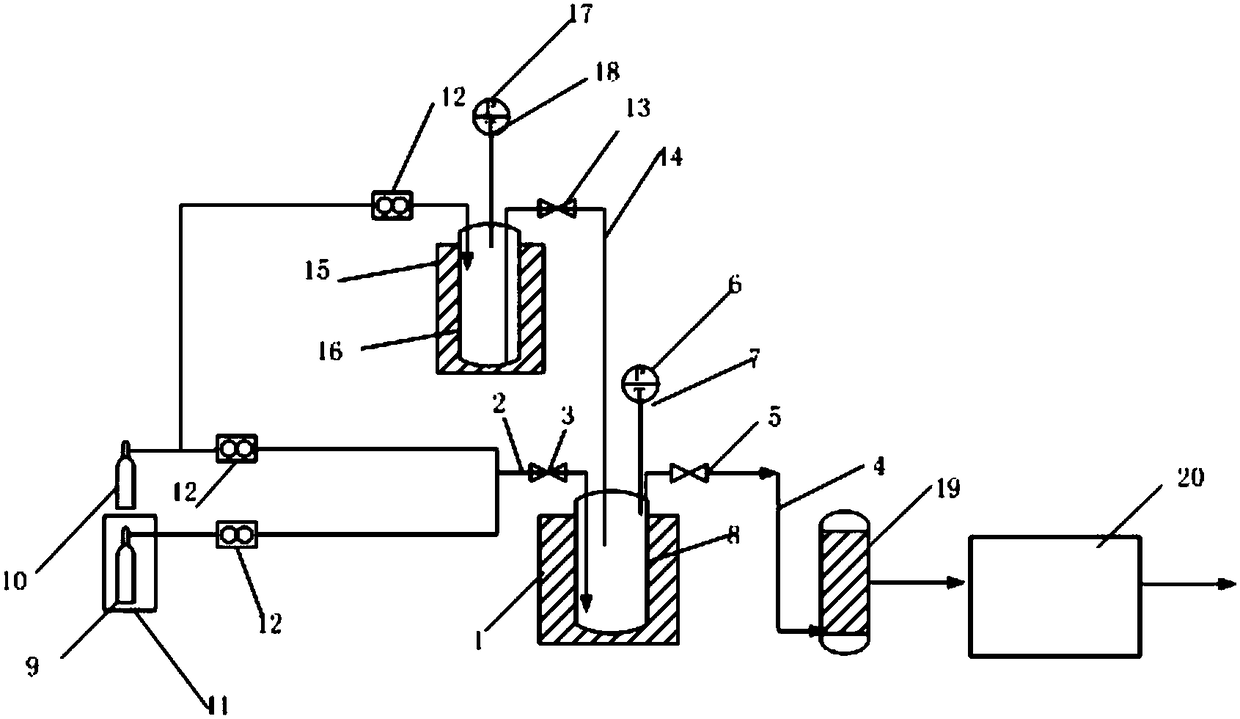

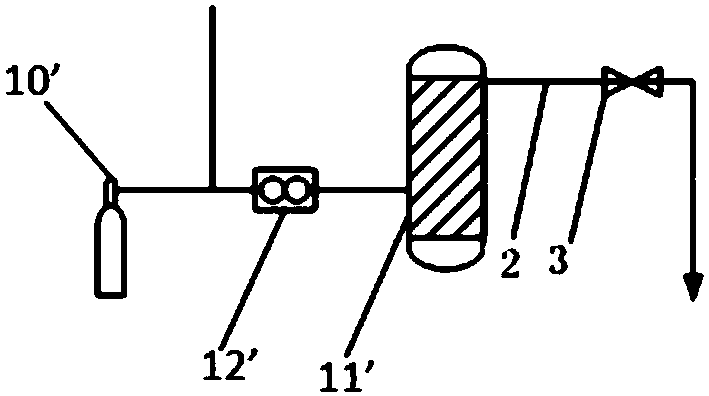

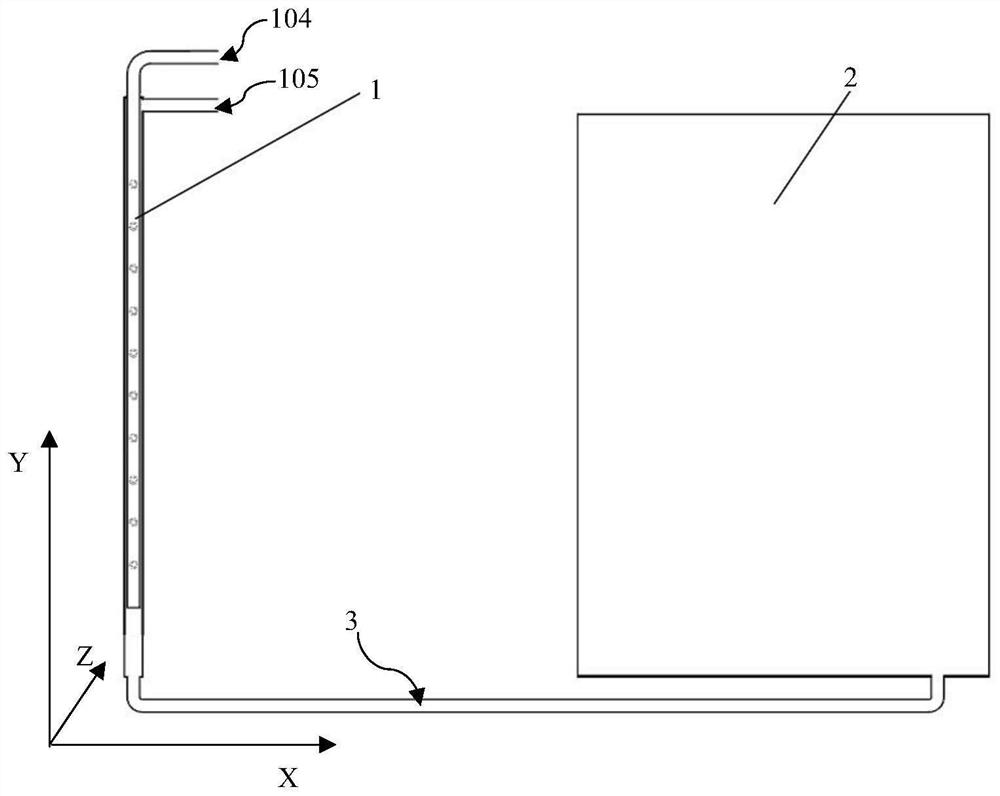

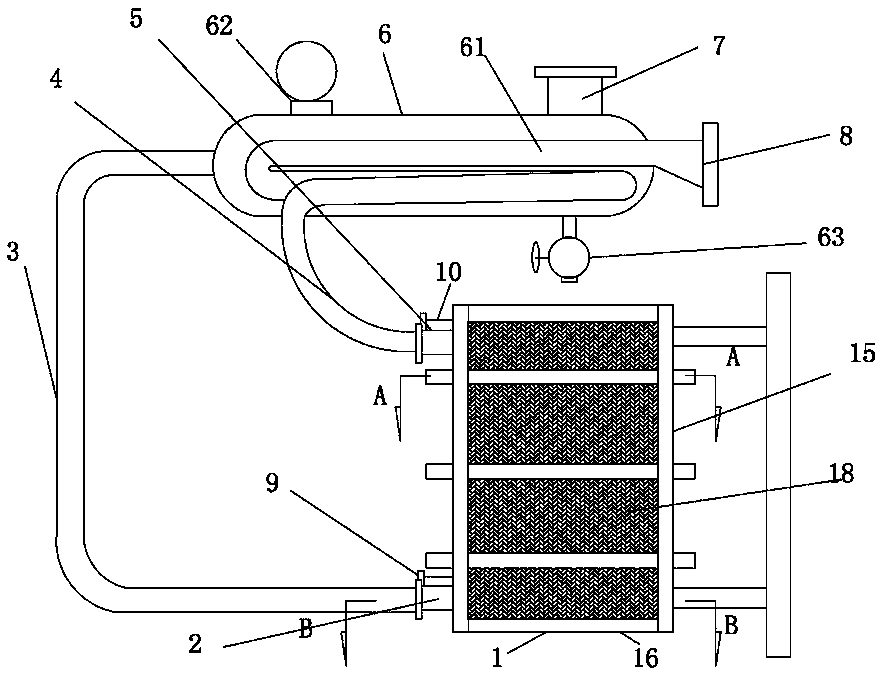

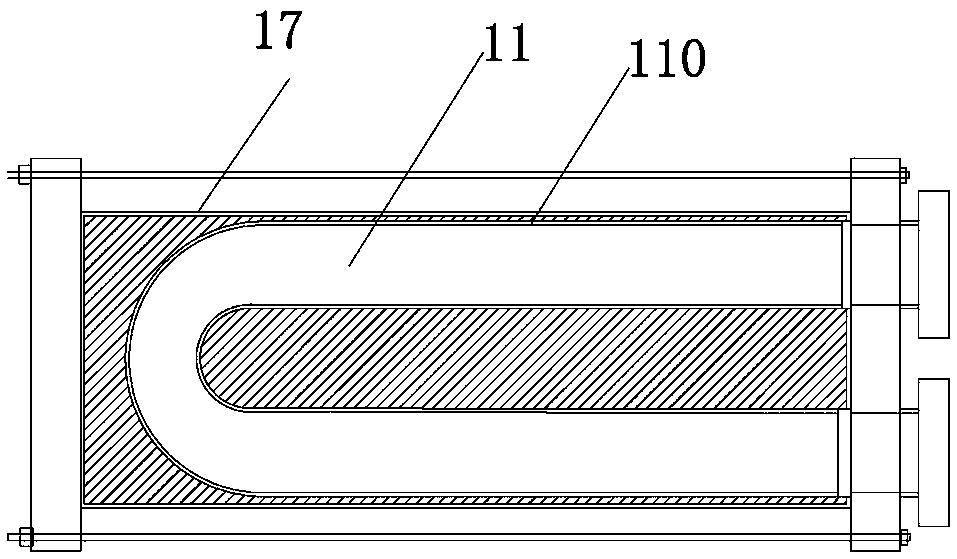

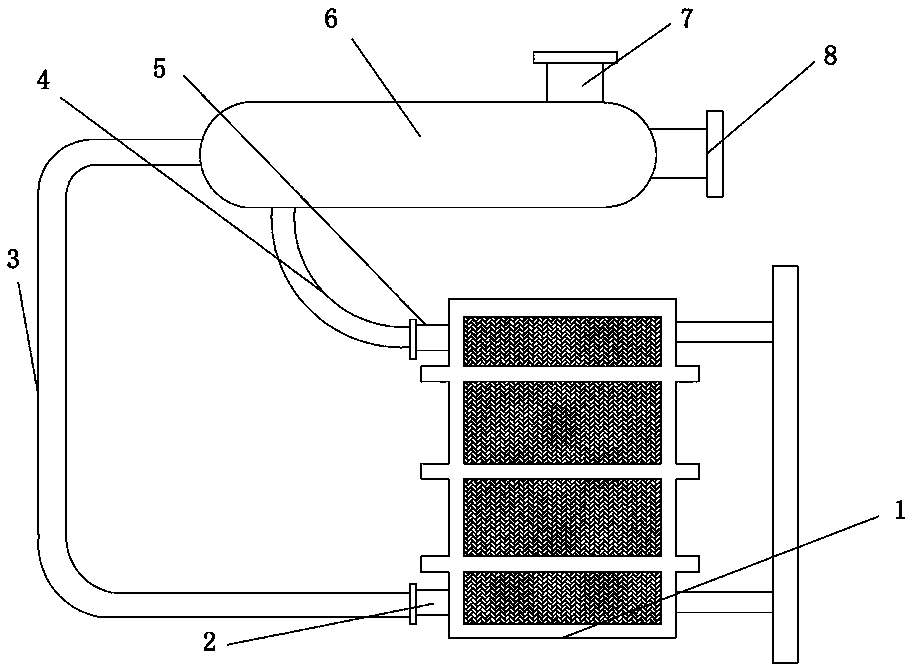

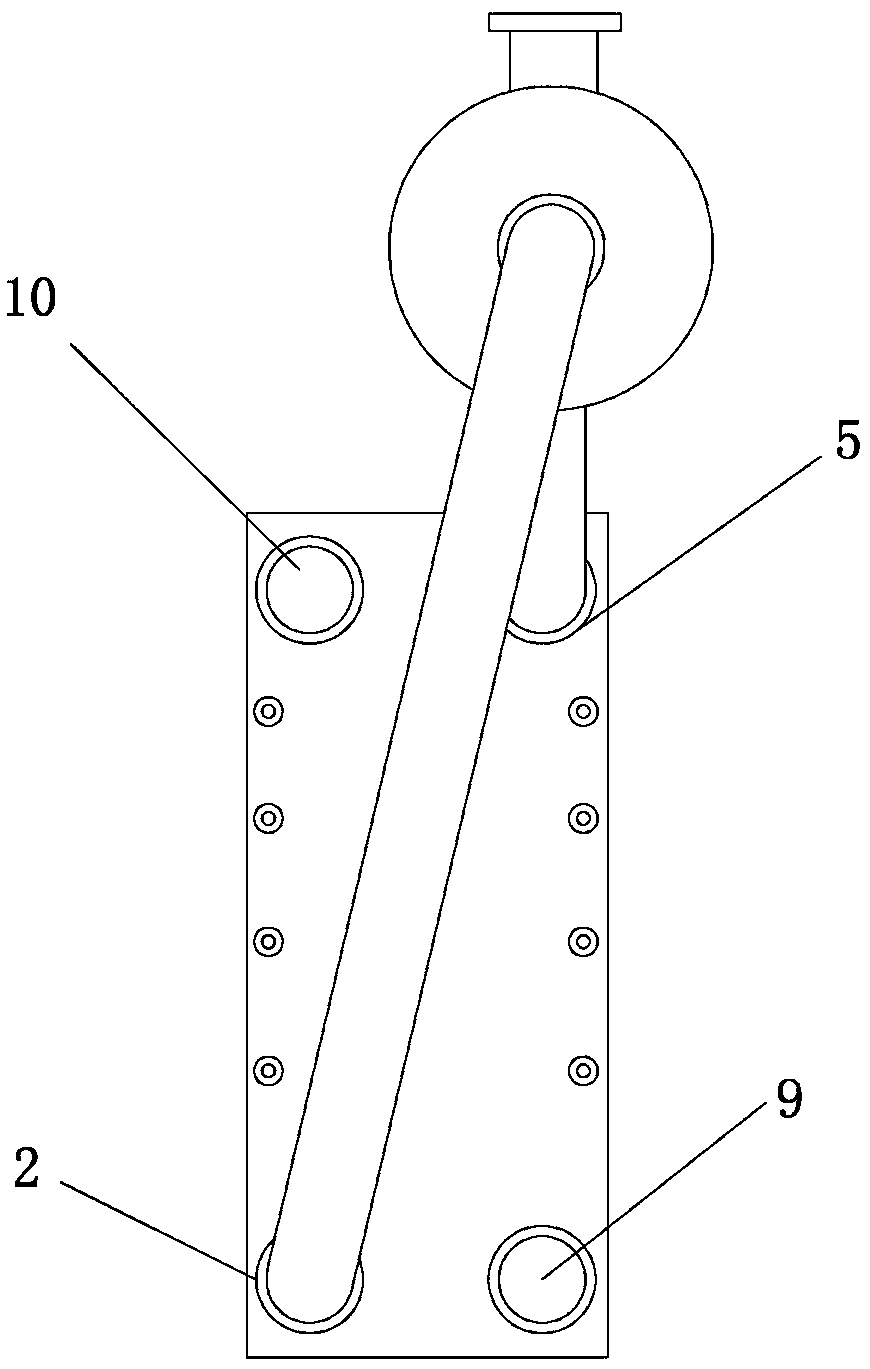

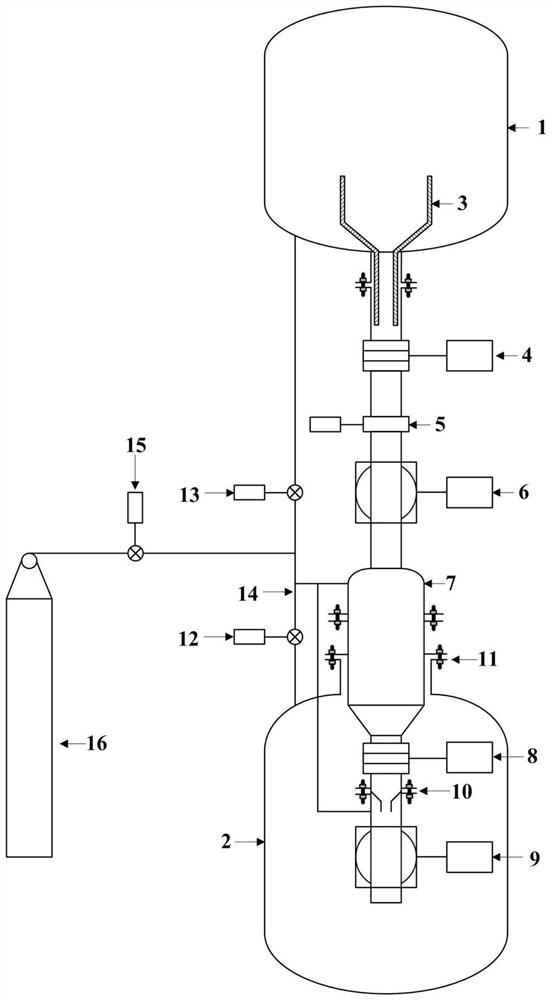

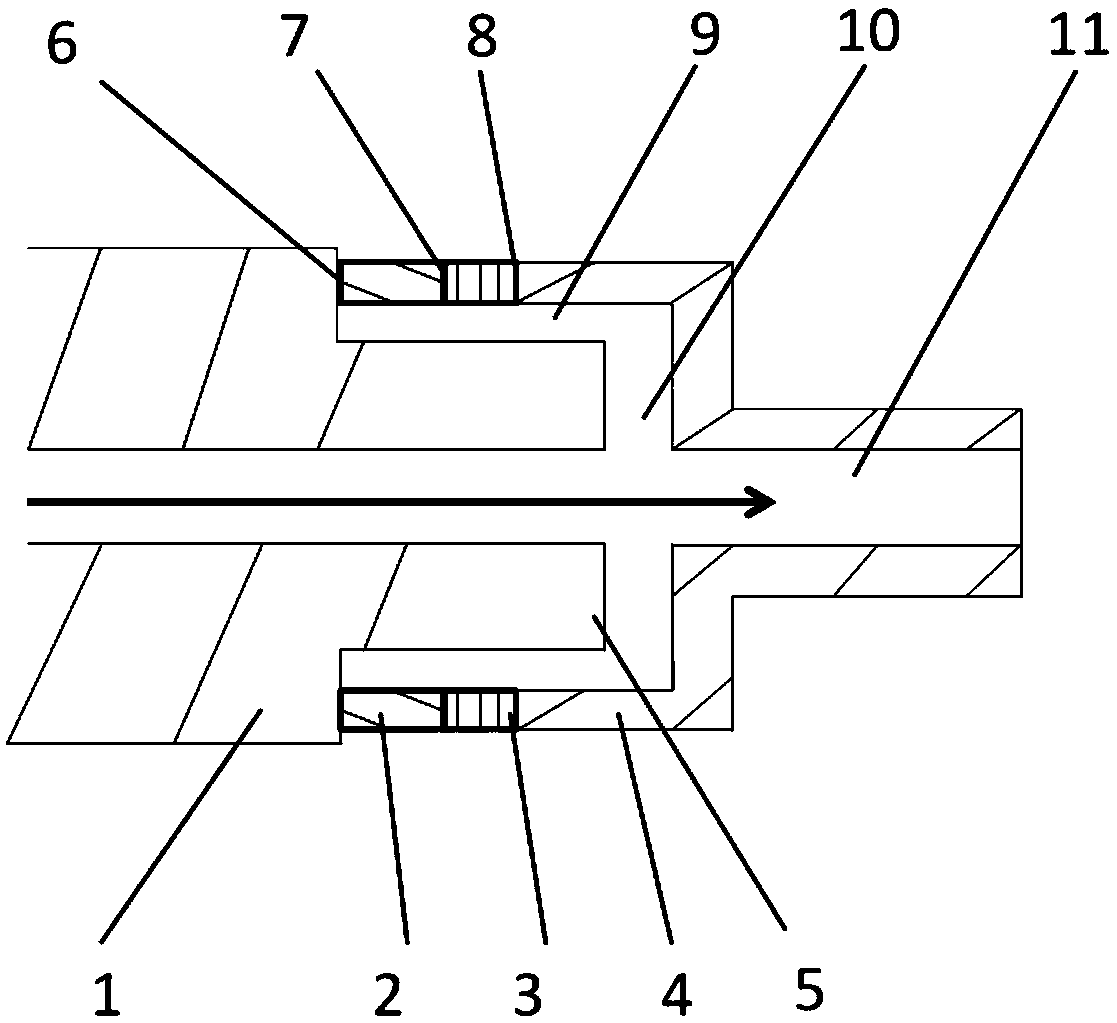

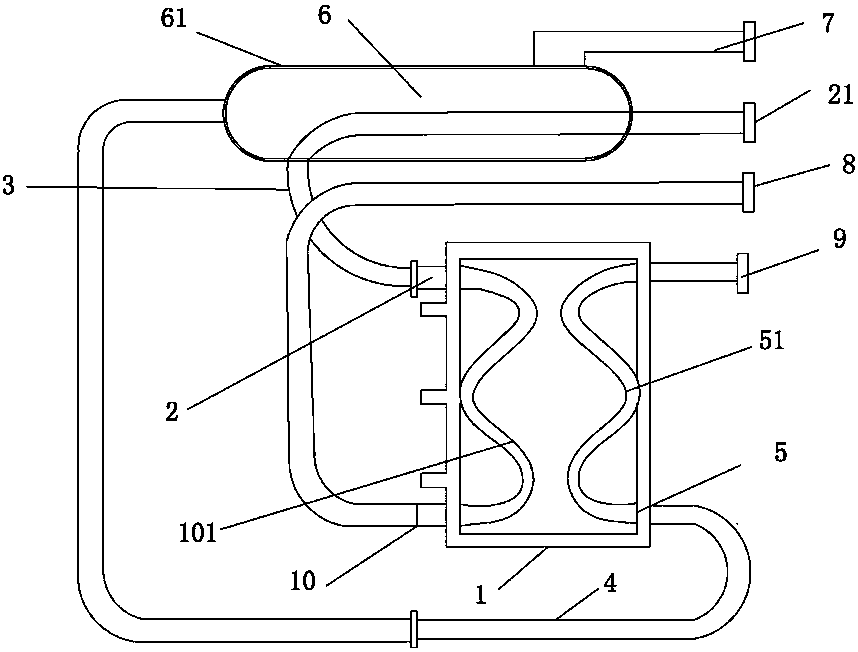

System and method for monitoring high-temperature corrosive atmosphere of water cooling wall of boiler

ActiveCN105675810AReduce temperature requirementsLow air tightness requirementsAnalysing gaseous mixturesPower stationFlue gas

The invention discloses a system and a method for monitoring high-temperature corrosive atmosphere of a water cooling wall of a boiler.The system for monitoring the high-temperature corrosive atmosphere of the water cooling wall of the boiler comprises a primary flue gas dilution sampling unit, a secondary flue gas dilution sampling unit, a diluted flue gas analyzing unit, a system reverse blowing unit and a compressed air unit.The system and the method for monitoring the high-temperature corrosive atmosphere of the water cooling wall of the boiler have the advantages that components of flue gas can be monitored at the normal temperature, all valves are arranged on compressed air pipelines, accordingly, influence of high temperatures and dust can be ingeniously prevented, long-term continuous and reliable running of the system can be guaranteed, the system and the method have cost merits, and the running safety and economic efficiency of the boiler of a power station can be obviously improved.

Owner:INNER MONGOLIA JINGNENG KANGBASHI THERMAL POWER CO LTD

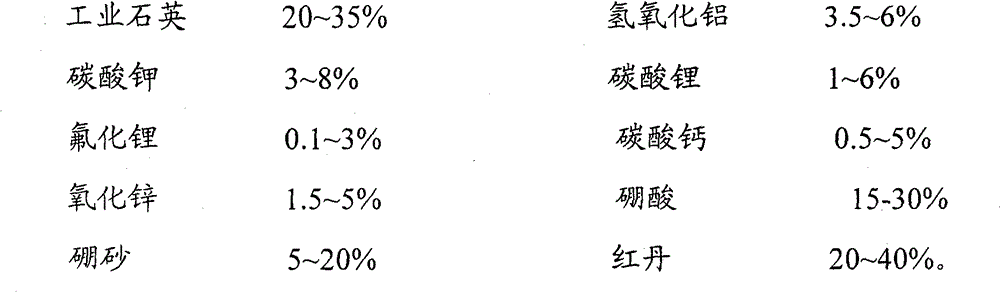

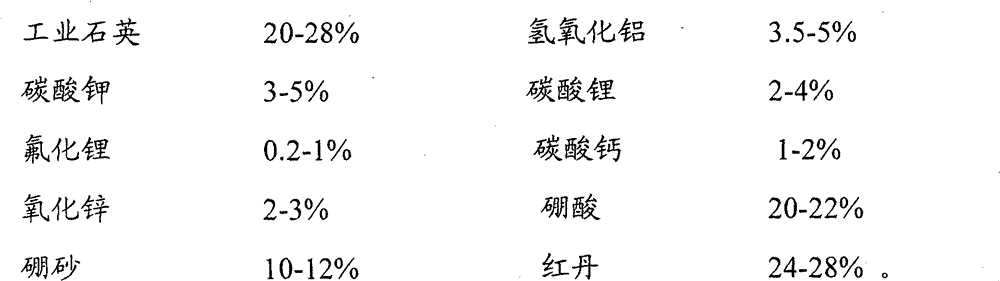

Low-temperature melting block finished glaze and preparation method thereof

ActiveCN102134167ATo achieve the purpose of low temperature glaze firingReduce energy consumptionAluminium hydroxideTemperature resistance

The invention discloses a low-temperature melting block finished glaze and a preparation method thereof. The low-temperature melting block finished glaze is prepared by uniformly mixing the following materials in parts by weight: 90-94 parts of low-temperature melting block and 6-10 parts of kaolin, wherein the low-temperature melting block comprises mineral materials, mineralizing agents and fluxing agents; the mineral materials are industrial quartz and aluminium hydroxide; the mineralizing agents are potassium carbonate, lithium carbonate and lithium fluoride; and the fluxing agents are calcium carbonate, zinc oxide, boric acid, sodium borate and red lead. In the low-temperature melting block finished glaze prepared by the invention, qualified ceramic can be glaze-fired at the temperature of 850-900 DEG C, so that the temperature resistance requirement on kiln furnace equipment is reduced, the energy consumption of a ceramic product is reduced, further the manufacturing cost is reduced and ceramic pigment generates brighter color on the ceramic product.

Owner:JIANGSU BAIFU TECH CO LTD

Preparation method for engineering ceramic acid and alkali resistant container

ActiveCN103641447AGood acid and alkali resistanceHigh mechanical strengthClaywaresEconomic benefitsPerformance index

The invention discloses a preparation method for an engineering ceramic acid and alkali resistant container. The preparation method comprises steps of batching of blank material raw materials, forming of the blank material, batching of glaze material raw materials, preparation of the glaze material, biscuiting, glaze application and sintering. The engineering ceramic acid and alkali resistant container has advantages of high acid resistance, high alkali resistance, particularly being free from pollution of media, high mechanical strength, high compactness, high dimensional precision, low water absorption, good heat stability, small thermal expansion coefficients, leak resistance and the like. The carcass is compact, the glaze is bright and clean, and there are no defects of pin holes, glaze shrinkage, thin glaze and the like. The defective percentage is lowered, and the production efficiency is raised. Temperature-resistant requirements to a kiln device are eliminated, and the production cost is lowered. The novel engineering ceramic acid and alkali resistant container has good appearance quality and performance indexes, and is an ideal product raising economic benefits.

Owner:江苏省宜兴彩陶工艺厂

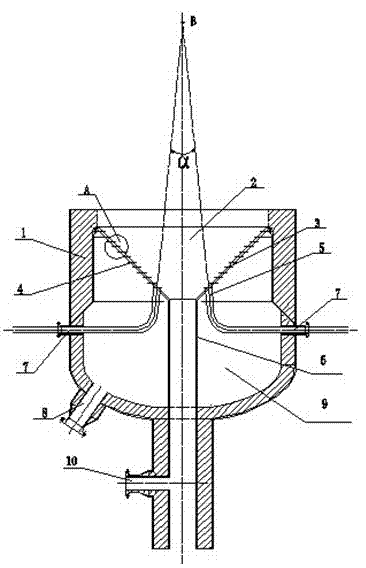

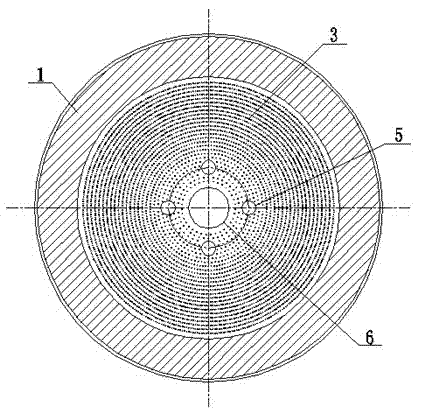

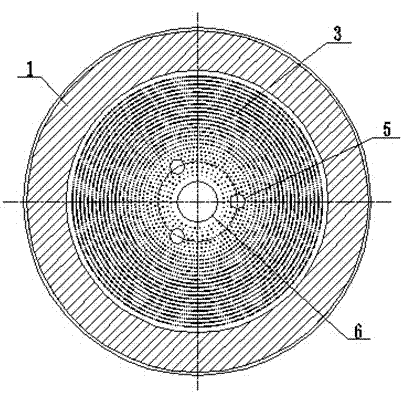

Gas distributor for ash agglomerating fluidized-bed gasification furnace

InactiveCN102827644AAvoid scour wearAvoid Vibration FractureGranular/pulverulent flues gasificationFluidized bed gasifierEngineering

The invention provides a gas distributor for an ash agglomerating fluidized-bed gasification furnace. The gas distributor comprises a gasification furnace shell, a tapered distribution plate, at least three distributed injection pipes, a slagging pipe and a gas inlet pipe of a gas chamber, wherein one end of the slagging pipe is connected to the bottom of the tapered distribution plate, and is open, and the other end of the slagging pipe penetrates through the gasification furnace shell, and is connected with a gasification agent gas source. The gas distributor is characterized in that one end of each distributed injection pipe is connected to the lower part of the tapered distribution plate, and is open, and the other end of each distributed injection pipe penetrates through the gasification furnace shell, and is connected with the gasification agent gas source; and openings of the distributed injection pipes in the tapered distribution plate are symmetrically and uniformly distributed about the center of the slagging pipe. The gas distributor is high in fluidization performance, adapted to long-cycle running, simple in structure and applicable to a large-sized fluidized-bed gasification furnace.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

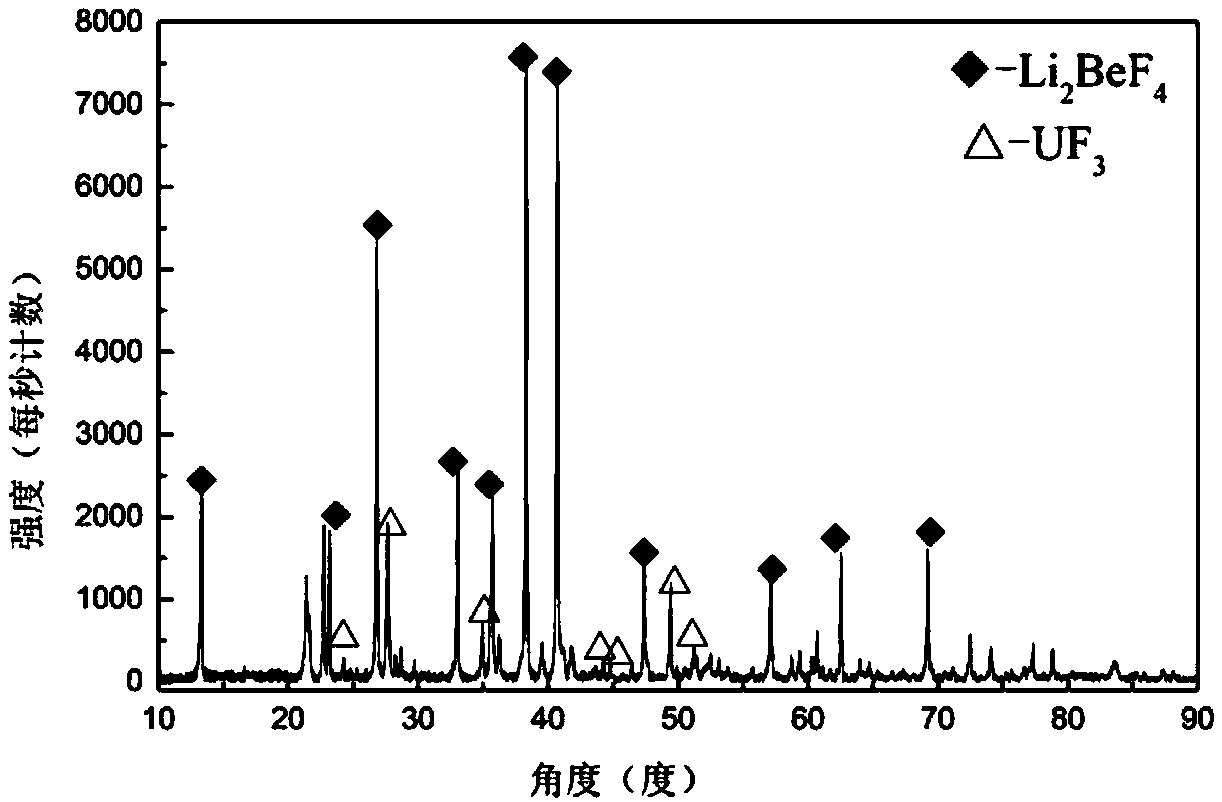

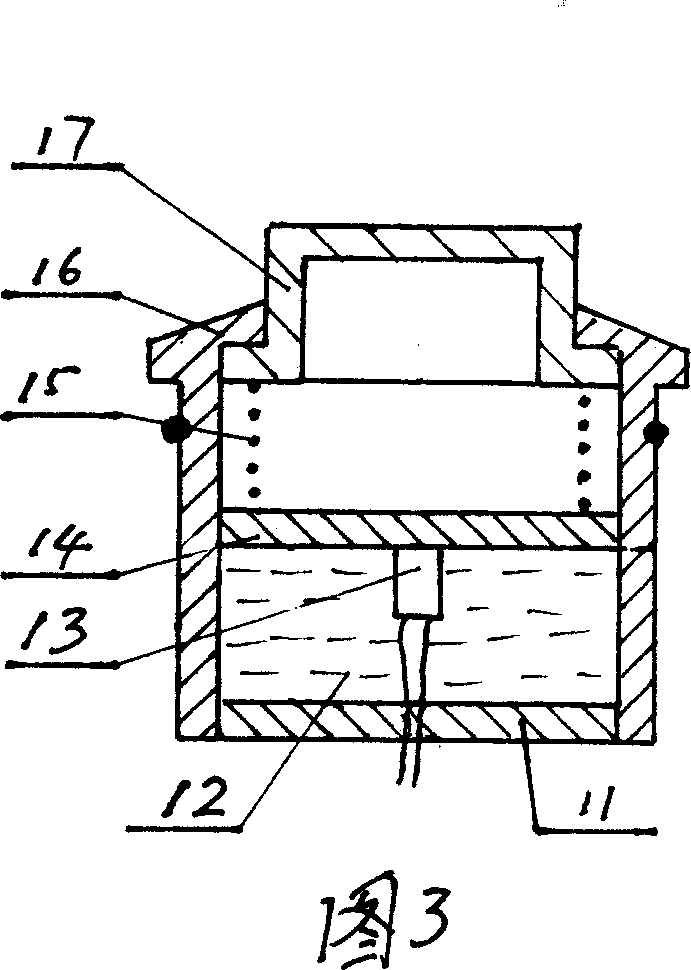

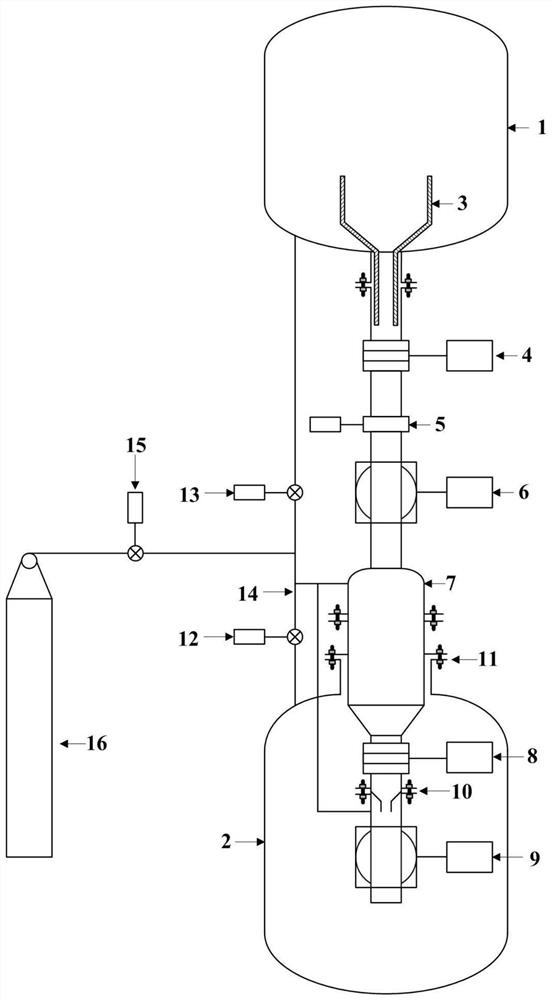

Device and method for preparing fuel salt of molten salt reactor

ActiveCN108109710AEasy to produceSimple processNuclear energy generationReactors manufactureGas supply equipmentEngineering

The invention relates to a device for preparing fuel salt of a molten salt reactor. The device comprises a gas supply system and a tail gas treatment system which are connected with a reaction system,wherein the reaction system comprises a reaction kettle containing reducing metal and a reaction heating furnace used for heating the reaction kettle; the gas supply system comprises gas supply equipment supplying inert gas and / or UF6gas into the reaction kettle; and the tail gas treatment system comprises treatment equipment for absorbing excess UF6 gas and tail gas in the reaction kettle. The invention further provides a method for preparing fuel salt of the molten salt reactor through the device. The device directly reduces UF6 in molten salt to prepare UF3 and / or UF4 to obtain fuel salt,simplifies the production process of molten salt, and has the advantages of short technical process, simple and flexible operation, no radioactive powder operation, material cost saving and energy saving.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

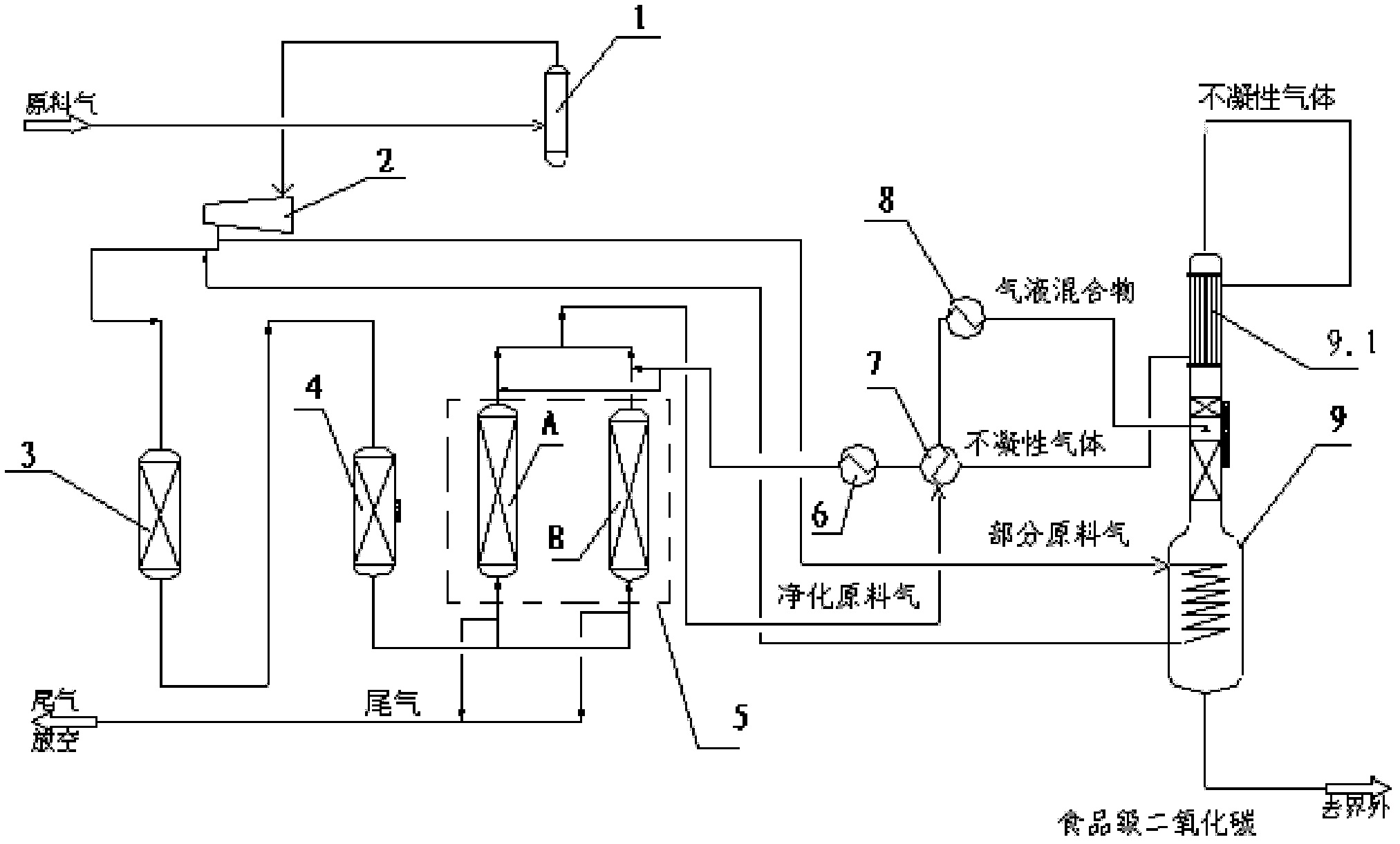

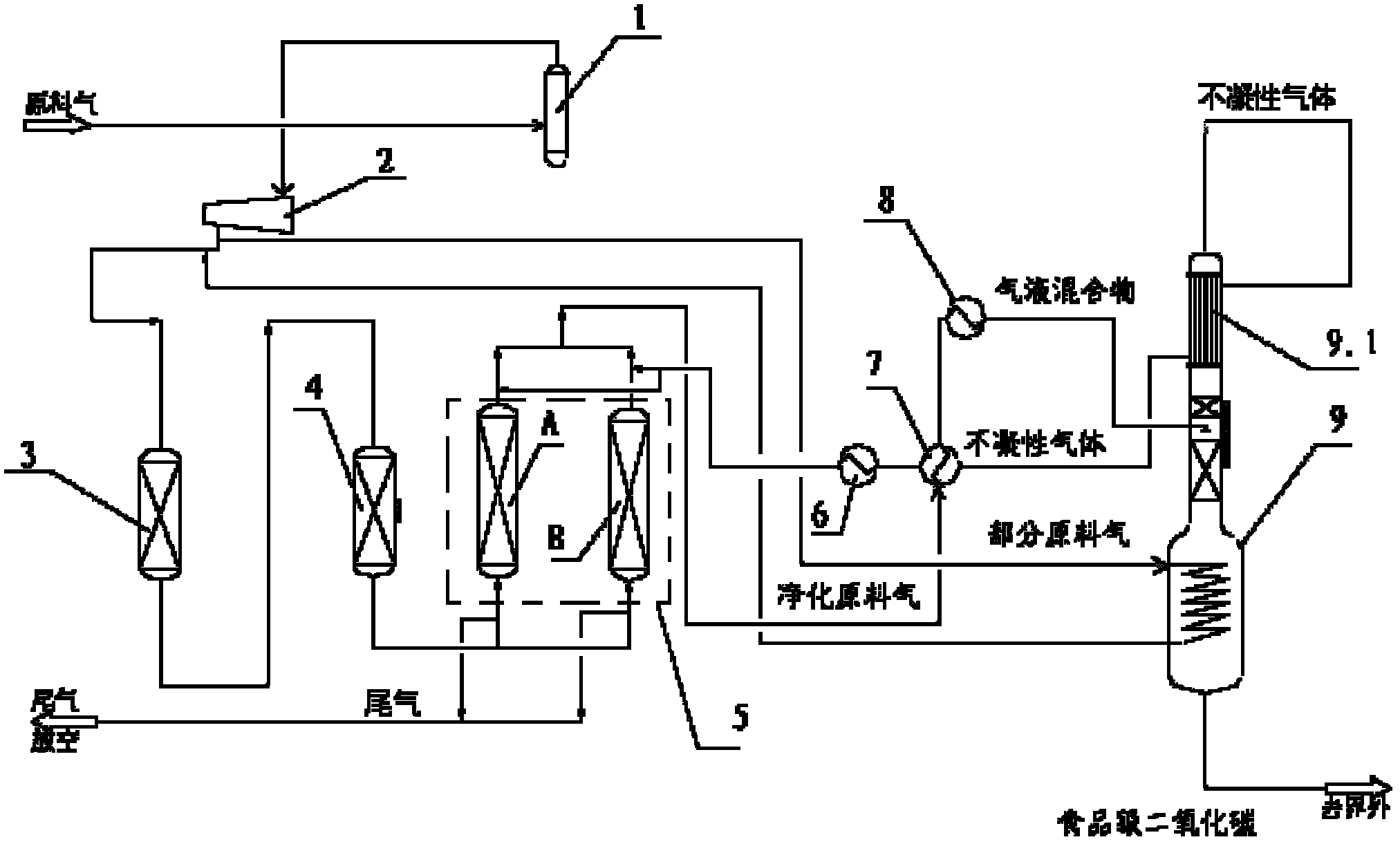

Technological method for preparing food-grade CO2 based on high-concentration carbon dioxide exhaust gas

The invention relates to a technological method for preparing food-grade CO2 based on high-concentration carbon dioxide exhaust gas, wherein, the technological method solves the problems of complicated preparation technology, high energy consumption, high equipment investment, high running cost and large occupied area of prior food-grade CO2. The technological method adopts the technical scheme as follows: feed gas of high-concentration carbon dioxide is processed through compression, purification edulcoration, dehydration, rectification and cooling, and then the food-grade CO2 is obtained. The technological method is characterized in that part of feed gas enters a CO2 medium-pressure low-temperature rectifying tower in a rectification step so as to supply heat to a reboiler at the tower bottom after feed gas is compressed to reach the gage pressure of 4 to 6 MpaG; and then part of feed gas that is processed through heat exchange and residual feed gas are mixed and then enter the purification edulcoration step. The technological method has the advantages of simple technological process, low energy consumption of system operation, small occupied area, low equipment investment and low running cost.

Owner:WUHUAN ENG

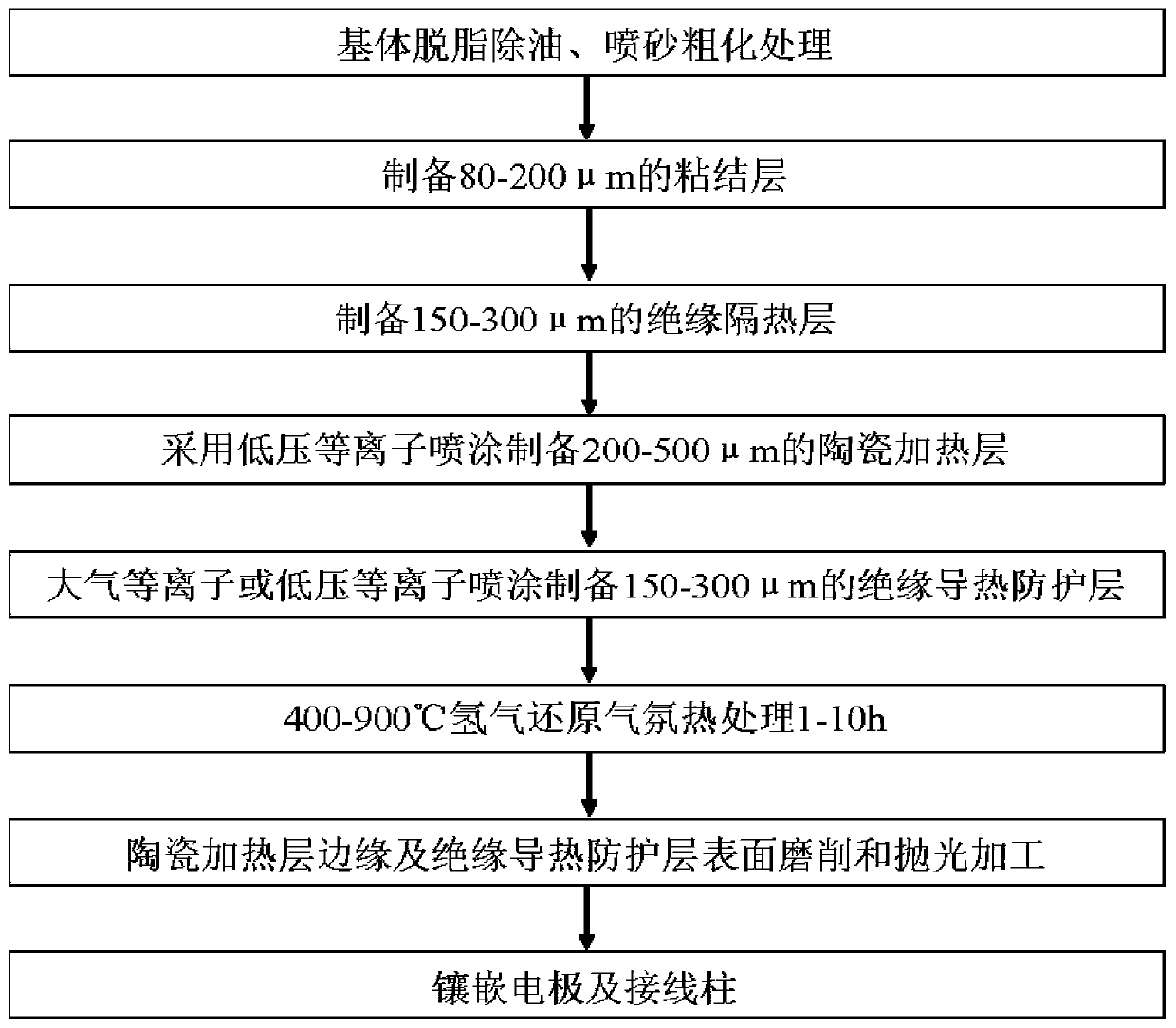

TiO2-based electric heating coating and preparation method thereof

ActiveCN110117765ARestore heating effectLow running costMolten spray coatingOhmic-resistance electrodesDopantElectrical resistance and conductance

The invention discloses a TiO2-based electric heating coating and a preparation method thereof. The electric heating coating which coats the surface of a base body comprises a bonding layer, an insulating and heat-insulating layer, a ceramic heating layer and an insulating and heat-conducting protective layer sequentially from bottom to top, and is connected with a power supply through electrodesinlaid at the two ends of the ceramic heating layer and binding posts thereon. The ceramic heating coating material is a TiO2-based ceramic material; a dopant comprises at least one of Al2O3, MgAl2O4,Cr2O3 and YSZ; and the resistance value and the heating effect can be controlled by regulating and controlling the thickness of the coating, the dopant materials and the proportioning. The electric heating coating is good in interlayer bonding, uniform and dense in tissue, high in heating speed and uniform in temperature distribution, and can meet long-time stable operation at the temperature of350 DEG C under the condition of low energy consumption; furthermore, the preparation method is high in efficiency and low in cost, and the preparation process is environmentally-friendly and pollution-free.

Owner:GUANGDONG INST OF NEW MATERIALS

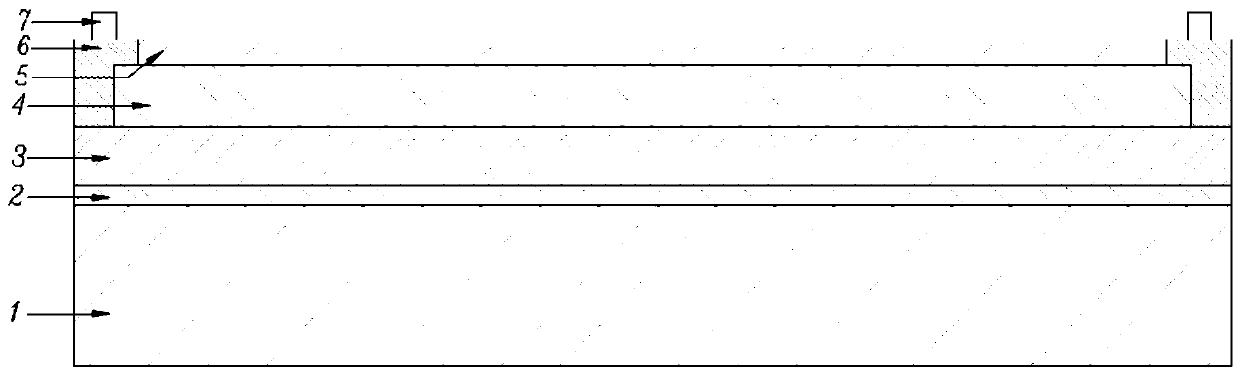

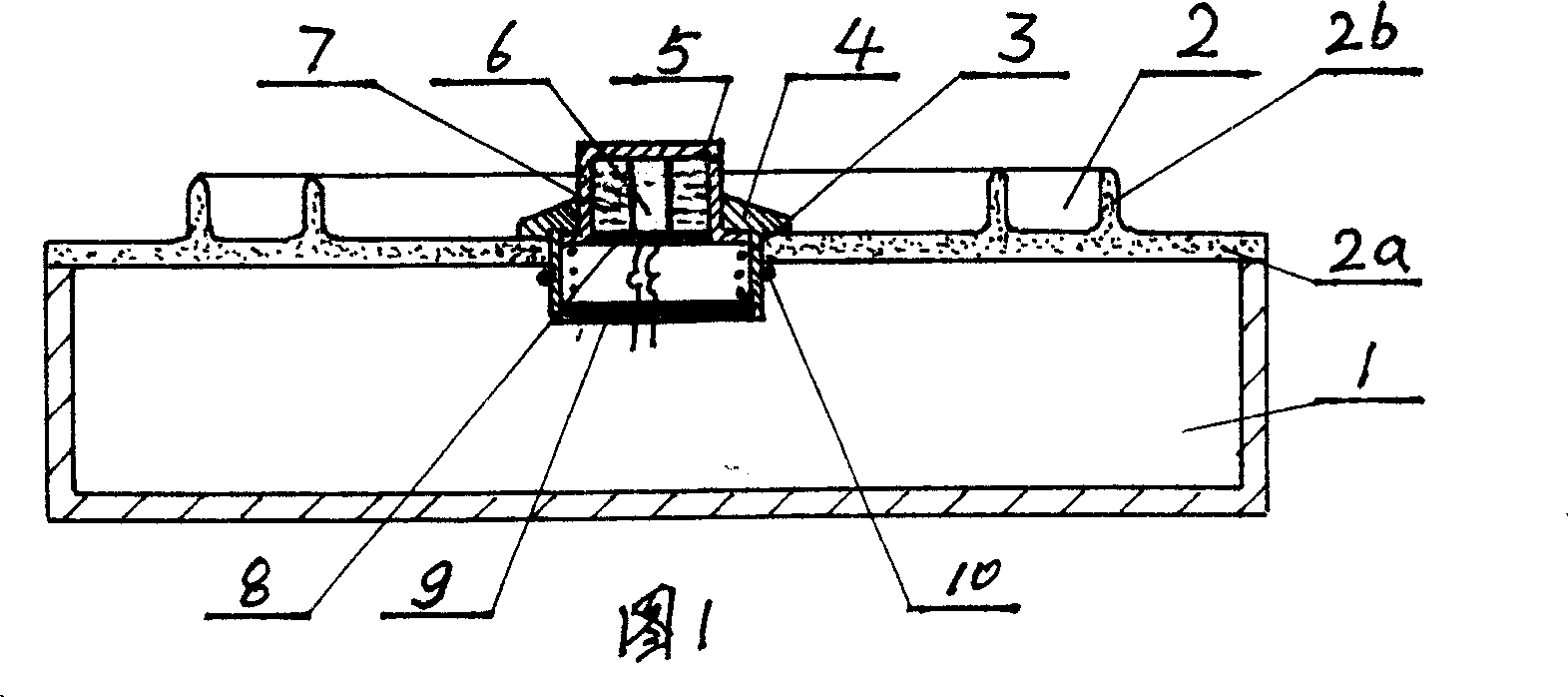

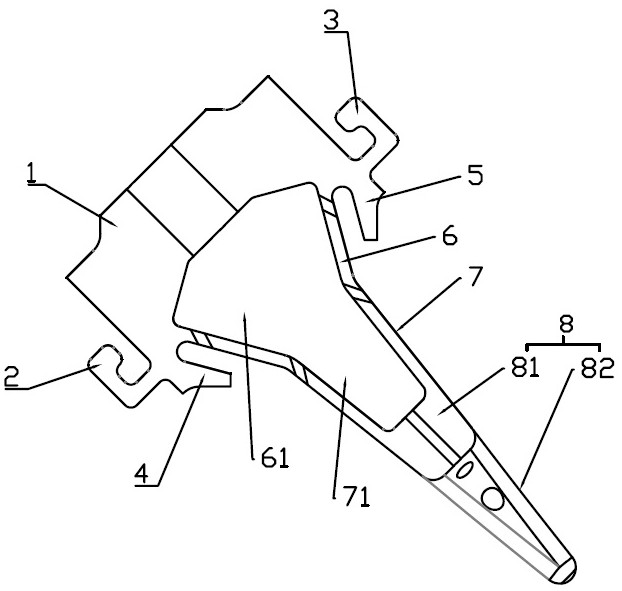

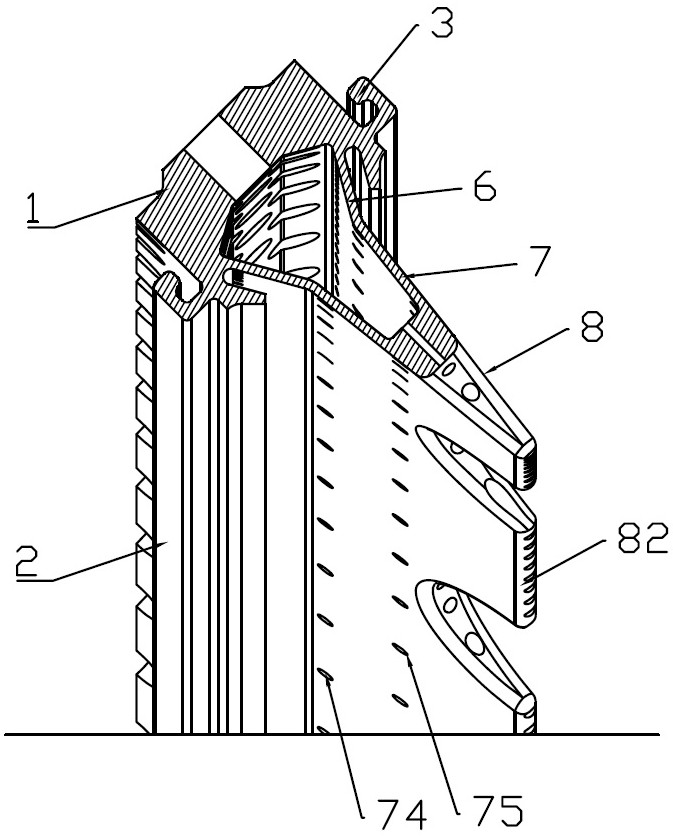

Electromagnetic oven

InactiveCN101055094AEnsure direct contactGuaranteed temperature control accuracyDomestic stoves or rangesLighting and heating apparatusEngineeringSilica gel

The invention discloses an induction cooker which includes body 1, panel 2 equipped on the body 1, temperature probe device equipped on the panel 2 and which includes temperature probe body 4 and probe cap 5 and so on, wherein the probe cap 5 can slide in relation to the temperature probe body 4, and temperature probe 6 and heat conduction silica gel 7 are installed in the probe cap. The panel includes panel body 2a, protruding ring 2b and protruding rib 2c, and the temperature probe device is mounted on the panel body 2a in the protruding ring 2a, therefore, the temperature probe device can directly contact with pan bottom thereby accurately and quickly detecting the temperature of the pan bottom, and can reduce the cooker temperature thereby improving working condition for electronic element then prolonging service life.

Owner:袁明

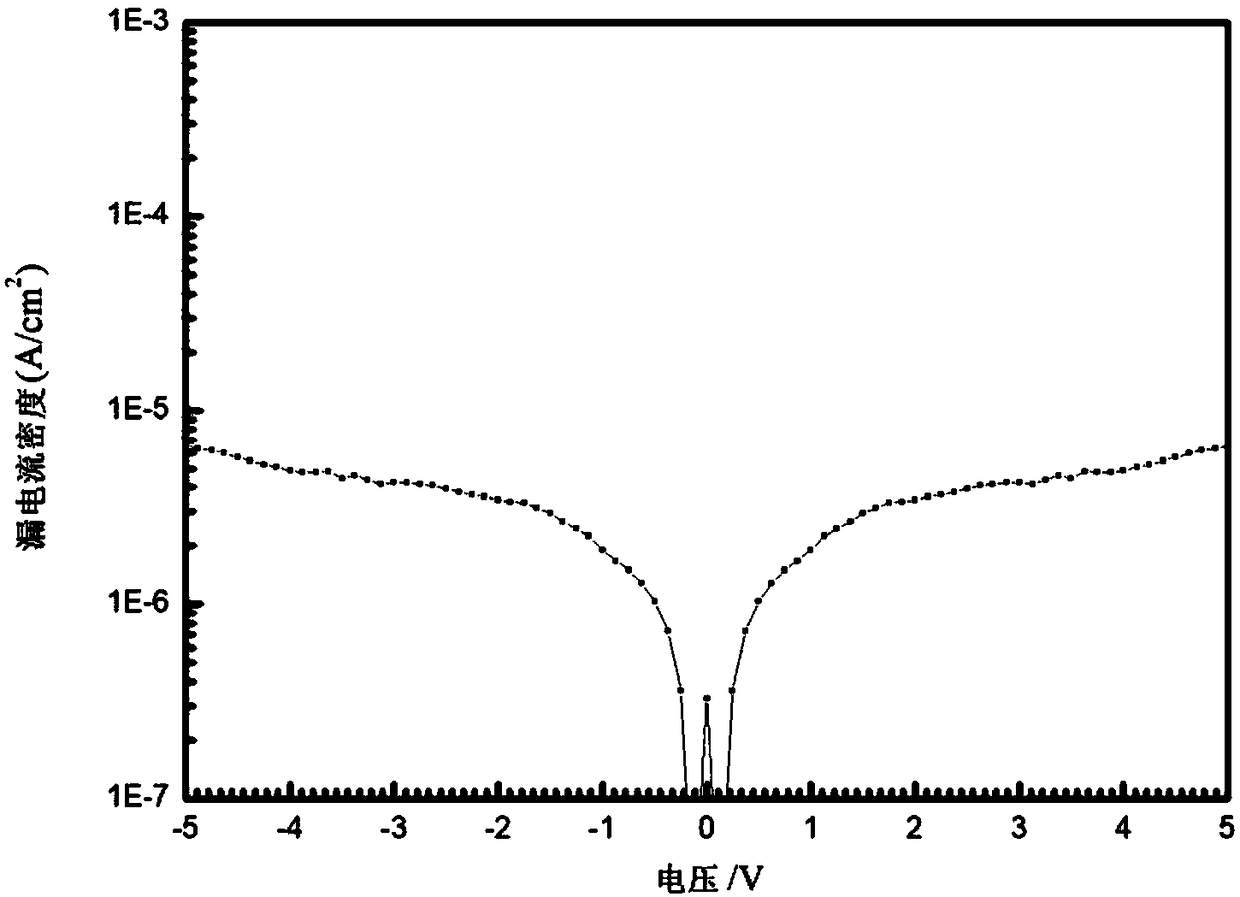

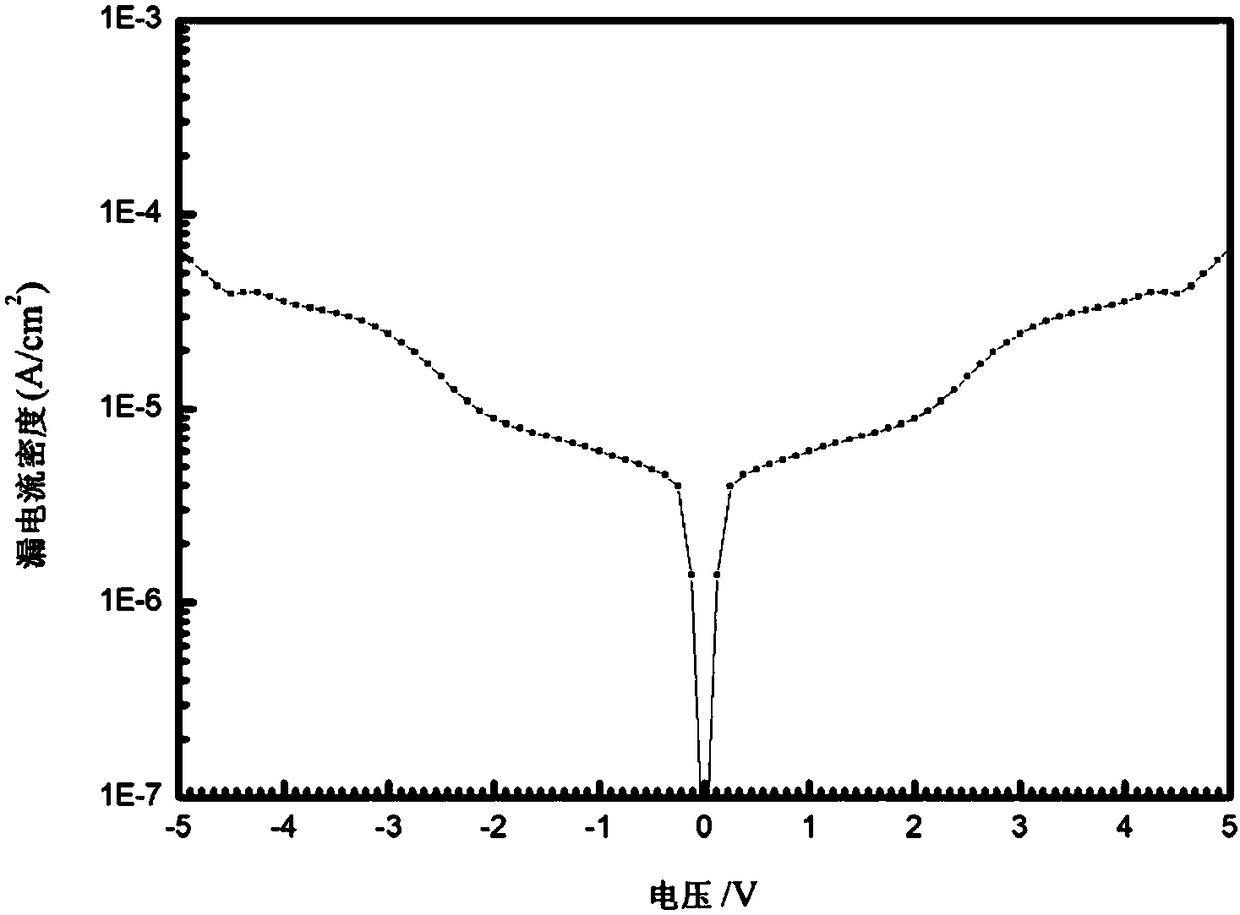

Method for preparing zirconium oxide insulating layer thin film and stack layer structure by solution method

InactiveCN108389777AReduce temperature requirementsReduce processingSolid-state devicesSemiconductor/solid-state device manufacturingZirconium hydrideSpins

The invention belongs to the technical field of a thin film transistor, and discloses a method for preparing a zirconium oxide insulating layer thin film and a stack layer structure by a solution method. Zr(NO<3>)<4>.5H<2>O is dissolved into ethylene glycol monomethyl ether to be stirred and aged to obtain a precursor solution; an ITO glass substrate is spin coated with the obtained precursor solution, and next, annealing treatment at a temperature of 200 DEG C is performed for 1-2h to obtain the zirconium oxide insulating layer thin film; and the zirconium oxide insulating layer thin film issubjected to magnetron sputtering to plate a circular Al electrode to obtain an MIM stack layer structure. Through Zr(NO<3>)<4>.5H<2>O, the precursor solution comprising a nitrato ZrO<2> insulating layer is obtained, and organic impurities in a wet film can be removed at a relatively low annealing temperature, so that the temperature resistance requirement on the substrate is relatively low; and meanwhile, ultraviolet light treatment needed in the conventional low-temperature process is avoided, so that complexity of the annealing process is lowered.

Owner:SOUTH CHINA UNIV OF TECH

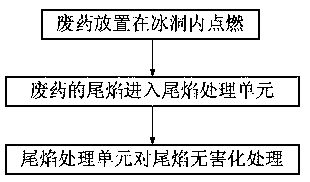

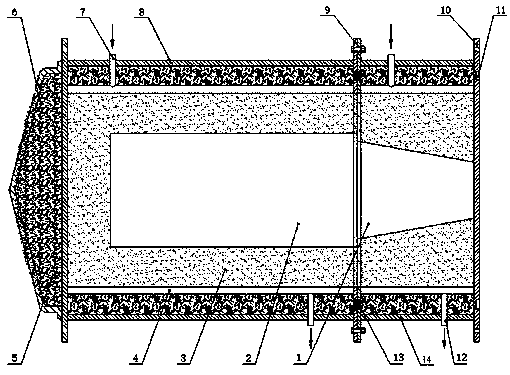

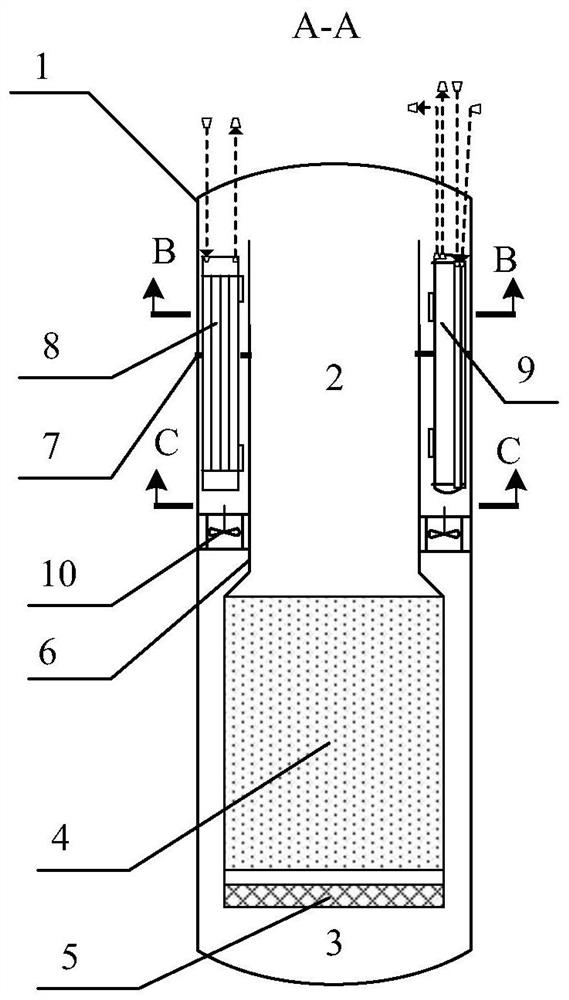

Waste medicine combustion system, method and device

ActiveCN111006224ALower combustion temperatureBurn quicklyIce productionIncinerator apparatusCombustion systemThermodynamics

The invention provides a waste medicine combustion system. The waste medicine combustion system comprises a waste medicine combustion unit, wherein the waste medicine combustion unit is provided withan ice hole structure; waste medicines are placed in the ice hole structure; the waste medicine combustion unit communicates with a tail flame treatment unit; the ice hole structure is made of ice; tail flame generated by combustion of the waste medicines in the ice hole structure of the waste medicine combustion unit is guided into the tail flame treatment unit; and the tail flame treatment unitperforms harmless treatment on the tail flame. The combustion speed of the medicines is determined by the combustion surface and the surface temperature, and a solid propellant (medicine) used by an engine can control the combustion surface through shaping so as to control the combustion speed. However, the waste medicines are irregular fragments or powder, and the combustion surface cannot be controlled, so that the ice hole structure is used for controlling rapid rise of the surface temperature, and the combustion speed is well controlled. If heat released after combustion of the waste medicines is positively fed back, the temperature can rise rapidly, and the waste medicines are combusted by adopting the ice hole structure, namely, the heat is absorbed, so that the temperature rise speed is reduced, and the combustion speed is controlled.

Owner:西安蓝坤工程科技有限公司

Multipurpose heat transport system for small villiaumite cooling high-temperature reactor

ActiveCN113689963ATo achieve simultaneous operationReduce volumeNuclear energy generationFast fission reactorsProcess engineeringReactor design

The invention discloses a multipurpose heat transport system for a small villiaumite cooling high-temperature reactor. The multipurpose heat transport system comprises a reactor container, a hot pool, a cold pool, a reactor core, a reactor core flow distribution plate, a cold / hot pool shroud, a cold / hot pool partition plate, a villiaumite-carbon dioxide heat exchanger, a main heat-waste heat integrated heat exchanger and an axial flow pump. The system has two circulation modes of forced circulation and natural circulation, and has three operation modes of compact operation, comprehensive operation and full-power operation; an external power circulation system is directly connected in a compact operation mode; an external heat transport system is connected in the comprehensive operation mode; and in the full-power operation mode, an external power circulation system and an external heat transportation system are connected at the same time. A reactor core loop, a main heat transport loop and a waste heat discharge system are combined at the same time, simultaneous operation and flexible switching of in-reactor circulation, main heat transport and waste heat transport are achieved, compact and efficient utilization of energy is achieved in a limited space, and the process of autonomously mastering the small villiaumite cooling high-temperature reactor design technology in China is promoted.

Owner:XI AN JIAOTONG UNIV

Center body of flame tube for radial staged combustion chamber

PendingCN114777159ASimple structureLight in massContinuous combustion chamberCombustion chamberWorking environment

The invention belongs to the technical field of gas turbine engines, and particularly relates to a center body of a flame tube for a radial staged combustion chamber, the center body is annular and can be arranged between a main combustion stage flame head and an on-duty stage flame head, a plurality of air inlet holes are formed in the front side of the center body, and a plurality of air outlet holes are formed in the rear side of the center body. A plurality of center holes are formed in the rear side of the center body; an annular cavity is formed in the center body, and the center hole and the air inlet hole are both communicated with the annular cavity; a plurality of inclined holes are formed in the inner cavity wall and the outer cavity wall of the annular cavity, airflow is led out of the center body, and a cooling air film is formed outside the center body. The center body has the advantages of being simple in structure, convenient to install, high in reliability, long in service life and the like. Mutual independent stable combustion of on-duty level flames and main combustion level flames can be achieved, and cross flame of the on-duty level flames and the main combustion level flames can be achieved when working conditions are switched. The center body can be made of a high-temperature alloy material, so that ablation in a high-temperature working environment for a long time is avoided.

Owner:成都中科翼能科技有限公司

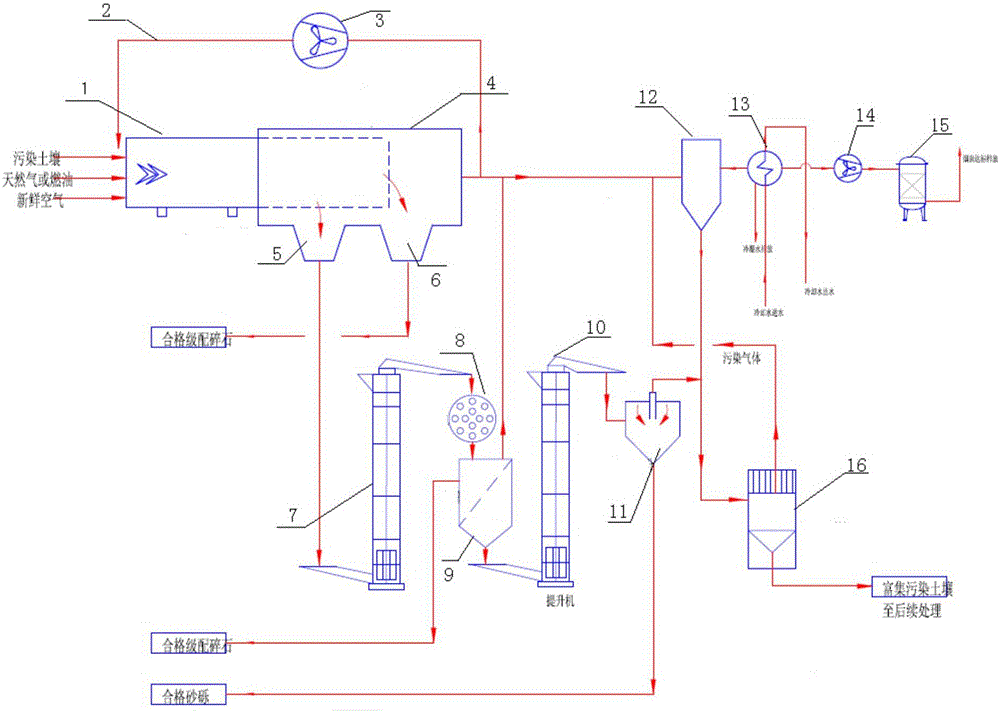

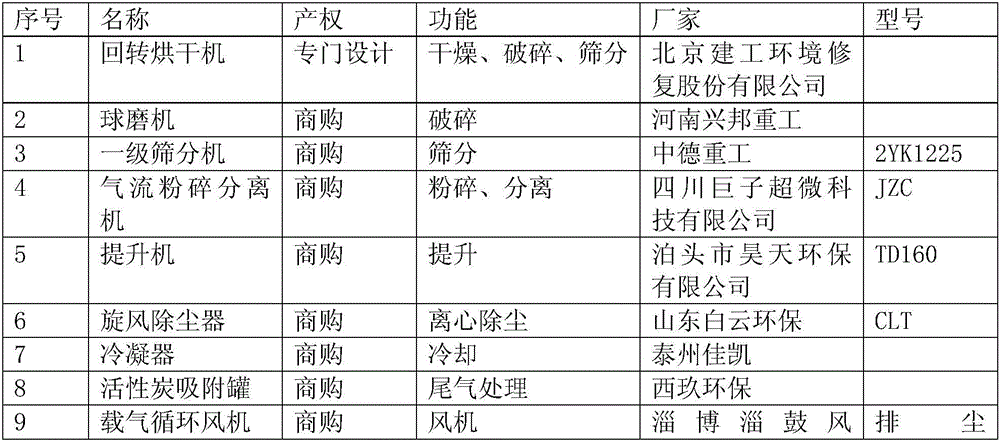

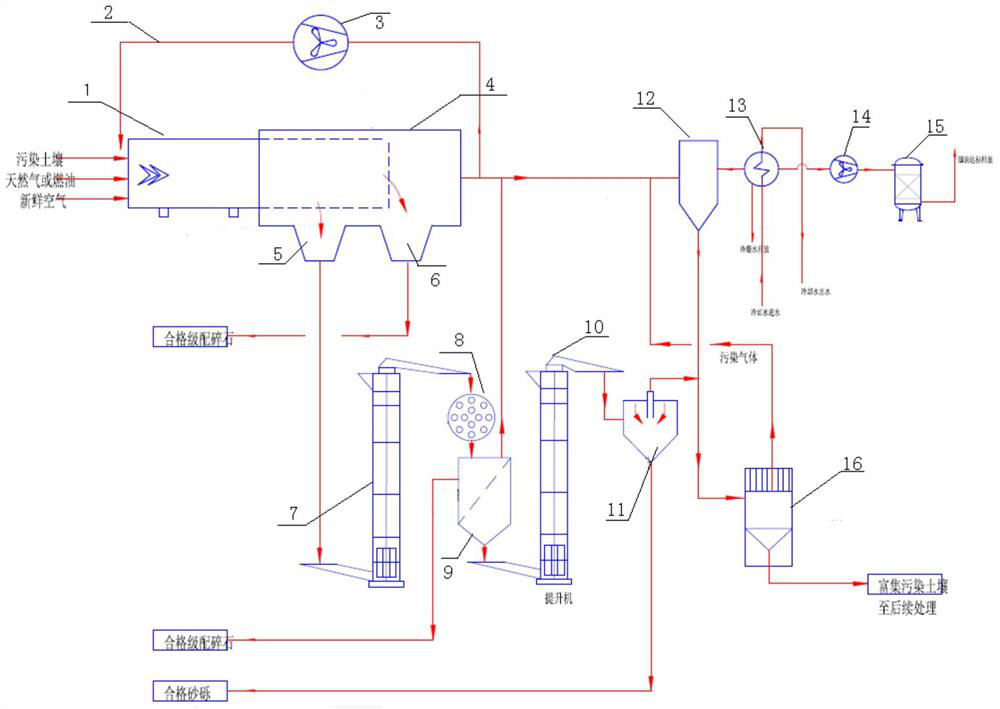

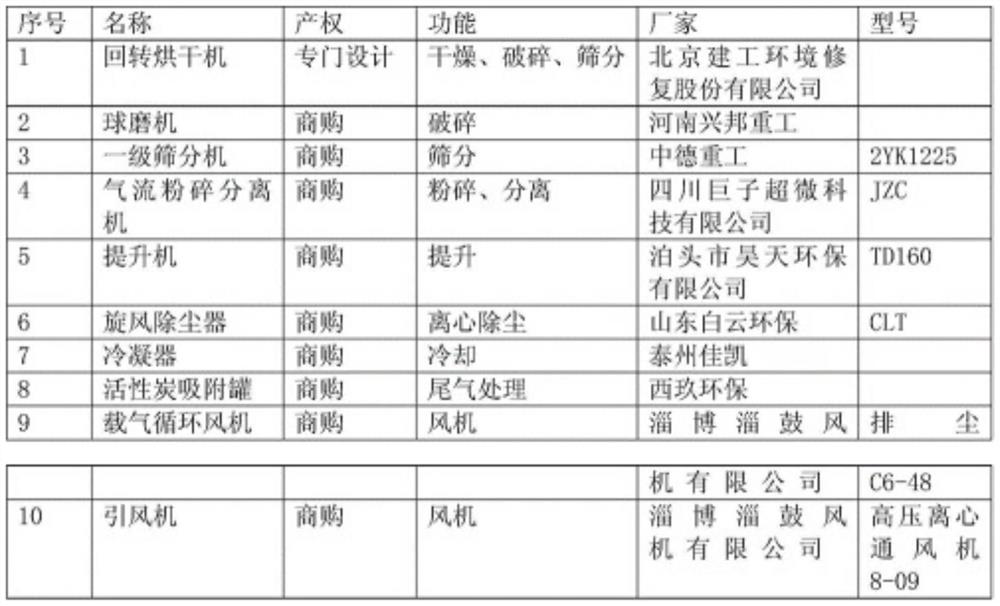

Contaminated soil medium-temperature dry-screen weight reduction treatment system and application

ActiveCN105921503AReduce energy consumptionSmall temperature differenceContaminated soil reclamationCombustionReduction treatment

The invention discloses a contaminated soil medium-temperature dry-screen weight reduction treatment system and an application, and belongs to the technical field of contaminated soil weight reduction treatment. The system comprises a rotary dryer and a heating device, wherein the rotary dryer is provided with a metal cylinder with a horizontal inclination angle; the heating device is composed of combustion equipment and a flue gas circulating system connected between the combustion equipment and the rotary dryer; and the heating device is used for providing a temperature higher than or equal to 65 DEG C and lower than 130 DEG C to soil materials in the metal cylinder of the rotary dryer. The contaminated soil medium-temperature dry-screen weight reduction treatment system is remarkable in weight reduction effect especially for contaminated soil which is relatively high in moisture content, more in clay, not obvious in normal-temperature screening reduction or not suitable for leaching.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

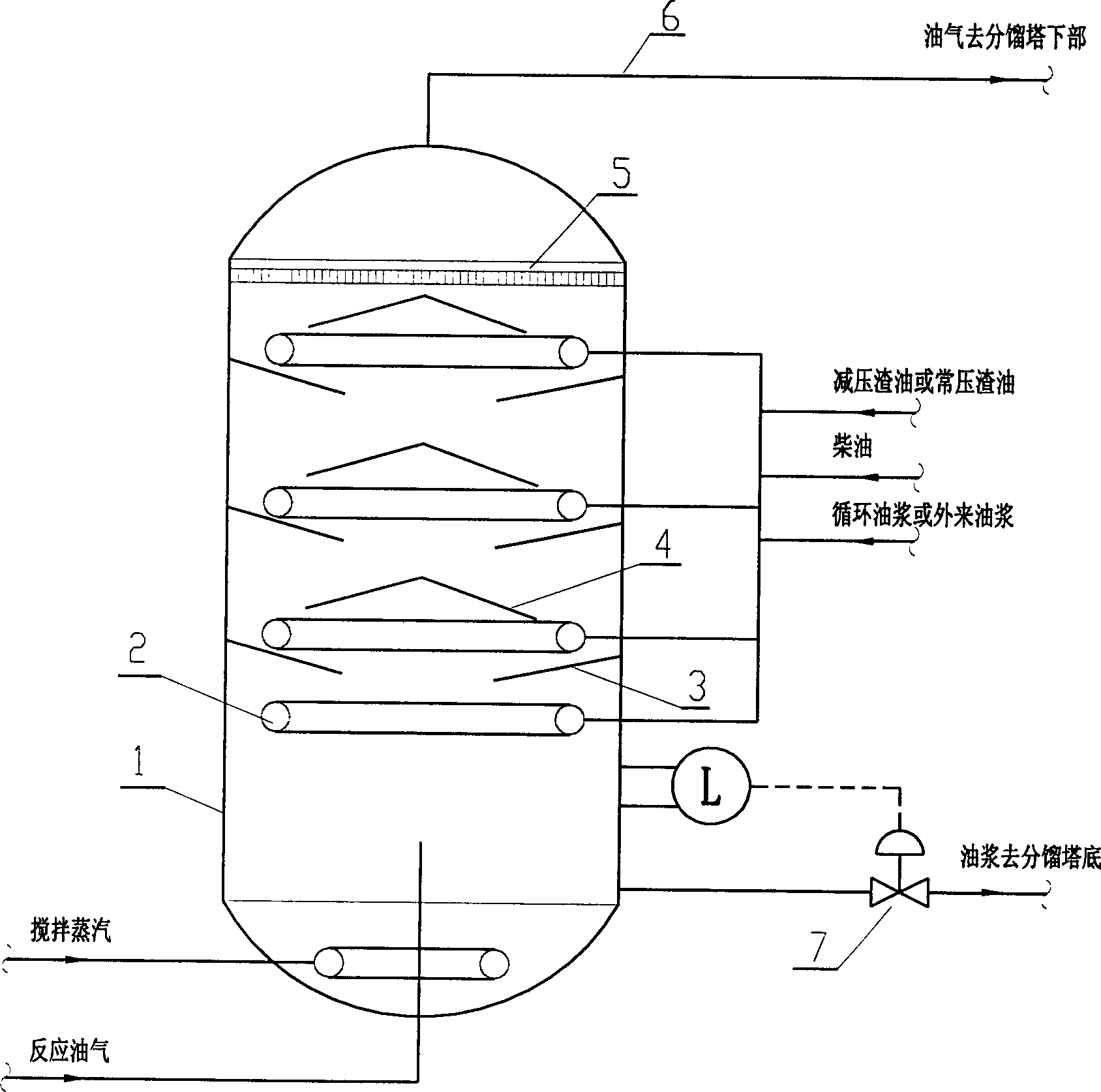

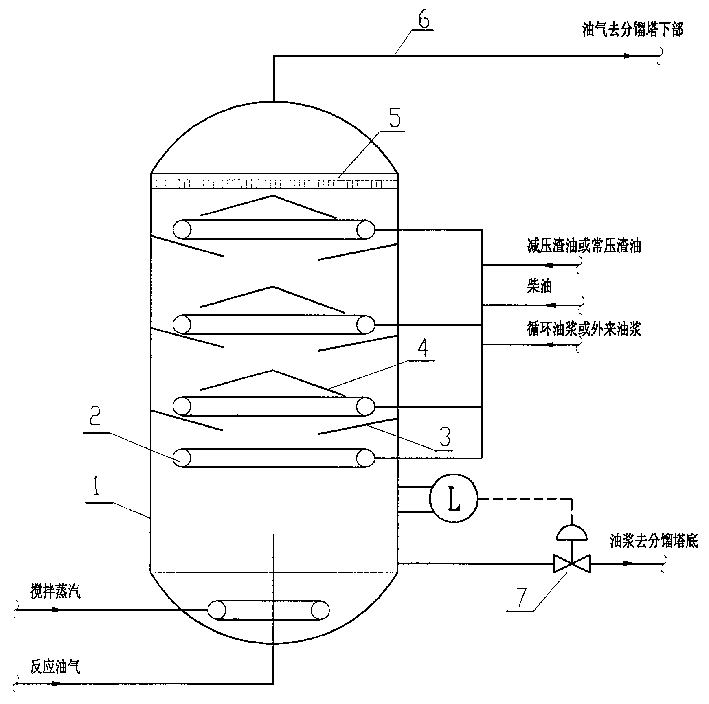

Method for recovering catalytic reaction oil and gas heat energy and cooling

InactiveCN1189539CAvoid cokingImprove heat transfer efficiencyThermal non-catalytic crackingFluidised-bed furnacesThermal energyLiquid medium

A process for cooling the oil vapour at 580-670 deg.c during catalytic cracking reaction and recovering its heat energy is characterized by use of an oil vapour cooler arranged on the top of reaction settling unit. Said cooler contains multiple layers of shaped baffle and the cooling liquid medium and counter-flow high-temp oil vapour for direct contact. Its advantage is high heat exchange efficiency.

Owner:SINOPEC ENG

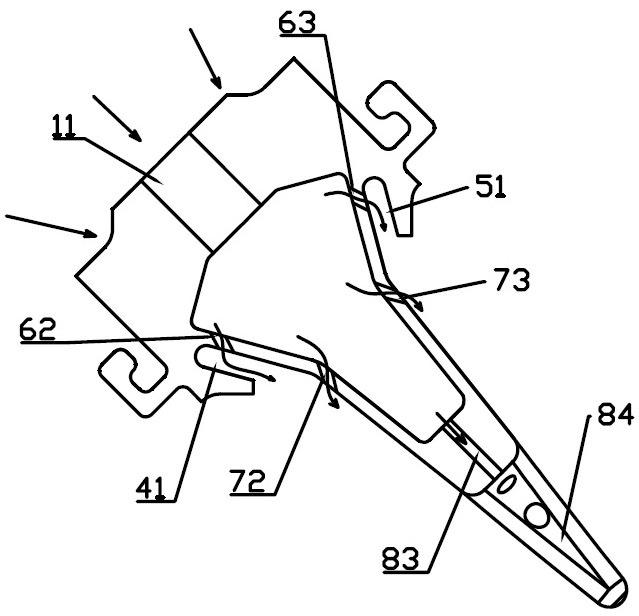

Combined fuel supply device, combustion chamber and fuel supply method

ActiveCN113513408AAchieve thermal protectionSpeed up evaporationTurbine/propulsion fuel supply systemsGas turbine plantsCombustion chamberInjector nozzle

The invention discloses a combined fuel supply device, a combustion chamber and a fuel supply method. The combined fuel supply device comprises a fuel supply mechanism extending in the radial direction, a radial stabilizer arranged behind the fuel supply mechanism and a connecting section used for connecting the fuel supply mechanism and the radial stabilizer. The fuel supply mechanism comprises a fuel injection rod and a fuel supply pipe which is coaxially distributed with the fuel injection rod and arranged at the outer side of the fuel injection rod, a plurality of fuel injection nozzles which are used for fuel injection and distributed in the radial direction are formed in the fuel injection rod, openings of the fuel injection nozzles are located at the outer side of the fuel supply pipe, and the fuel injection direction of the fuel injection nozzles is perpendicular to the incoming flow direction. According to the combined fuel supply device, the thermal protection problem under the high-temperature large-incoming-flow condition and the efficient combustion organization problem under the low-temperature large-incoming-flow condition can be solved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Full-automatic high-temperature-melt release mechanism and control method thereof

ActiveCN112191287AReduce heat absorptionReduce temperature requirementsReagent containersProcess engineeringEnvironmental geology

The invention discloses a full-automatic high-temperature-melt release mechanism and a control method thereof. The release mechanism comprises a temporary storage container, wherein the upstream portion of the temporary storage container is connected with a low-pressure container loaded with a smelting furnace through an upstream release pipeline; a protective gate valve and an upstream main sealing valve are sequentially arranged on the portion, from the low-pressure container to the upstream release pipeline of the temporary storage container, of the temporary storage container; a downstreamrelease pipeline is arranged on the downstream portion of the temporary storage container, a melt release valve and a downstream main sealing valve are arranged on the downstream release pipeline, the melt release valve is arranged on the side close to the temporary storage container, and the downstream main sealing valve is arranged on the side away from the temporary storage container; the temporary storage container and downstream devices thereof are arranged in a bottom high-pressure container; and the temporary storage container separately communicates with the low-pressure container, the bottom high-pressure container and a pressure source through pressure balance pipelines. The problem that high-temperature melt is difficult to transfer from a low-pressure environment to a high-pressure environment is solved.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

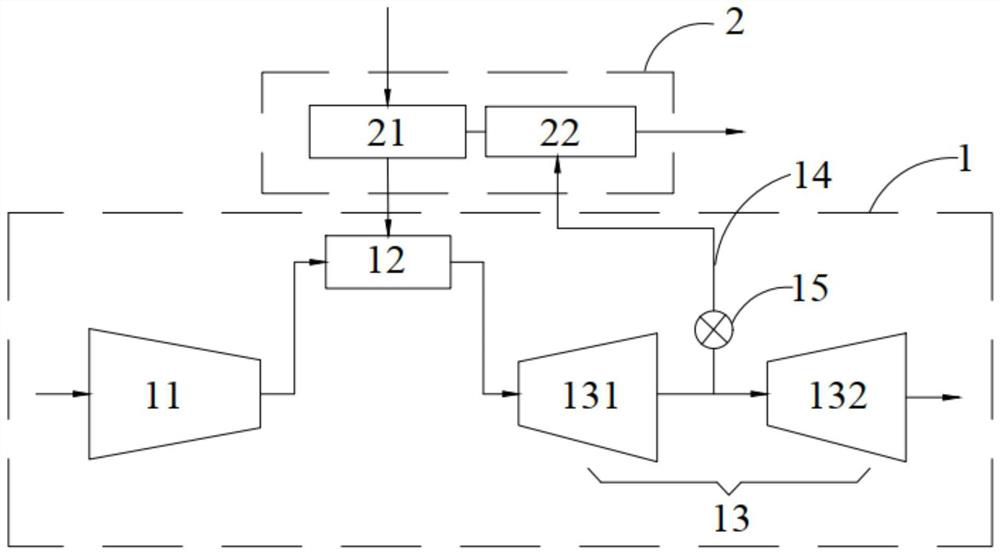

Gas turbine system

PendingCN111878234AReduce temperature requirementsImprove system efficiencyGas turbine plantsJet propulsion plantsCombustion chamberGas compressor

The invention relates to the technical field of gas turbines, and discloses a gas turbine system. The gas turbine system involves a gas turbine and a supercharging unit; the gas turbine comprises a first gas compressor, a combustion chamber and a turbine assembly, wherein the combustion chamber is provided with an air inlet, a gas inlet and an exhaust port, a gas outlet of the first gas compressorcommunicates with the air inlet, a gas outlet of the supercharging unit communicates with the gas inlet, the exhaust port of the combustion chamber is provided with an exhaust pipeline, and the turbine assembly is arranged on the exhaust pipeline and comprises at least two stages of turbines arranged in the flowing direction of gas in the exhaust pipeline; and the pressurizing unit comprises a second air compressor and a pressurizing driving turbine used for driving the second air compressor to act, and an air inlet of the supercharging driving turbine communicates with a part between two adjacent stages of turbines in the turbine assembly through a drainage branch. According to the gas turbine system, the problems that an existing gas turbine usually adopts a system configuration mode of"gas compressor and gas turbine", so that the occupied area is large, and the cost is high are solved.

Owner:新奥能源动力科技(上海)有限公司

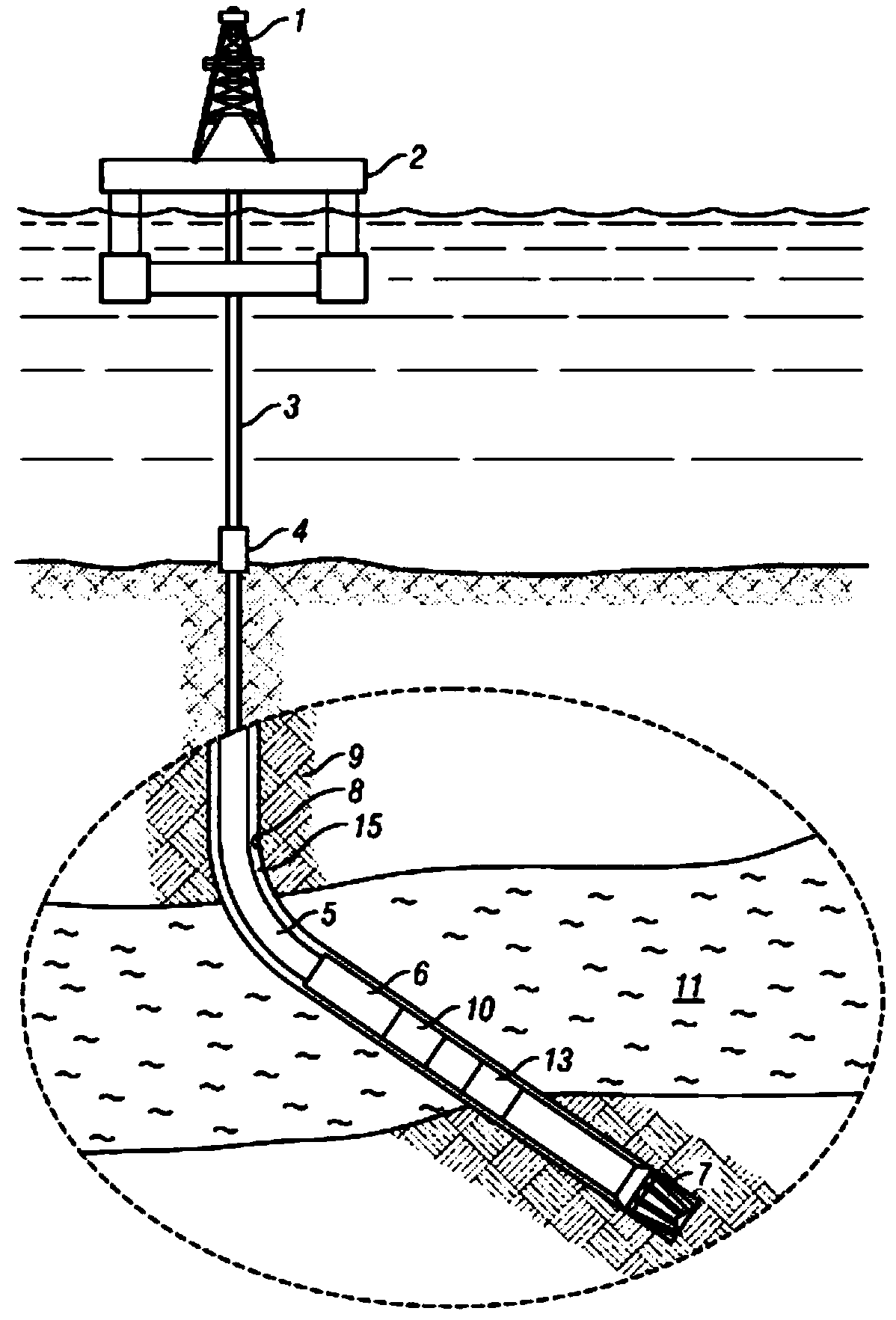

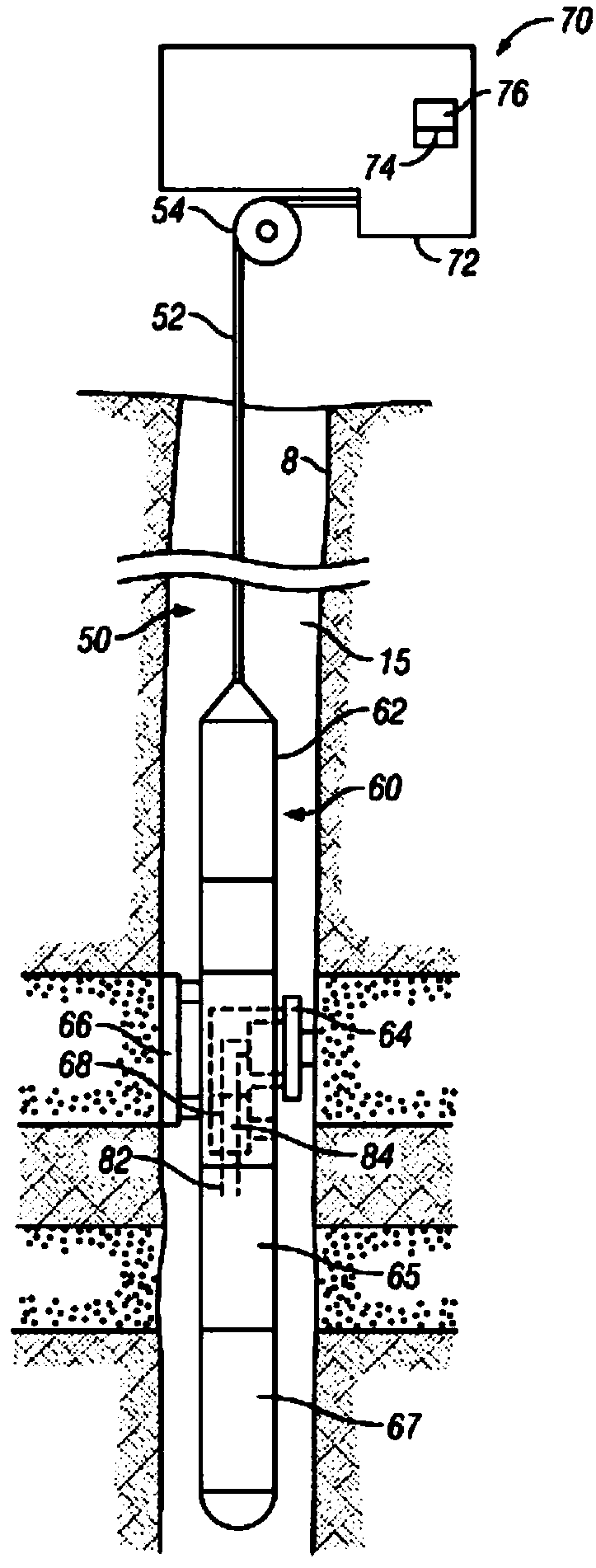

Device and method for transferring pressure to downhole electronic components by pressure transfer media

InactiveCN109577949AReduce temperature requirementsReduce pressure requirementsConstructionsEngineeringHigh pressure

The invention discloses a device and a method for transferring pressure to downhole electronic components by pressure transfer media. The device comprises an outer casing arranged in a downhole fluidhaving hydrostatic pressure. At least one cavity filled with the pressure transfer media is formed in the outer casing, the downhole electronic components are fixed into the pressure transfer media inthe cavities, the outer casing is provided with openings in communication with the cavities, the openings are sealed with elastic shielding members, the outer walls of the elastic shielding members contact with the downhole fluid to receive the hydrostatic pressure of the downhole fluid, and the hydrostatic pressure is transferred to the electronic components through the pressure transfer media.Compared with the prior art, the device and the method have the advantages that the downhole electronic components can work stably in corrosive and vibratory impact environments with high temperatureand high pressure during the oil and gas drilling process.

Owner:XI'AN PETROLEUM UNIVERSITY

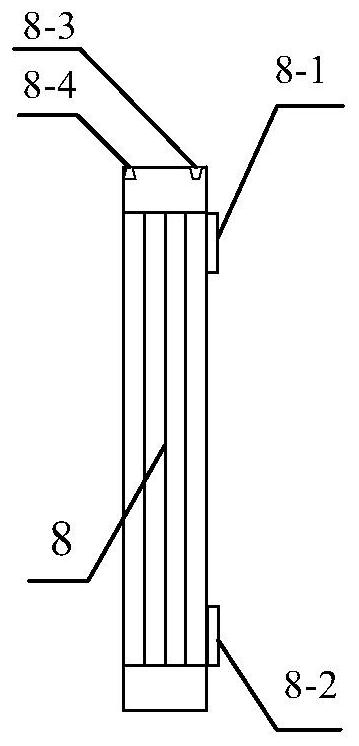

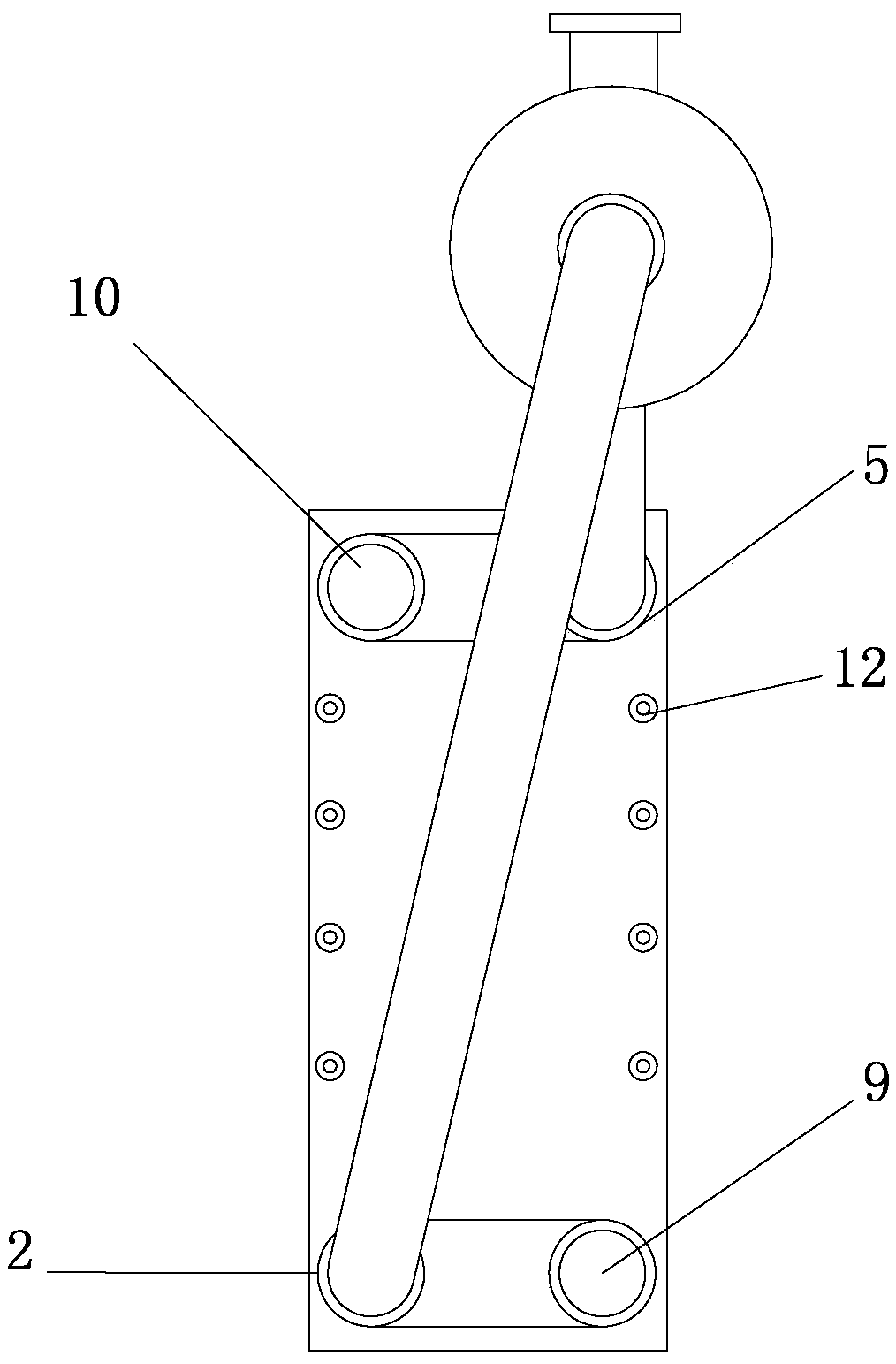

Novel heat exchanging unit

InactiveCN109579578AAvoid damageReduce temperature requirementsHeat exchange apparatusStationary plate conduit assembliesTemperature resistanceEngineering

The invention discloses a novel heat exchanging unit, which is mainly composed of a heat exchanger and an attemperator. An attemperator steam inlet tube and a cold water outlet and inlet tube are arranged on the upper part of the attemperator, and a heat exchanger water inlet, a heat exchanger steam inlet, a condensate water outlet and a heat exchanger water return opening are formed in the heat exchanger. High-temperature steam is subjected to heat exchanging in the attemperator firstly, at the moment, the temperature of the high-temperature steam is decreased correspondingly, then the high-temperature steam enters the heat exchanger to be subjected to heat exchanging, at the moment, the temperature of the steam entering the heat exchanger is effectively decreased, in this way, damage toa rubber pad is avoided, and thus the requirement for temperature resistance of the rubber pad is lowered.

Owner:XIAOGAN JIARUI APPLICATION TECHNOLOGY DEVELOPMENT CO LTD

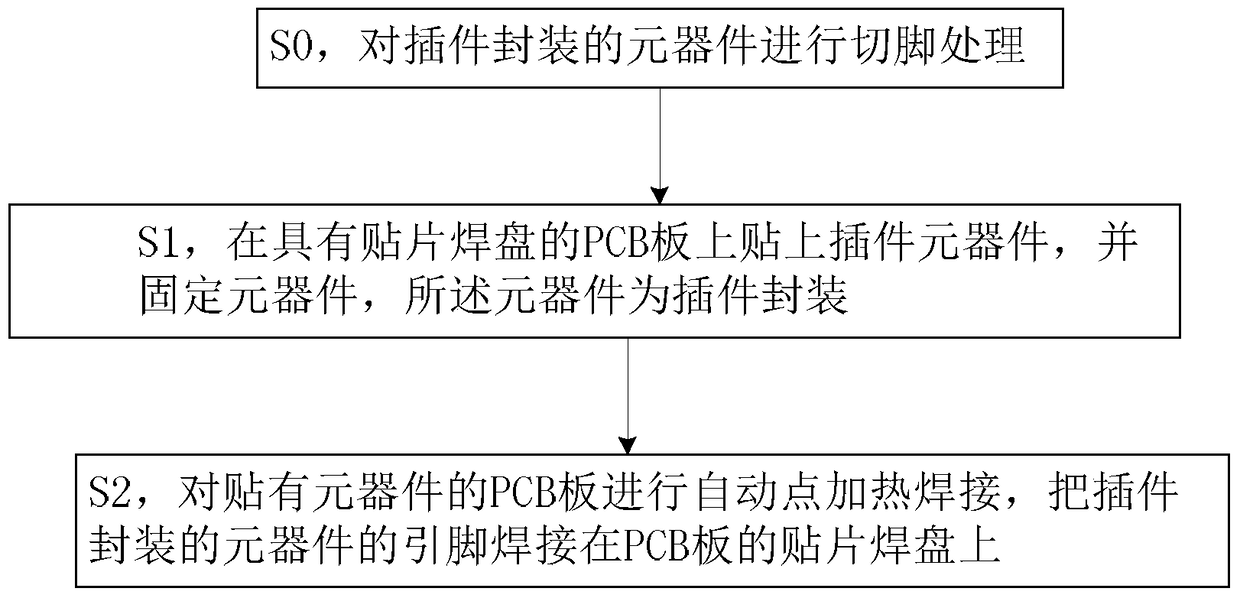

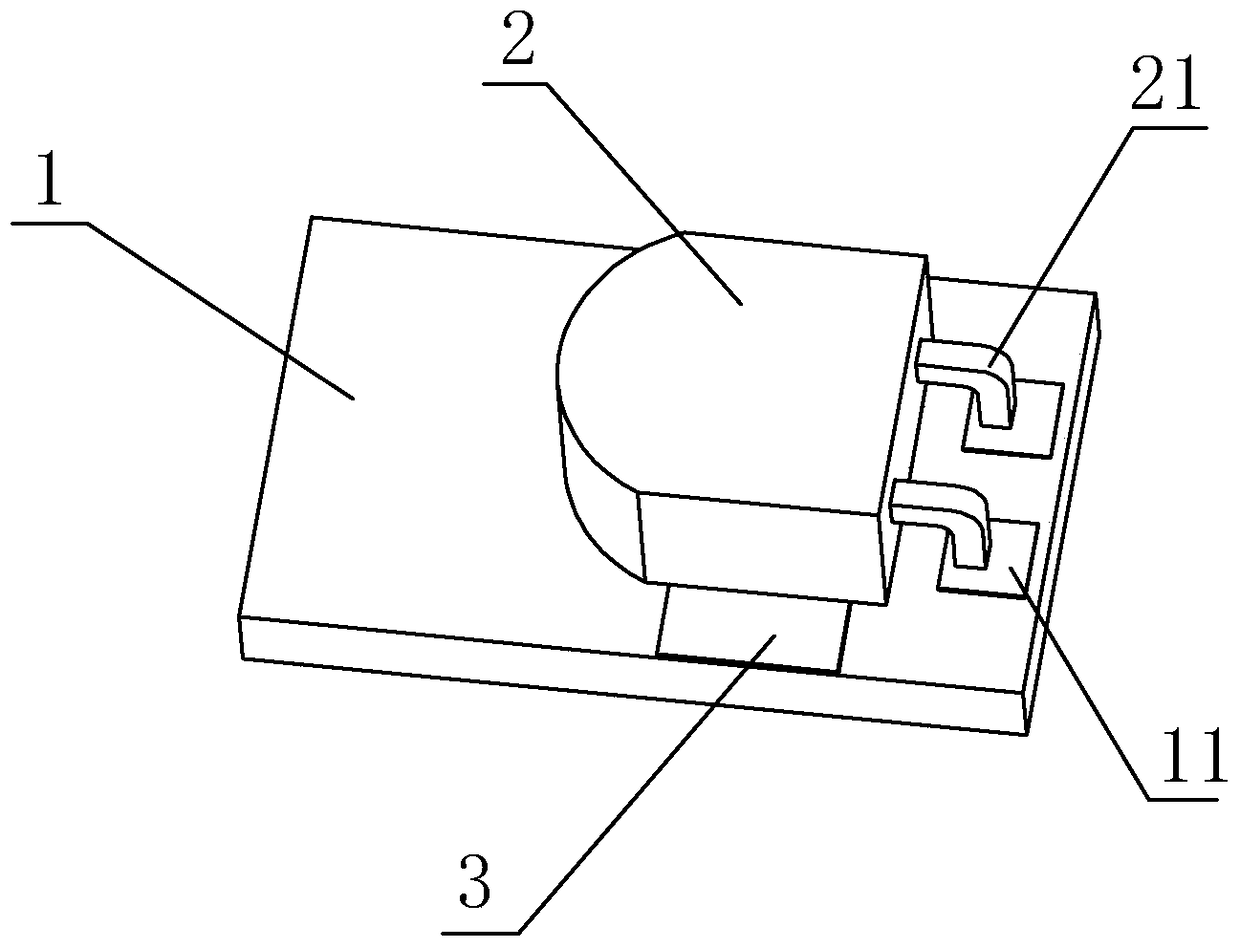

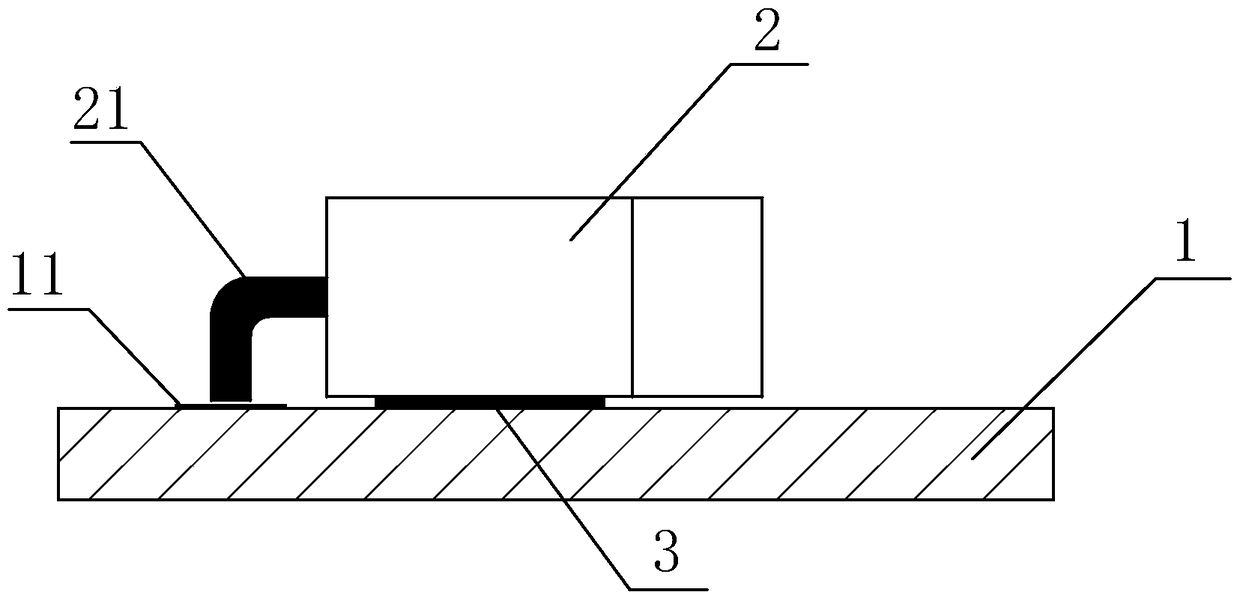

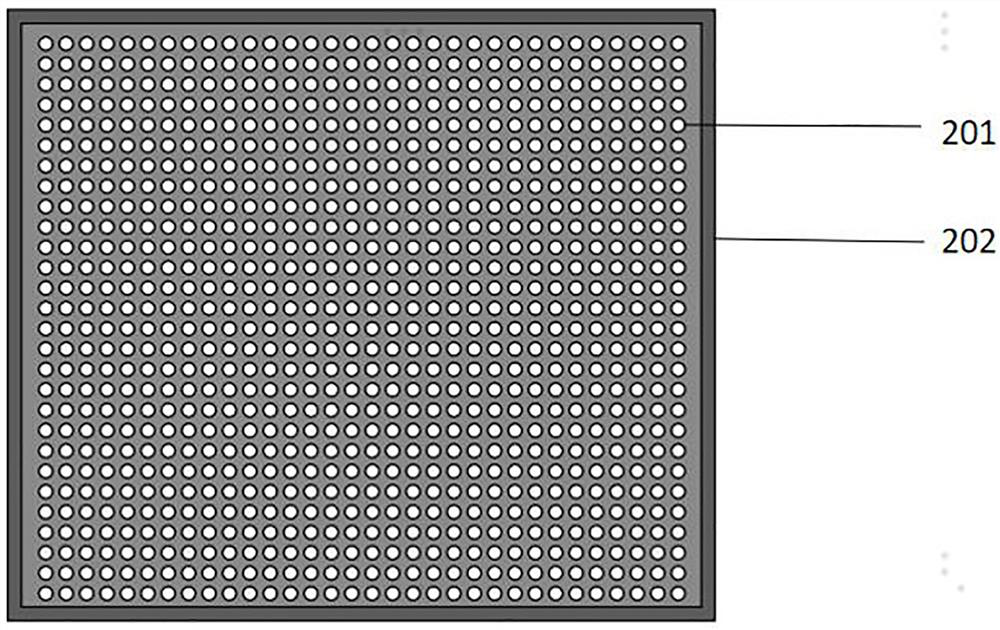

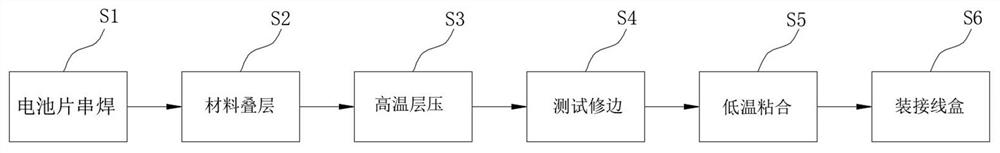

The pcba processing method and pcba board based on the combination of plug-in component technology and patch technology

ActiveCN104507271BReduce temperature requirementsIncrease productivityPrinted circuit assemblingPrinted circuit aspectsPondingSurface mounting

The invention discloses a plug-in component technology and surface mount technology combination based PCBA (printed circuit board assembly) machining method and a PCBA. The method includes the steps: S1, attaching a plug-in component on a PCB with a surface mount bonding pad, and fixing the component which is packaged in a plug-in manner; S2, subjecting the PCB mounted with the component to automatic spot heating welding, and welding pins of the component in plug-in package on the surface mount bonding pad of the PCB. The PCB is provided with the plug-in packaged component and the surface mount bonding pad, and the pins of the plug-in packaged component are welded on the surface mount bonding pad. The advantages of plug-in technology and the surface mount technology are fused, the plug-in packaged component and the PCB with the surface mount ponding pad are utilized, and the automatic spot heating welding technology is combined, so that labor cost and material cost of PCBA machining are saved, the requirement on temperature resistance of the component is lowered, production efficiency and product percent of pass of the PCB are increased, and good social and economic benefits are gained. The method can be widely applied to various PCBA machining technologies.

Owner:深圳市凯健奥达科技有限公司

Steam-water heat exchange unit

InactiveCN109579574AReduce the temperatureReduce temperature requirementsStationary tubular conduit assembliesStationary plate conduit assembliesReducerEngineering

The invention discloses a steam-water heat exchange unit. The heat exchange unit is mainly composed of a plate heat exchanger and a temperature reducer, wherein a temperature reducer steam inlet pipeand a hot water outlet pipe are arranged above the temperature reducer, and a temperature reducer water return port, a heat exchanger steam inlet, a condensate water outlet and a heat exchanger waterreturn port are formed in the plate heat exchanger. According to the heat exchange unit, low-temperature flowing-back water is subjected to primary heat exchange in the plate heat exchanger, then enters the temperature reducer for heat exchange, and finally is discharged from the hot water outlet pipe; and whole equipment is of a secondary heat exchange structure, high-temperature steam is firstlysubjected to heat exchange in the temperature reducer and at the moment, the temperature of the high-temperature steam is correspondingly reduced, then the high-temperature steam enters the plate heat exchanger for heat exchange, the temperature of the steam entering the plate heat exchanger for the moment is effectively reduced, so that the damage to a rubber mat is avoided, and the temperatureresistance requirement of the rubber mat is reduced.

Owner:XIAOGAN JIARUI APPLICATION TECHNOLOGY DEVELOPMENT CO LTD

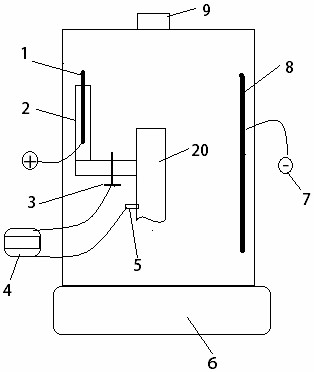

Wet-type electrostatic precipitator for waste gas treatment and using method thereof

PendingCN111804438AImprove conductivityEasy to cleanExternal electric electrostatic seperatorElectrode constructionsWater vaporExhaust fumes

The invention provides a wet-type electrostatic precipitator for waste gas treatment. The wet-type electrostatic precipitator comprises an acid-resistant and alkali-corrosion-resistant metal dischargeelectrode, a dust collection electrode, a high-voltage discharge circuit, a waste gas main pipe, a waste gas branch, a purified gas outlet and a dust collection cavity, wherein the waste gas branch is connected to the side wall of the waste gas main pipe through a control valve, and part of the metal discharge electrode is sleeved in the waste gas branch. According to the wet-type electrostatic precipitator, acidic and alkaline waste gas, water vapor and dust can be removed, and the discharge electrode is not prone to be oxidized or bonded with oil stain to lose the discharge function.

Owner:NANTONG JIANGSHAN AGROCHEM & CHEM LIMITED LIABILITY

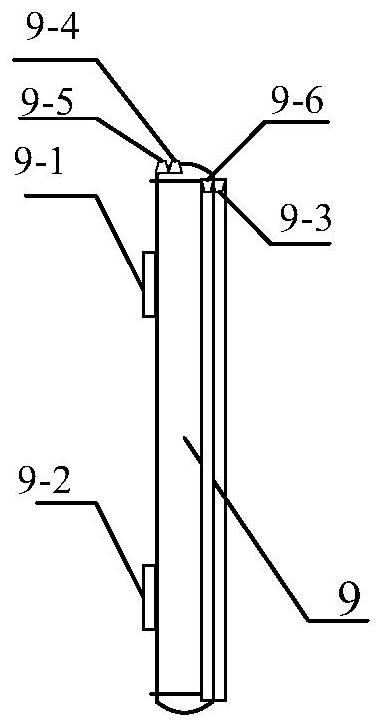

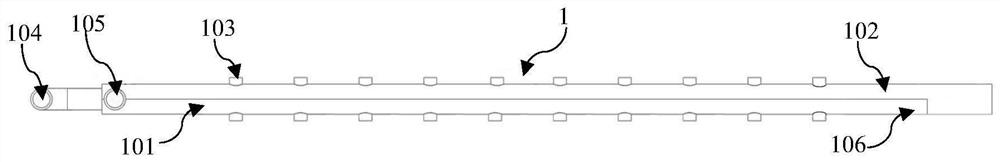

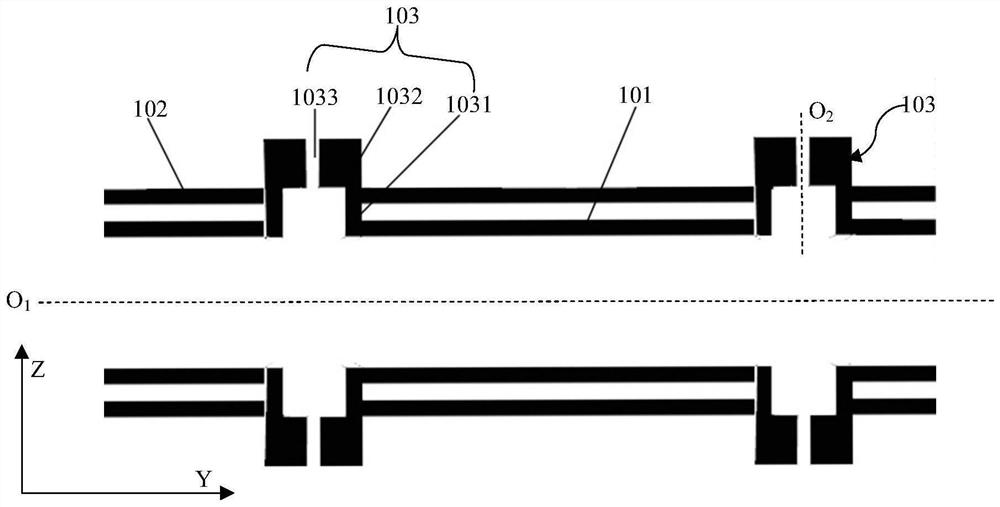

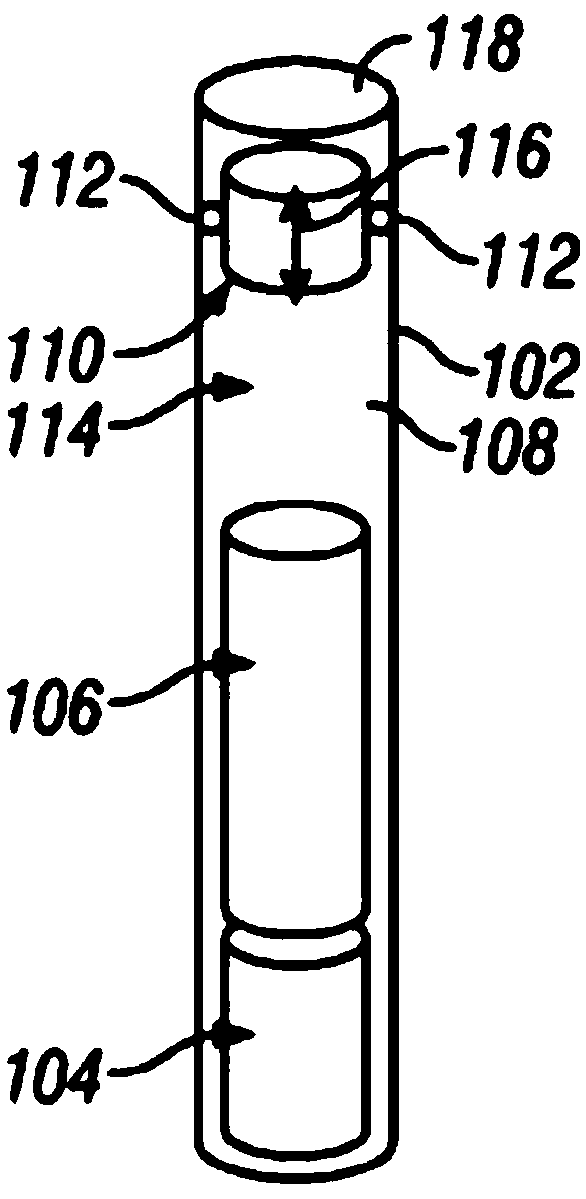

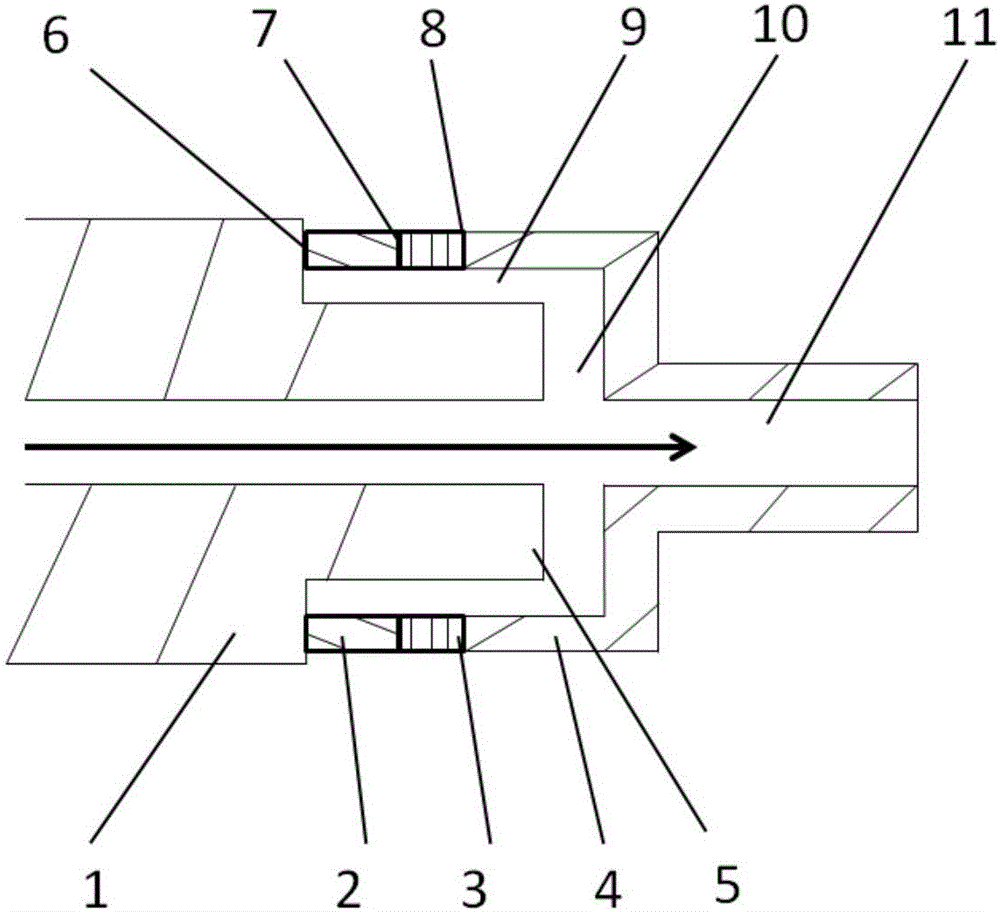

Ion source discharging module and operating method thereof

ActiveCN106887375AAvoid chippingReduce temperature requirementsIon sources/gunsQuartzMaterials science

The invention provides an ion source discharging module and an operating method thereof. The ion source discharging module comprises: a ceramic tube including a part with a larger outer diameter and a part with a smaller outer diameter; a metal member disposed on the periphery of the part with a smaller outer diameter and connected with the part with a larger outer diameter of the ceramic tube; a glass tube which is disposed on the periphery of the part with a smaller outer diameter, the left of which is connected with the metal member and the right of which is connected with a quartz tube, wherein the distance between the metal member and the outer edge of the part with a smaller outer diameter and the distance between the glass tube and the outer edge of the part with a smaller outer diameter are both greater than zero; and the quartz tube comprising a part with a larger inner diameter and a part with a smaller inner diameter, wherein the end portion of the part with a larger inner diameter is connected to the right of the glass tube, and the distance between the quartz tube and the part with a smaller outer diameter is greater than zero. The ion source discharging module has good reliability and simple structure.

Owner:CHINA INNOVATION INSTR CO LTD +1

A kind of automatic release mechanism of high temperature melt and control method thereof

ActiveCN112191287BAchieve releaseReduce heat absorptionReagent containersProcess engineeringPressure balance

The invention discloses a fully automatic release mechanism for high-temperature molten matter and its control method. The release mechanism of the invention includes a temporary storage container; the upstream of the temporary storage container is connected to a low-pressure container equipped with a melting furnace through an upstream release pipeline, and A protective gate valve and an upstream main sealing valve are sequentially provided on the upstream release pipeline from the low-pressure container to the temporary storage container; a downstream release pipeline is provided downstream of the temporary storage container, and a melt release pipe is provided on the downstream release pipeline. valve and a downstream main sealing valve, the melt release valve is arranged on a side close to the temporary storage container, and the downstream main sealing valve is arranged on a side away from the temporary storage container; the temporary storage container and its The downstream devices are all installed in the bottom high-pressure container; the temporary storage container communicates with the low-pressure container, the bottom high-pressure container and the pressure source respectively through pressure balance pipelines. The invention breaks through the difficulty of transferring high-temperature molten matter from a low-pressure environment to a high-pressure environment.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

Ion source discharge module and working method thereof

The invention provides an ion source discharging module and an operating method thereof. The ion source discharging module comprises: a ceramic tube including a part with a larger outer diameter and a part with a smaller outer diameter; a metal member disposed on the periphery of the part with a smaller outer diameter and connected with the part with a larger outer diameter of the ceramic tube; a glass tube which is disposed on the periphery of the part with a smaller outer diameter, the left of which is connected with the metal member and the right of which is connected with a quartz tube, wherein the distance between the metal member and the outer edge of the part with a smaller outer diameter and the distance between the glass tube and the outer edge of the part with a smaller outer diameter are both greater than zero; and the quartz tube comprising a part with a larger inner diameter and a part with a smaller inner diameter, wherein the end portion of the part with a larger inner diameter is connected to the right of the glass tube, and the distance between the quartz tube and the part with a smaller outer diameter is greater than zero. The ion source discharging module has good reliability and simple structure.

Owner:CHINA INNOVATION INSTR CO LTD +1

Low-temperature melting block finished glaze and preparation method thereof

ActiveCN102134167BReduce energy consumptionReduce temperature requirementsAluminium hydroxideTemperature resistance

Owner:JIANGSU BAIFU TECH CO LTD

Duplex heat exchanger

InactiveCN109579588AReduce the temperatureReduce temperature requirementsIndirect heat exchangersWater pipeEngineering

The invention discloses a duplex heat exchanger. The duplex heat exchanger is mainly composed of a plate heat exchanger and a desuperheater, a desuperheater steam inlet tube and a cold water inlet tube are arranged at the upper part of the desuperheater, an M-shaped steam heat exchanger tube and an M-shaped hot water heat exchanger tube are arranged in the plate heat exchanger longitudinally, an internal heat tube of the desuperheater is of a straight-array structure, and a heat exchanger water returning opening is used for being connected with a heating device water returning pipeline and connected with a desuperheater water returning opening through the M-shaped hot water heat exchanger tube, the desuperheater water returning opening is connected with a cold water inlet of an internal heat exchanger pipeline of the desuperheater through the water returning tube, a steam inlet of the desuperheater is connected with a heat exchanger steam inlet of the plate heat exchanger through a steam conveying tube, and the heat exchanger steam inlet is connected with a heat exchanger steam outlet through the M-shaped hot water heat exchanger tube. According to the duplex heat exchanger, once heat exchanging is conducted on the low temperature reflux water in the desuperheater, then enters the heat exchanger for heat exchanging, and finally discharged from the heat exchanger water returningopening, the whole equipment is of a twice heat exchanging structure, and the heat recovery rate can be up to more than 90%.

Owner:HUBEI ZHIQUAN PATENT TECH APPL DEV CO LTD

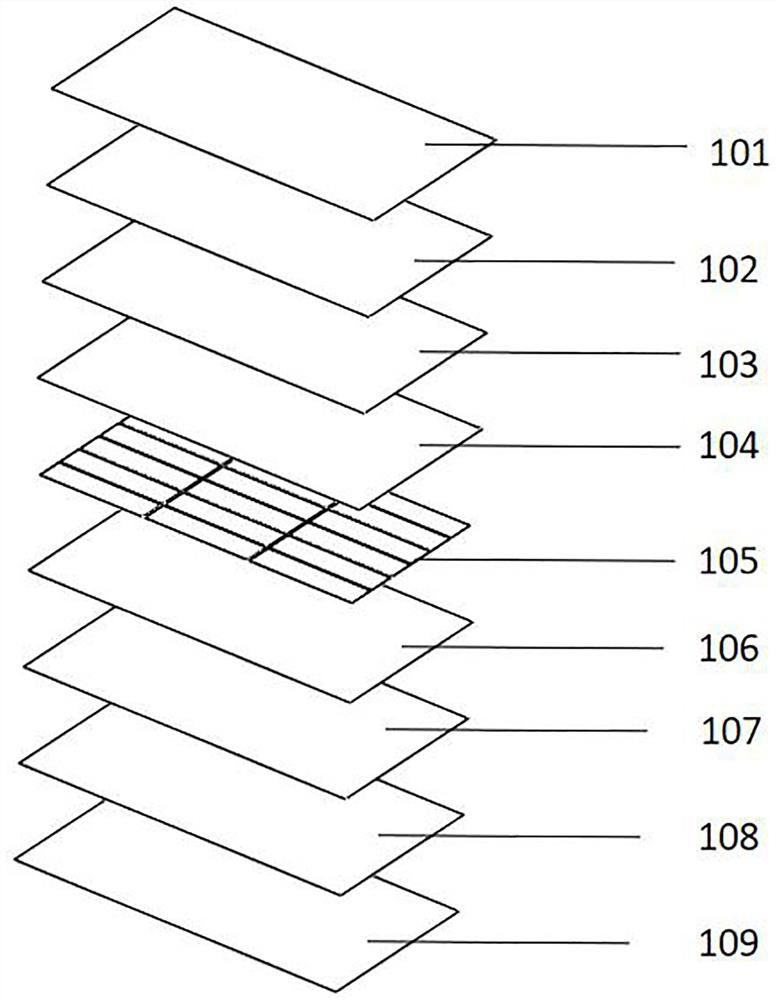

A kind of lightweight solar power generation panel and preparation method thereof

ActiveCN114068745BReduce temperature requirementsStrong shape and structure compatibilitySynthetic resin layered productsElectrical equipmentPolystyreneAcrylonitrile

Owner:SHENZHEN HELLO TECH ENERGY CO LTD

A Medium-temperature Dry Screening Reduction Treatment System for Contaminated Soil and Its Application

ActiveCN105921503BReduce energy consumptionAvoid clumpingContaminated soil reclamationReduction treatmentSoil science

The invention discloses a polluted soil medium-temperature dry screening reduction treatment system and its application, belonging to the technical field of contaminated soil reduction treatment. The system of the present invention includes a rotary dryer, a metal cylinder with a horizontal inclination angle; a heating device, composed of combustion equipment and a flue gas circulation system connected between the combustion equipment and the rotary dryer, to the The soil material in said metal cylinder of the rotary dryer provides a temperature greater than or equal to 65°C and less than 130°C. The system of the present invention is particularly effective in reducing the amount of polluted soil with high water content, large amount of clay and insignificant sieving reduction at normal temperature, or unsuitable for leaching.

Owner:BCEG ENVIRONMENTAL REMEDIATION CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com