A kind of lightweight solar power generation panel and preparation method thereof

A solar power generation panel, lightweight technology, applied in the field of solar cells, can solve the problems of increased material cost and processing difficulty, small solar panels, limited optional materials, etc., and achieves strong shape and structure compatibility, low cost, and wide range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

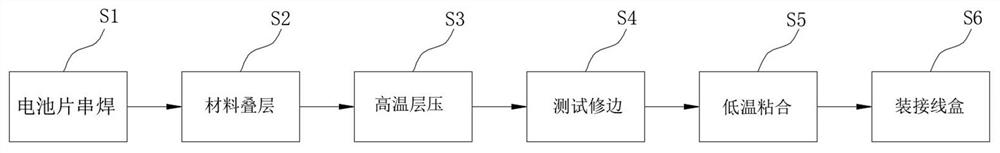

[0072]This embodiment provides a method for preparing a light-weight solar power generation panel. The preparation method specifically includes the following steps:

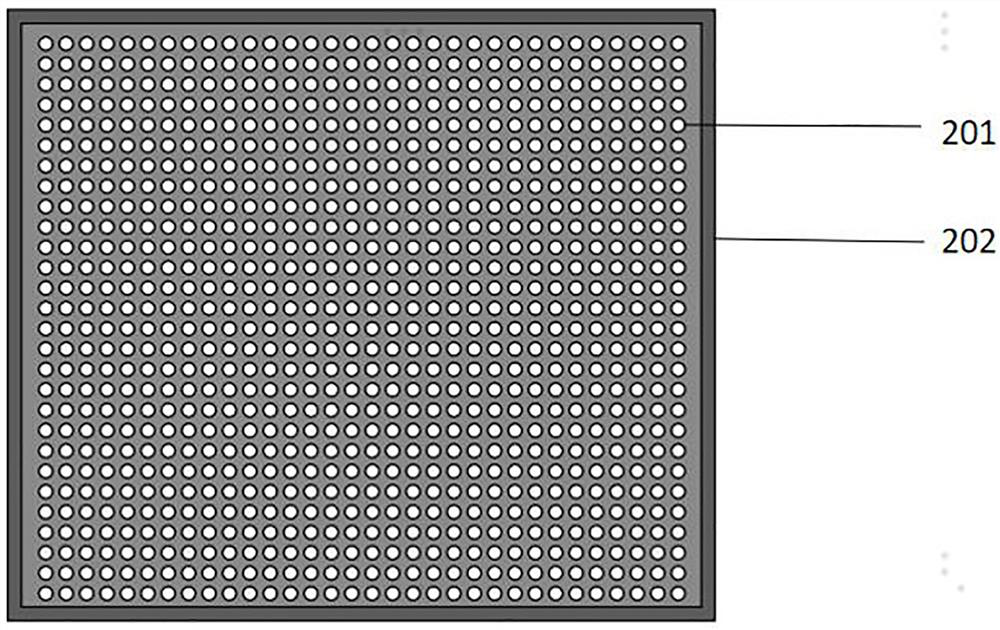

[0073] S1 battery slice series welding: connect the battery slices in series and in parallel to form a string with a certain voltage and current, and lead out the positive and negative electrodes to obtain the battery layer 105;

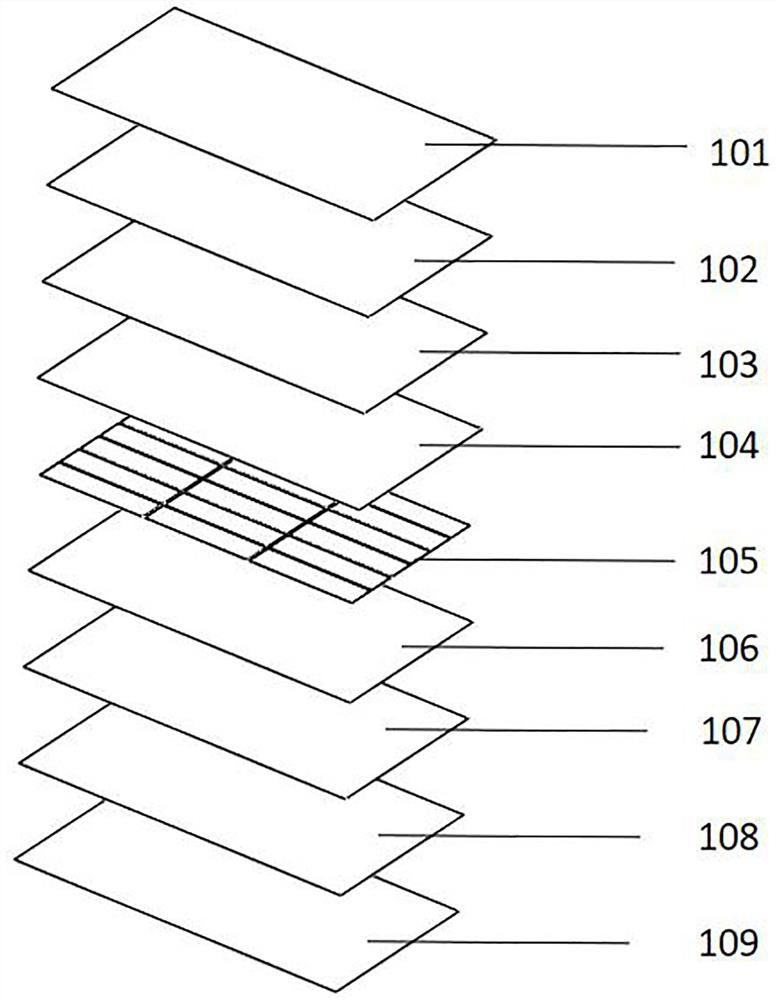

[0074] S2 material lamination: Lay a layer of high temperature cloth on the carrier, weather-resistant layer 109 (ETFE), fourth adhesive layer 108, support layer 107 (PET), third adhesive layer 106, battery layer 105, second adhesive layer 104 and insulating layer 103 (PET) are sequentially stacked on the carrier from bottom to top;

[0075] S3 high-temperature lamination: Lay Teflon on the surface of the laminated uppermost insulating layer 103 (PET) to protect its surface clean and non-sticky, and send it into the laminator together with the carrier for high-temperature lamination. 1...

Embodiment 2

[0080] This embodiment provides a method for preparing a light-weight solar power generation panel. The preparation method specifically includes the following steps:

[0081] S1 battery slice series welding: connect the battery slices in series and in parallel to form a string with a certain voltage and current, and lead out the positive and negative electrodes to obtain the battery layer 105;

[0082] S2 material lamination: Lay a layer of high temperature cloth on the carrier, weather-resistant layer 109 (ETFE), fourth adhesive layer 108, support layer 107 (PET), third adhesive layer 106, battery layer 105, second adhesive layer 104 and insulating layer 103 (PET) are sequentially stacked on the carrier from bottom to top;

[0083] S3 high-temperature lamination: Lay Teflon on the surface of the laminated uppermost insulating layer 103 (PET) to protect its surface clean and non-sticky, and send it into the laminator together with the carrier for high-temperature lamination. ...

Embodiment 3

[0088] This embodiment provides a method for preparing a light-weight solar power generation panel. The preparation method specifically includes the following steps:

[0089] S1 battery slice series welding: connect the battery slices in series and in parallel to form a string with a certain voltage and current, and lead out the positive and negative electrodes to obtain the battery layer 105;

[0090] S2 material lamination: Lay a layer of high temperature cloth on the carrier, weather-resistant layer 109 (ETFE), fourth adhesive layer 108, support layer 107 (PET), third adhesive layer 106, battery layer 105, second adhesive layer 104 and insulating layer 103 (PET) are sequentially stacked on the carrier from bottom to top;

[0091] S3 high-temperature lamination: Lay Teflon on the surface of the laminated uppermost insulating layer 103 (PET) to protect its surface clean and non-sticky, and send it into the laminator together with the carrier for high-temperature lamination. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com