Ion source discharge module and working method thereof

A discharge module and ion source technology, applied in the field of ion sources, can solve problems that cannot be effectively solved, and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

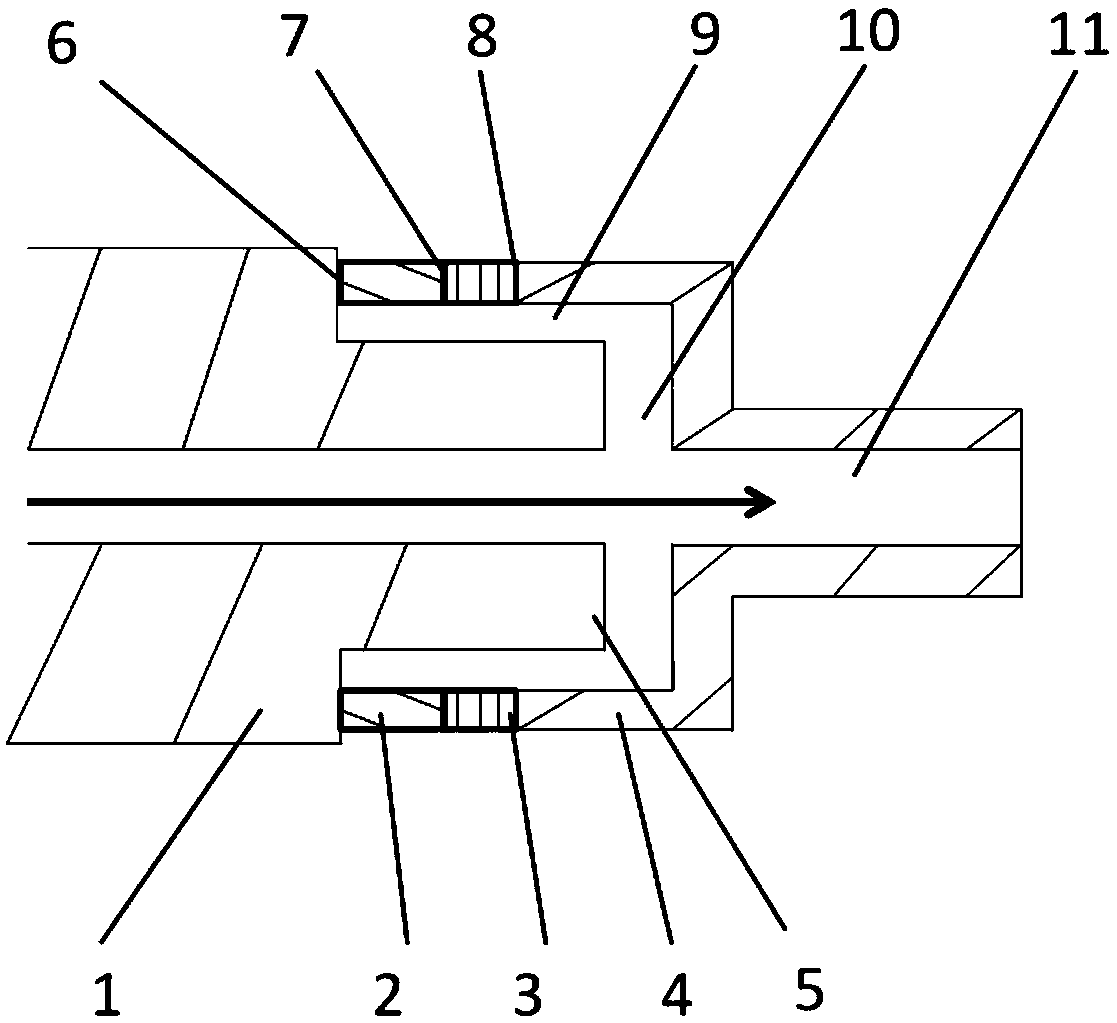

[0024] figure 1 Schematically provides a simplified structural diagram of the ion source discharge module of the embodiment of the present invention, as figure 1 As shown, the ion source discharge module includes:

[0025] Ceramic tube 1, such as high-purity alumina ceramics, 99 porcelain, 95 porcelain, 90 porcelain or 85 porcelain, the ceramic pipe includes a part with a larger outer diameter and a part with a smaller outer diameter;

[0026] Metal piece 2, such as silver, molybdenum, niobium, tantalum or Kovar, said metal piece is arranged on the periphery of said smaller outer diameter part and connected with the larger outer diameter part of said ceramic tube;

[0027] Glass tube 3 adopts ordinary glass, and the glass tube is arranged on the periphery of the smaller part of the outer diameter, the left side is connected with the metal part, and the right side is connected with the quartz tube; the metal part and the glass tube are connected with the outer part. The dista...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com