Low-temperature melting block finished glaze and preparation method thereof

A low-temperature frit and finished product technology, which is applied in the field of low-temperature frit finished glaze and its preparation, can solve the problems of high firing temperature, achieve the effects of reducing temperature resistance requirements, bright colors, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

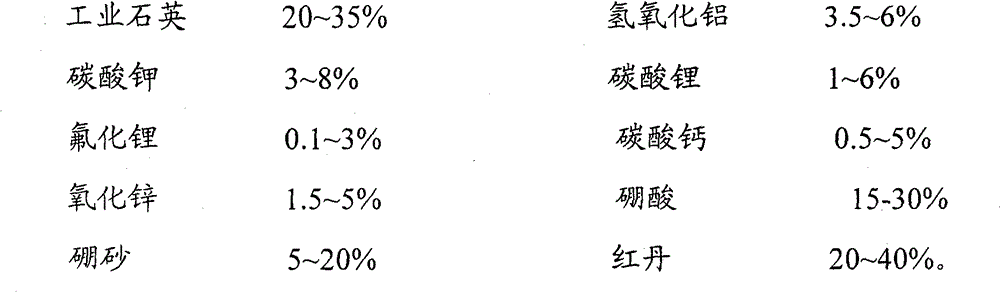

[0037] (1) Preparation of low-temperature frit: proportioning by weight percentage of the following raw materials:

[0038] Industrial Quartz 30% Aluminum Hydroxide 5%

[0039] Potassium Carbonate 5.5% Lithium Carbonate 2.5%

[0040] Lithium Fluoride 1.5% Calcium Carbonate 3.5%

[0041] Zinc Oxide 4% Boric Acid 20%

[0042] Borax 8% Red lead 20%

[0043]Weigh the raw materials of the above components, sieve (above 40 mesh), stir and mix for 20-30 minutes and homogenize, then melt at a temperature of 1400 ° C, and the melting cycle is 6 hours, and the invention can be obtained. low-temperature frit.

[0044] (2) Low-temperature frit finished glaze:

[0045] 90 parts by weight of low-temperature frit and 10 parts by weight of kaolin are uniformly mixed, ball-milled, filtered, dried, and powdered at a drying temperature of 145°C to obtain the finished low-temperature frit glaze of the present invention.

Embodiment 2

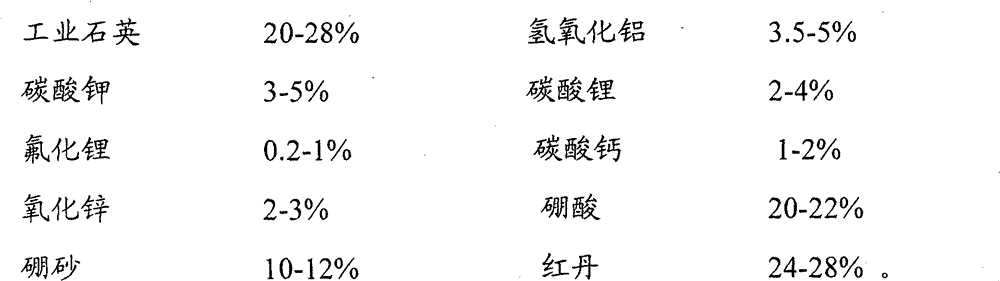

[0047] (1) Preparation of low-temperature frit: proportioning by weight percentage of the following raw materials:

[0048] Industrial Quartz 26.5% Aluminum Hydroxide 4.5%

[0049] Potassium Carbonate 3.8% Lithium Carbonate 3%

[0050] Lithium Fluoride 0.3% Calcium Carbonate 1.3%

[0051] Zinc Oxide 2.4% Boric Acid 21.2%

[0052] Borax 10.5% Red lead 26.5%

[0053] Weigh the raw materials of the above components, sieve (above 40 mesh), stir and mix for 20-30 minutes and homogenize, then melt at a temperature of 1450 ° C, and the melting cycle is 7 hours to obtain the present invention. low-temperature frit.

[0054] (3) Low-temperature frit finished glaze:

[0055] 92 parts by weight of low-temperature frit and 8 parts by weight of kaolin are uniformly mixed, ball-milled, filtered, dried and powdered at 140°C to obtain the finished low-temperature frit glaze of the present invention.

Embodiment 3

[0057] (1) Preparation of low-temperature frit: proportioning by weight percentage of the following raw materials:

[0058] Industrial Quartz 25.5% Aluminum Hydroxide 5%

[0059] Potassium Carbonate 4.6% Lithium Carbonate 4%

[0060] Lithium Fluoride 0.9% Calcium Carbonate 2%

[0061] Zinc Oxide 3% Boric Acid 15%

[0062] Borax 12% Red lead 28%

[0063] Weigh the raw materials of the above components, sieve (above 40 mesh), stir and mix for 20-30 minutes and homogenize, then melt at a temperature of 1500 ° C, and the melting cycle is 5.5 hours to obtain the present invention. low-temperature frit.

[0064] (2) Low-temperature frit finished glaze:

[0065] 91 parts by weight of low-temperature frit and 9 parts by weight of kaolin are uniformly mixed, ball-milled, filtered, dried and powdered at a drying temperature of 150°C to obtain the finished low-temperature frit glaze of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com