Method for preparing zirconium oxide insulating layer thin film and stack layer structure by solution method

A technology of laminated structure and insulating layer, applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of complex annealing process and annealing equipment, unfavorable large-area treatment, etc., to avoid ultraviolet light treatment, The effect of low temperature resistance requirements and reduced complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Precursor preparation: 2.576g Zr(NO 3 ) 4 ·5H 2 O (zirconium nitrate pentahydrate) was dissolved in 10 ml of ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.6 mol / L precursor solution.

[0021] (2) Substrate preparation: deposit a layer of 150nm ITO electrode on the surface of the glass substrate, wash and dry to obtain the ITO glass substrate.

[0022] (3) Spin-coat the precursor solution obtained in step (1) on the ITO glass substrate according to the selected process parameters, the spin-coating speed is 6000rpm, the gluing time is 40s, the gluing times are 3 times, and the annealing temperature between each gluing is 200 °C for 4 min, and then annealed at 200 °C for 1 h to obtain a zirconia insulating layer film.

[0023] (4) On the zirconia insulating layer film of step (3), the circular Al electrode of 100nm is plated by magnetron sputtering, prepares MIM (ITO / ZrO 2 / Al) laminated structure.

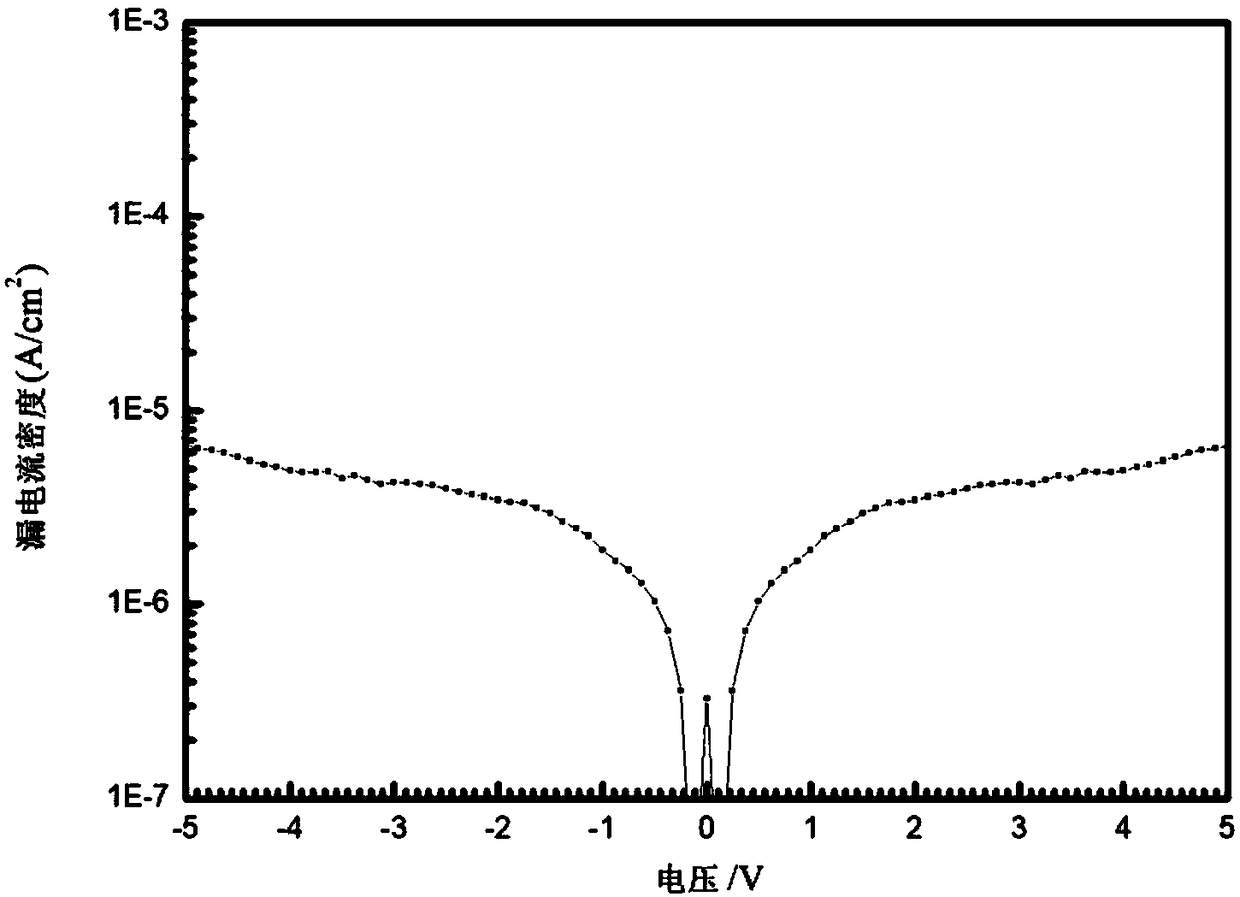

[0024] The obtained ZrO of this embod...

Embodiment 2

[0028] (1) Precursor preparation: 1.288g Zr(NO 3 ) 4 ·5H 2 O (zirconium nitrate pentahydrate) was dissolved in 10 ml of ethylene glycol monomethyl ether (2-MOE), stirred and aged to obtain a 0.3 mol / L precursor solution.

[0029] (2) Substrate preparation: deposit a layer of 150nm ITO electrode on the surface of the glass substrate, wash and dry to obtain the ITO glass substrate.

[0030] (3) Spin coat the precursor solution obtained in step (1) on the ITO glass substrate according to the selected process parameters. °C for 4 min, and then annealed at 200 °C for 1 h to obtain a zirconia insulating layer film.

[0031] (4) On the zirconia insulating layer film of step (3), the circular Al electrode of 100nm is plated by magnetron sputtering, prepares MIM (ITO / ZrO 2 / Al) laminated structure.

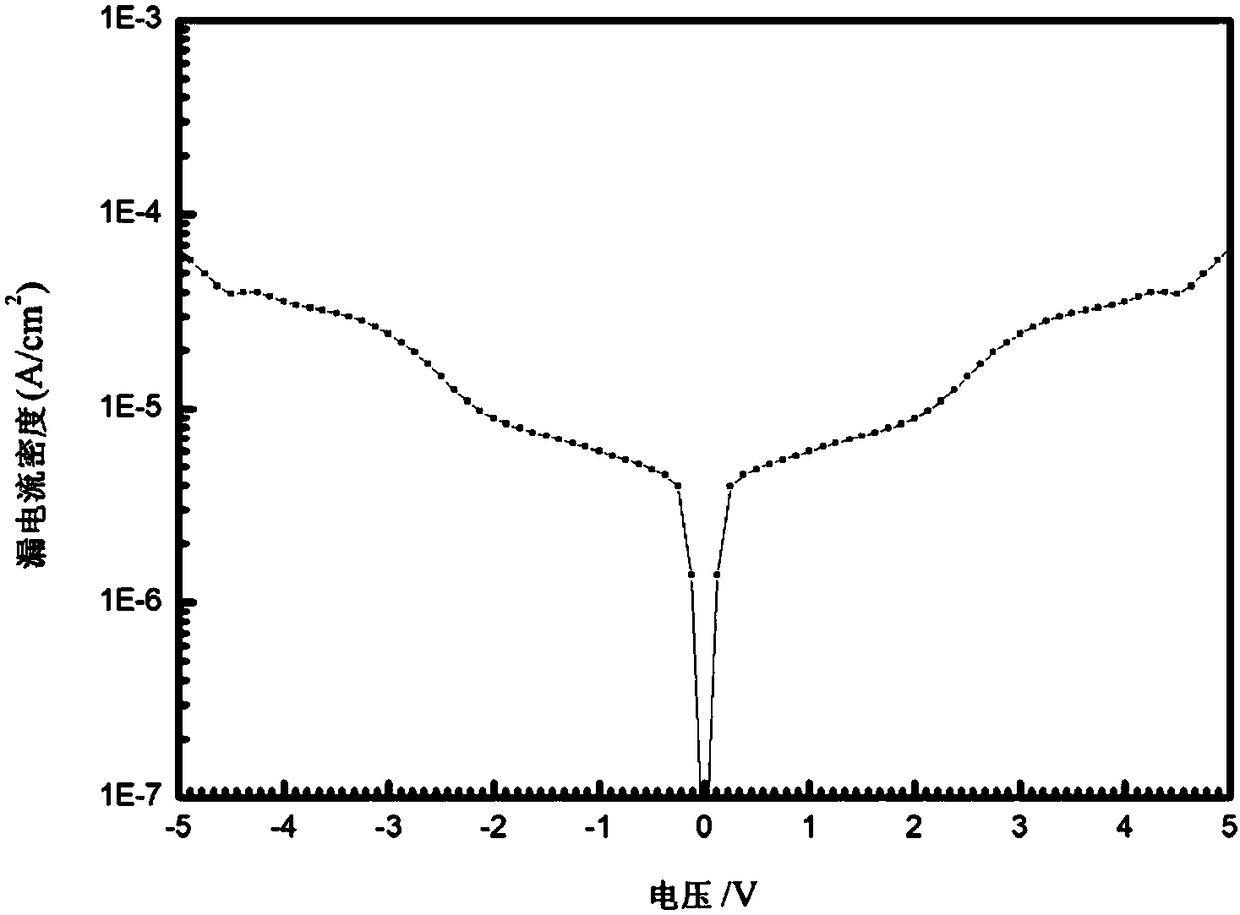

[0032] The obtained ZrO of this embodiment 2 The leakage current test results of the insulating film are as follows: image 3 shown.

[0033] The test results show that the ZrO pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current density | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com