Patents

Literature

156 results about "Ultraviolet light treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

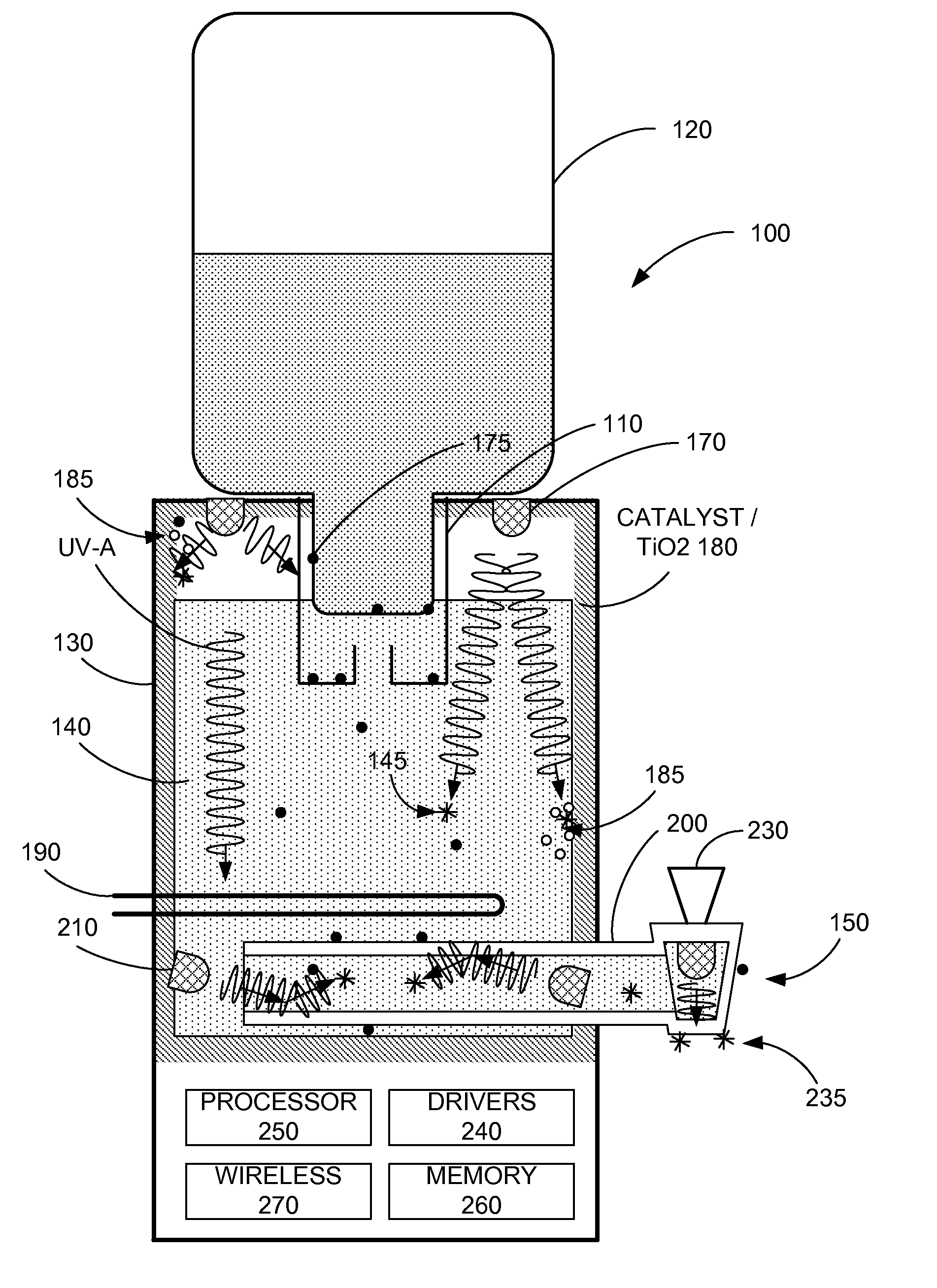

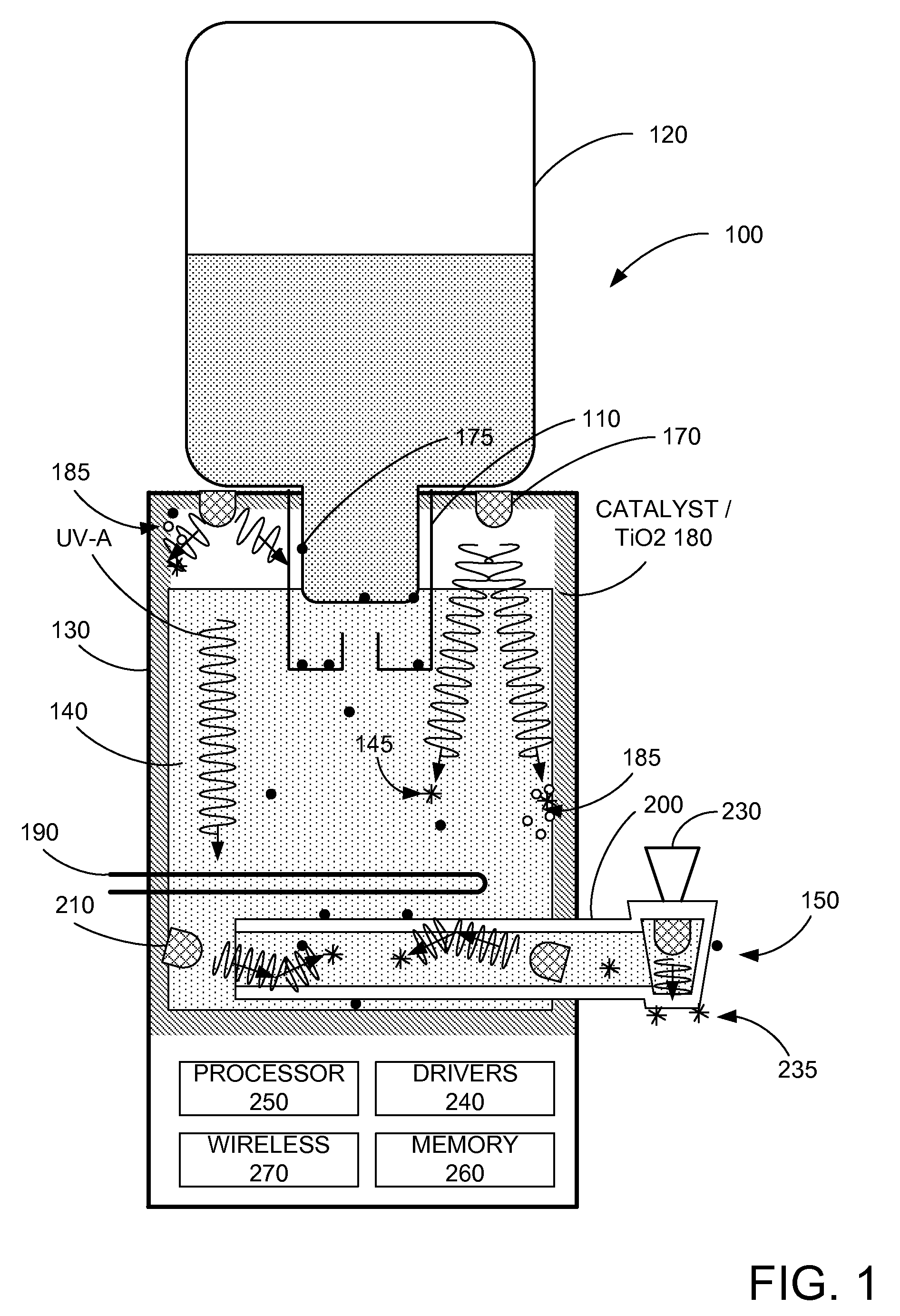

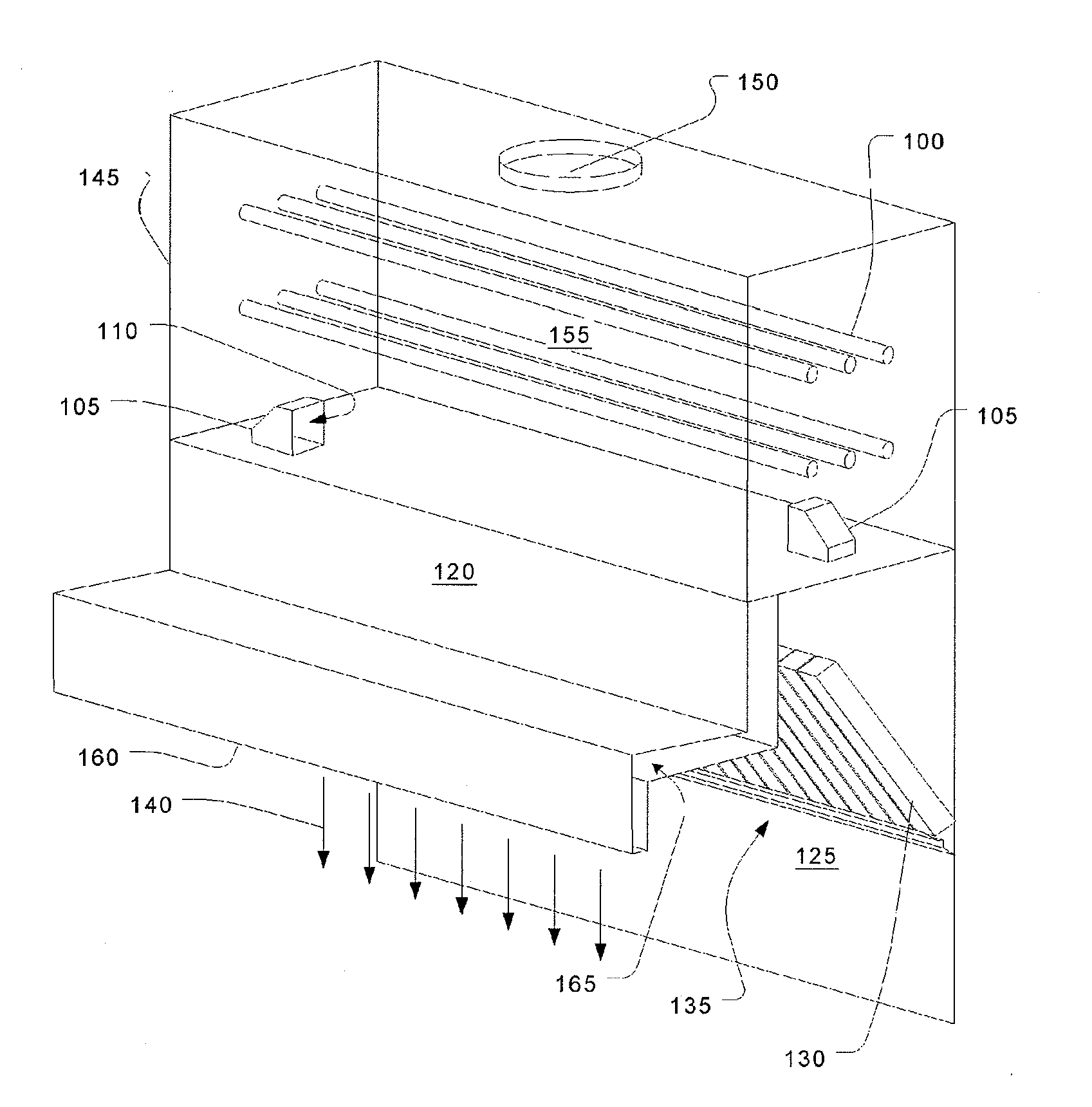

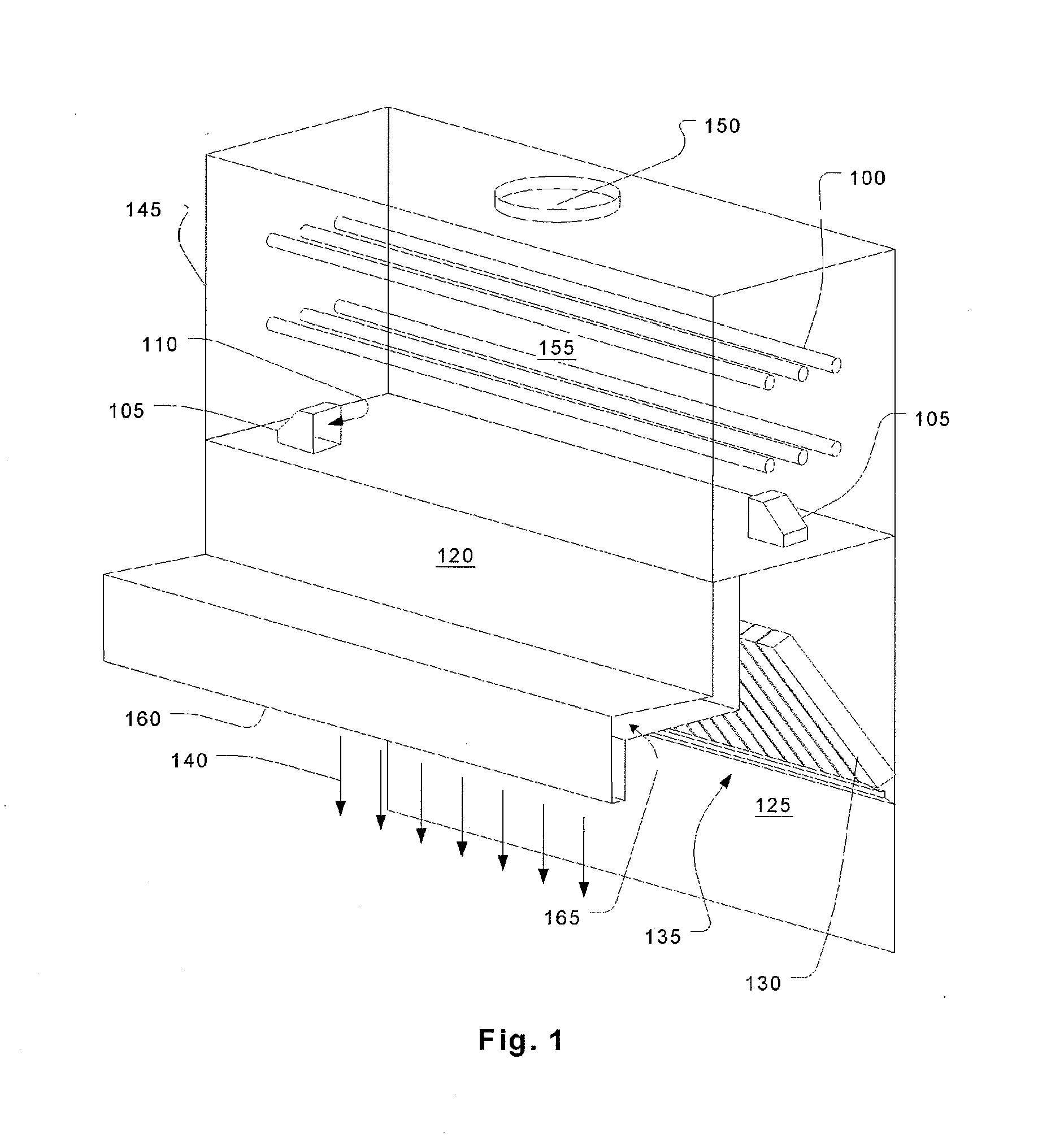

Ultraviolet light treatment chamber

ActiveUS20100078574A1Easy and economical implementationHigher effective treatment dosMaterial analysis using wave/particle radiationWater/sewage treatment by irradiationUltravioletEngineering

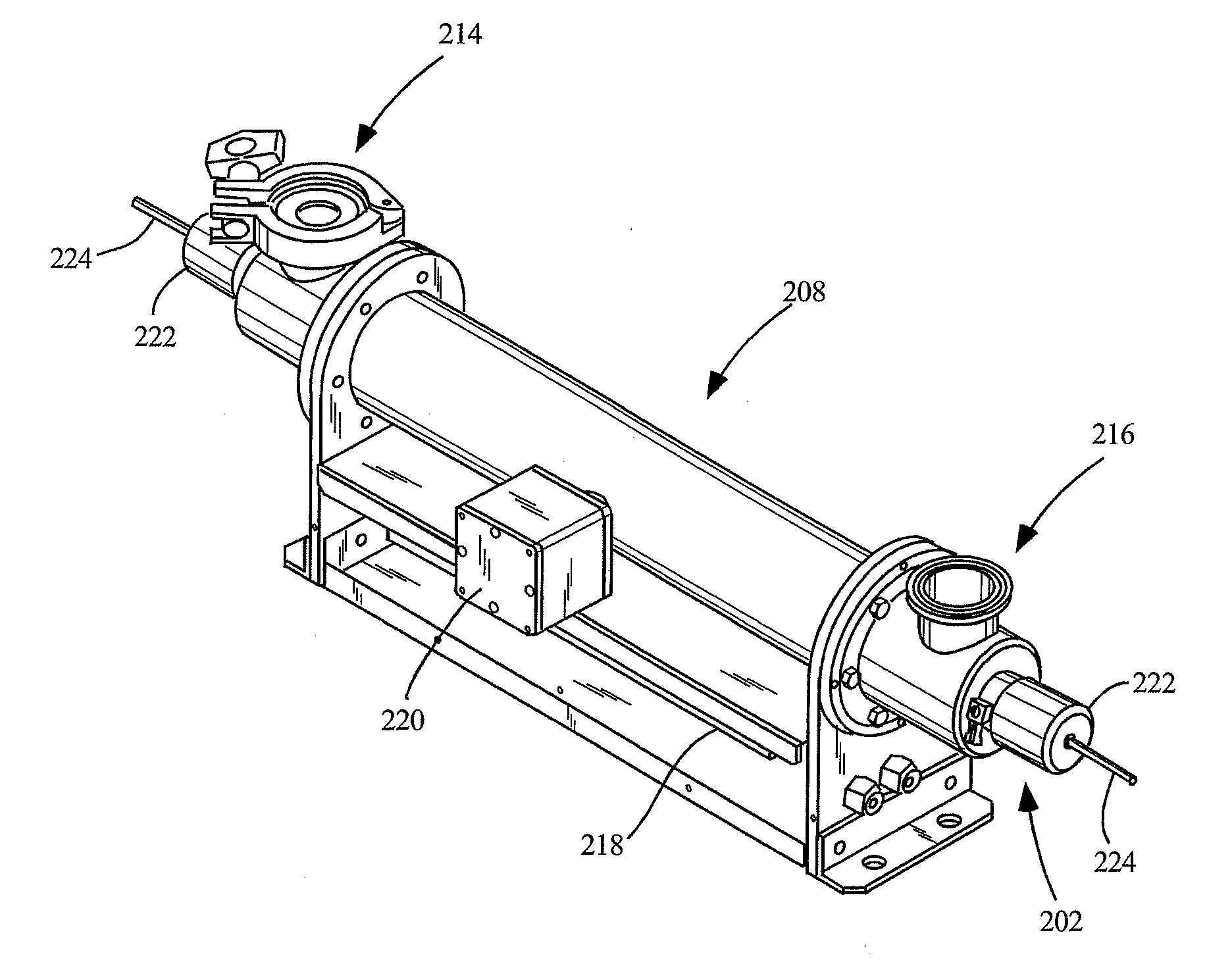

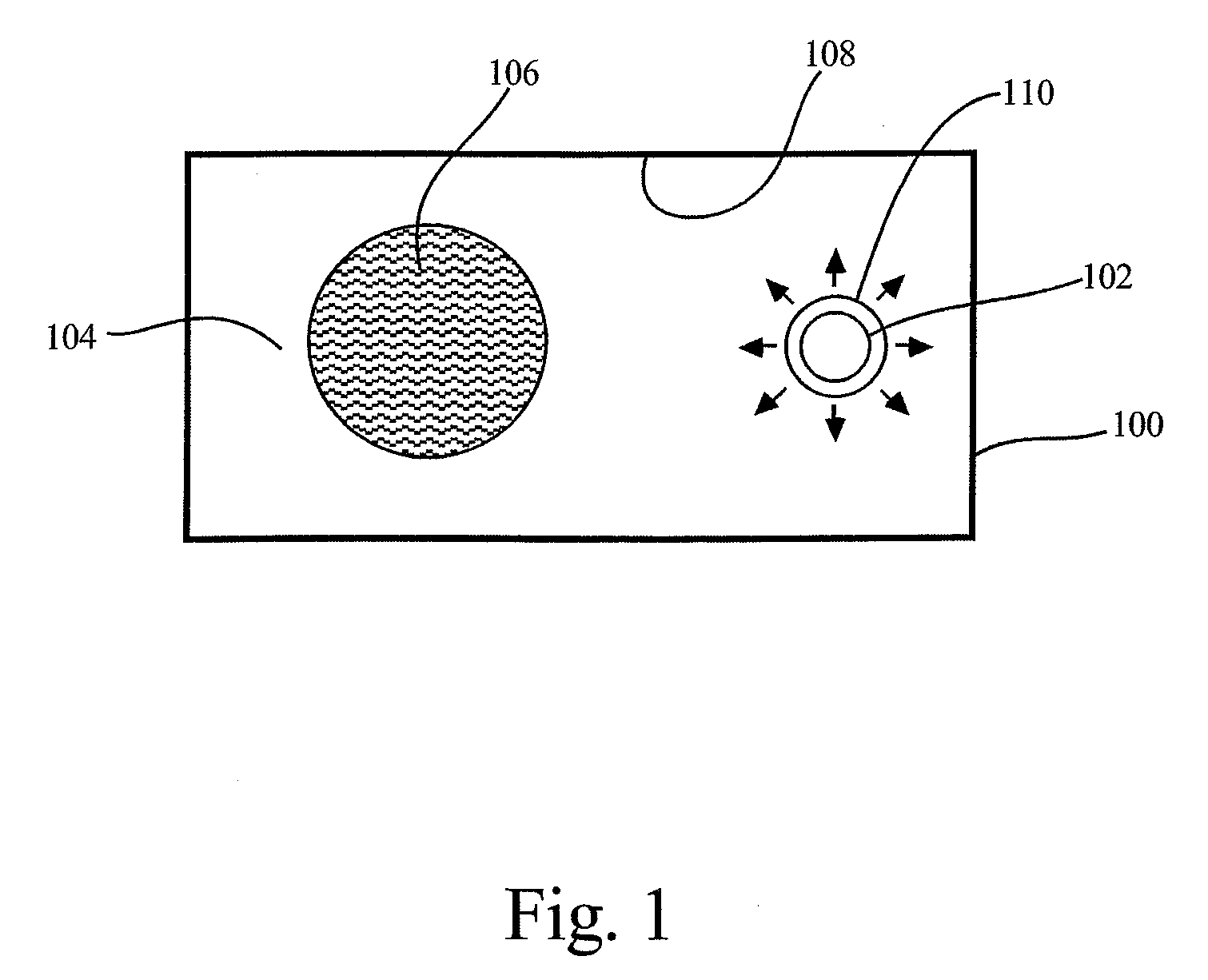

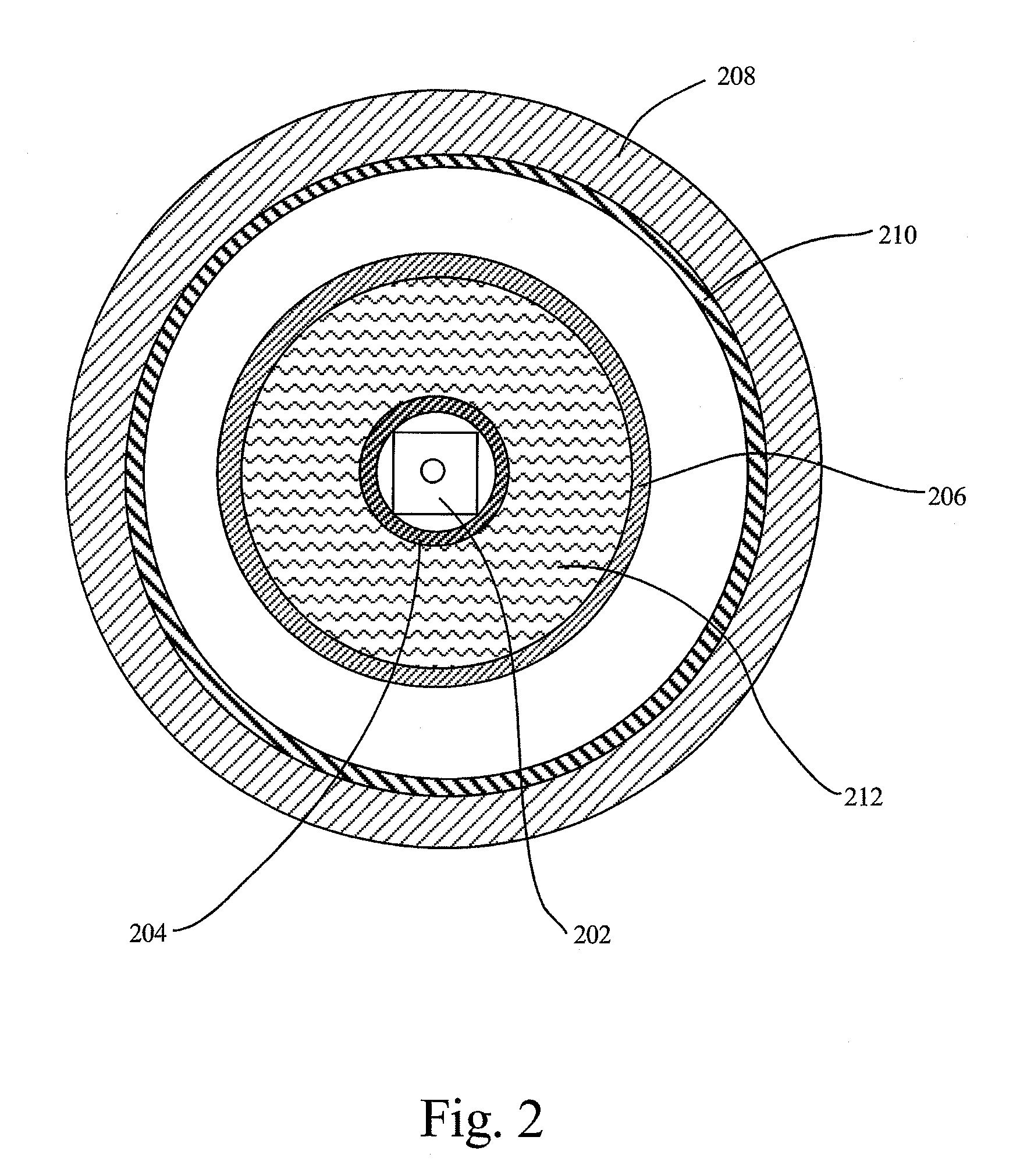

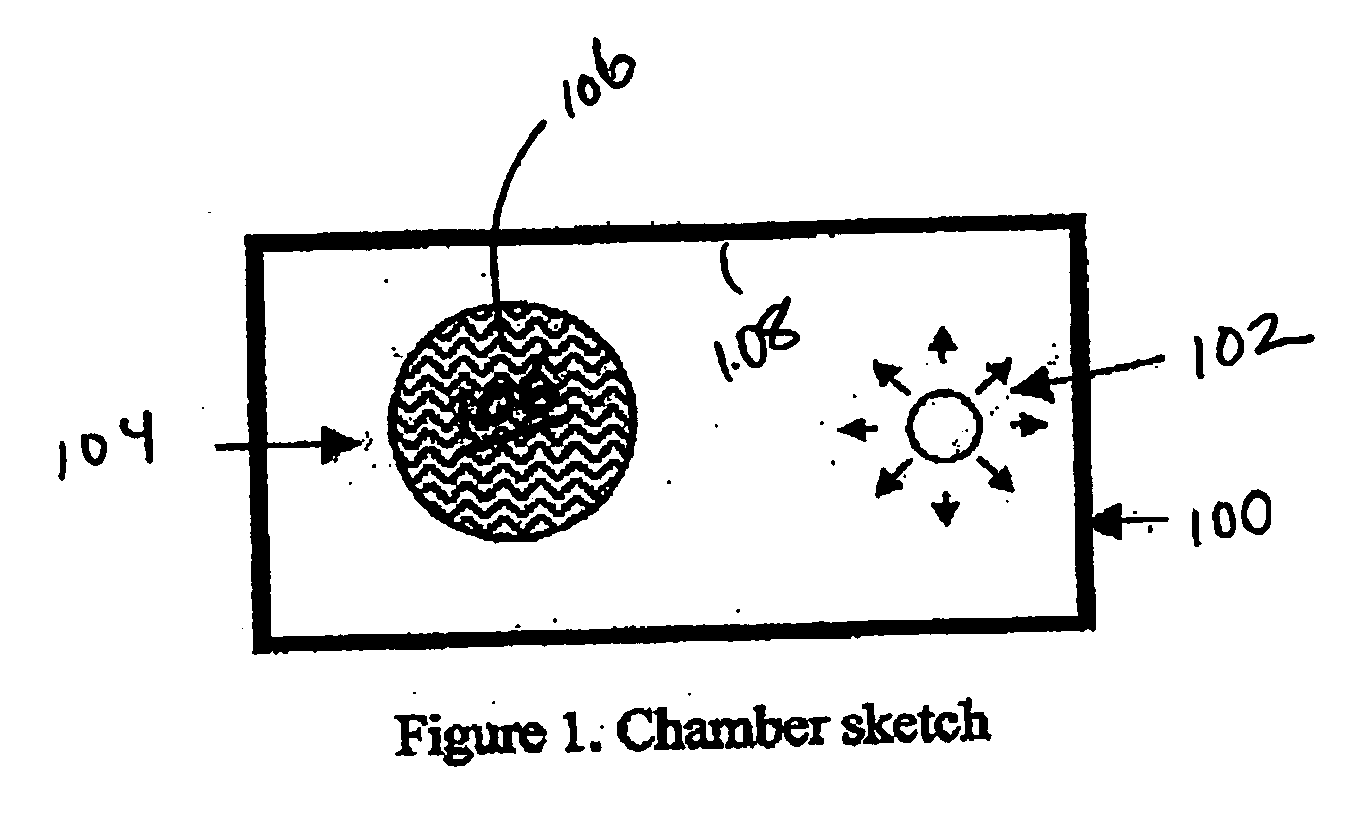

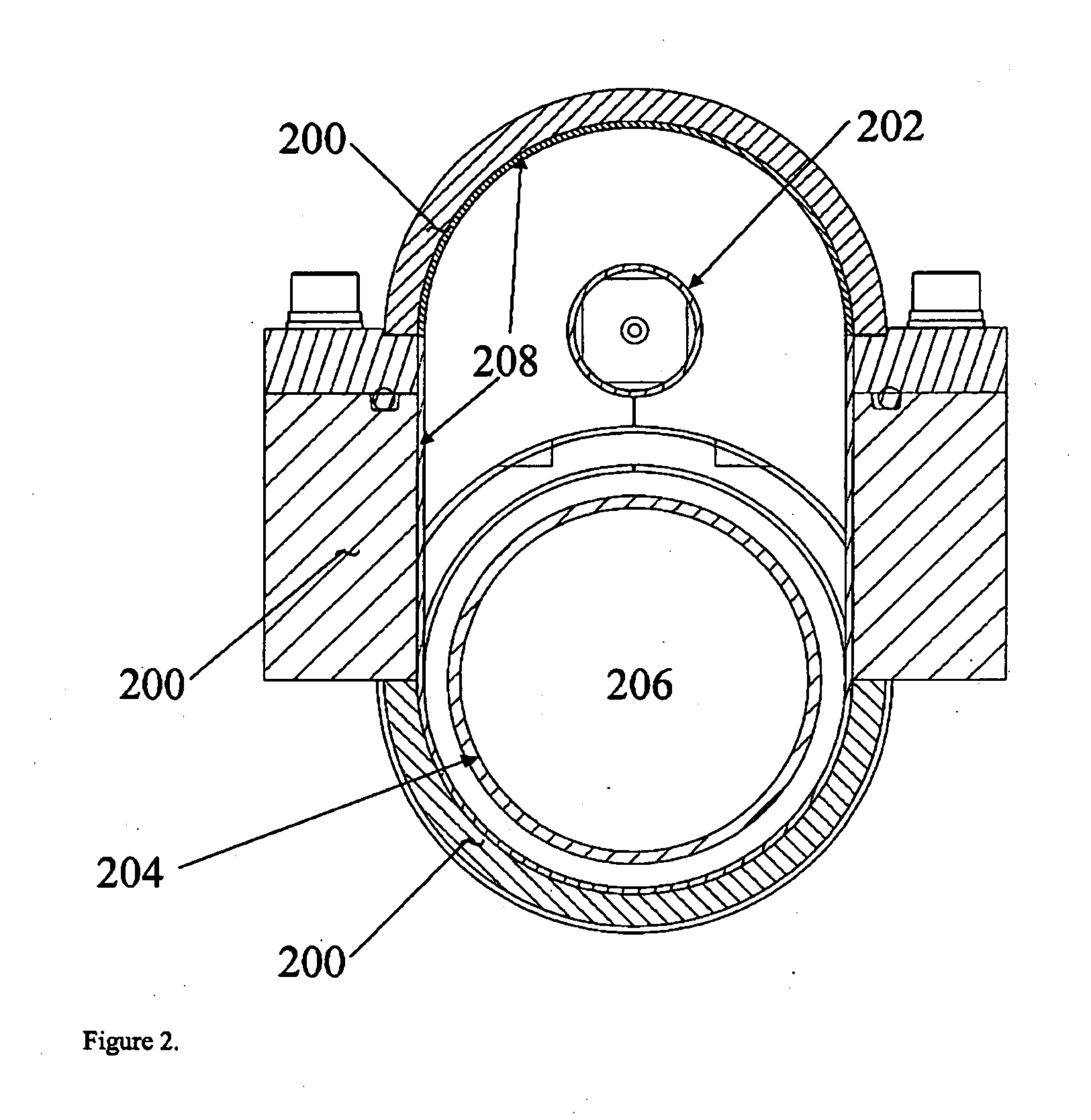

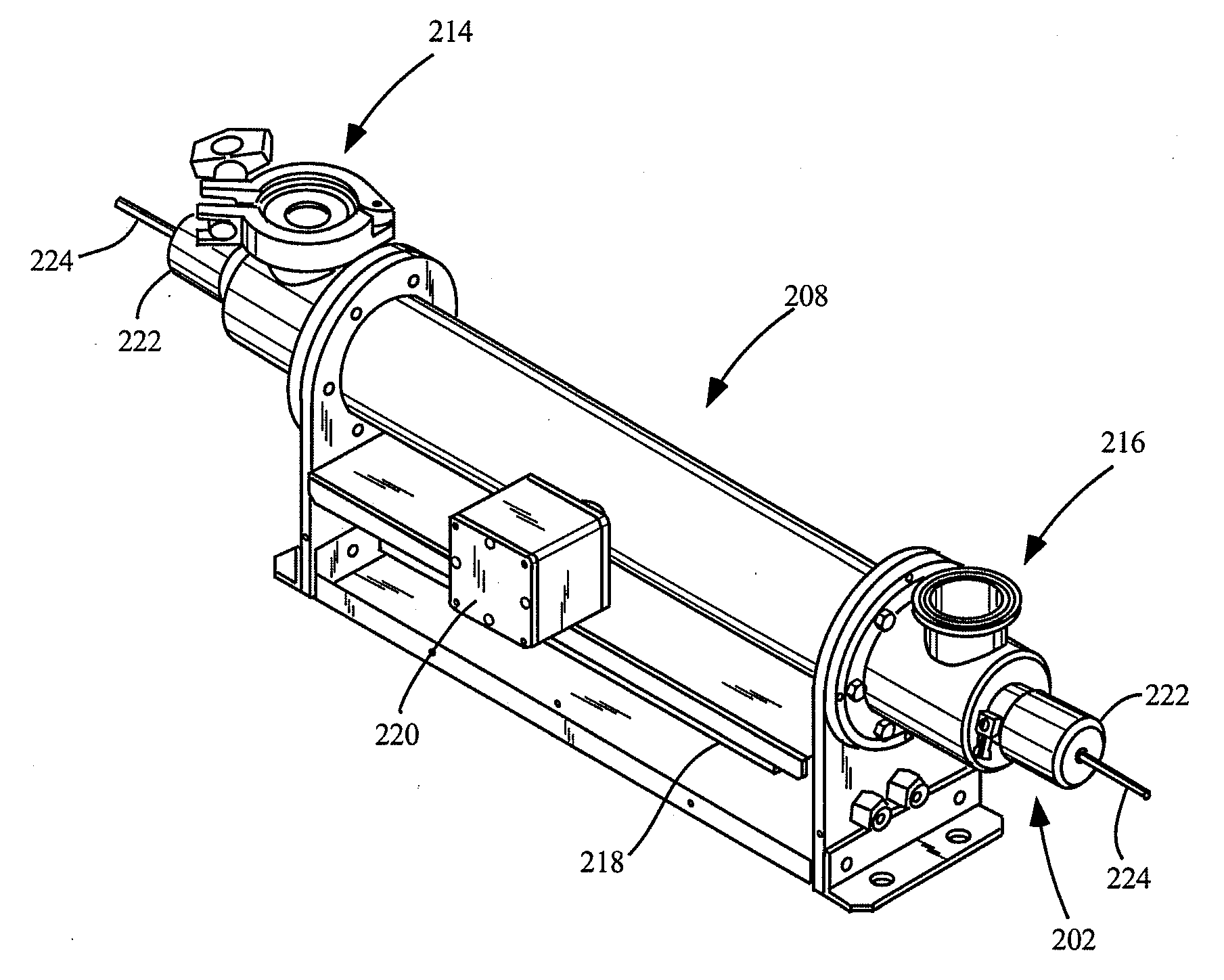

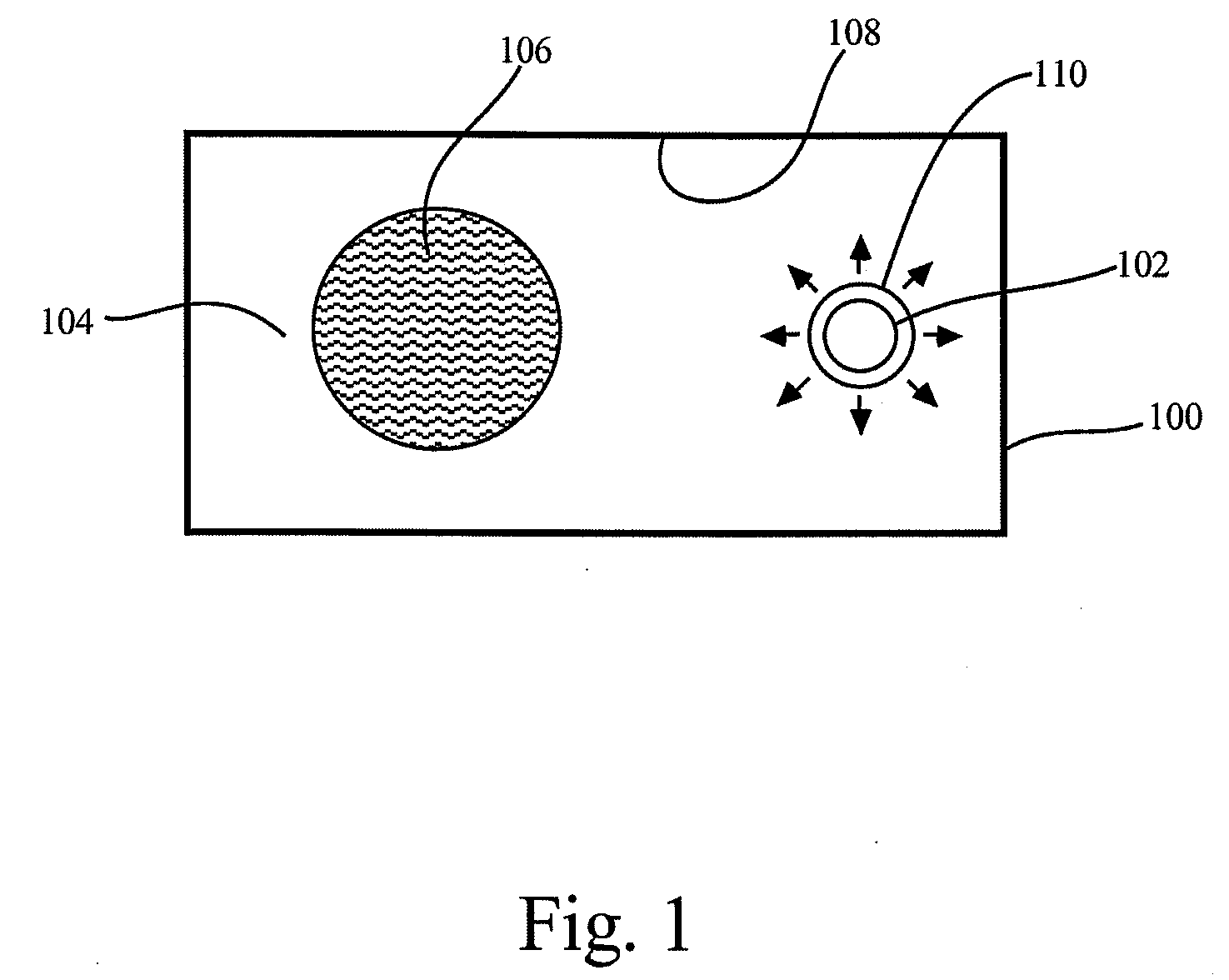

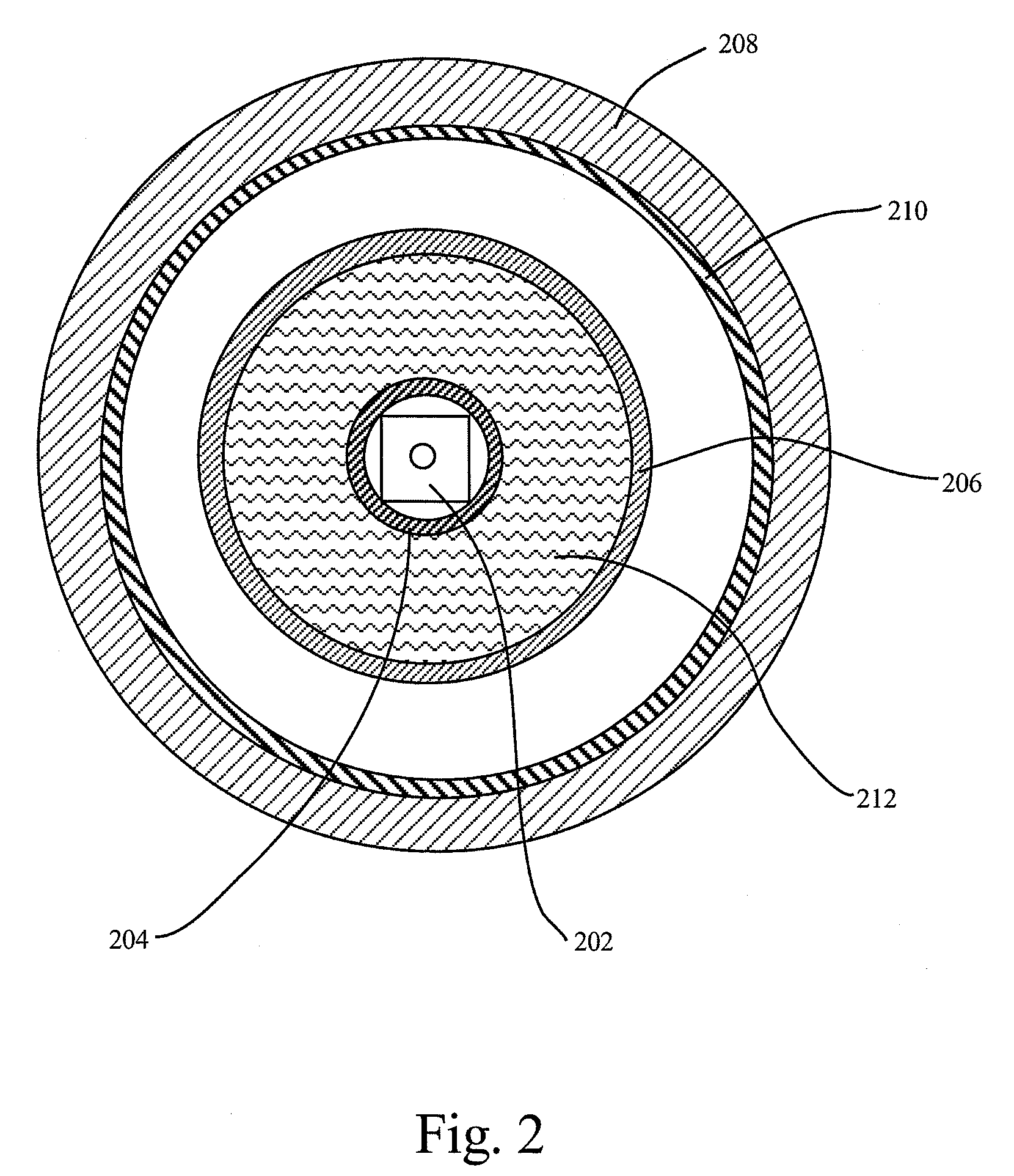

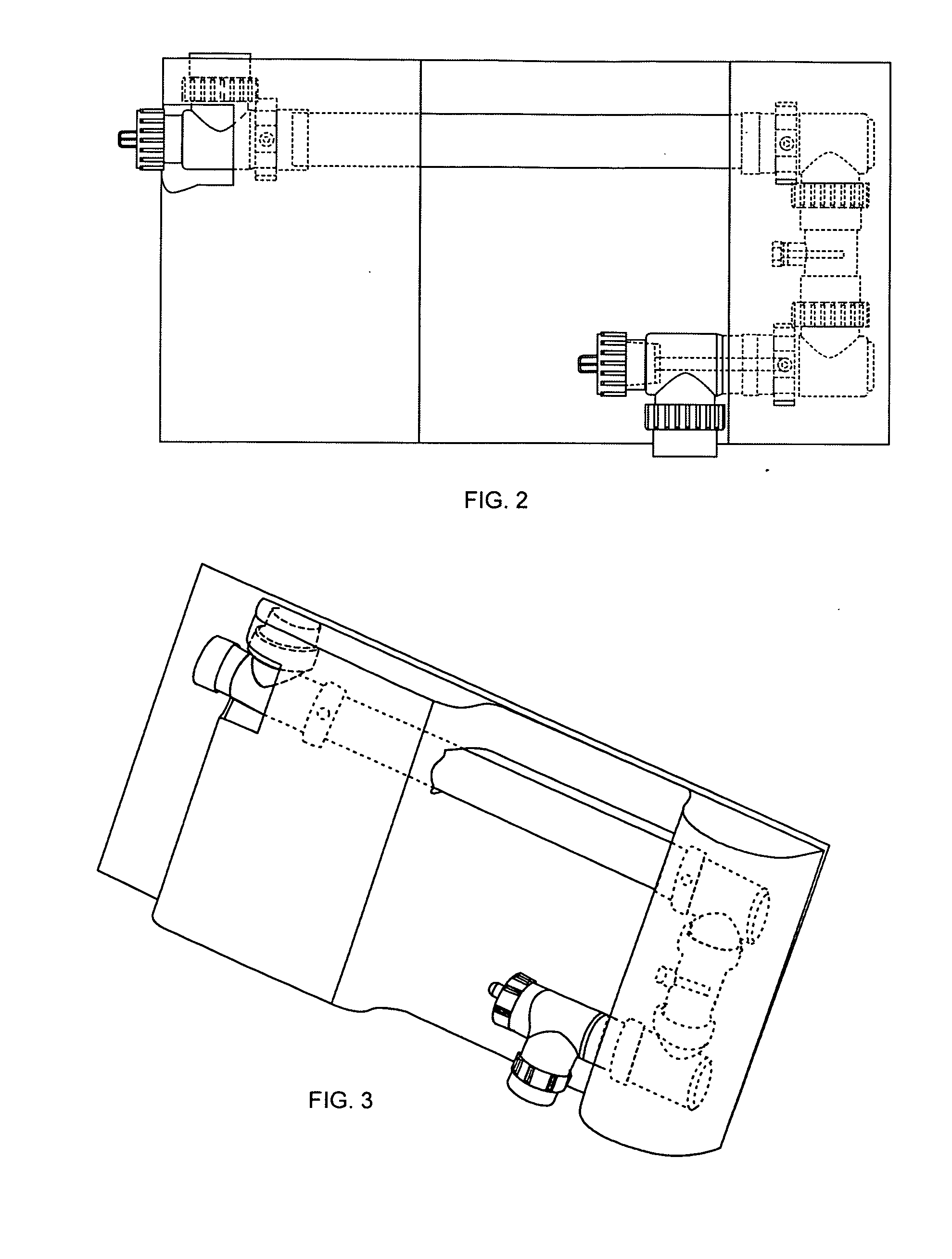

An apparatus for the treatment of a liquid that includes a chamber having at least one inner surface, the chamber adapted for passage of a fluid therethrough. The chamber is at least 80 percent enclosed. The apparatus also includes an optional ultraviolet-transmissive tube disposed within the chamber and also adapted for the passage of the liquid therethrough. The apparatus further includes an ultraviolet lamp disposed within the chamber and, optionally, within the ultraviolet-transmissive tube. A reflective material is interposed between the chamber and the transmissive tube. The reflective material is adapted so as to reflect at least a portion of light emitted by the ultraviolet lamp, wherein the reflective material is at least 80 percent reflective.

Owner:NEO TECH AQUA SOLUTIONS

Ultraviolet light treatment chamber

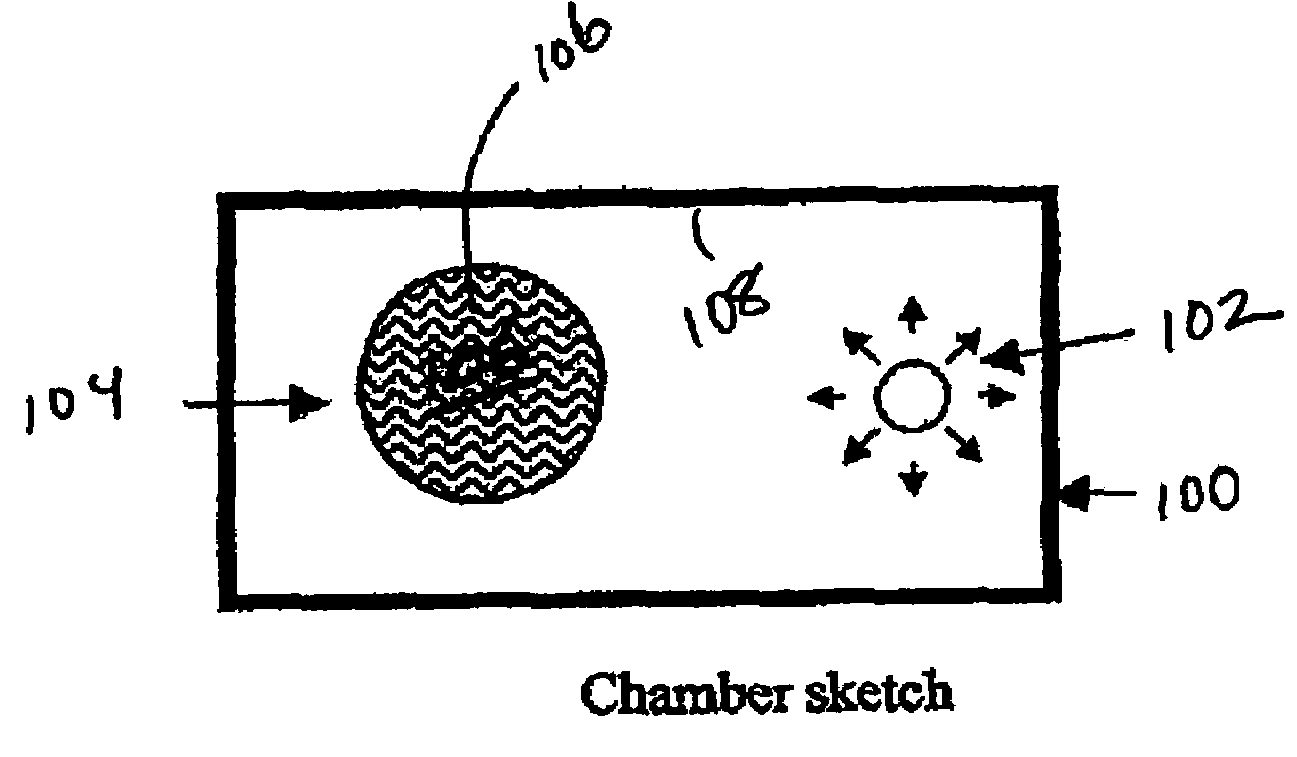

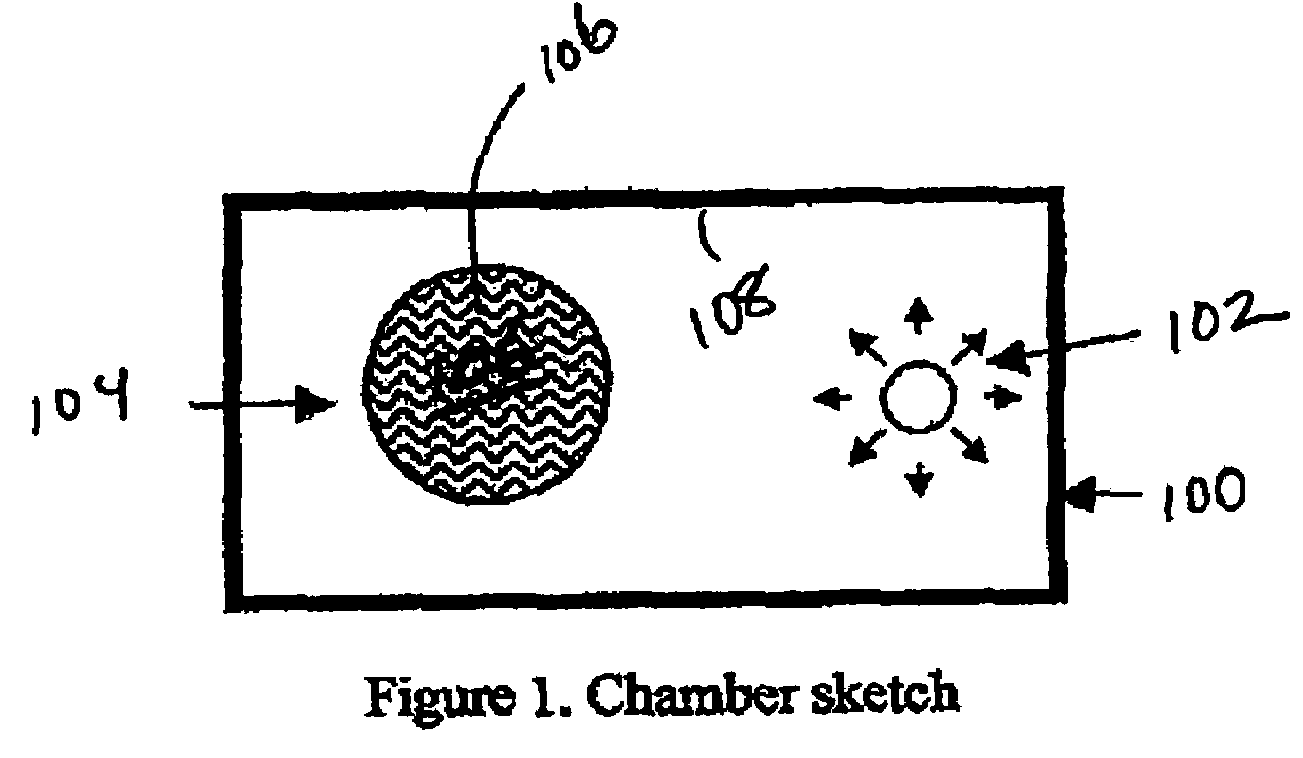

ActiveUS20070045561A1Improve reflectivityVacuum evaporation coatingSolid sorbent liquid separationUltraviolet lightsUltraviolet light treatment

This invention relates generally to methods and apparatuses for the treatment of liquids and gases using ultraviolet light. In one embodiment, a substantially enclosed chamber coated with a reflective material containing an ultraviolet lamp and an ultraviolet transmissive tube running through the chamber for the treatment of liquid passed therethrough is disclosed.

Owner:NEO TECH AQUA SOLUTIONS

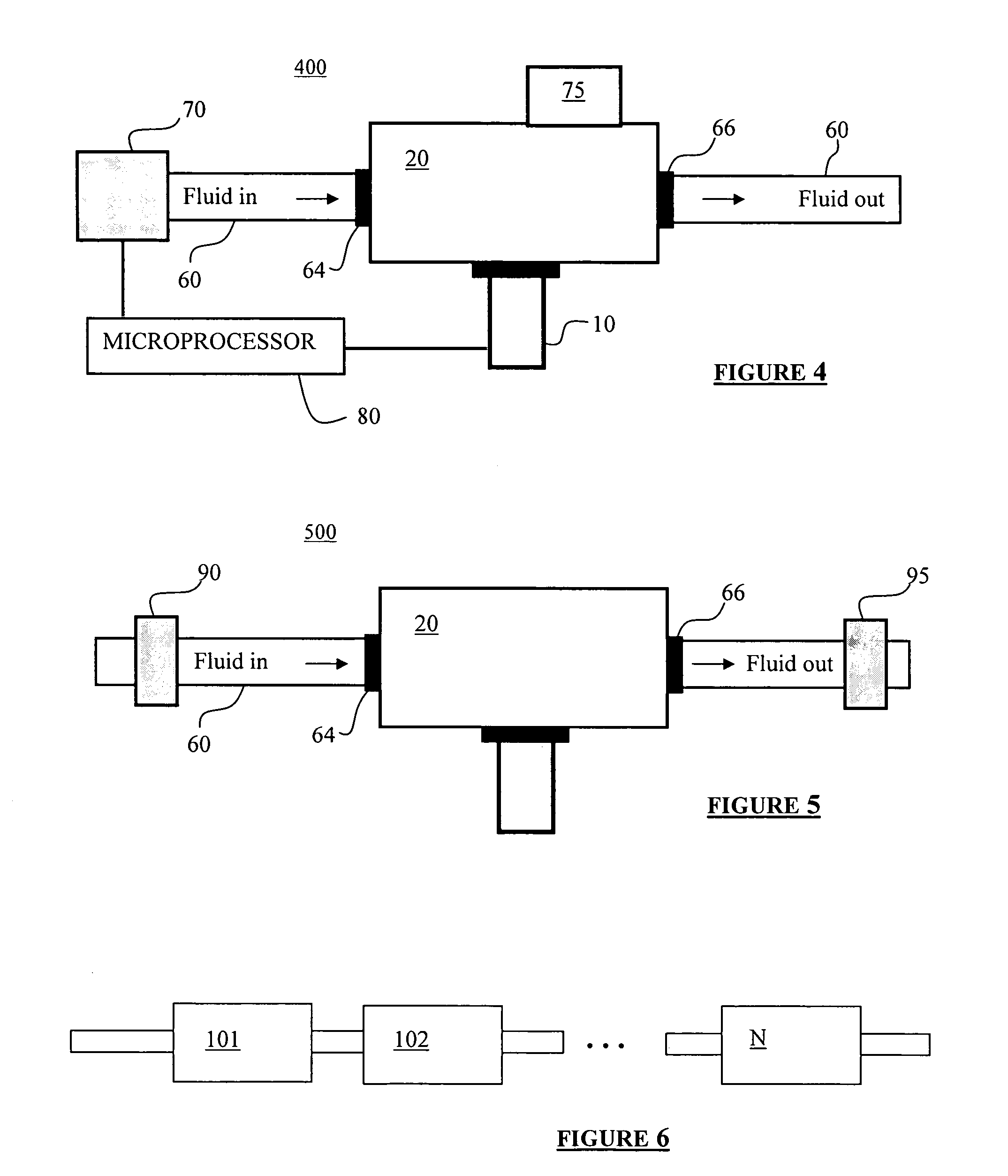

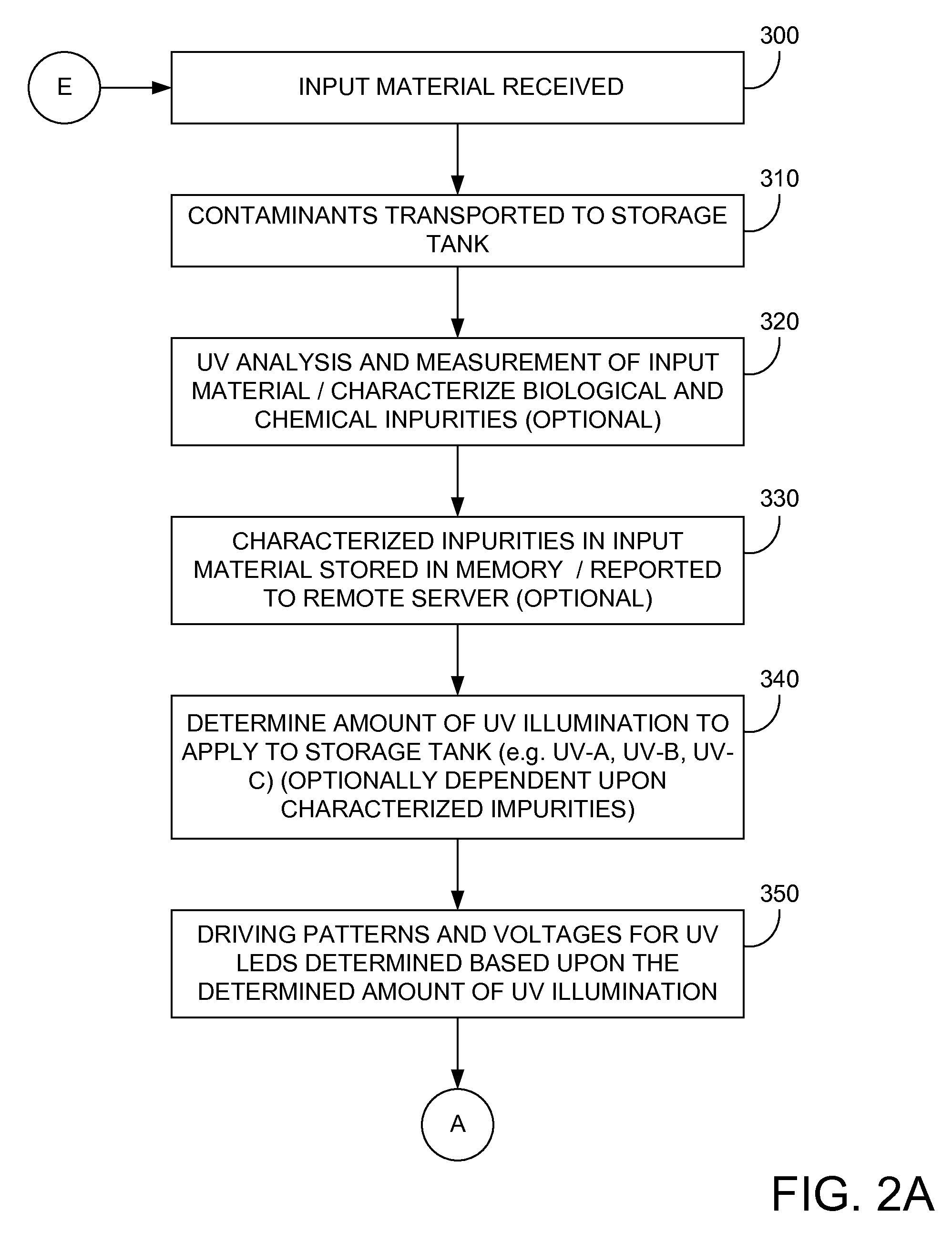

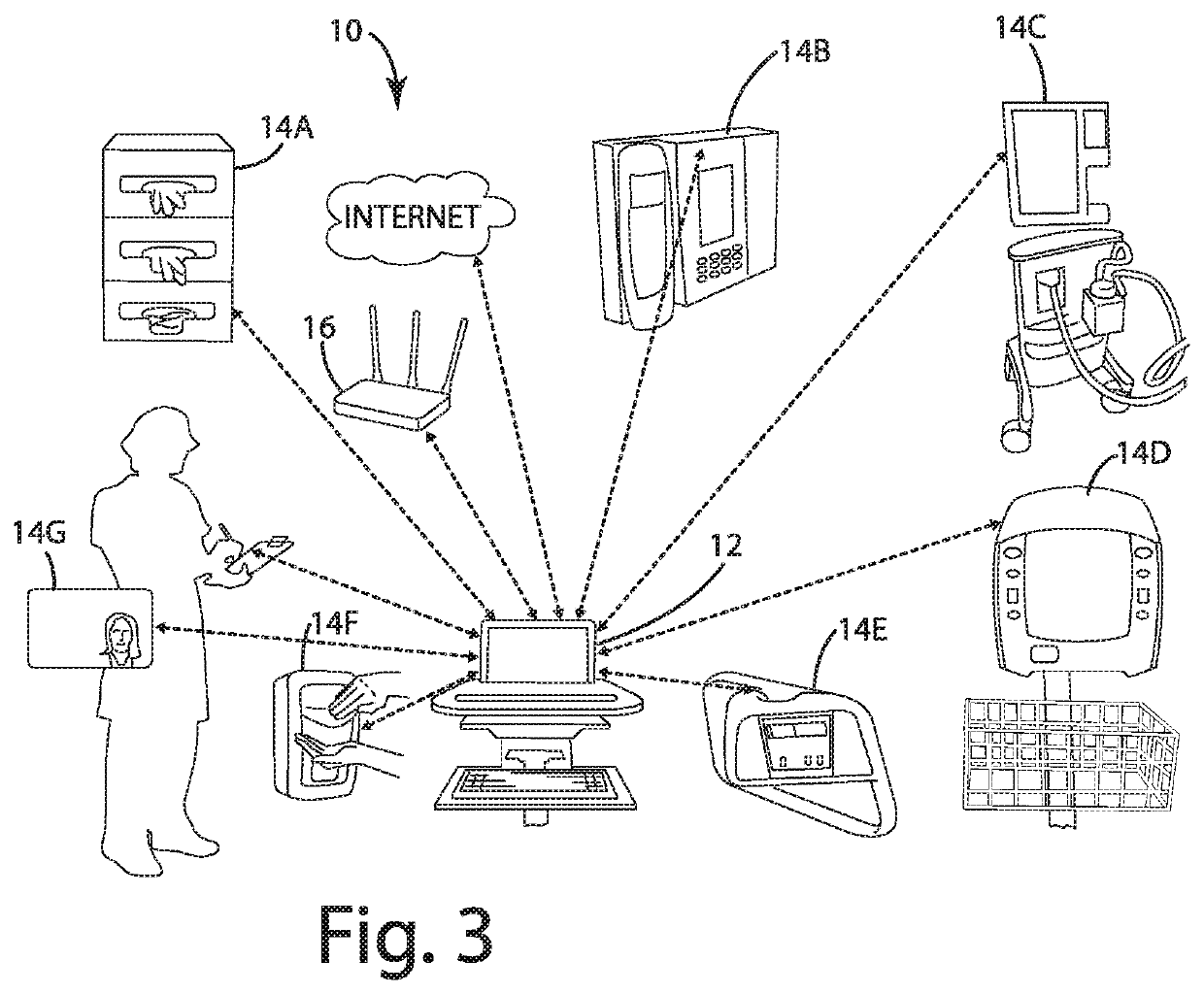

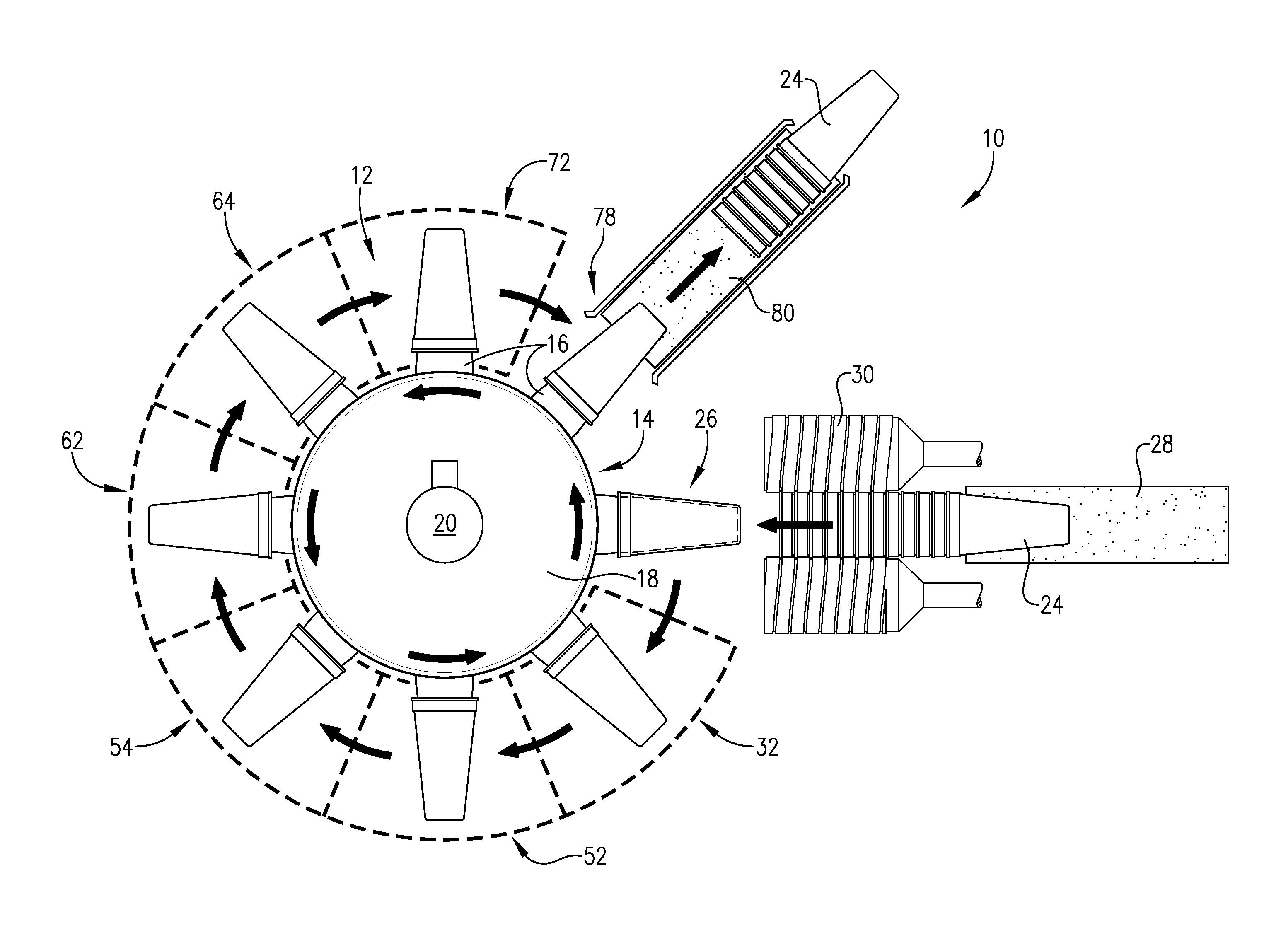

Systems and methods for contaminant detection within a fluid, ultraviolet treatment and status notification

InactiveUS7160370B2Reduce infectivityHarmful effectCombination devicesAuxillary pretreatmentUltravioletDistribution system

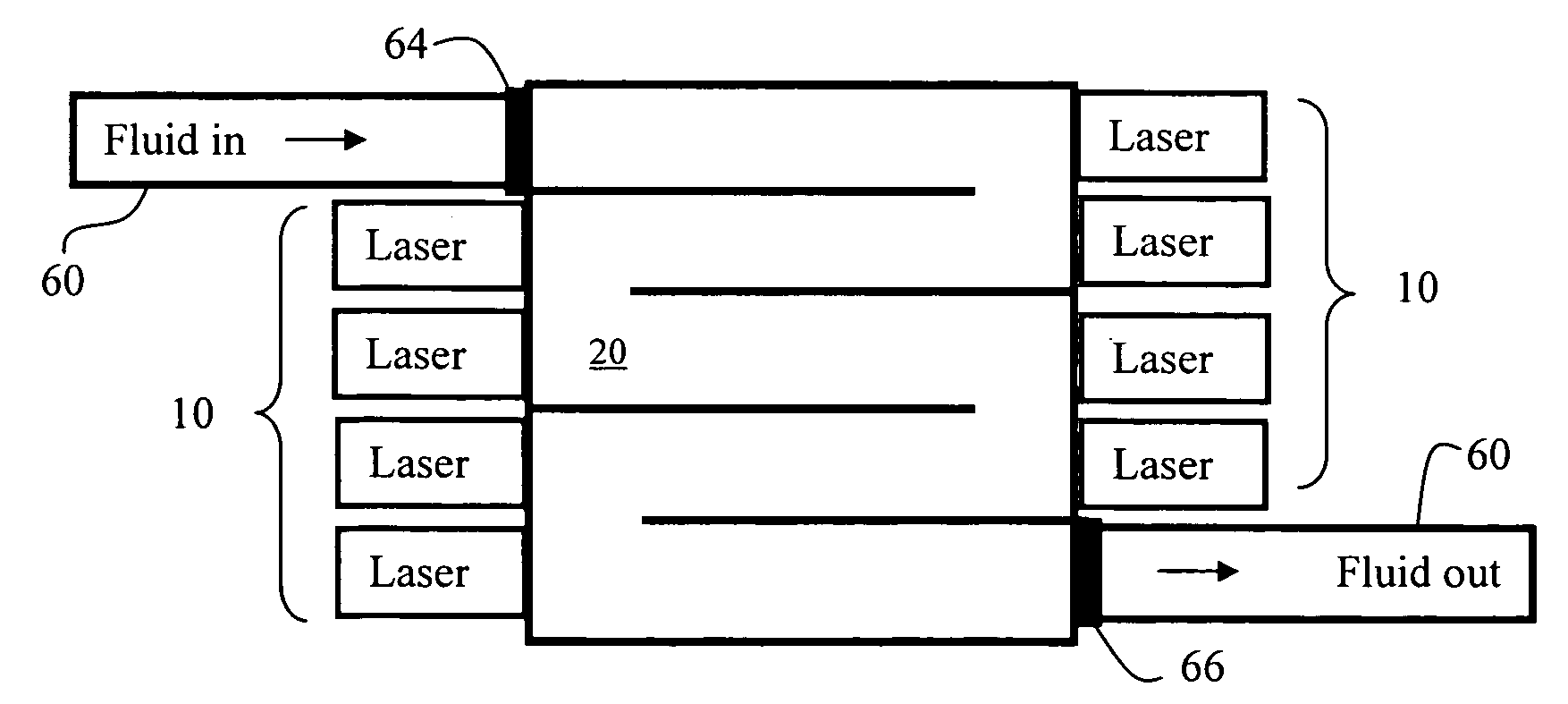

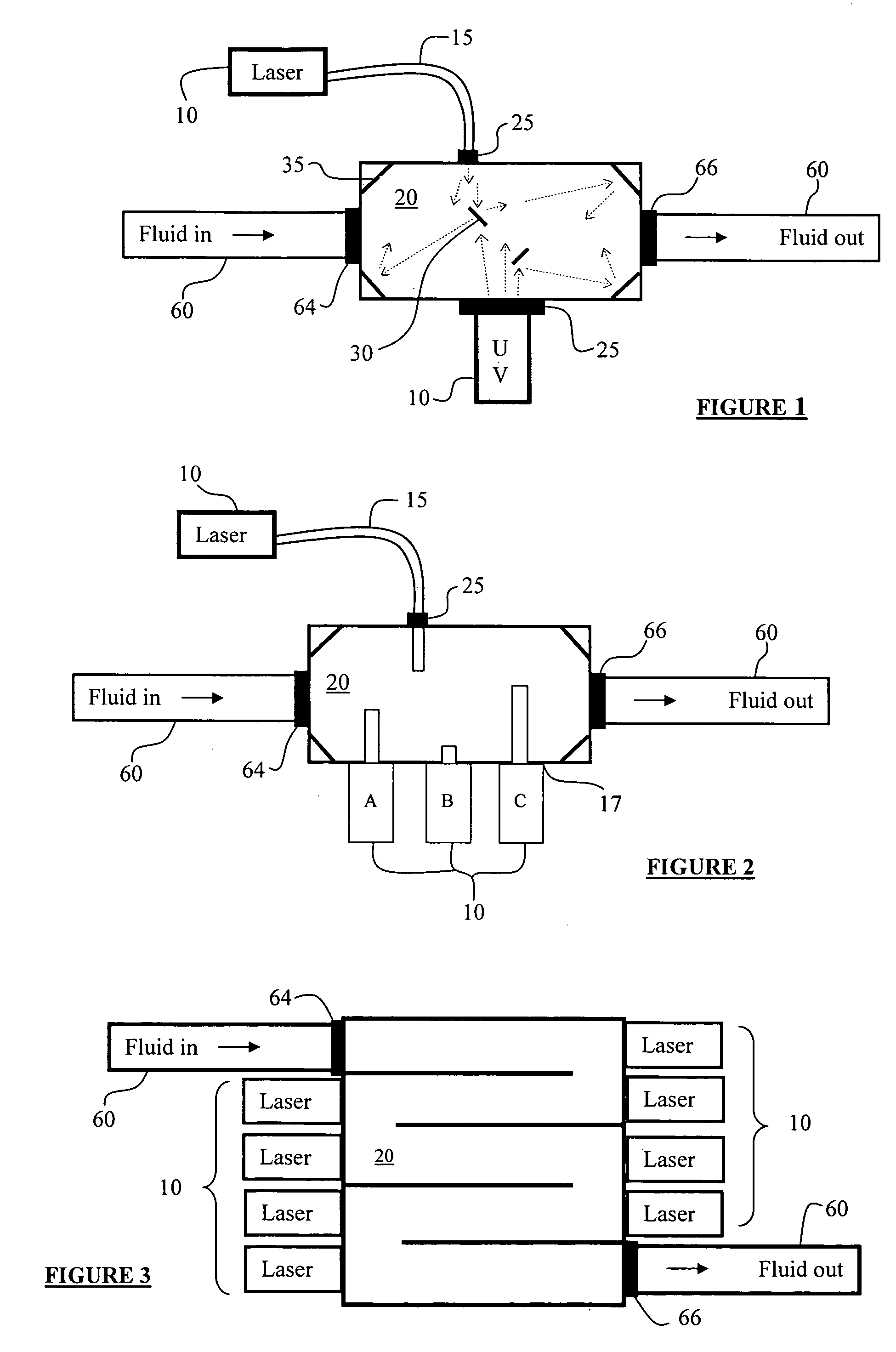

A fluid-borne (e.g., water, air) biological and chemical hazard detection and treatment system can include sensors (e.g., flow rate, contaminant detectors), treatment using ultraviolet laser-emitted light, can be microprocessor controlled and can communicate and be controlled over data networks. Treatment and detection systems can be deployed at various stages along a fluid distribution system, allowing for protection coverage and redundancy. During treatment, fluid enters into and / or passes through a “treatment area” wherein the fluid is subjected to light emanating from a laser at wavelengths within the ultraviolet range. DNA for microorganisms contained within fluid (including blood) are reactive to laser light as they pass through treatment areas and are rendered un-infective. Treatment systems can be staged in close proximity, providing more than one treatment area and associated light sources to a fluid stream. Such staging can provide for concentrated redundancy prior to its delivery to the intended point of use.

Owner:SALTECH CORP

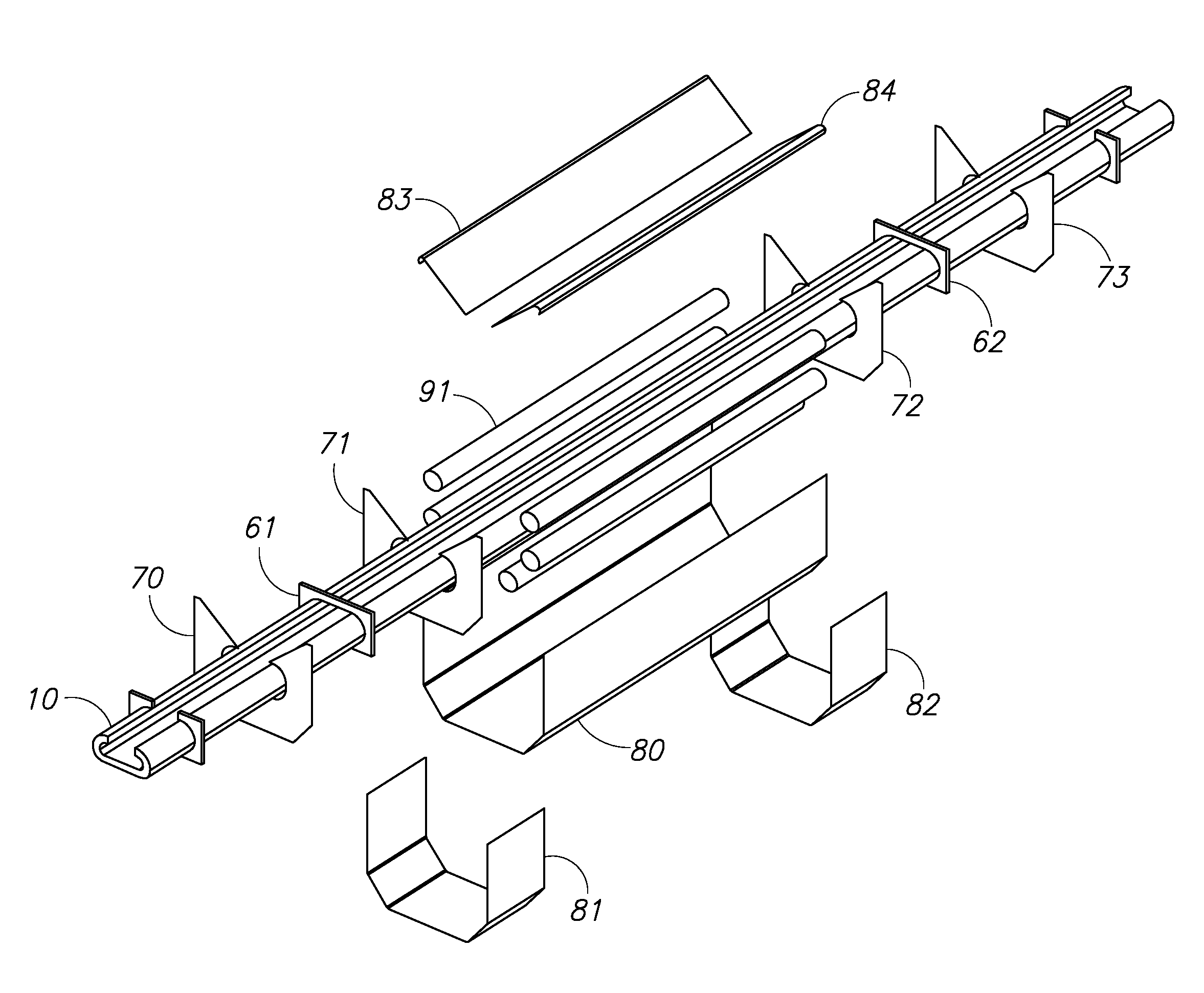

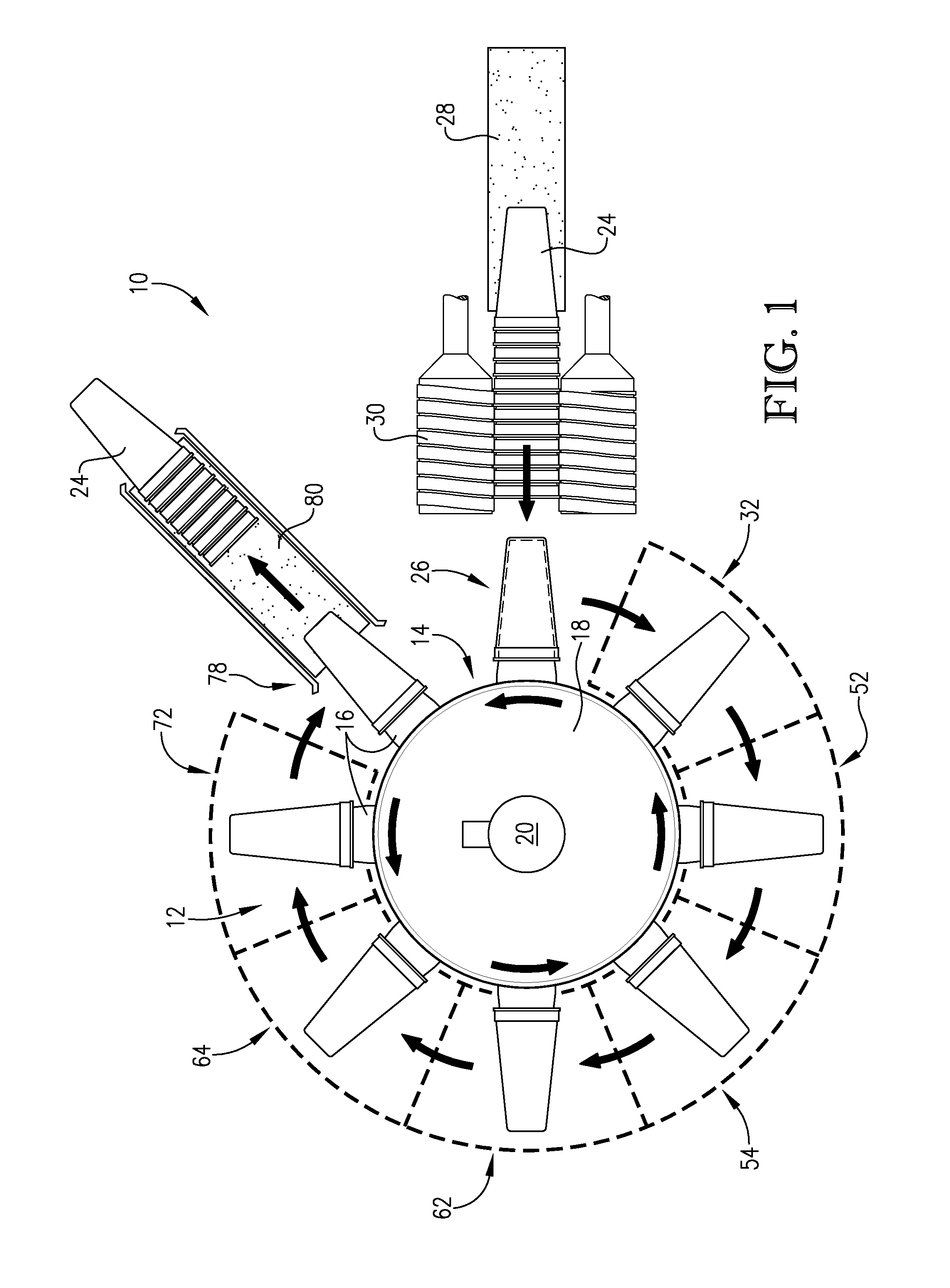

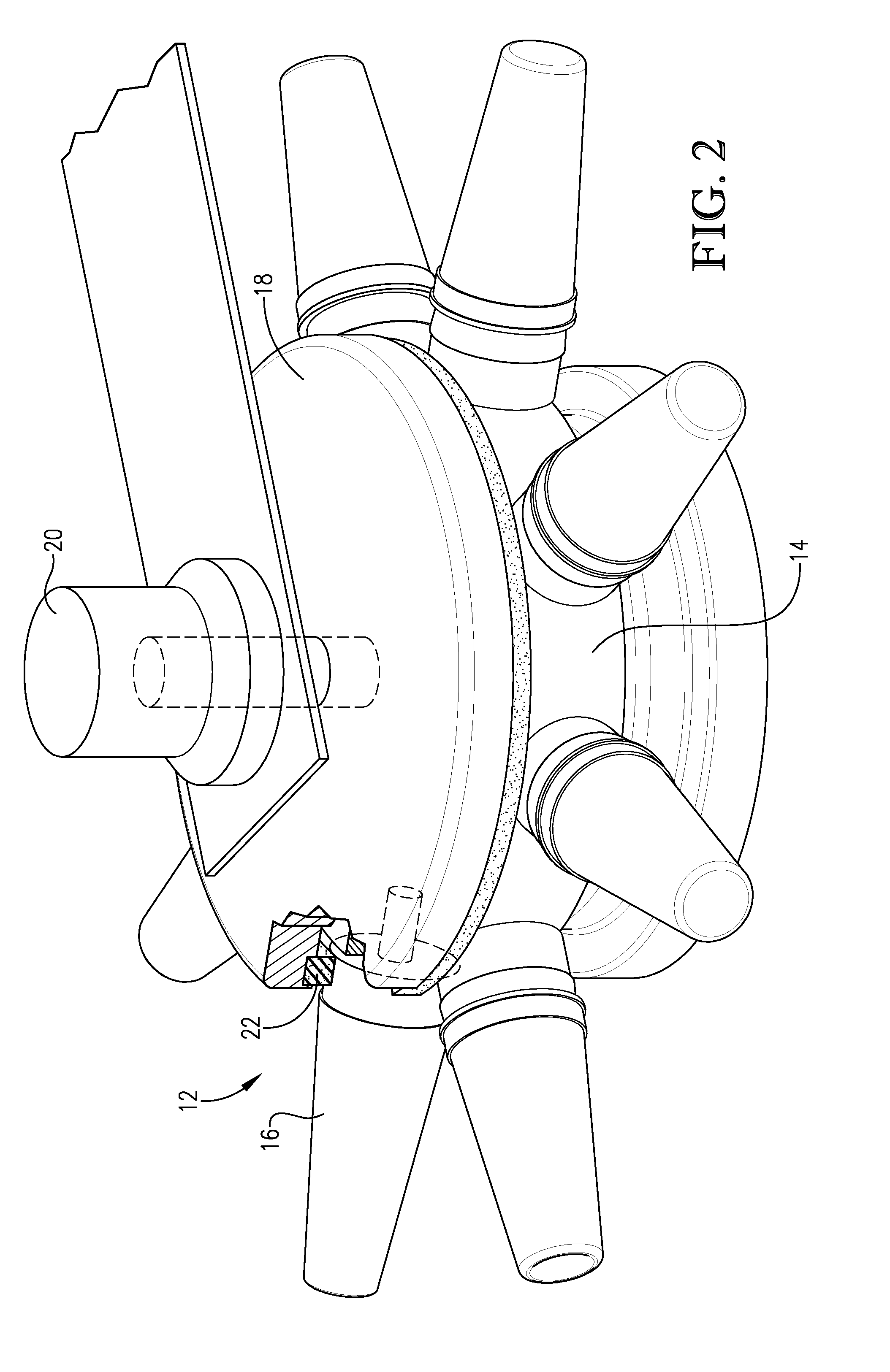

Belt treatment system

InactiveUS20150028228A1Long exposure timeConvenient treatmentRadiation therapyEscalatorsUltravioletEngineering

A handrail sanitization system incorporates ultraviolet light treatment into long straight sections of the handrail run, most preferably along the hidden return area of the endless loop forming the moving handrail. This treatment area allows for longer exposure times to the UV light and facilitates the treatment of the entire outer surface of the handrail. In some versions, an additional dosage controller is provided.

Owner:ROTECHN HLDG

Ultraviolet light treatment chamber

ActiveUS7511281B2Improve reflectivityVacuum evaporation coatingSolid sorbent liquid separationUltraviolet lightsUltraviolet light treatment

This invention relates generally to methods and apparatuses for the treatment of liquids and gases using ultraviolet light. In one embodiment, a substantially enclosed chamber coated with a reflective material containing an ultraviolet lamp and an ultraviolet transmissive tube running through the chamber for the treatment of liquid passed therethrough is disclosed.

Owner:NEO TECH AQUA SOLUTIONS

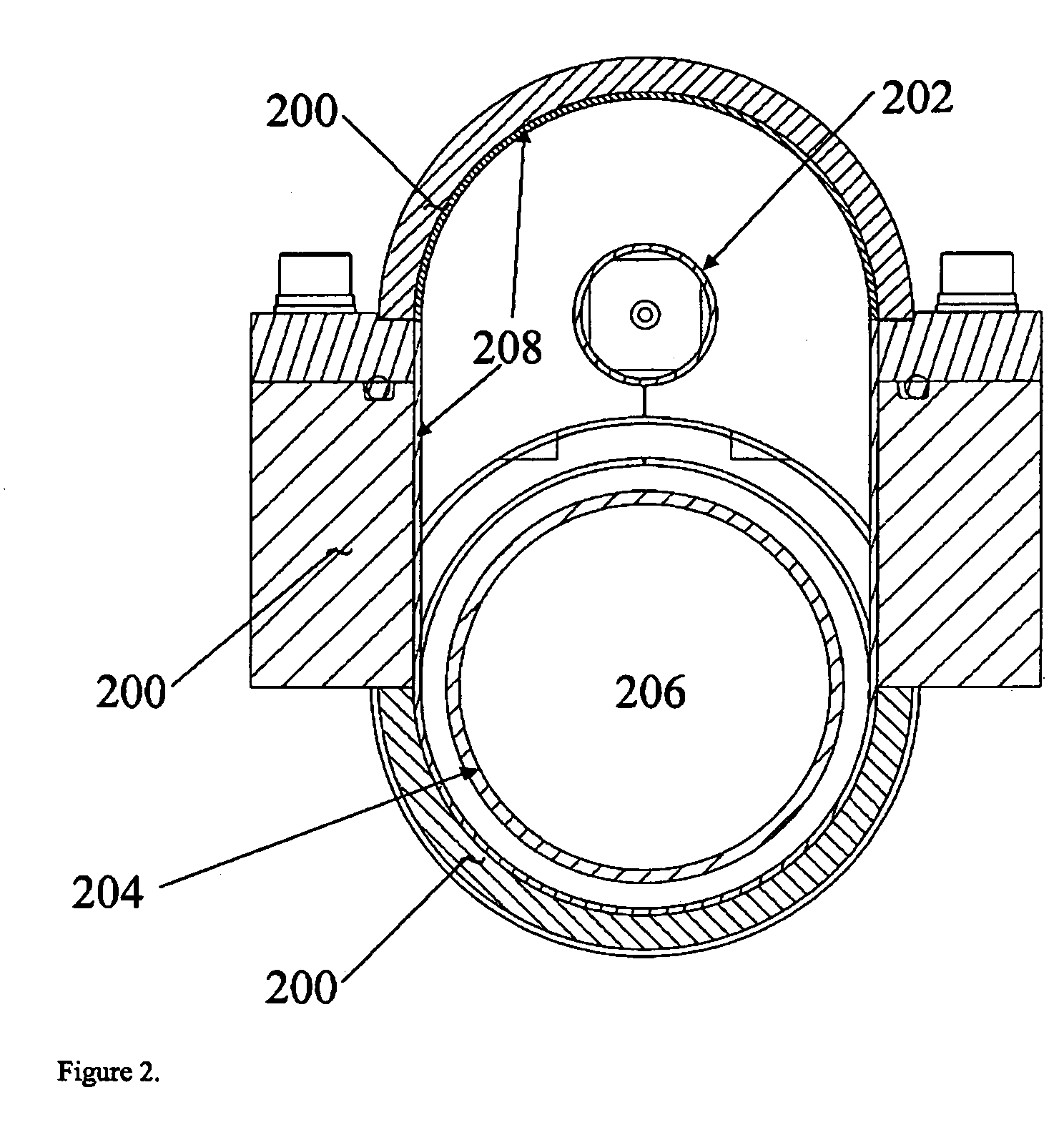

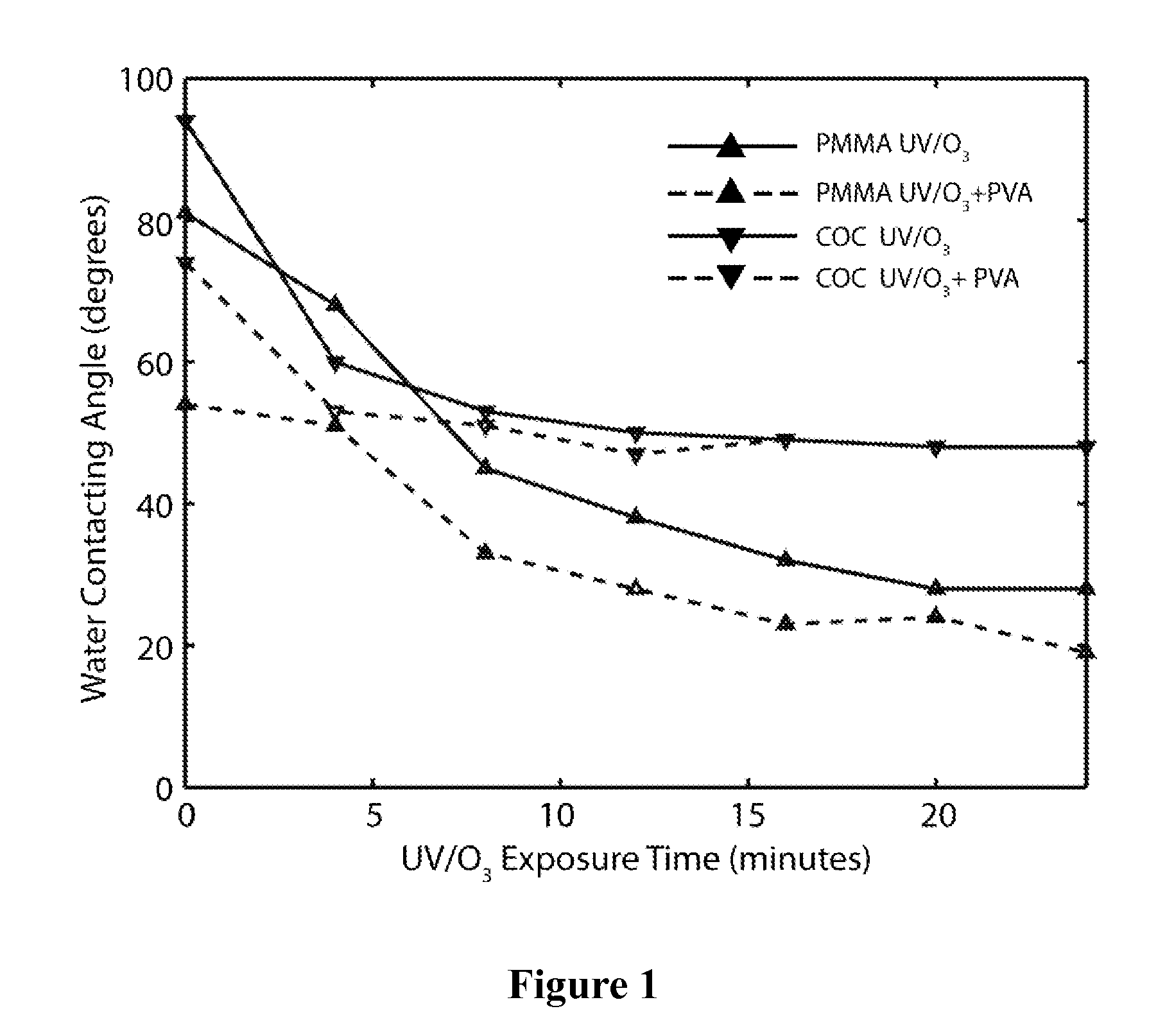

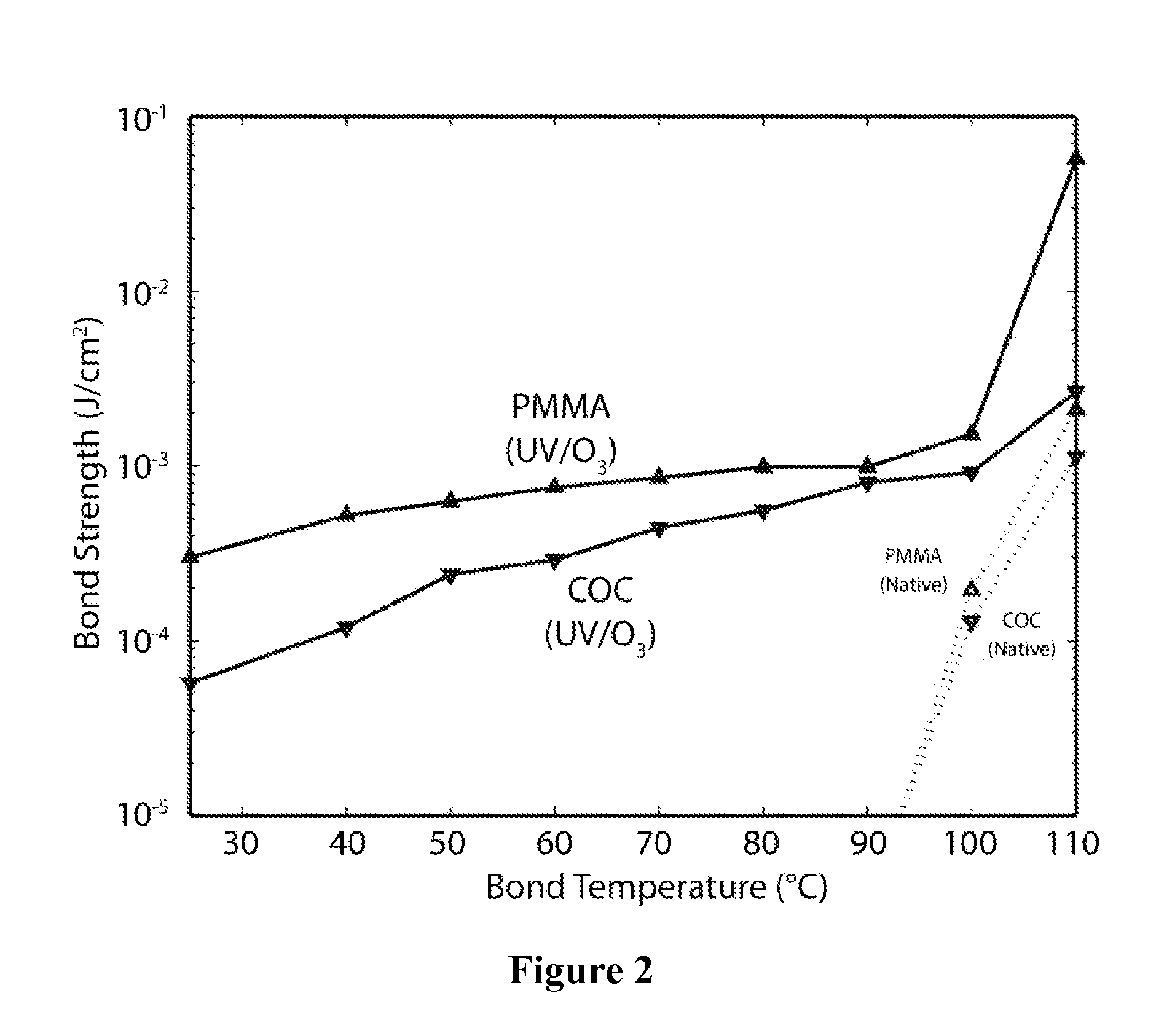

Low Temperature Polymer Bonding Using UV/Ozone Surface Treatment

InactiveUS20090227755A1High bonding strengthLow costPretreated surfacesGroup 3/13 element organic compoundsThermoplasticVitrification

The present invention relates to a method for bonding two surfaces to one another. The invention particularly pertains to the use of such method in which one of the surfaces is a polymeric plastic (and more preferably a polymeric thermoplastic (especially poly-(methyl methacrylate) (“PMMA”) or cyclic olefin copolymer (“COC”)). More particularly, the invention relates to treating at least one of the contacting surfaces with UV in the presence of oxygen to thereby generate ozone (O3) and atomic oxygen under conditions of temperature below that of the glass transition temperature of the polymeric plastic. The UV / O3-mediated bonding results in high bond strength and zero-deformation method. This bonding method can be applied to micro / nano-scale polymer devices, and particularly to microfluidic devices, for a low cost, high throughput, high yield advantage.

Owner:UNIV OF MARYLAND

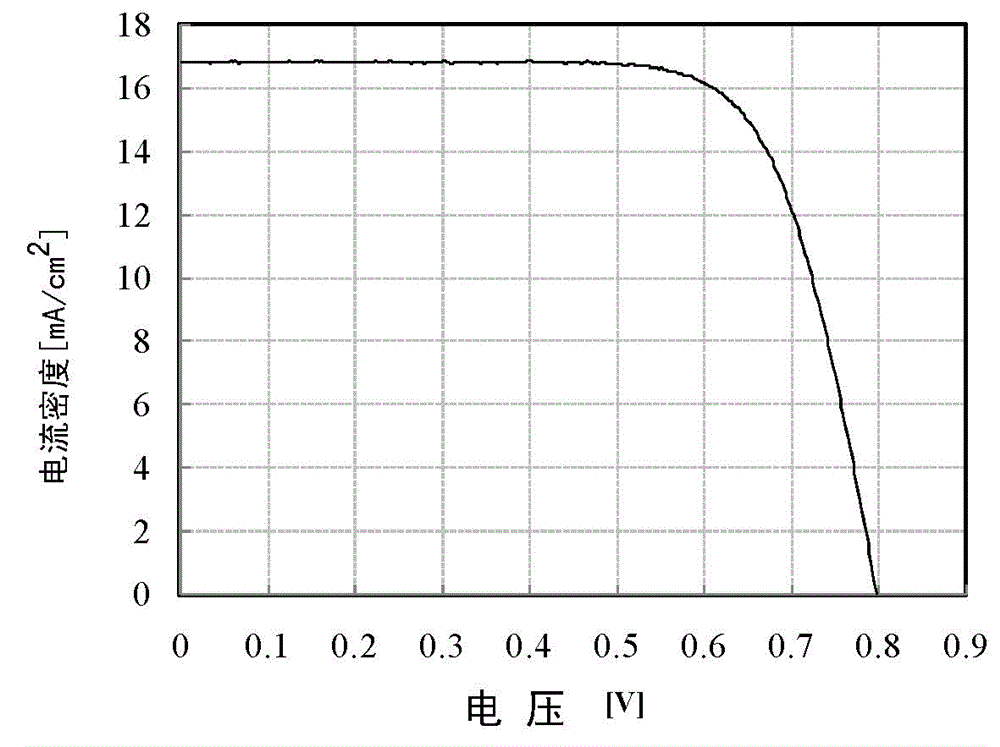

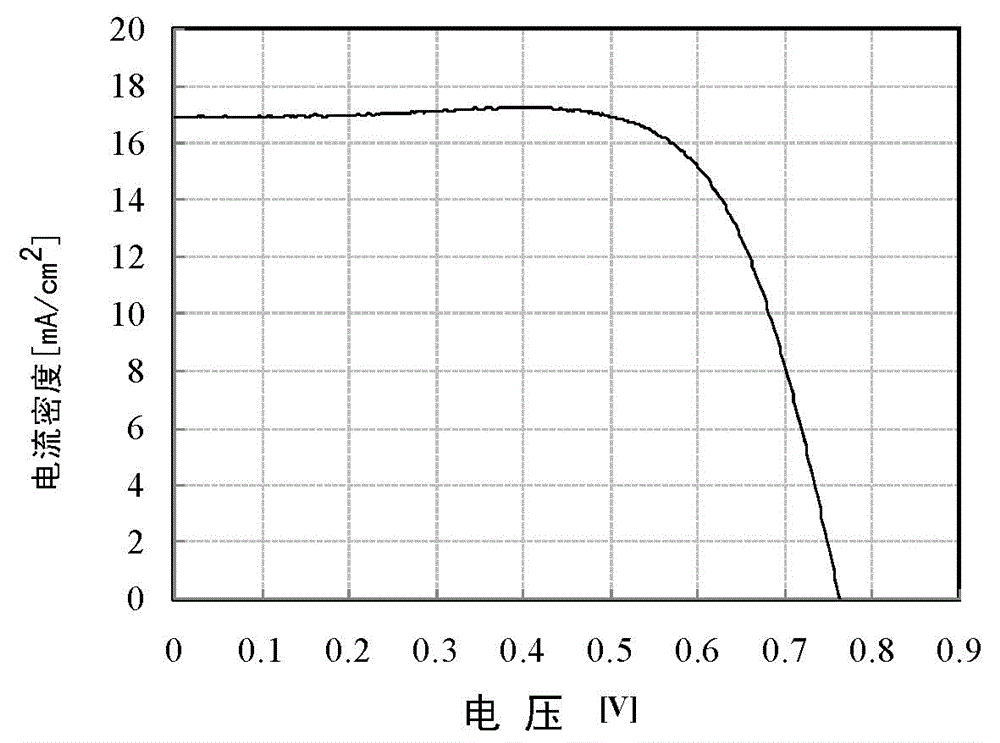

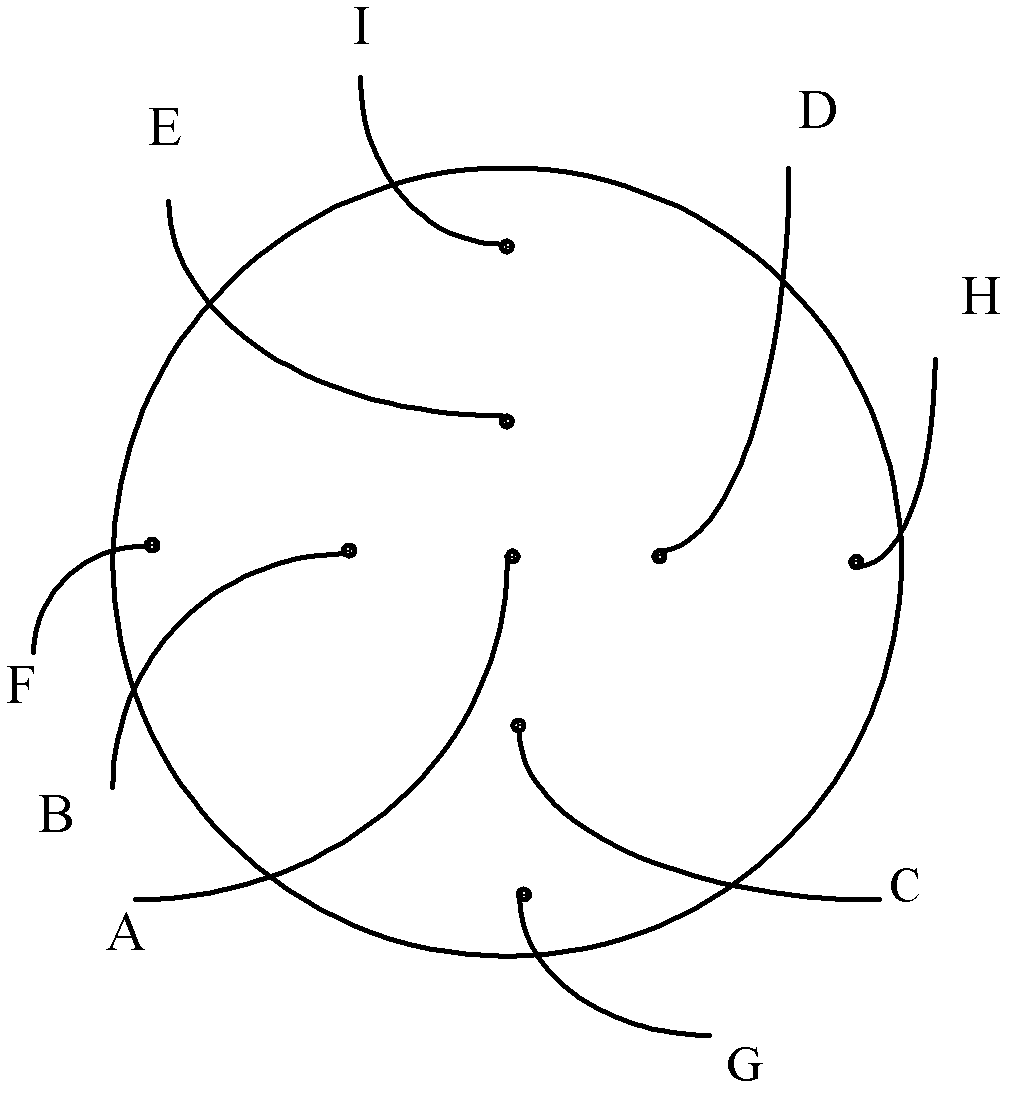

Method used for preparing TiO2/Cu2O nano heterojunction by composite mask method

ActiveCN103409778AFlat surfaceHighly orderedSurface reaction electrolytic coatingNanotechnologyHeterojunctionTio2 nanotube

The invention belongs to the field of photoelectric nano-material technologies, and more specifically relates to a method used for preparing TiO2 / Cu2O nano heterojunction by composite mask method. The method comprises following steps: titanium sheets are subjected to secondary anodic oxidation so as to obtain TiO2 nanotube array thin films; the TiO2 nanotube array thin films are immersed in a compound solution of phenyltriethoxysilane and methanol, and the TiO2 nanotube array thin films with super-hydrophobicity are prepared by mask method and ultraviolet light treatment; and then Cu2O nanocrystals produced by the high-frequency impulse electrodeposition method are uniformly distributed on the surface and inner wall of the TiO2 nanotube array thin films to obtain the TiO2 / Cu2O nano heterojunction. The photoelectric property of the TiO2 / Cu2O nano heterojunction is higher than 6 to 14 times of the photoelectric property of the TiO2 nanotube array; the photoelectric property is excellent; and the TiO2 / Cu2O nano heterojunction can be used as ideal materials for solar energy photoelectric conversion and solar energy efficient utilization.

Owner:HEFEI UNIV OF TECH

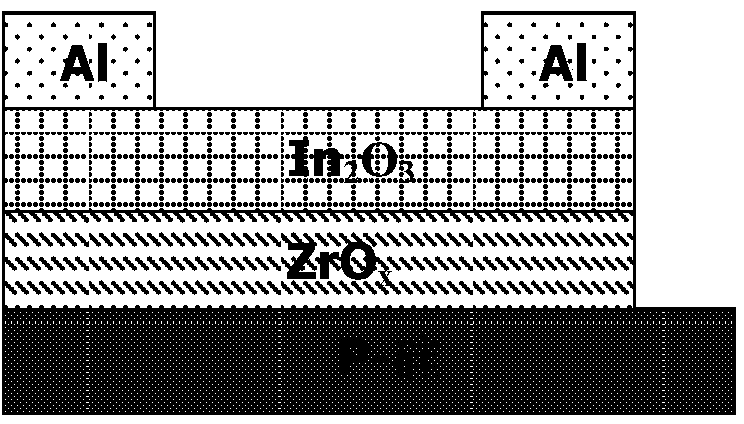

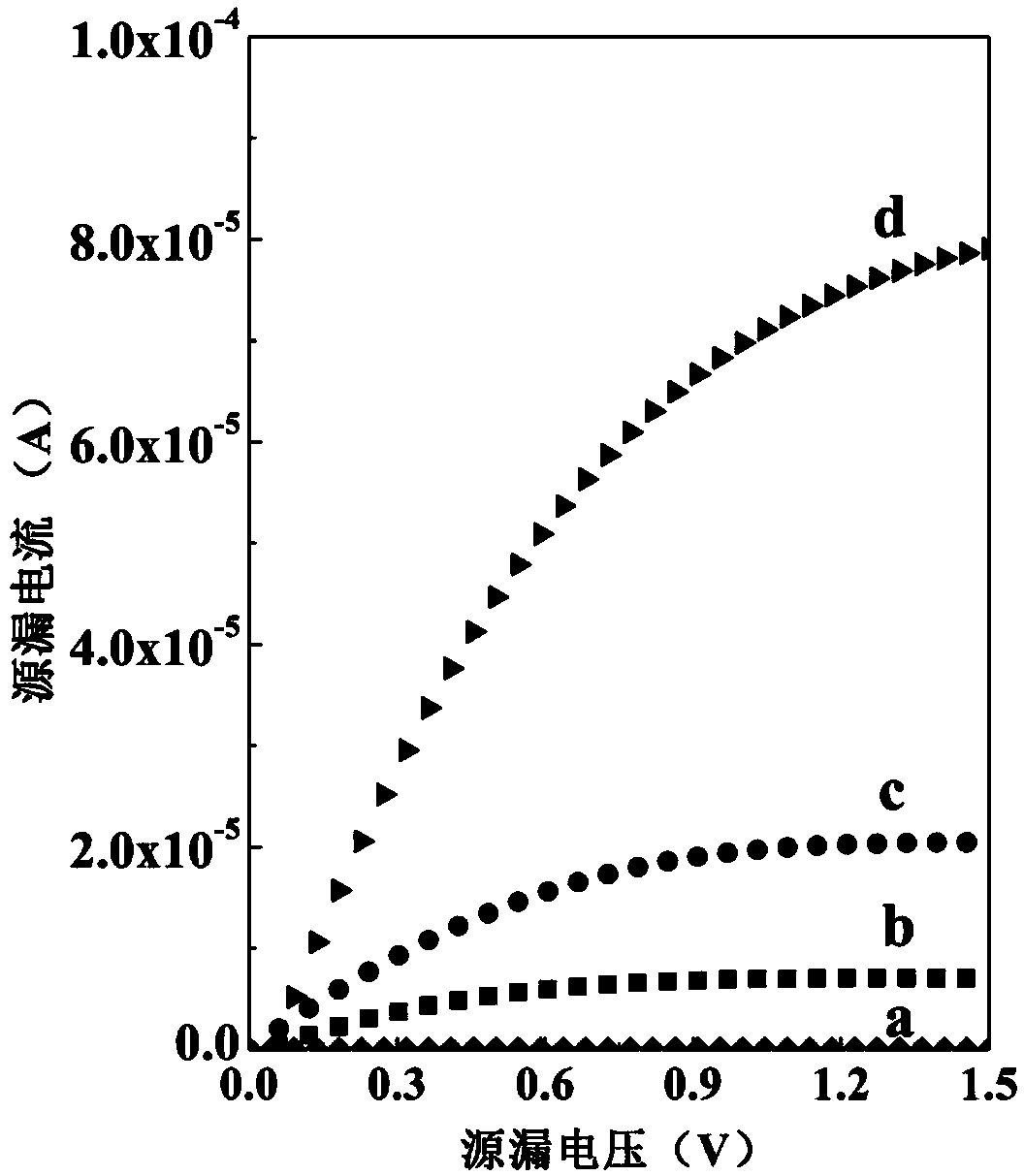

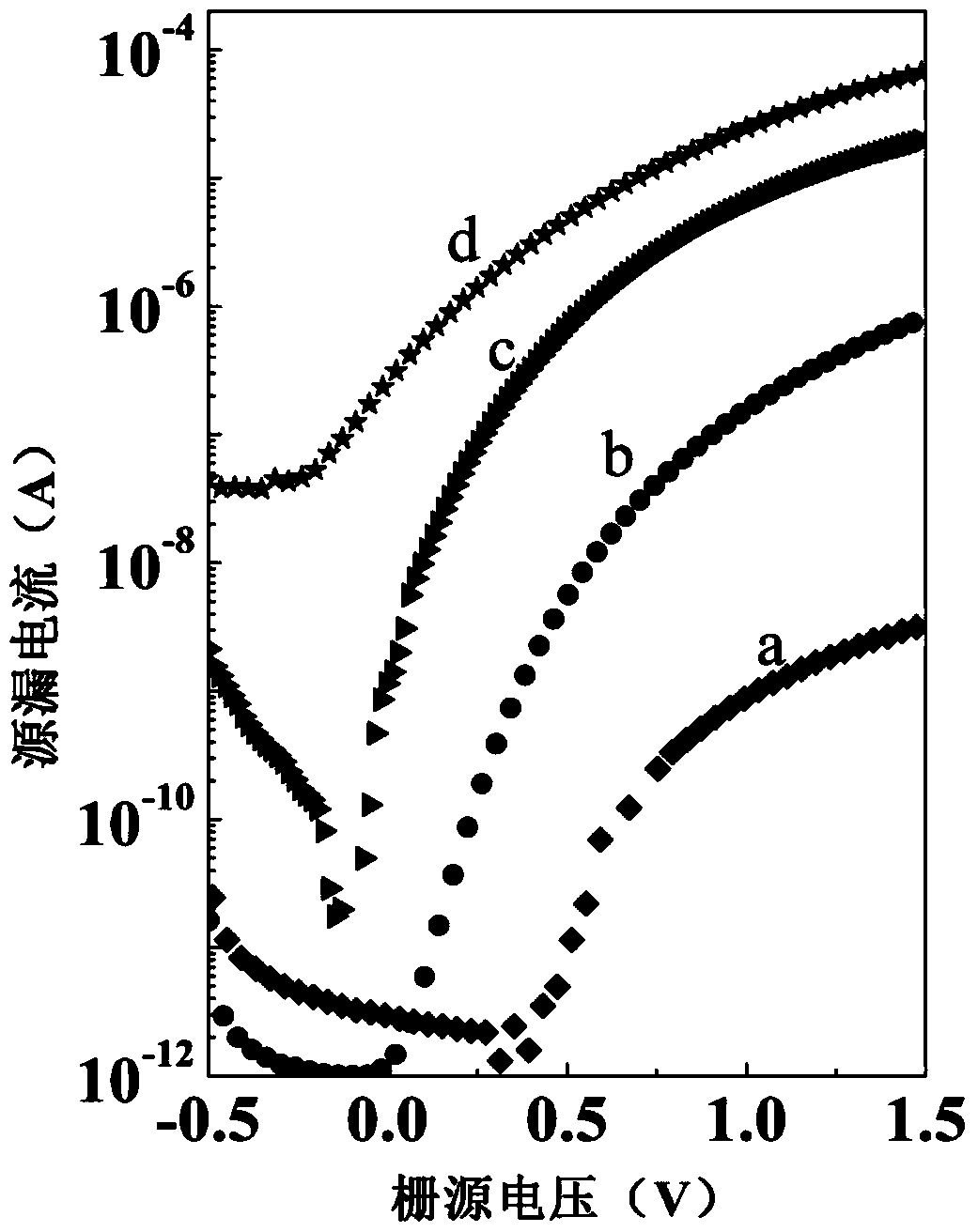

Method for manufacturing high-k dielectric layer water-based indium oxide thin film transistors

InactiveCN104009093AImprove transmittanceImprove adhesionTransistorMaterial nanotechnologyWater basedOxide thin-film transistor

The invention belongs to the technical field of manufacturing of semiconductor thin film transistors and relates to a method for manufacturing high-k dielectric layer water-based indium oxide thin film transistors. The method includes the steps that zirconium acetylacetonate is dissolved in dimethylformamide, and ethanol amine of the same molar weight as the zirconium acetylacetonate is added as a stabilizer, so that a precursor solution is formed; a sample is obtained by coating a cleaned low-resistance silicon substrate with the precursor solution in a spinning mode, and a sample obtained after light annealing is obtained by placing the sample below a high-pressure mercury lamp for ultraviolet light treatment; a thin film sample is obtained through annealing of the sample obtained after light annealing; an In2O3 channel layer is obtained by coating the surface of the obtained thin film sample with an In2O3 aqueous solution; finally, a source electrode and a drain electrode are manufactured on the In2O3 channel layer, and then the thin film transistors can be obtained. According to the overall implementation scheme, cost is low, processes are simple, the principle is reliable, product performance is good, the manufacturing process is environmentally friendly, application prospects are wide, and a feasible plan is provided for manufacturing the high-performance thin film transistors on a large scale.

Owner:QINGDAO UNIV

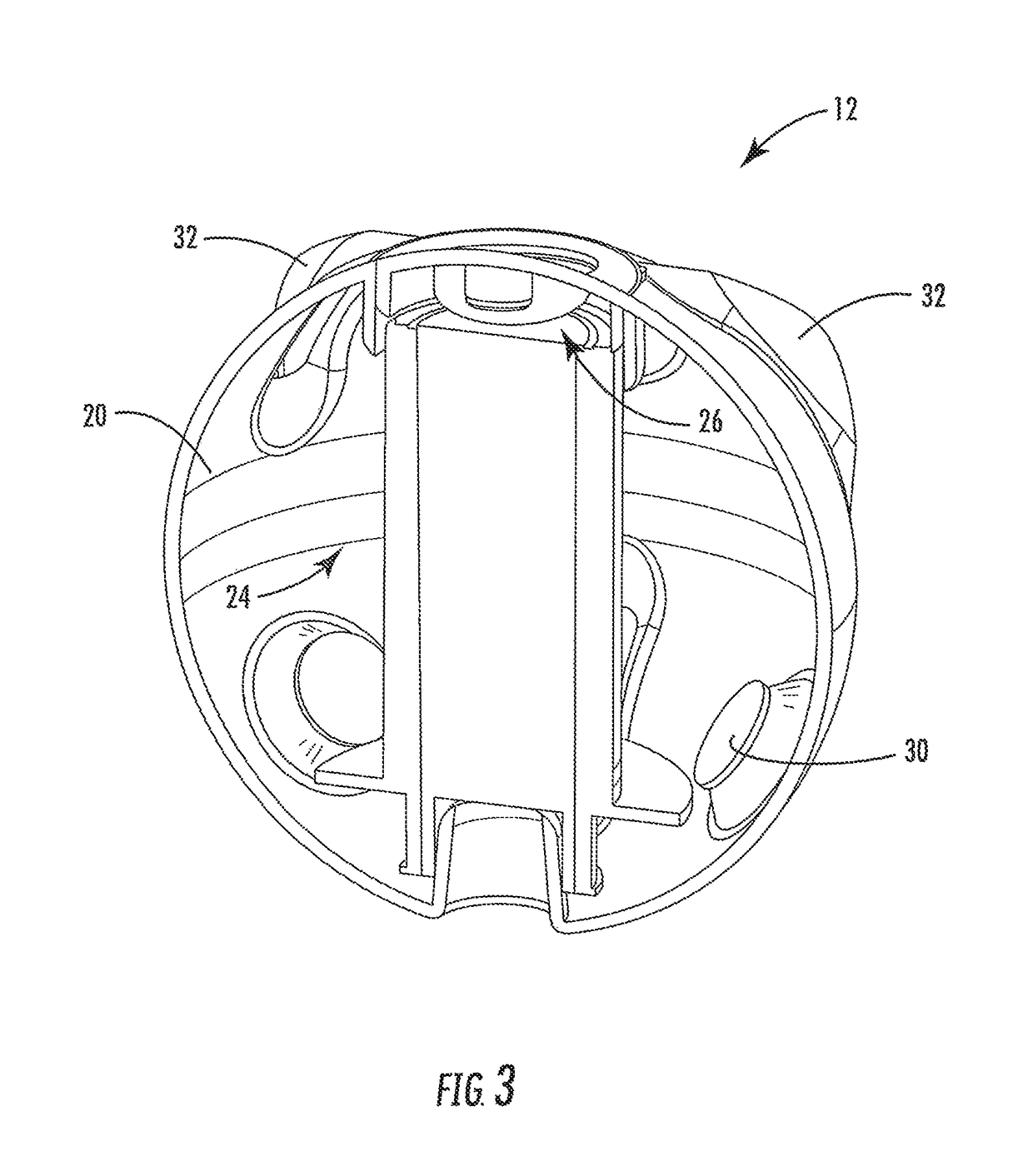

Ultraviolet light treatment chamber

ActiveUS20090155136A1Easy to implementEasy to useMedical devicesWater/sewage treatment by ion-exchangeUltravioletReflective layer

An apparatus for the treatment of a liquid comprising includes a chamber having at least one inner surface. The chamber is at least 80 percent enclosed. The apparatus also includes an ultraviolet (UV) transmissive tube and the UV transmissive tube disposed within the chamber and adapted for the passage of the liquid therethrough. The apparatus further includes an UV lamp and the UV lamp being disposed within the UV transmissive tube. A reflective material is interspersed between the chamber and the transmissive tube, and the reflective material is adapted so as to reflect at least a portion of light emitted by the UV lamp. Additionally, the reflective material is at least 80 percent reflective.

Owner:NEO TECH AQUA SOLUTIONS

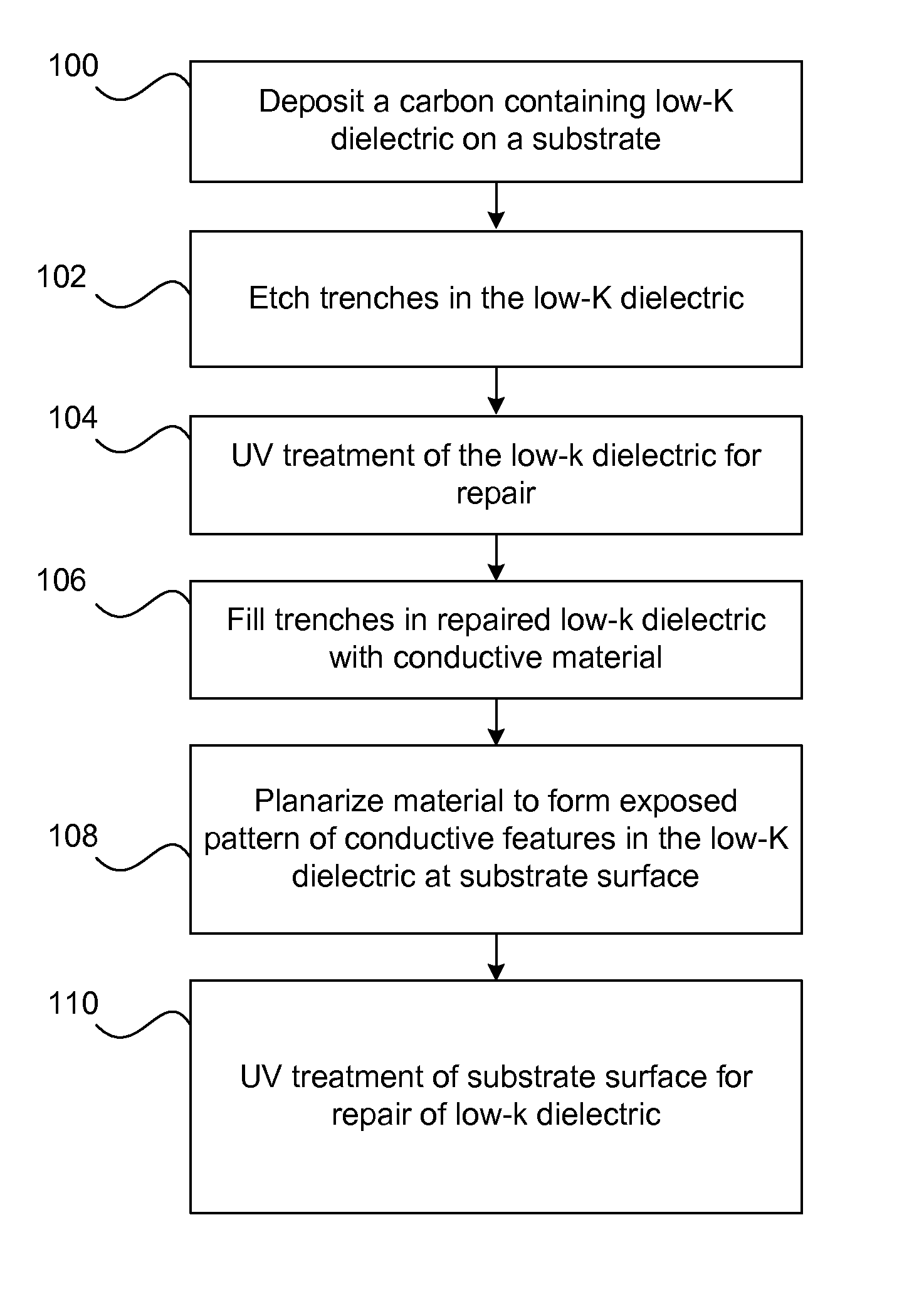

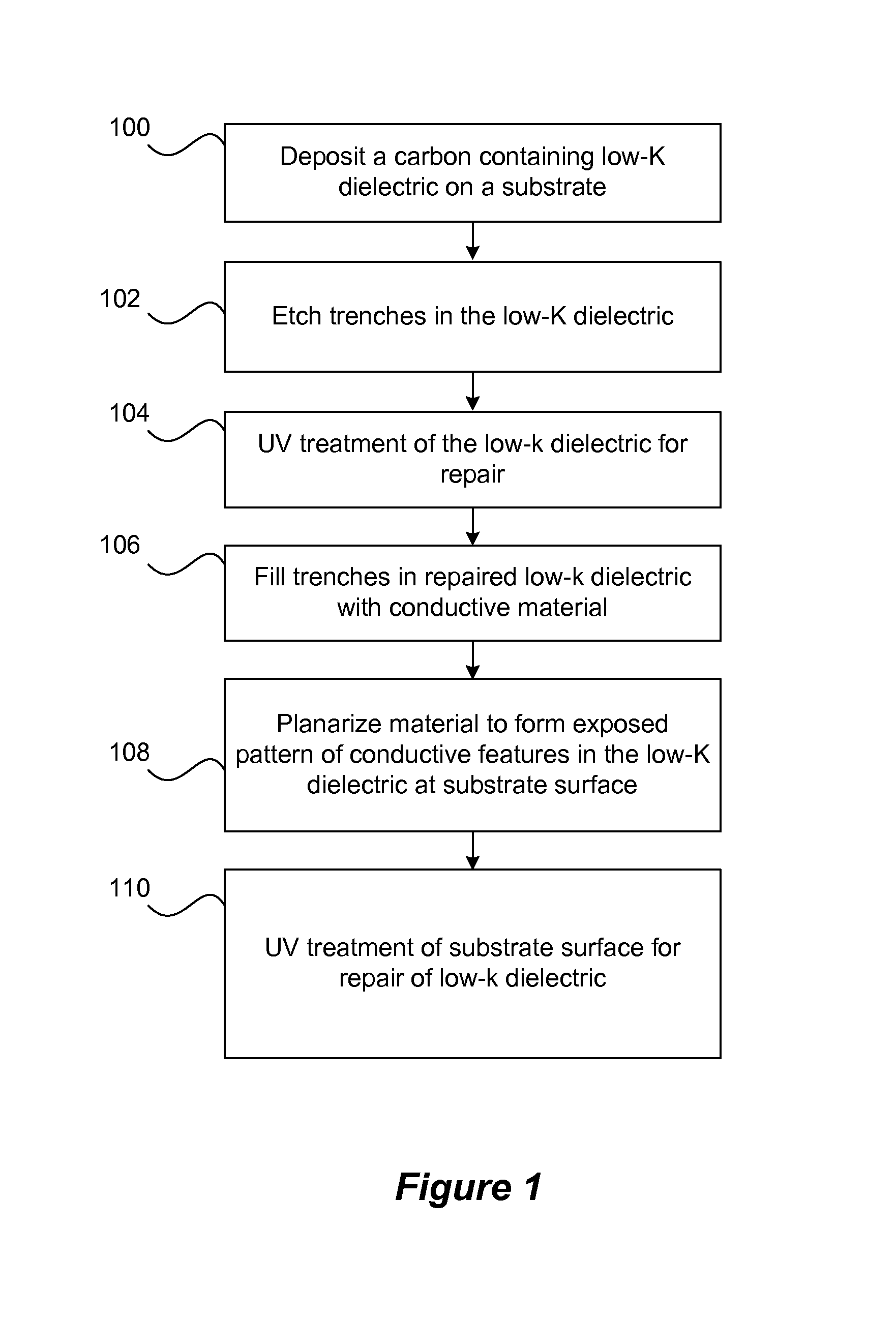

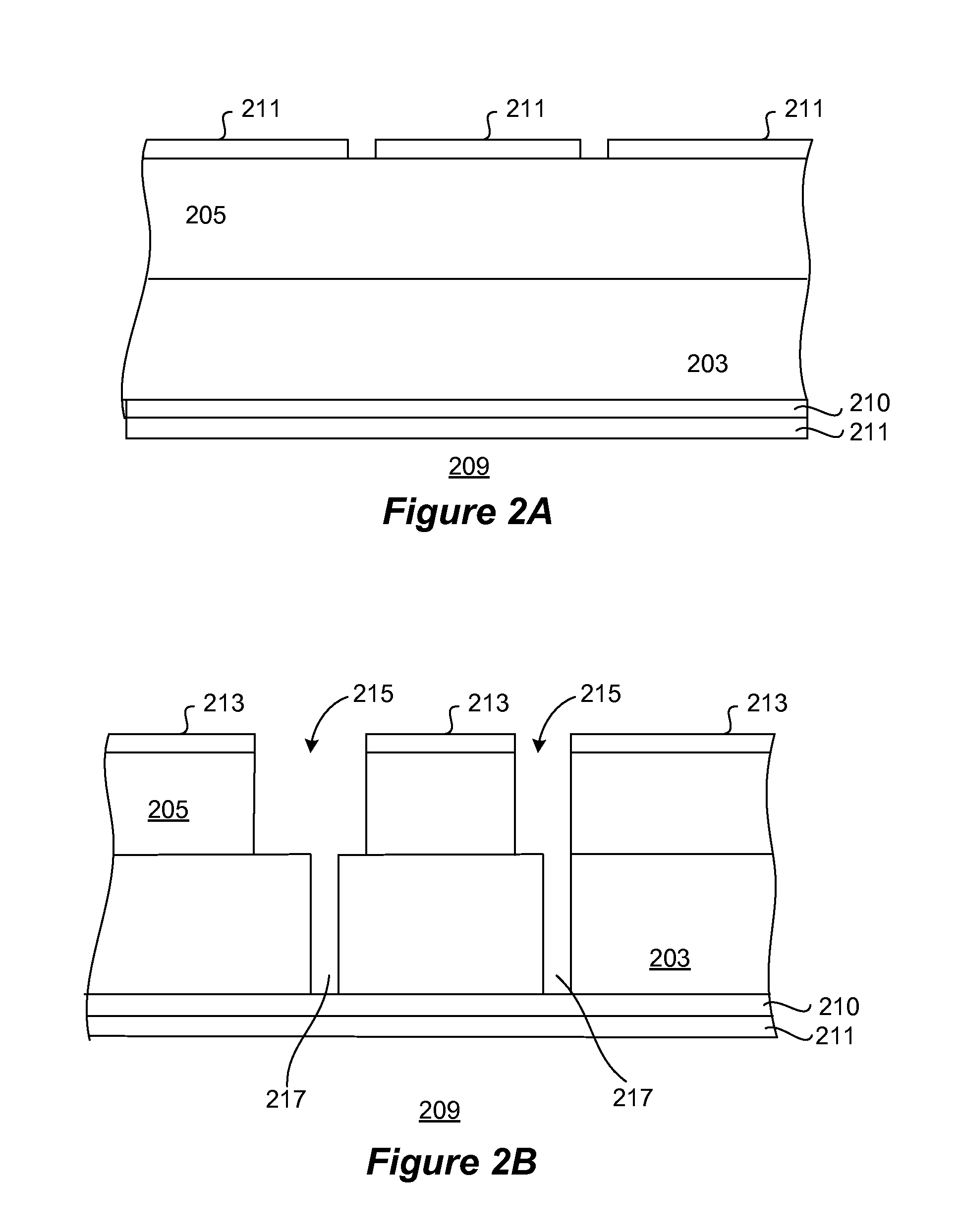

Carbon containing low-k dielectric constant recovery using UV treatment

ActiveUS8465991B2Reduces and minimizesExtent of k-recovery is greatly enhancedSemiconductor/solid-state device manufacturingEnergy based chemical/physical/physico-chemical processesDamage repairSilylation

A method for the ultraviolet (UV) treatment of carbon-containing low-k dielectric and associated apparatus enables process induced damage repair. The methods of the invention are particularly applicable in the context of damascene processing to recover lost low-k property of a dielectric damaged during processing, either pre-metallization, post-planarization, or both. UV treatments can include an exposure of the subject low-k dielectric to a constrained UV spectral profile and / or chemical silylating agent, or both.

Owner:NOVELLUS SYSTEMS

System and method for dispensing UV treated materials

InactiveUS20160278424A1Reduce formationInhibition formationWater treatment parameter controlWater/sewage treatment by irradiationEngineeringUv responsive

Owner:LARQ INC

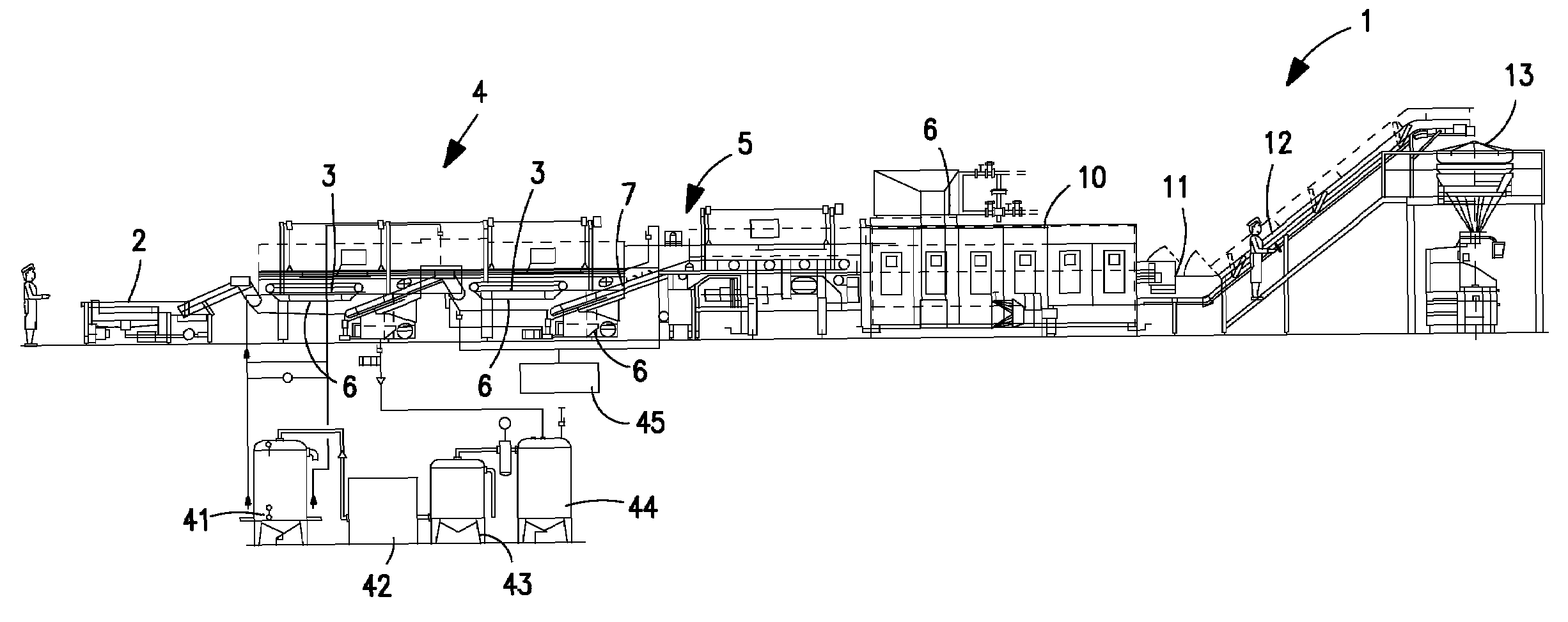

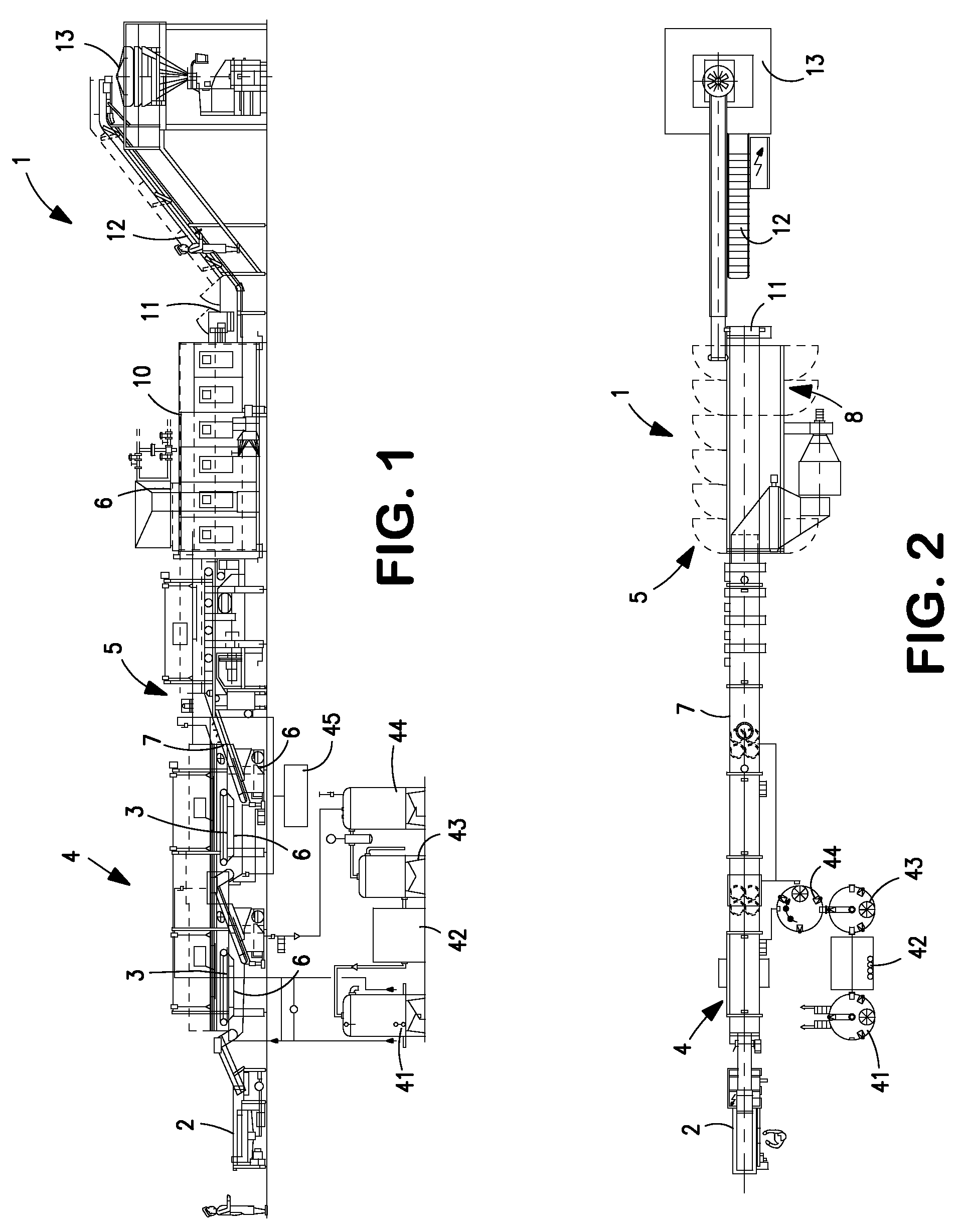

Process for washing and sterilising food products, particularly vegetables, and relevant apparatus

ActiveUS20070212457A1Reduce power consumptionReduce noise pollutionMilk preparationMilk preservationUltravioletAtmosphere

The present invention relates to a process for washing and sterilising food products, particularly vegetables, characterised in that it comprises the following steps: (a) treatment of said food products by ultrasounds, ultraviolet rays and micro filtering; (b) treatment of said food products under ozone atmosphere, ultraviolet rays and micro filtering; (c) treatment of said food products by ultraviolet rays; (d) dewatering and drying said food products under controlled atmosphere.The present invention further relates to an apparatus (1) for carrying out the above process.

Owner:TURATTI S R I

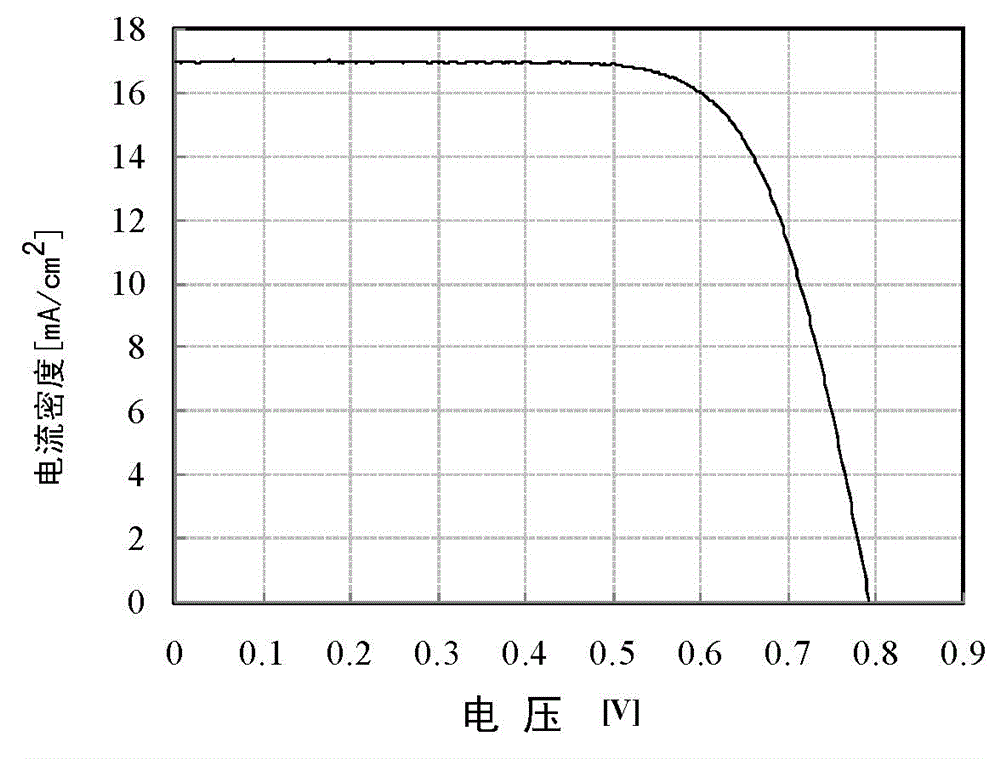

Preparing method of counter electrode for dye-sensitized solar cell

ActiveCN104485232AImprove electrocatalytic activityHigh catalytic activityLight-sensitive devicesPhotovoltaic energy generationSolar cellCatalyst poisoning

The invention provides a preparing method of a counter electrode for a dye-sensitized solar cell. Activating treatment is carried out on an electrocatalytic activity material film on a conductive substrate, and activating treatment comprises at least one of plasma treatment, ultraviolet light treatment and ozone treatment. The preparing method of the counter electrode for the dye-sensitized solar cell (DSSC), provided by the invention, can remove pollutants left on the porous structure of the counter electrode or pollutants absorbed to the surface of a catalyst, avoid or alleviate the poisoning condition of the catalyst in the CE (Counter Electrode) and improve the electrocatalytic activity of the counter electrode.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Apparatus and methods for ultraviolet light treatment of laundry

Owner:CLIFF SHIRP ENTERPRISES LLC

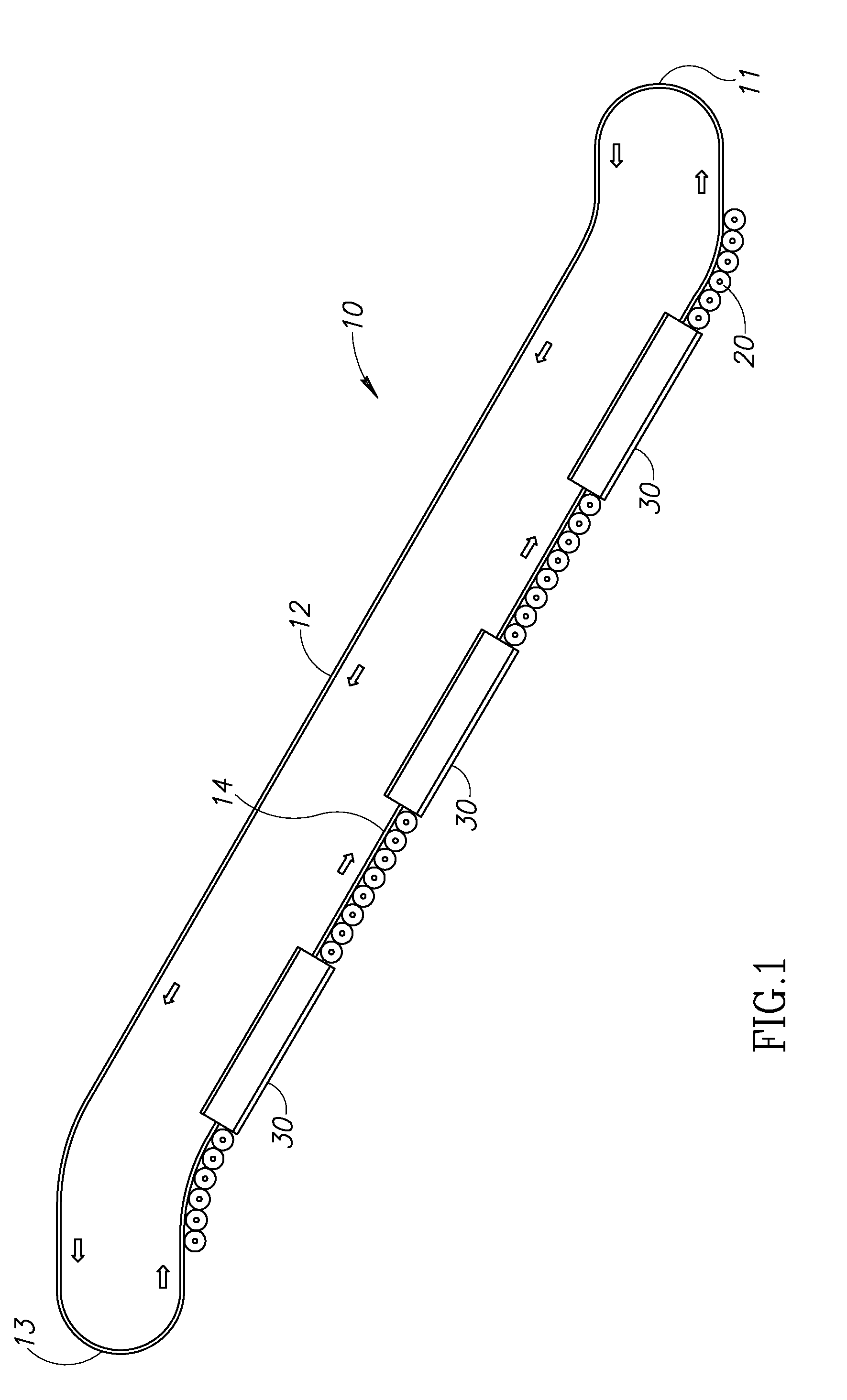

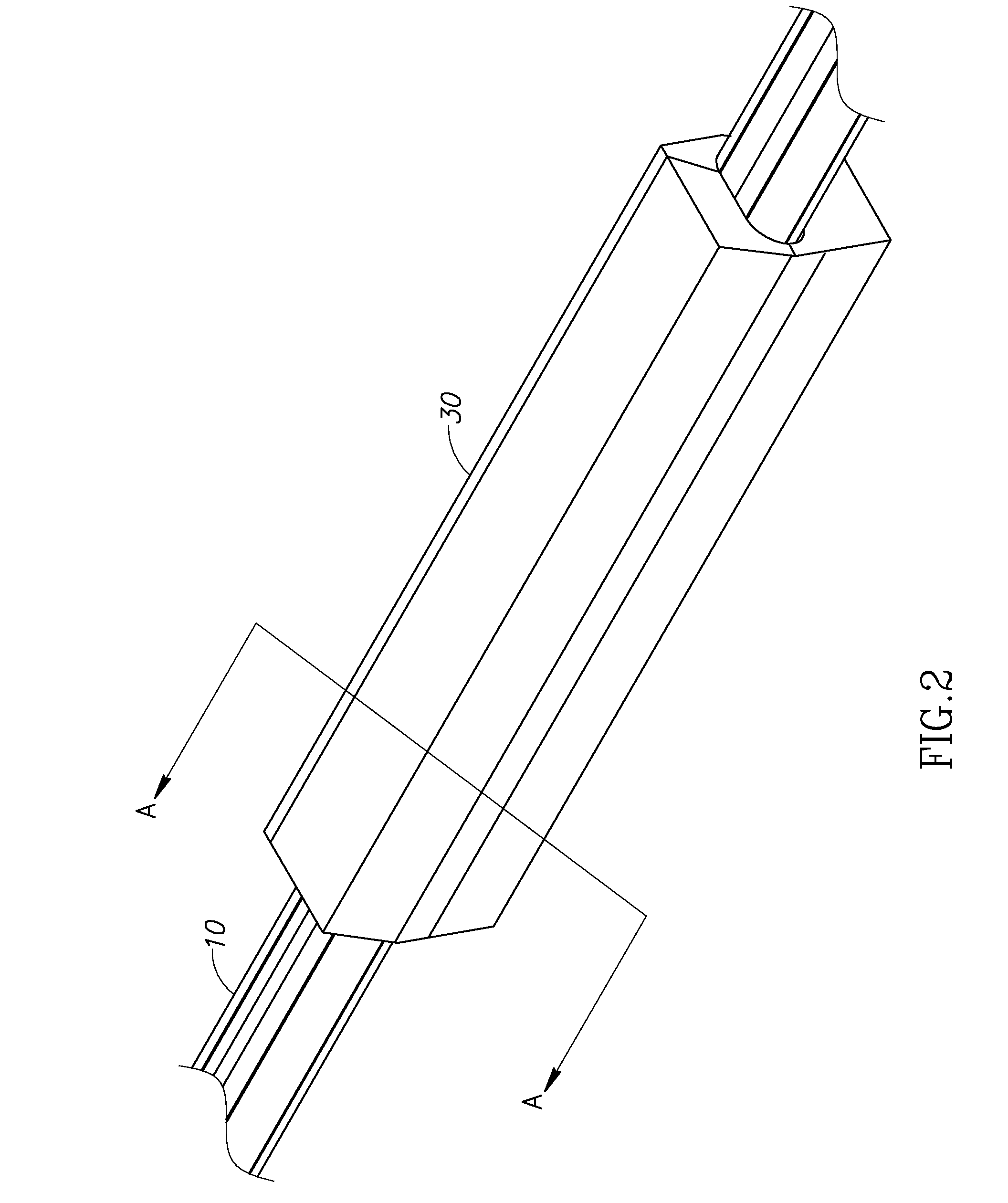

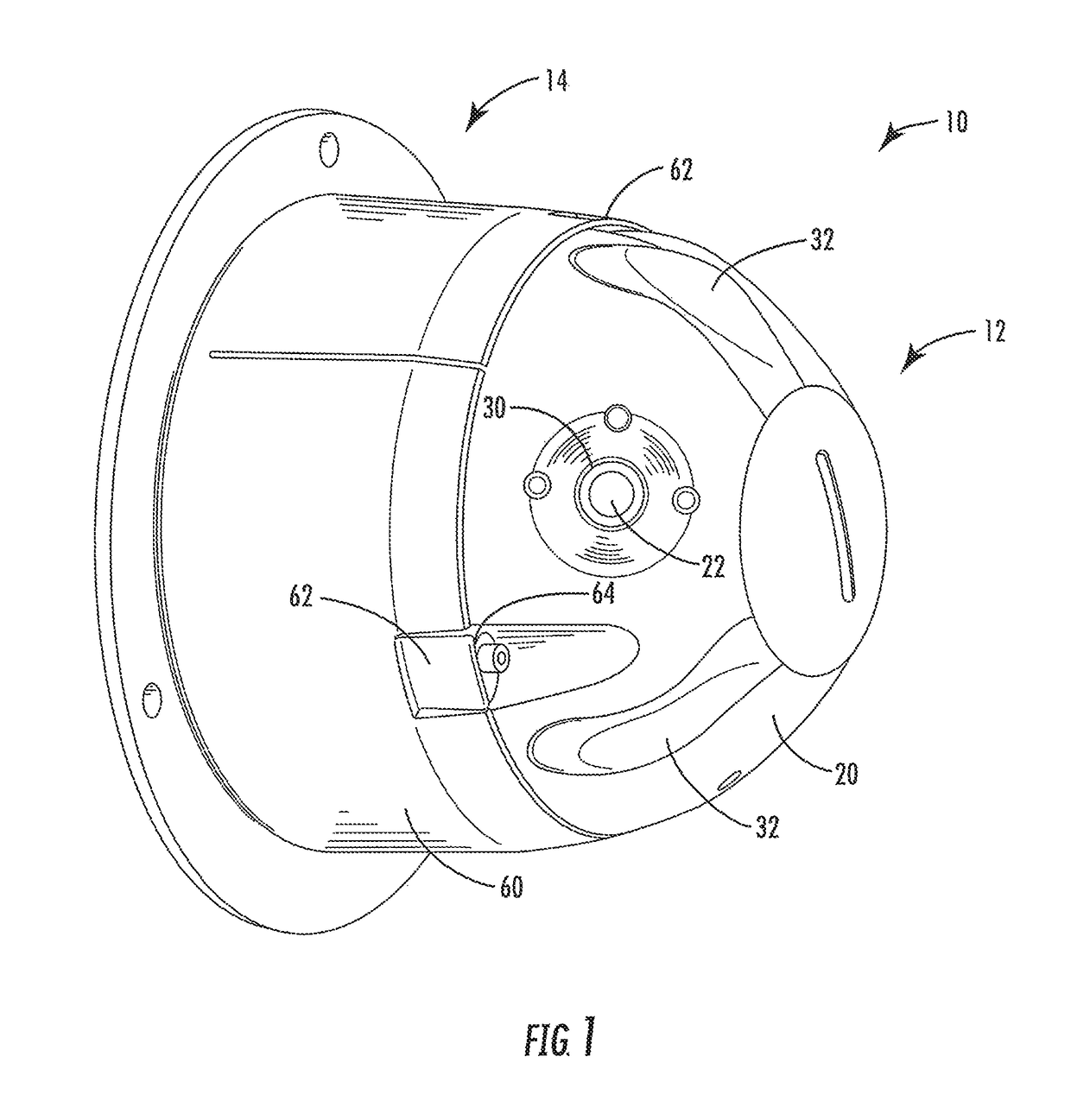

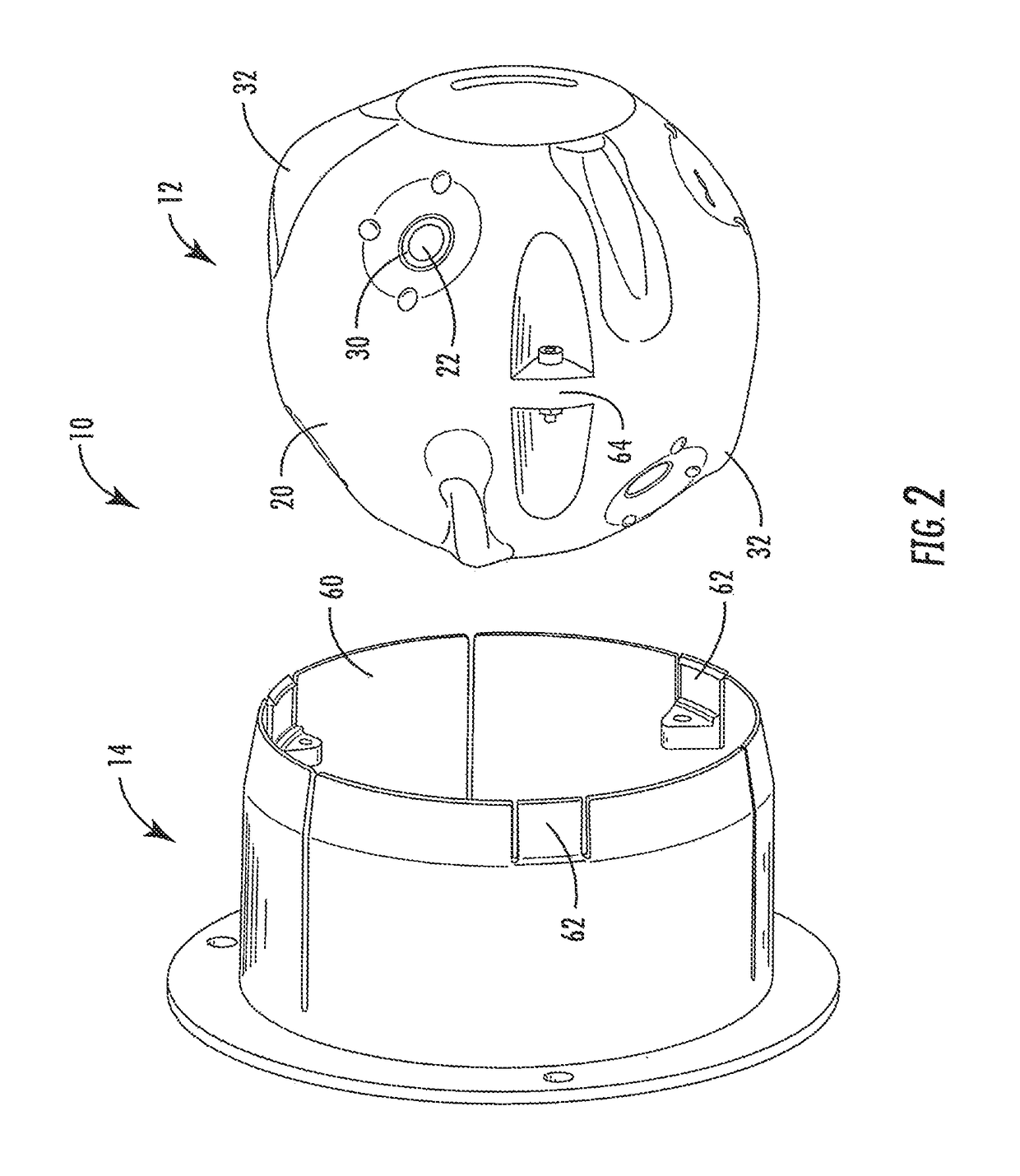

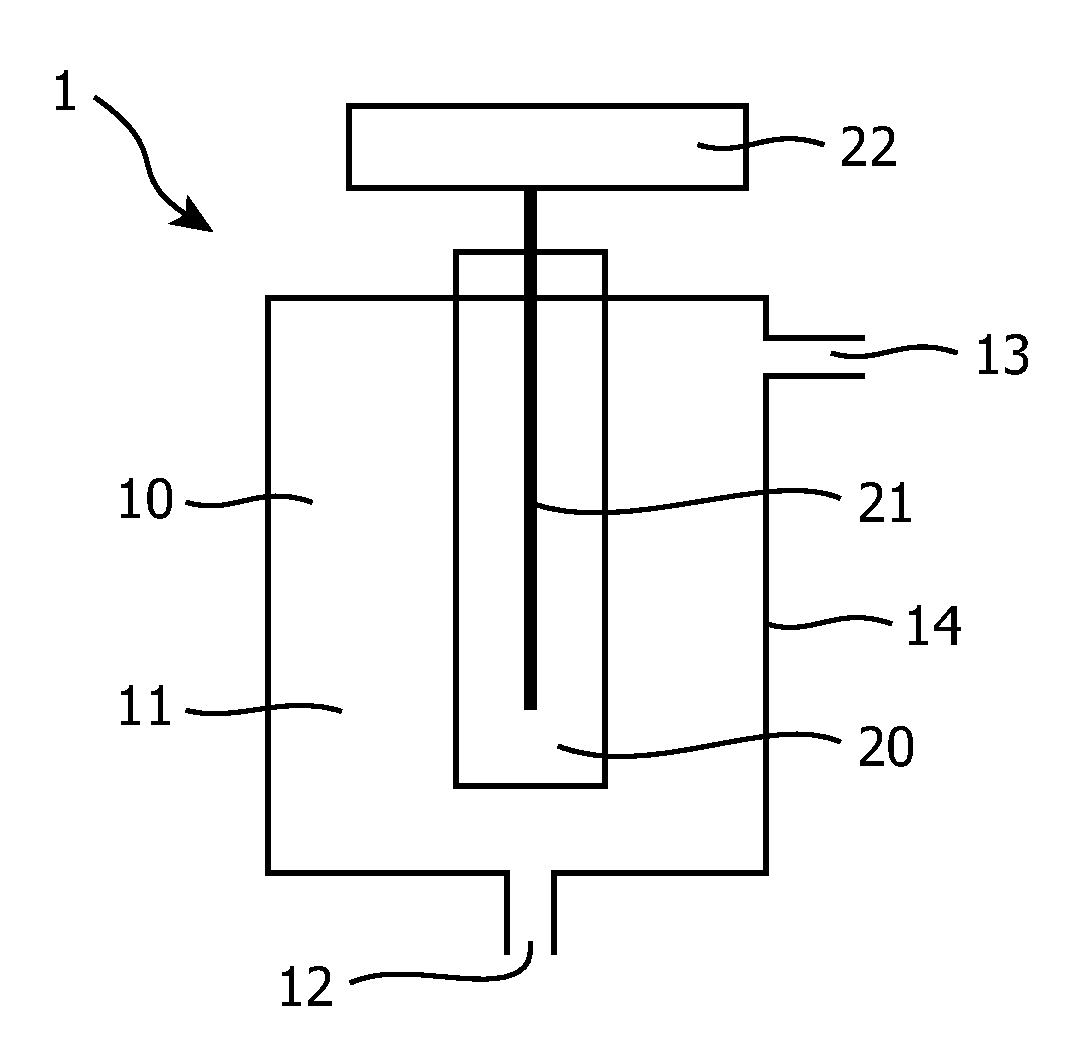

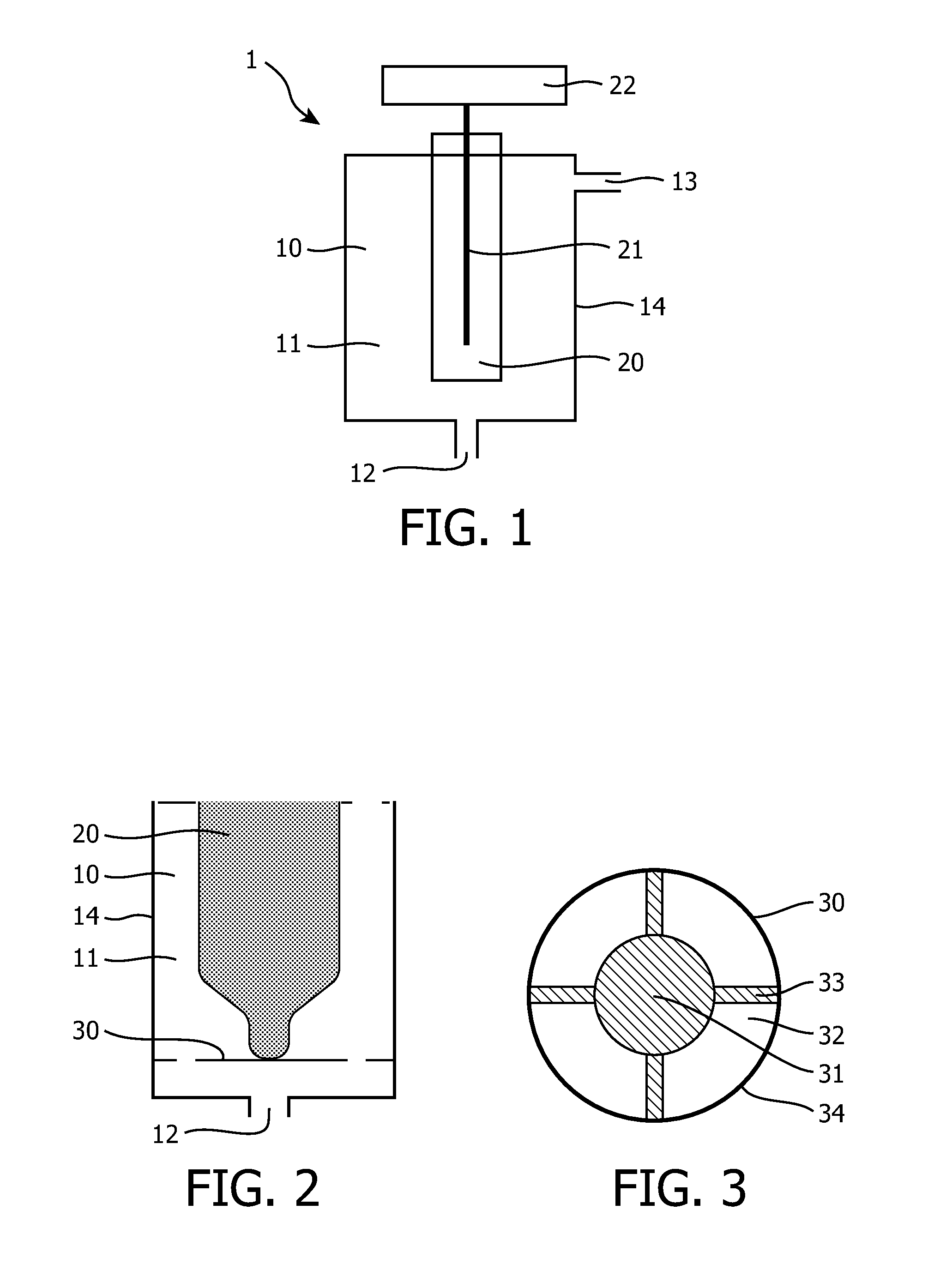

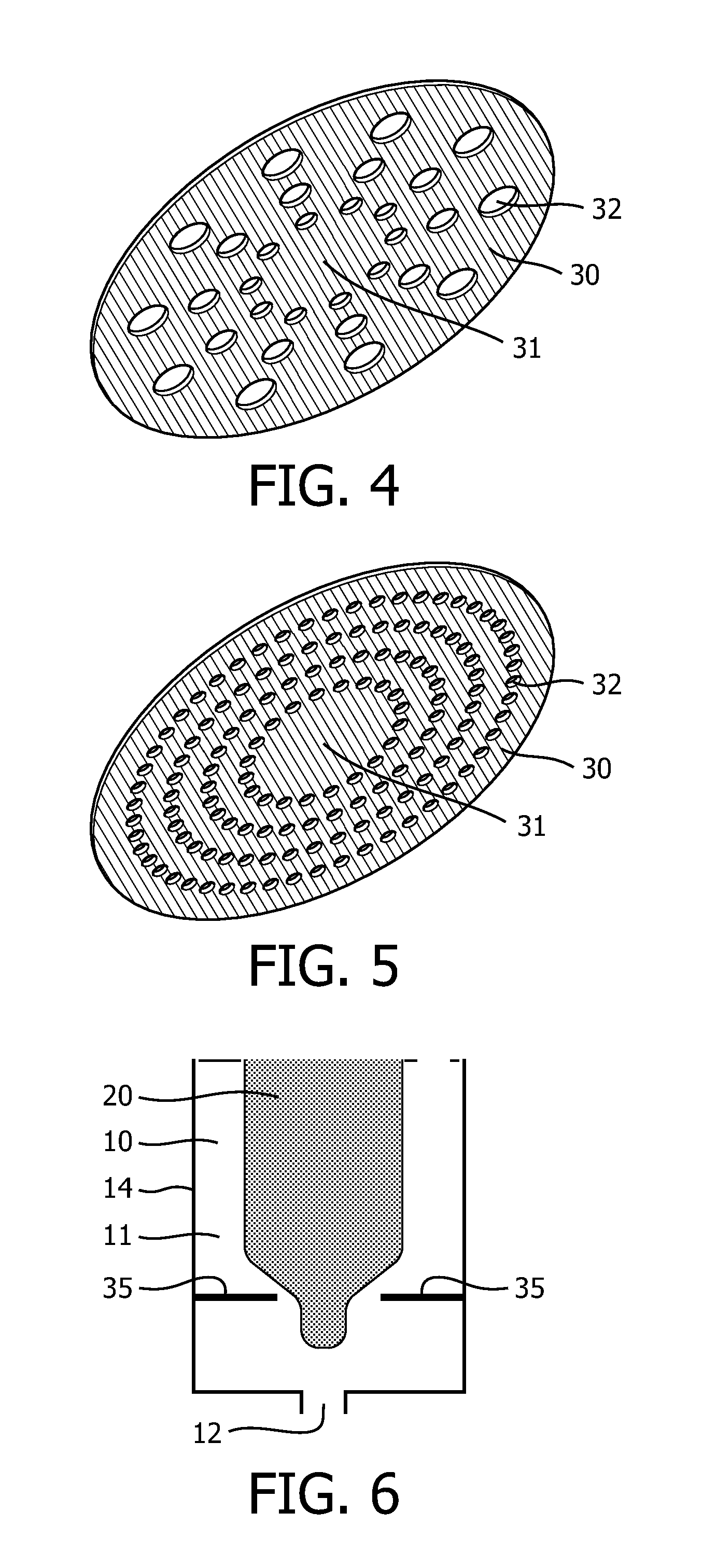

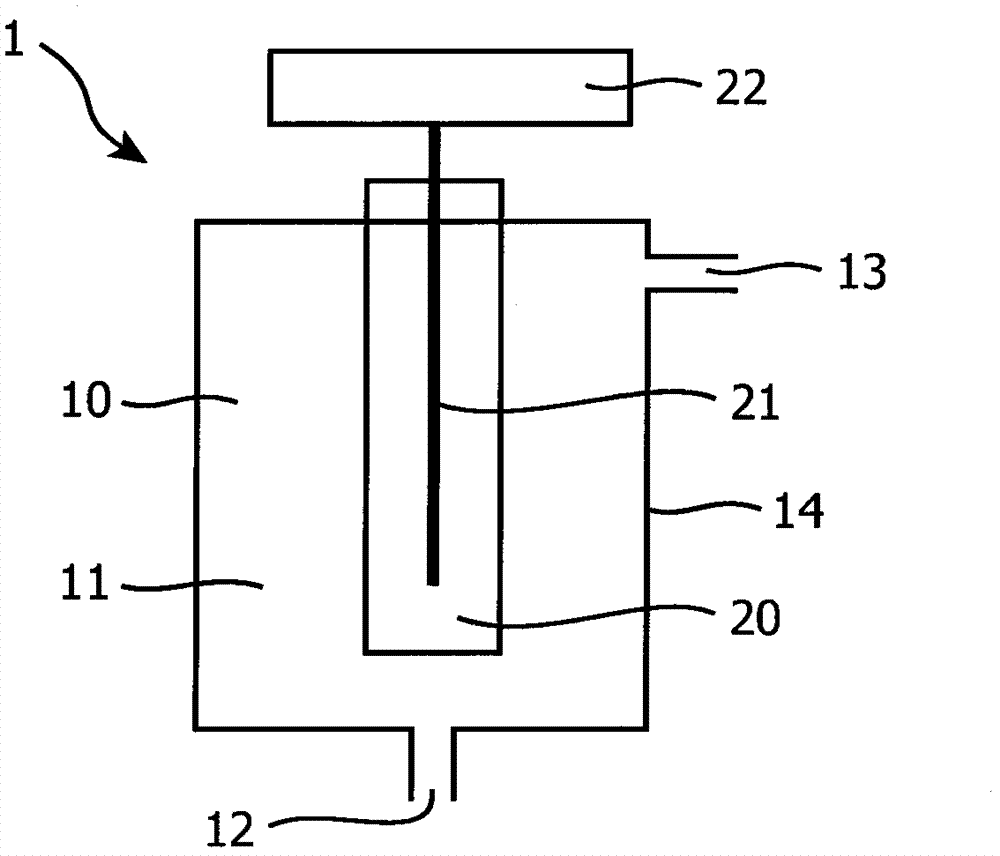

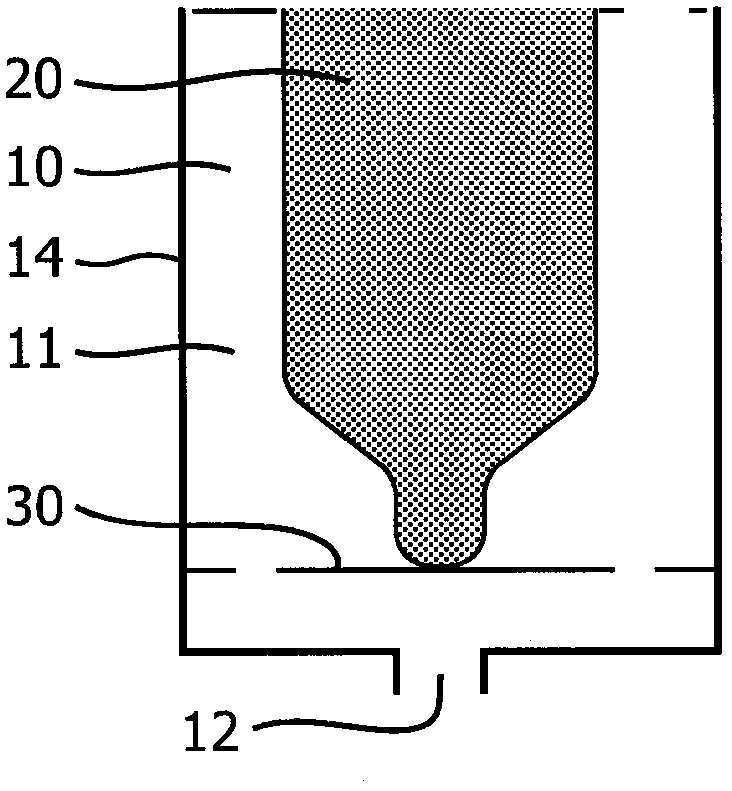

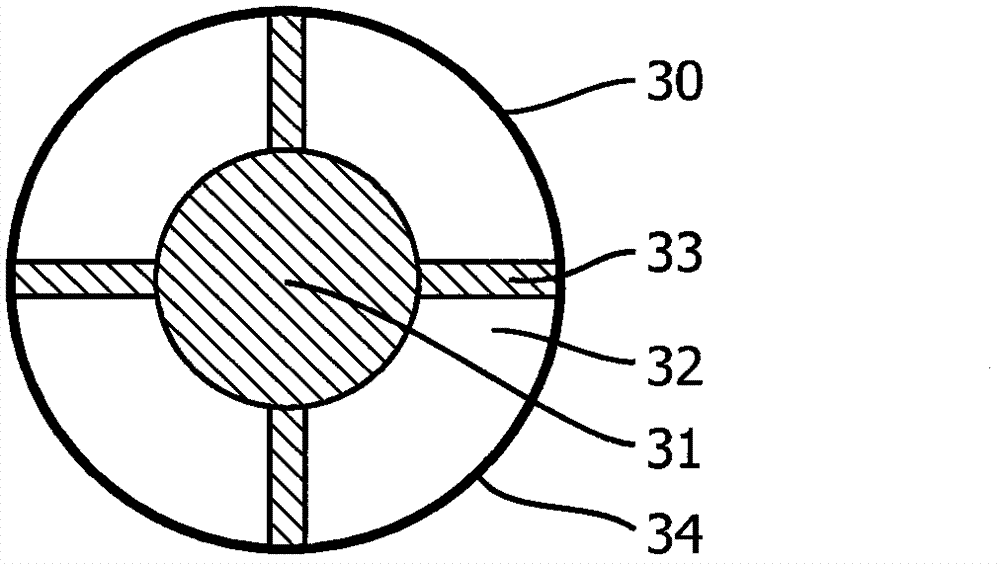

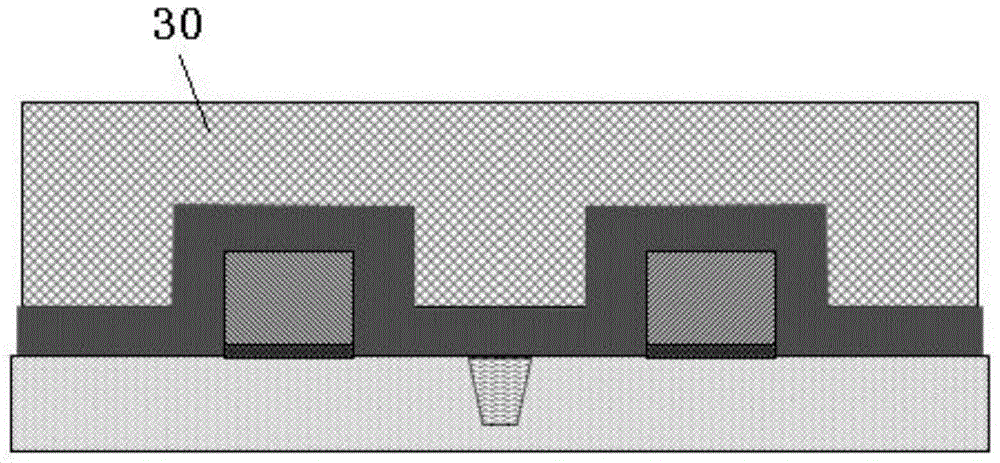

Device for subjecting a fluid to a disinfecting treatment by exposing the fluid to ultraviolet light

InactiveUS20130119266A1Improve conductivityUseful resultScattering properties measurementsWater/sewage treatment apparatusUltraviolet lightsLight emitting device

A device for subjecting a fluid to a disinfecting treatment by exposing the fluid to ultraviolet light comprises a reactor (10) having an inner space (11) in which means (20) for emitting ultraviolet light are arranged, an inlet (12) for letting fluid into the inner space (11), and an outlet for letting out fluid from the inner space (11). The light emission means (20) comprise a single electrode, wherein a wall (14) encompassing the inner space (11) is adapted to function as an electrode and comprises electrically conductive material, and wherein the device further comprises means (30) which also comprise electrically conductive material, and which are arranged for locally enhancing the electrical conductivity in a space between the reactor wall (14) and the light emission means (20). By applying these means (30), it is achieved that the disinfecting effect of the ultraviolet light treatment can be

Owner:SIGNIFY HLDG BV

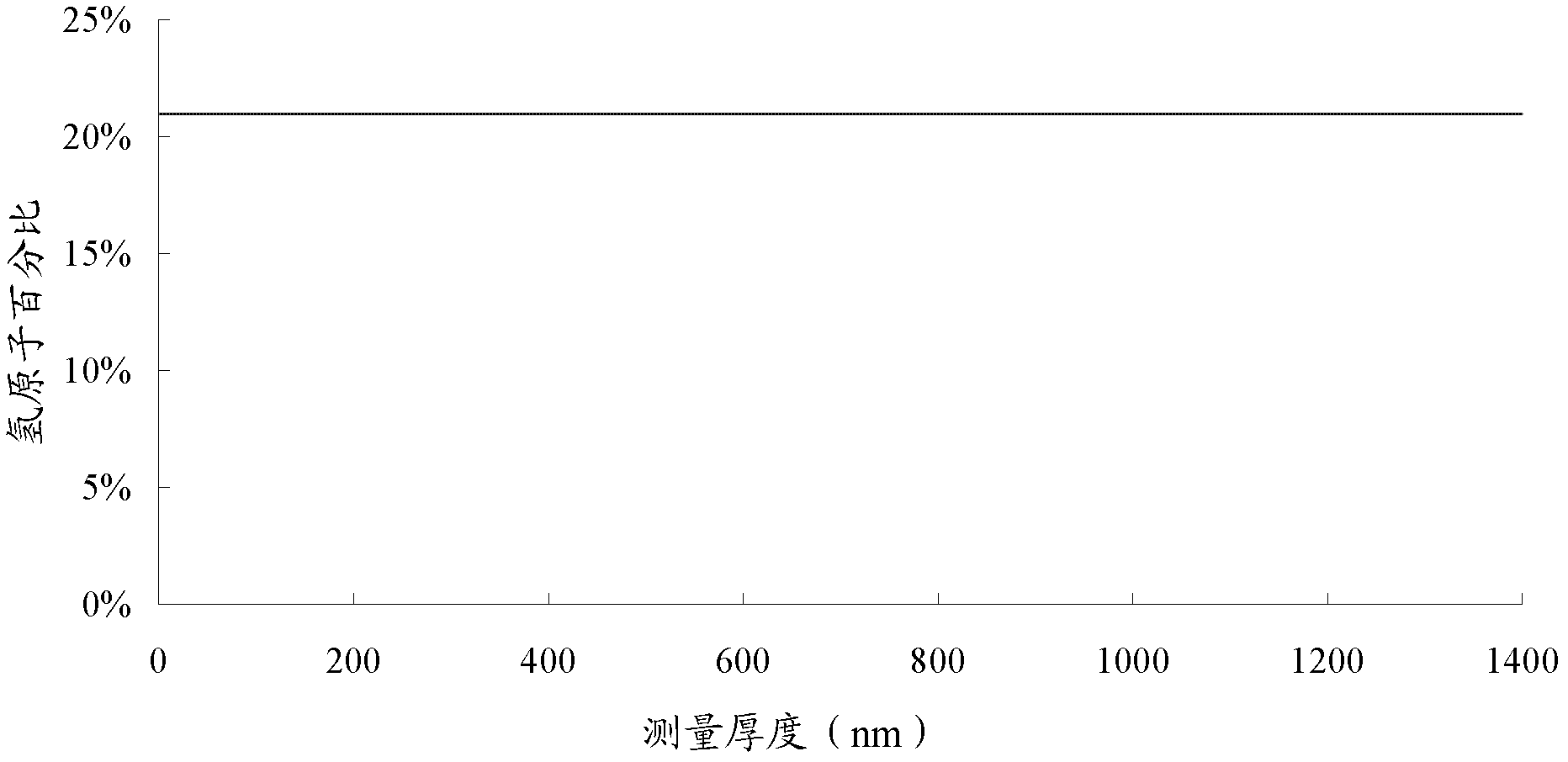

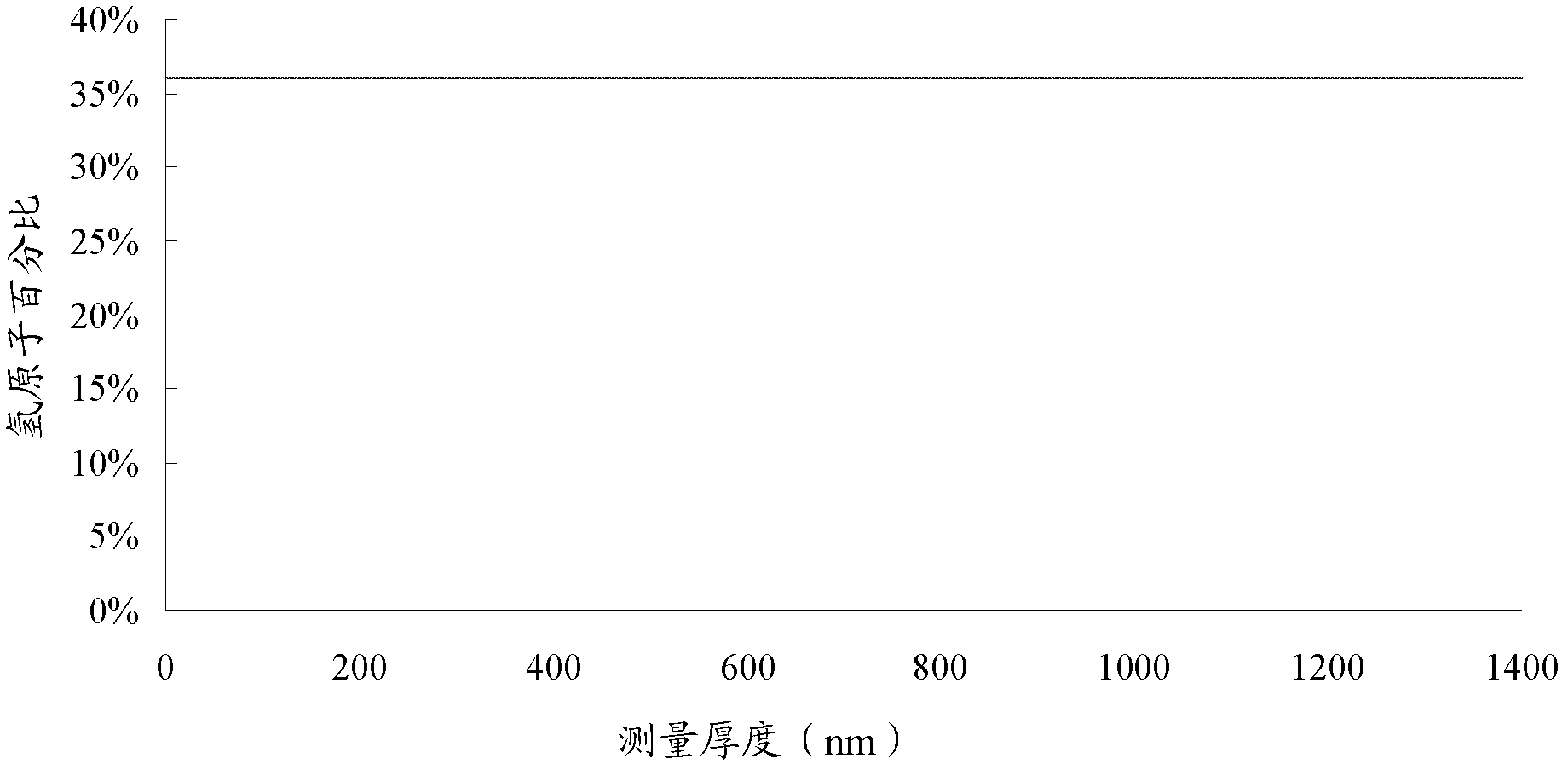

Amorphous carbon film processing method and opening forming method

ActiveCN102915953AUniform etch rateEvenly distributedSemiconductor/solid-state device manufacturingHydrogen atomHydrogen

The invention discloses an amorphous carbon film processing method and an opening forming method. The amorphous carbon film processing method comprises the following steps: a substrate is provided; an amorphous carbon film is formed on the surface of the substrate; the amorphous carbon film is subjected to annealing treatment; and the amorphous carbon film after the annealing treatment is subjected to ultraviolet light treatment. Through the treatment method of amorphous carbon film, provided by the invention, the distribution of hydrogen atoms in the amorphous carbon film is uniform, so that the etching speed of the amorphous carbon film is uniform, a flat and uniform etched surface in the etching process of different regions is favorably formed, and the performance of the semiconductor device is accordingly improved. Correspondingly, the invention also provides a method for forming an opening by etching the treated amorphous carbon film.

Owner:SEMICON MFG INT (SHANGHAI) CORP

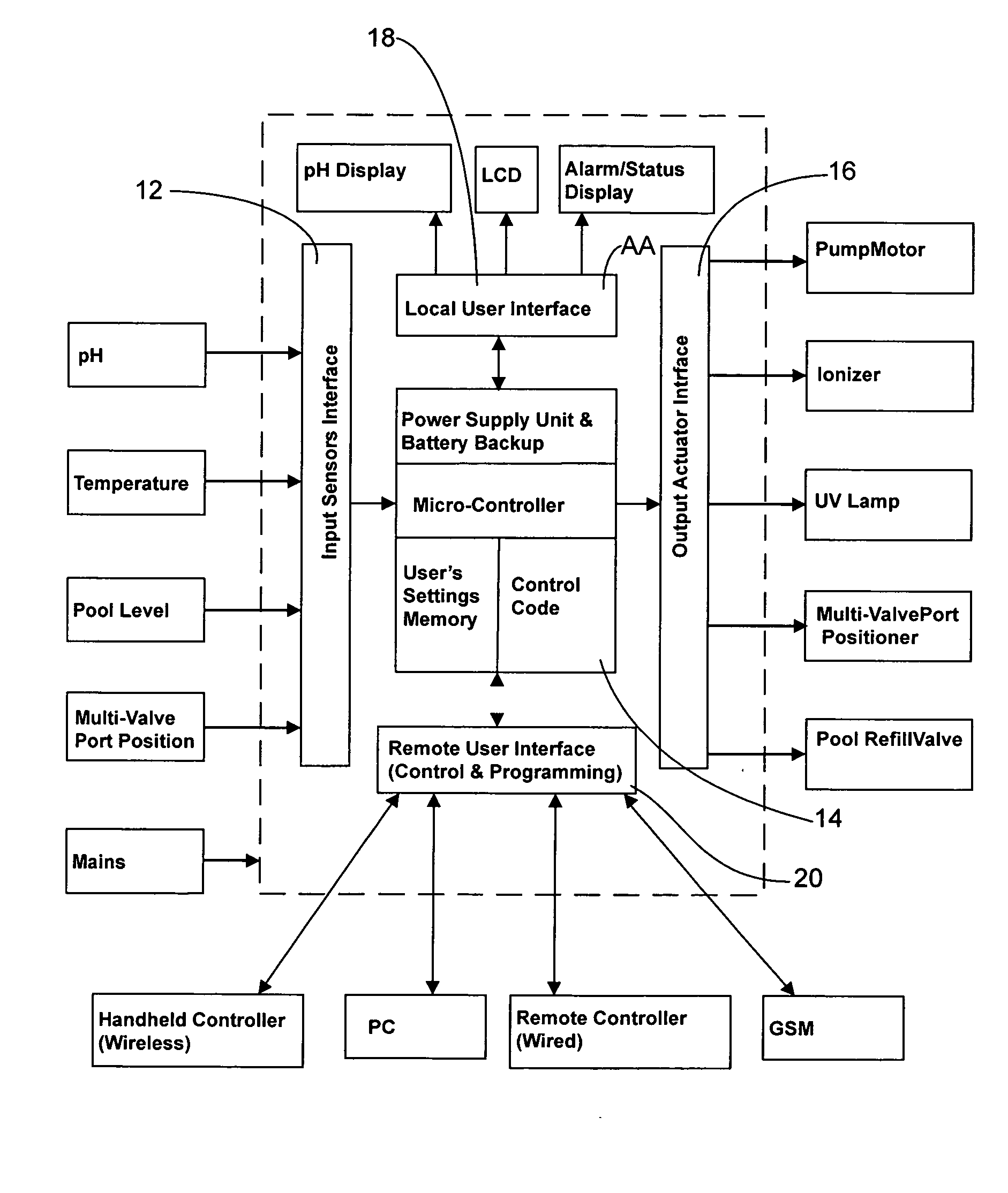

Management arrangement

InactiveUS20100096338A1Minimization requirementsIon-exchanger regenerationLoose filtering material filtersControl engineeringProcess engineering

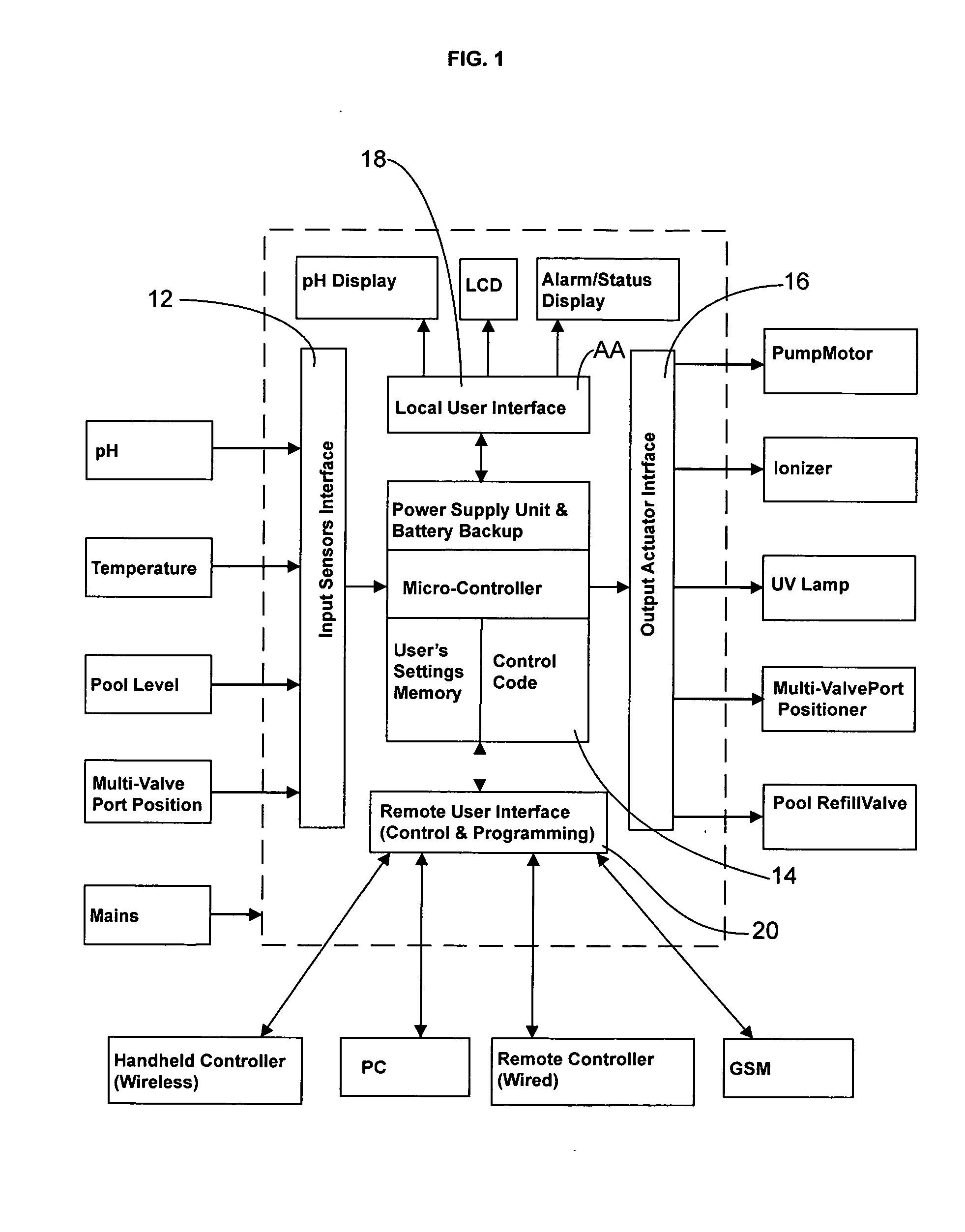

The invention discloses a management arrangement for a swimming pool. The arrangement includes a number of sensors being adapted to measure variables and generate input data relating to a swimming pool. The input data is processed by a processing unit to generate output data, which data is then used by an actuator to control equipment. Various operating parameters are programmable into the processing unit via an operator interface. The arrangement provides a combination of ultraviolet treatment and ion enrichment in order to disinfect or purify the water. The arrangement specifically regulates the ionization of the swimming pool water so as to substantially maintain a pre-determined ion concentration level with reduced operator intervention.

Owner:UVION

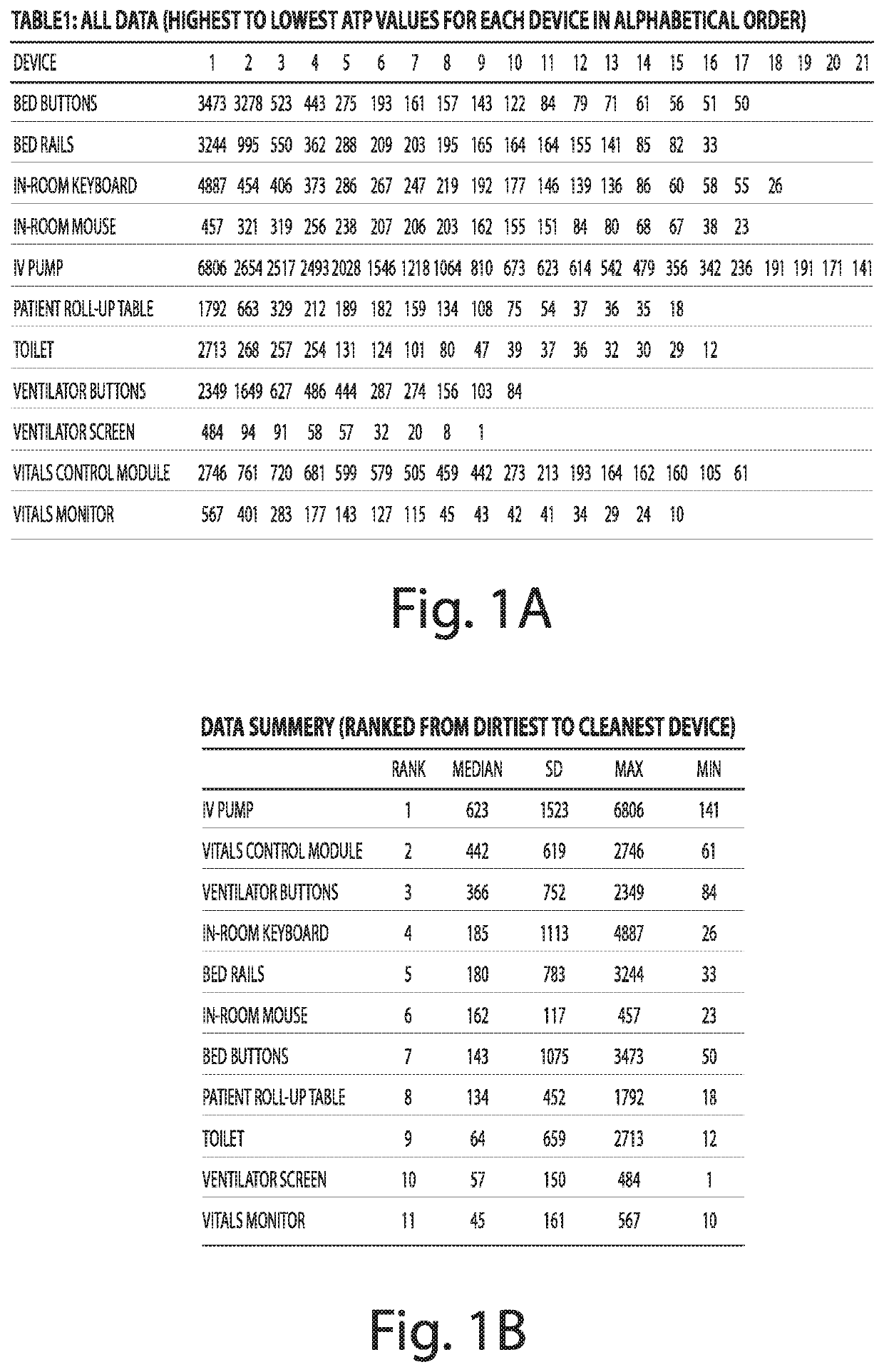

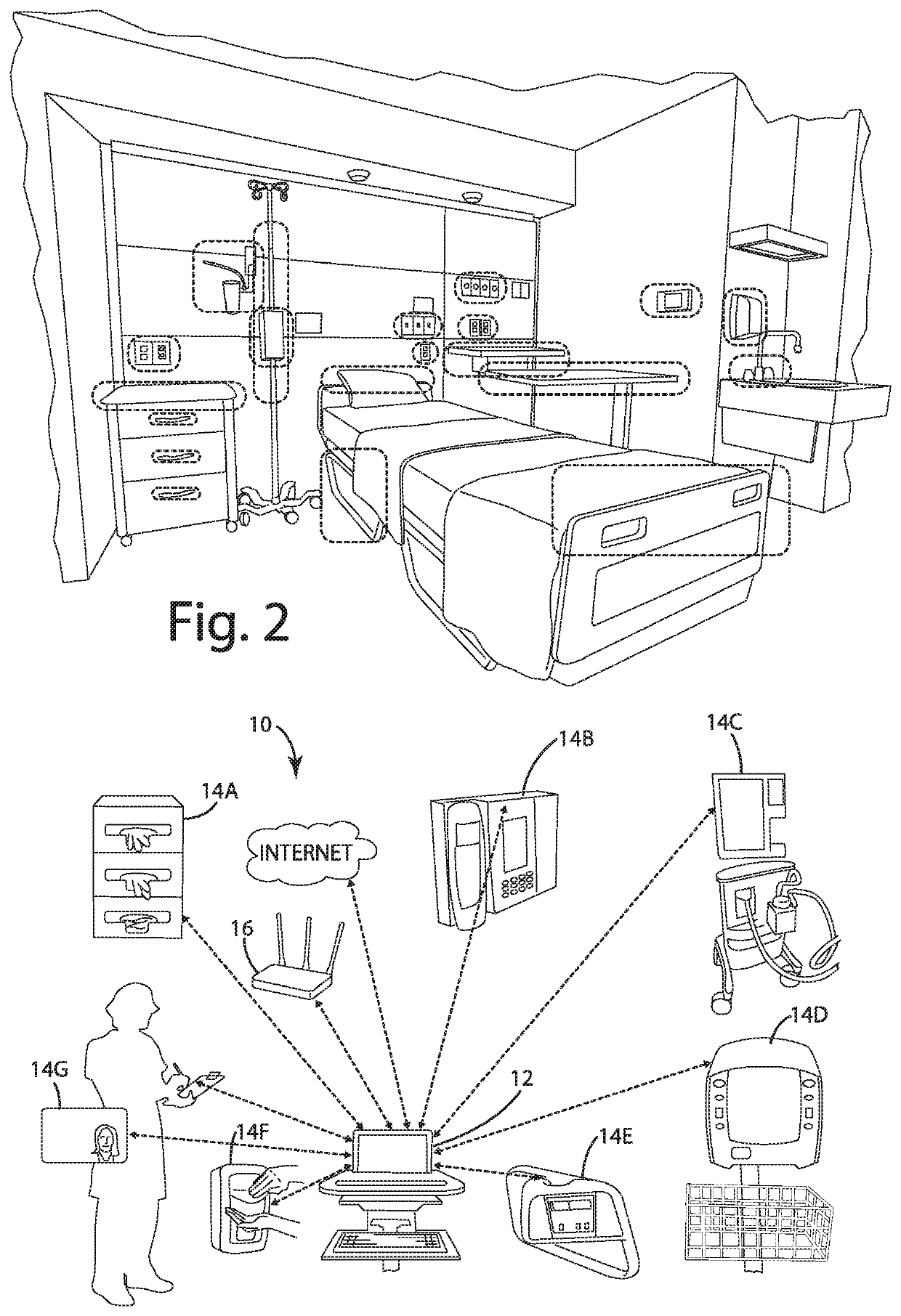

Disinfection behavior tracking and ranking

ActiveUS20210052757A1Promote resultsImprove the bactericidal effectLavatory sanitoryHealthcare resources and facilitiesCollection systemControl system

A low dose disinfection and control system that utilizes empirical and theoretical data to compare performance, sensor data, stored patterns, historical usage, use intensity indexes over time and tracking information to provide a sophisticated data collection system for disinfection. The data can be used to dynamically control UV treatment parameters. This tracking is designed to enable a learning and feedback tool that helps to modify behavior and the understanding of infection. The present invention provides a system for integrating UV treatment into products. The product may include an outer layer of UV transmissive material forming an external touch surface. The UV disinfection system includes a UV source internal to the product. In use, the internal UV source produces UV-C light that passes into and permeates the outer layer to treat the touch surface. A UV reflective layer may be disposed beneath the outer layer.

Owner:UV PARTNERS INC

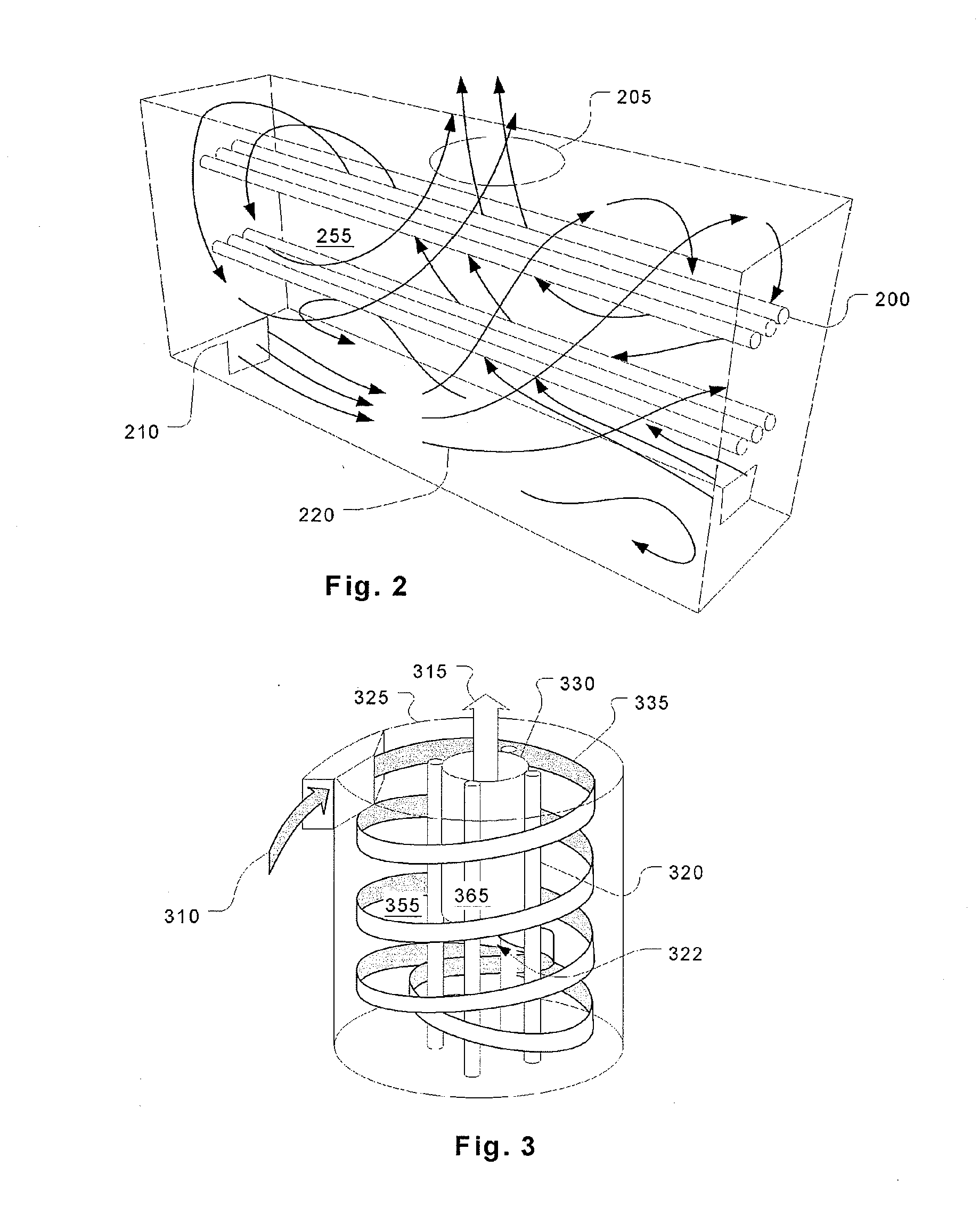

Fume treatment method and apparatus using ultraviolet light to degrade contaminants

ActiveUS20110250099A1Good effectCombination devicesDomestic stoves or rangesParticulatesUltraviolet lights

An ultraviolet treatment chamber for treating exhaust streams, particularly those containing organic particulates, utilizes ultraviolet light energy very efficiently. This is done by setting up a circulating flow in a treatment plenum so that all of the effluent experiences a substantially uniform residence time without the need for baffles or other flow controllers that would block the ultraviolet light.

Owner:HALTON GROUP LTD

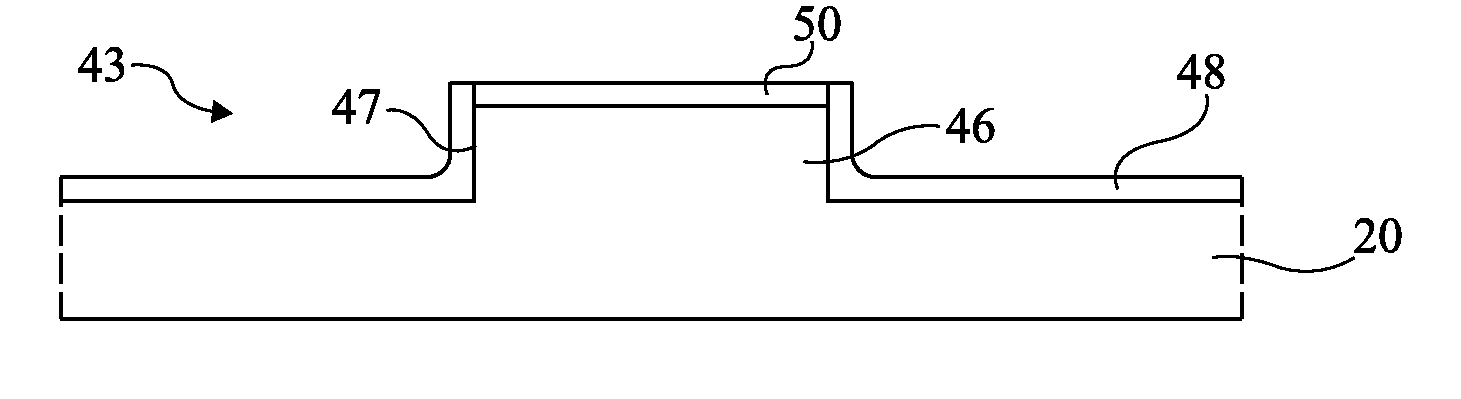

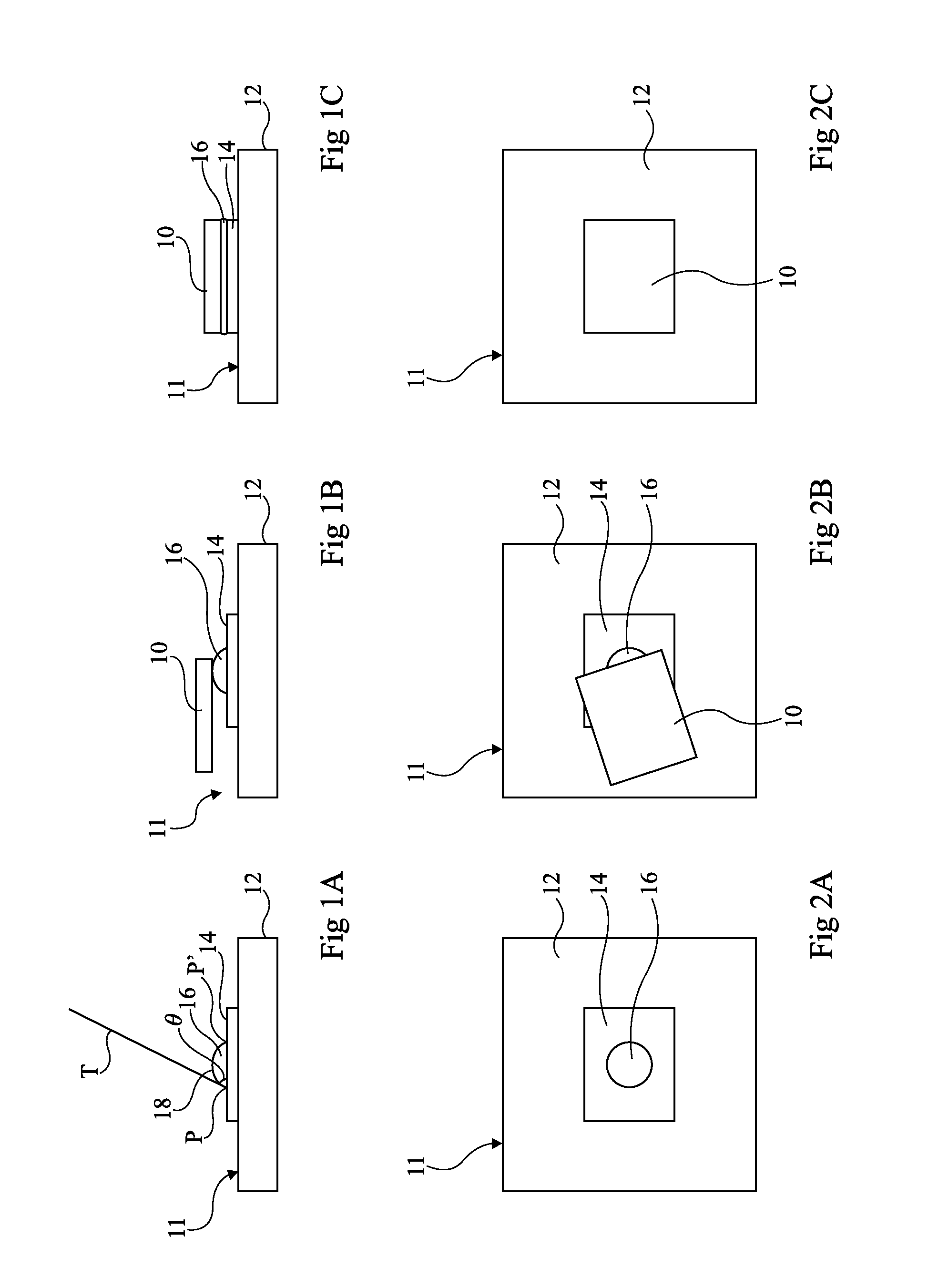

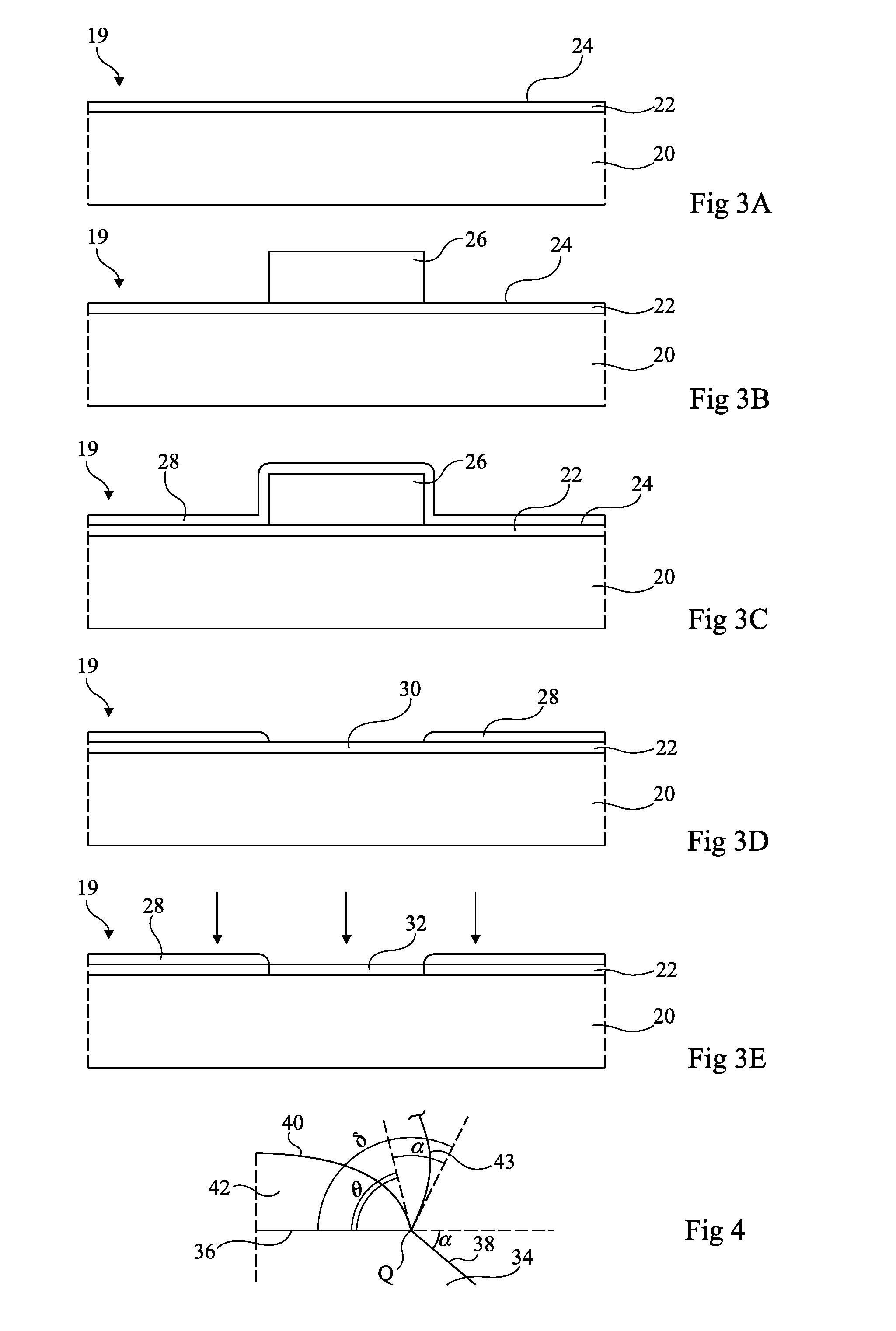

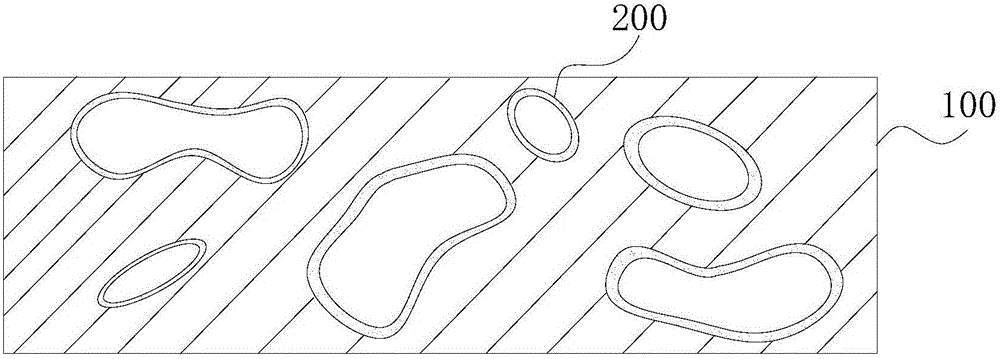

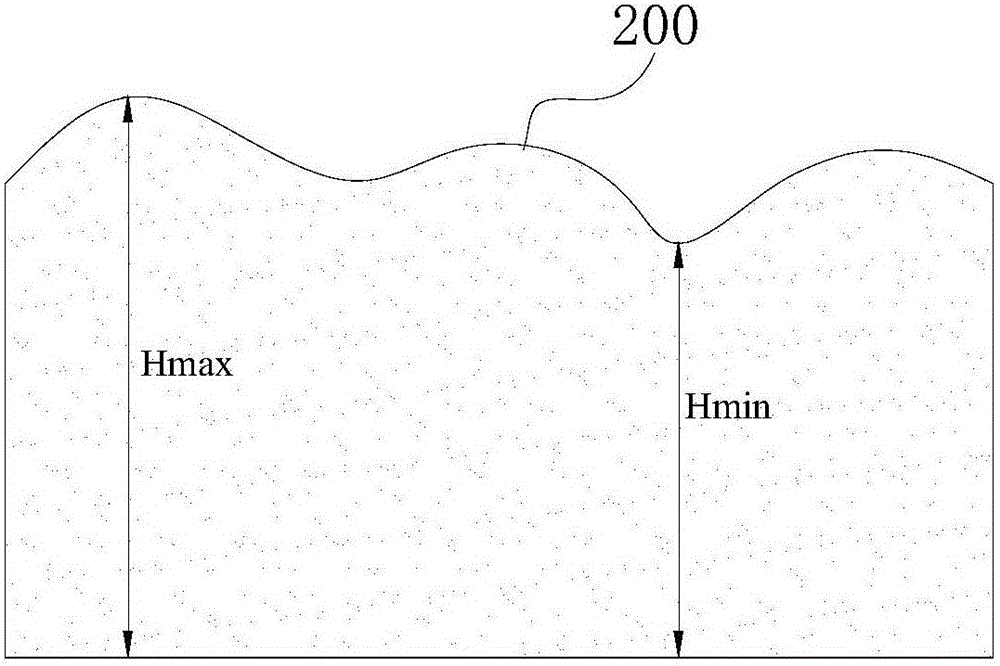

Method for producing at least one pad assembly on a support for the self-assembly of an integrated circuit chip on the support by the formation of a fluorinated material surrounding the pad and exposure of the pad and the fluorinated material to an ultraviolet treatment in the presence of ozone

ActiveUS20150287695A1Overcome disadvantagesImprove confinementDecorative surface effectsFinal product manufactureUltravioletSelf-assembly

A method for producing at least one pad assembly (32, 50) on a support (19, 43) for use in a method for self-assembling at least one element (10) on the support (19, 43), comprises fanning, on the support (19, 43), a layer (28, 48) of at least one fluorinated material around the location (30, 44) of the pad assembly (32, 50), the layer (28, 48) having a thickness greater than 10 nm. The layer (28, 48) and the location (30, 44) are exposed to an ultraviolet treatment in the presence of ozone to form the pad assembly (32, 50) at said location (30, 44), wherein a drop of liquid (16) having a static contact angle on the pad assembly (32, 50) less than or equal to 15°, after the exposure to the ultraviolet treatment, has a static contact angle on the layer (28, 48) greater than or equal to 100°.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Apparatus and method for de-inking printed surfaces

ActiveUS8980012B2Eliminate productionAid removalHollow article cleaningCleaning using toolsForeign matterHuman use

Apparatus and method for removing an ink image from a plastic substrate, particularly a plastic container such as a cup, are provided. A solvent capable of solvating the ink image is utilized in order to de-ink articles so that they can be recycled and re-imprinted thereby reducing waste associated with printing line start up. As the articles may be intended for use with food and beverage products, a safe and non-toxic solvent may be selected. However, to ensure that the article is not contaminated with foreign materials prior to human use, the de-inked article may undergo a rinse and drying operation to remove solvent residues and UV light treatment to eliminate any harmful microorganisms that may be present on the article's surfaces.

Owner:FULLER RON

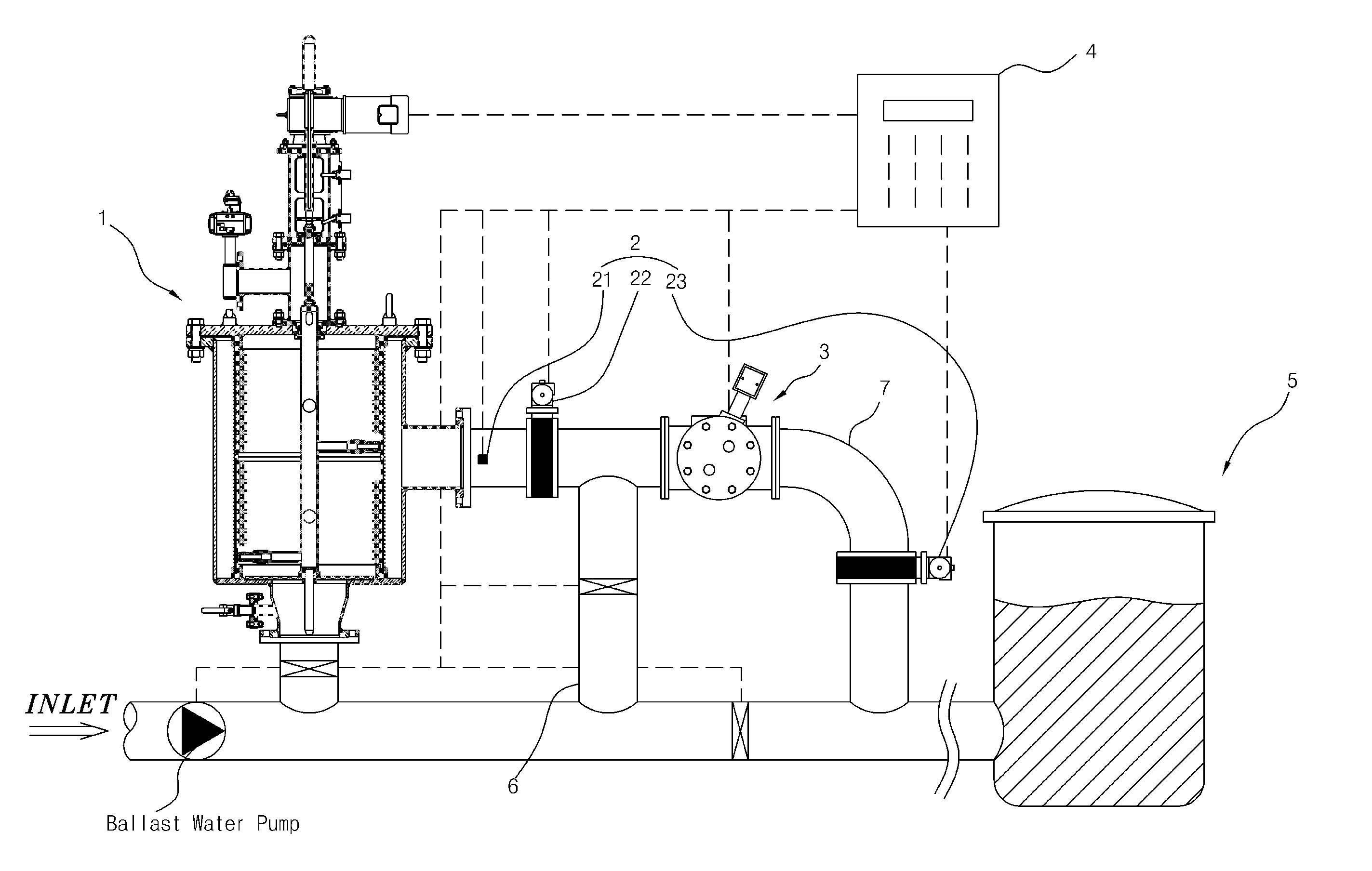

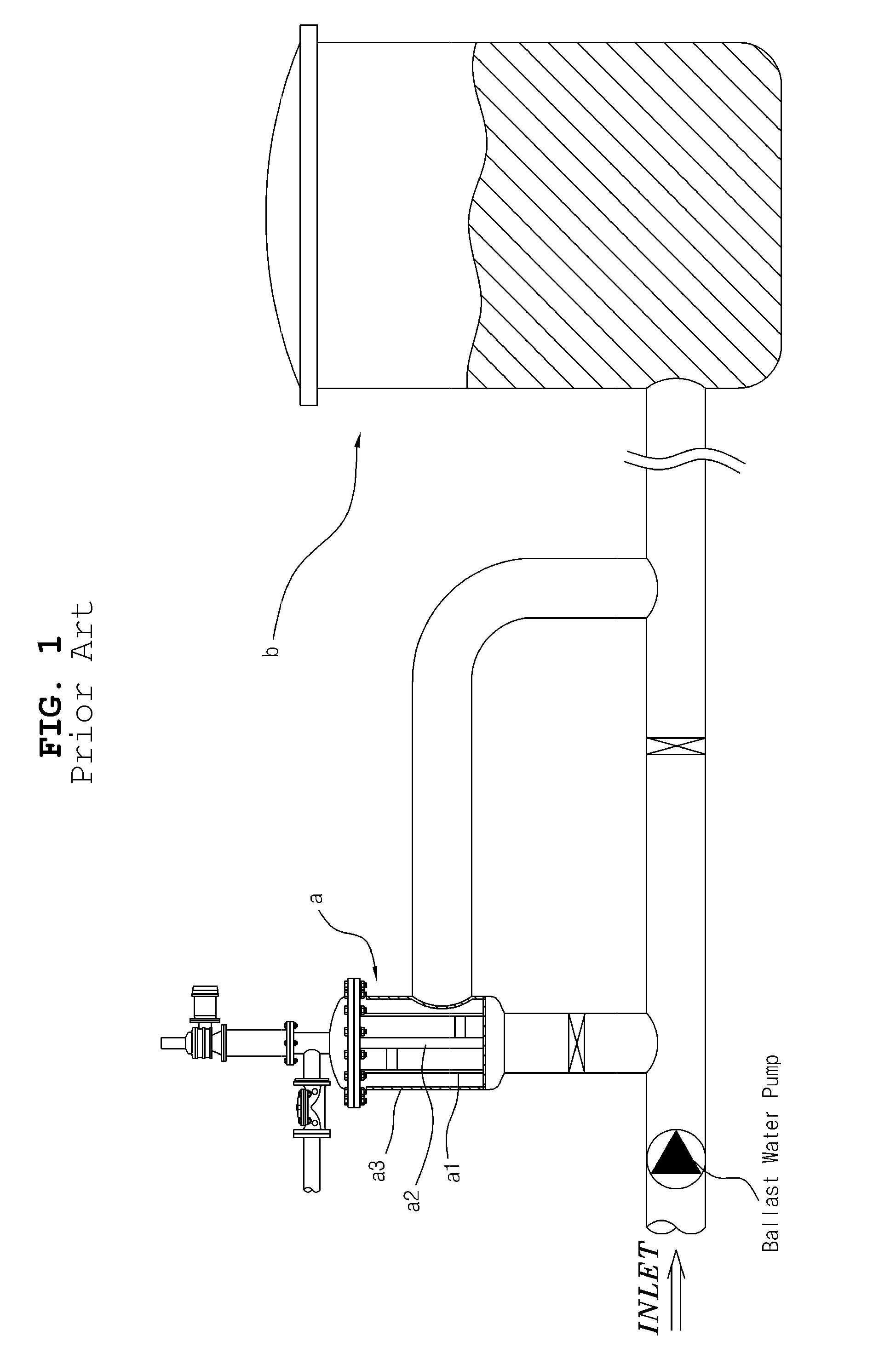

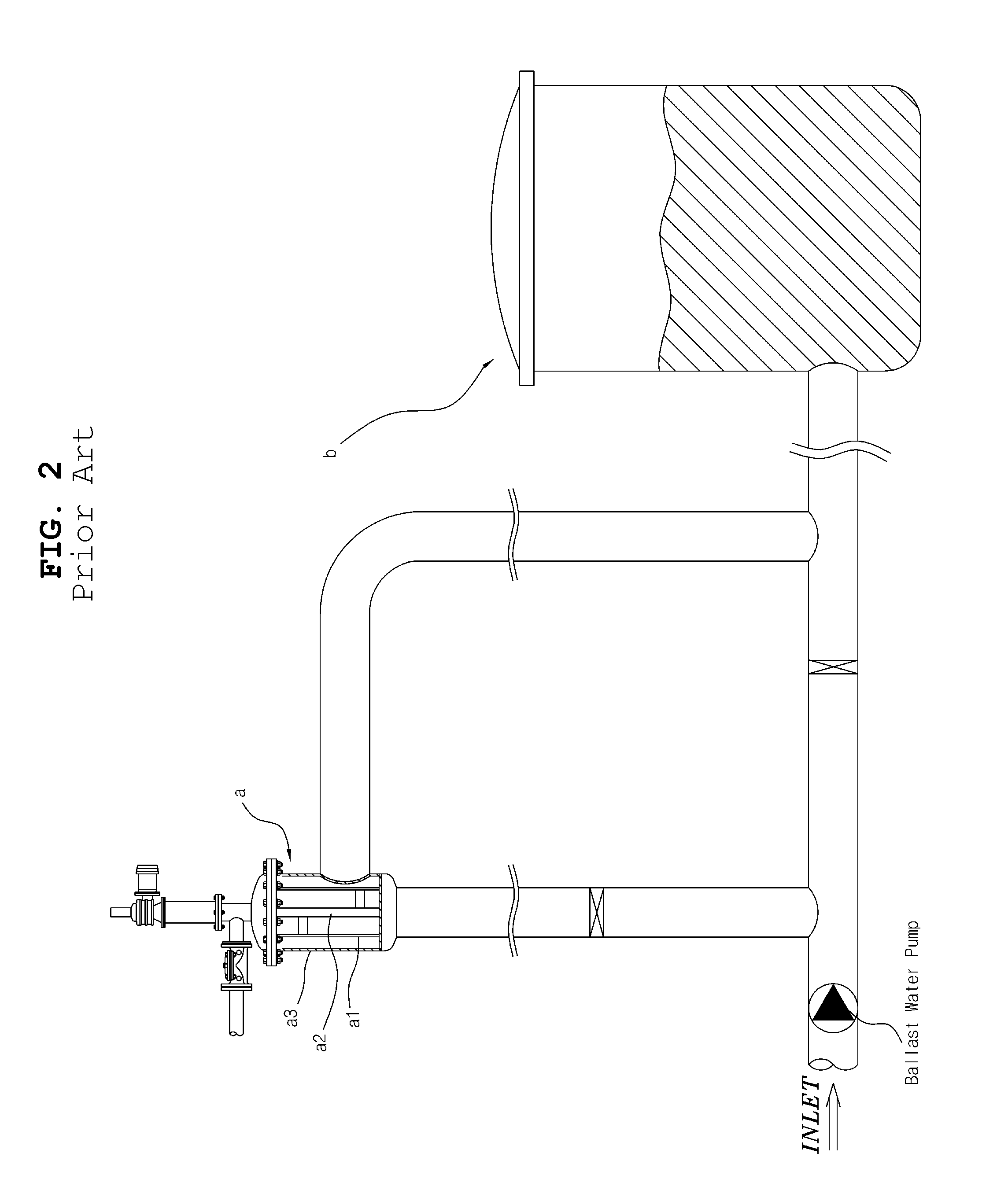

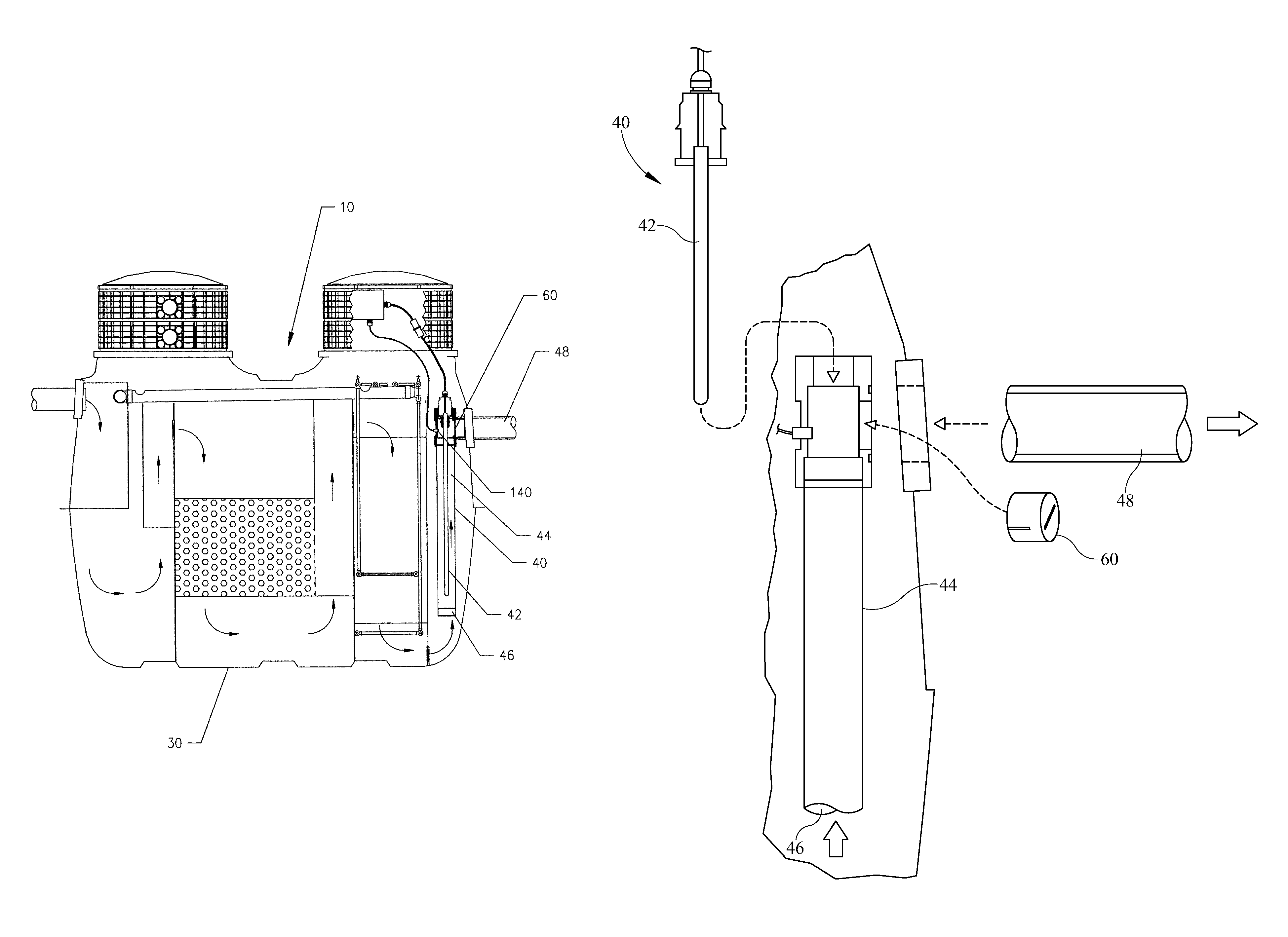

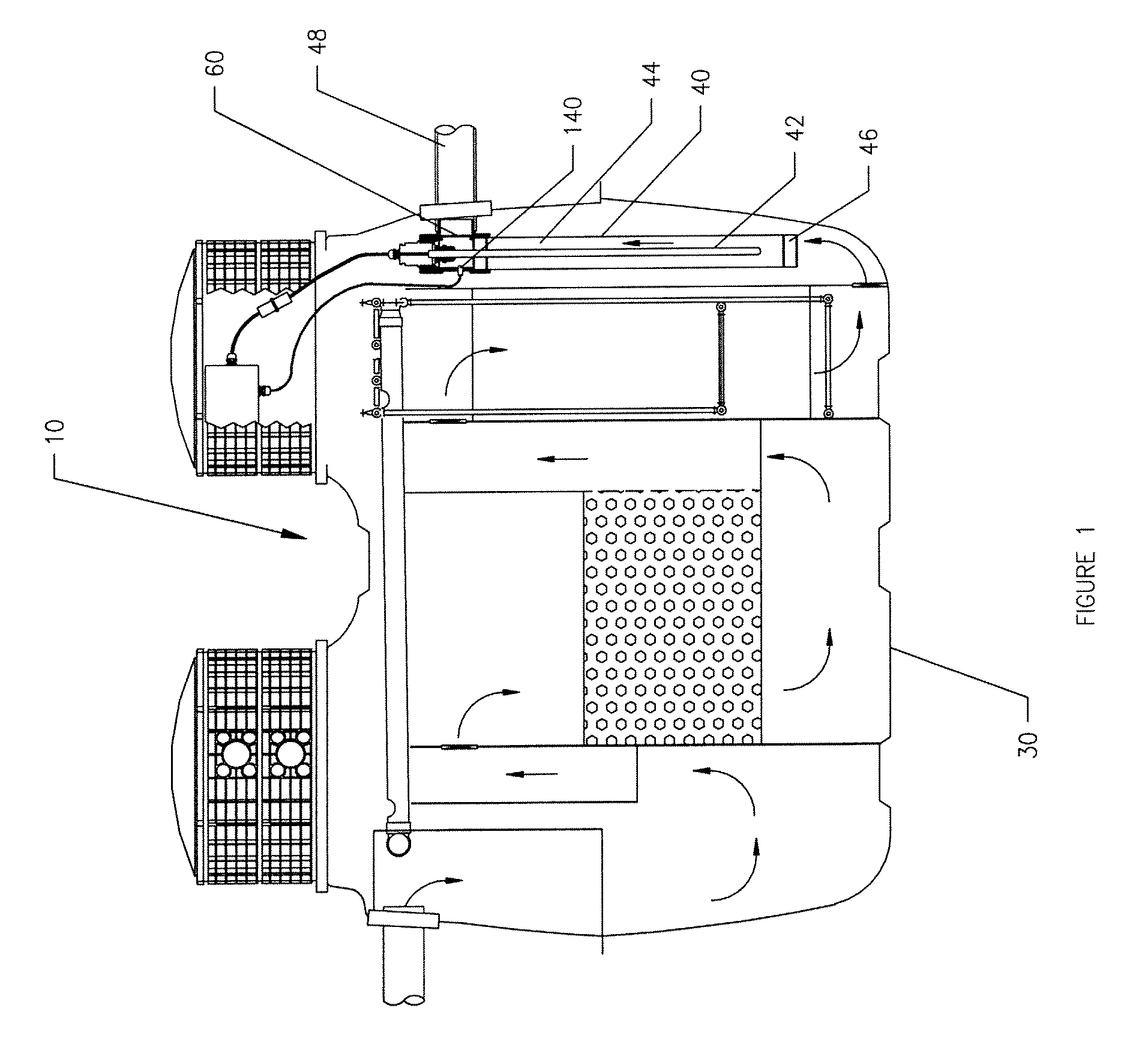

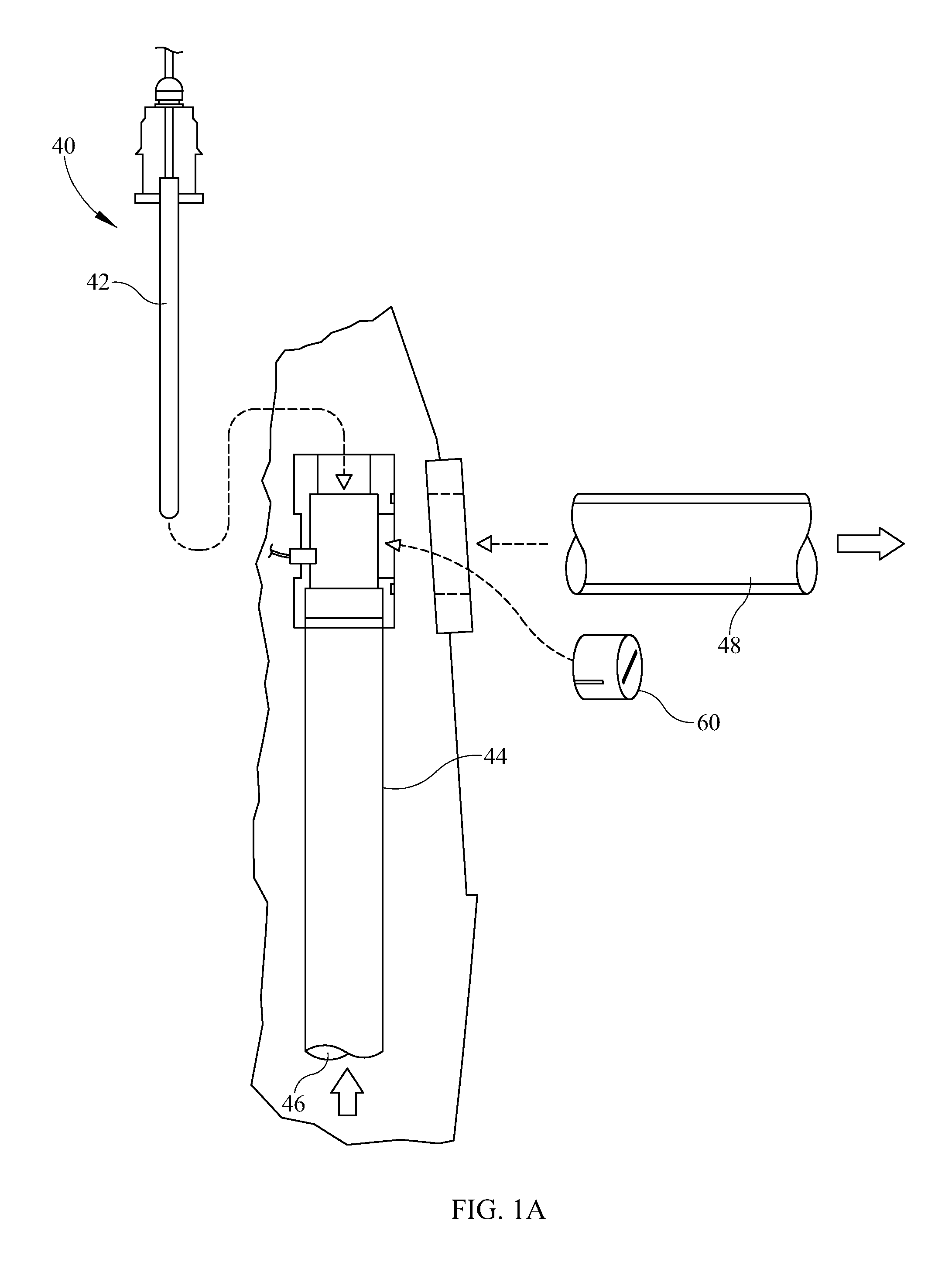

Ballast water treatment system having a back-pressure formation part and control method thereof

ActiveUS8980103B2Process stabilityGuaranteed uptimeAuxillariesSeawater treatmentWater useWater treatment system

Owner:PANASIA

UV disinfection system

InactiveUS8795600B2Treatment with aerobic and anaerobic processesDisinfectionUv disinfectionUltraviolet light treatment

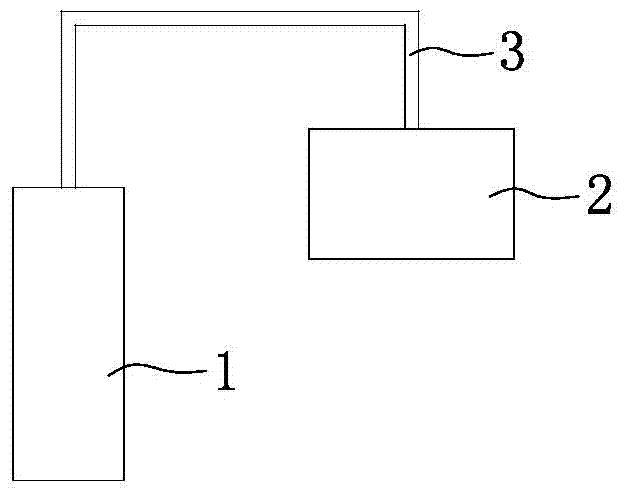

A UV Disinfection System is provided comprising a wastewater treatment device in combination with a UV treatment device. Multiple embodiments provide that the UV treatment device is contained substantially within the wastewater treatment device. Embodiments include those wherein the UV treatment device is substantially vertically oriented and extends downward from an outlet shared by the wastewater treatment device and the UV treatment device, thereby requiring all flow exiting the wastewater treatment device to pass through the UV treatment device.

Owner:ZOELLER PUMP

Device for subjecting a fluid to a disinfecting treatment by exposing the fluid to ultraviolet light

InactiveCN103025665AHigh strengthIncrease disinfection capacityWater/sewage treatment by irradiationWater/sewage treatment apparatusUltraviolet lightsLight emission

Owner:SIGNIFY HLDG BV

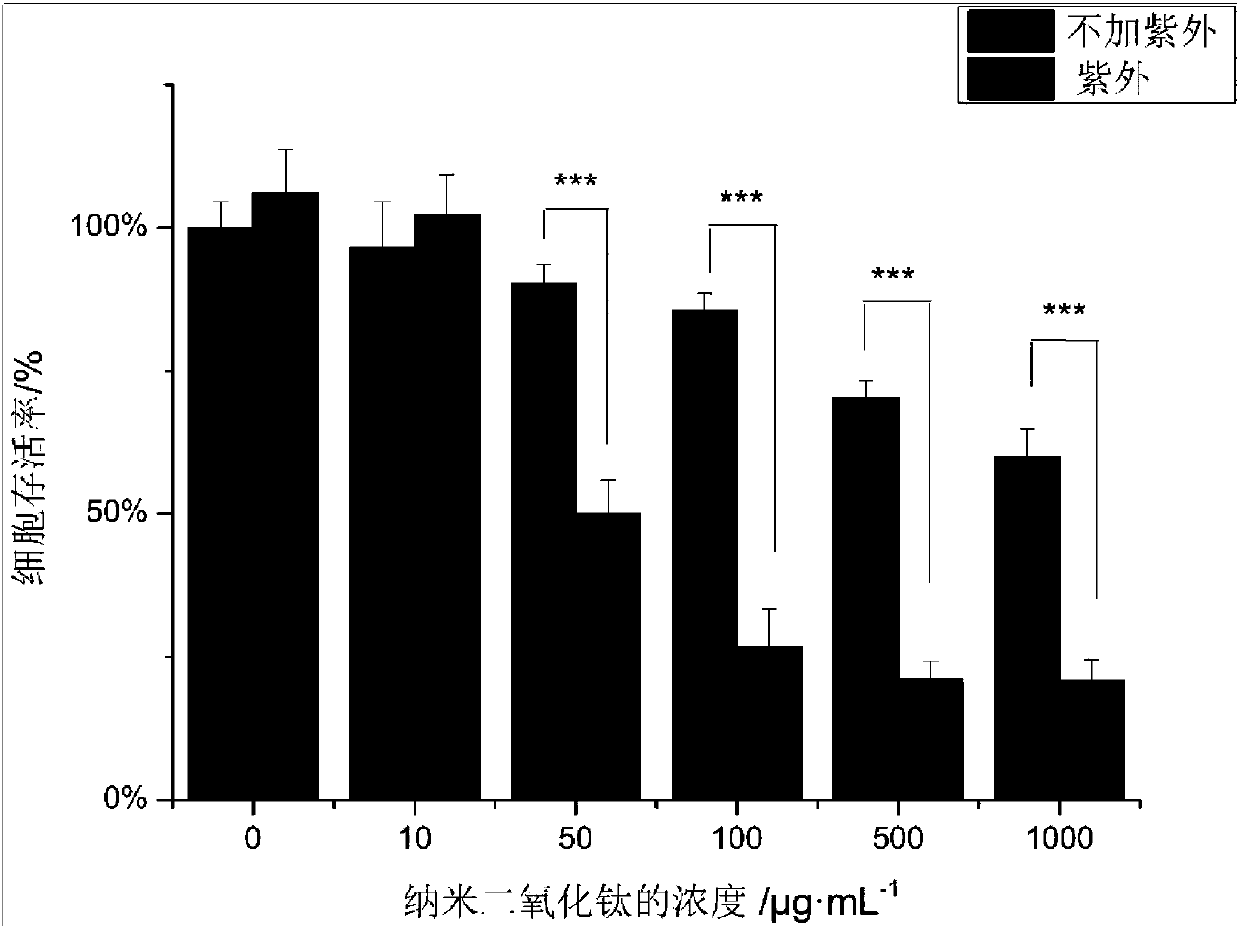

Skin safety evaluation method on nanometer titanium dioxide based on HaCaT cells

InactiveCN107746873AUnderstand deeperEffective evaluationMicrobiological testing/measurementColor/spectral properties measurementsUltravioletPhysical chemistry

The invention provides a skin safety evaluation method on nanometer titanium dioxide based on HaCaT cells, and belongs to the field of external material detection. The method comprises the following steps that the HaCaT cells are sequentially treated by nanometer titanium dioxide solutions with different concentrations and ultraviolet rays, and a cell survival rate is tested; the concentration ofthe nanometer titanium dioxide solution with the HaCaT cell survival rate reaching 50 to 90 percent is selected to be used as potential dangerous concentration; the ultraviolet ray treatment is combined, so that a sialic acid expression level in the cells and an ROS level in the cells generate constant change; finally, the influence of the potential dangerous concentration of nanometer titanium dioxide on the cell injury degree can be judged through detecting the change of the expression level of the sialic acid, so that a set of standard nanometer titanium dioxide skin safety evaluation method is obtained. The invention provides the reliable scientific basis for the safe use of the nanometer titanium dioxide and also provides reference for the safety evaluation of other nanometer materials.

Owner:HUAZHONG UNIV OF SCI & TECH

Ion implantation method for improving PMOS device performance

ActiveCN104157575AImprove performanceSemiconductor/solid-state device manufacturingPhotoresistDry etching

The invention provides an ion implantation method for improving PMOS device performance. The method comprises steps: at least one first transistor region and at least one second transistor region separated by an isolation area are formed on a silicon substrate, a first gate is formed on the first transistor region, and a second gate is formed on the second transistor region; a silicon nitride layer is deposited on the silicon substrate to enable the silicon nitride layer to fully cover the first transistor region, the second transistor region, the first gate and the second gate; a photoresist is applied to the silicon substrate to enable the photoresist to fully cover the first transistor region, the second transistor region, the first gate and the second gate; photoetching is carried out on the photoresist to remove the photoresist covering the first transistor region and the first gate; ultraviolet light treatment is carried out on the first transistor region; the photoresist in the second transistor region is removed; and dry etching is carried out on the silicon nitride layer so as to form side walls covering two sides of the first gate and side walls covering two sides of the second gate, and side walls at the top part of the gate and the source / drain end are etched and removed.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

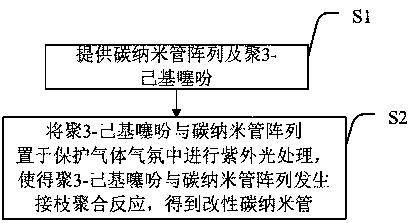

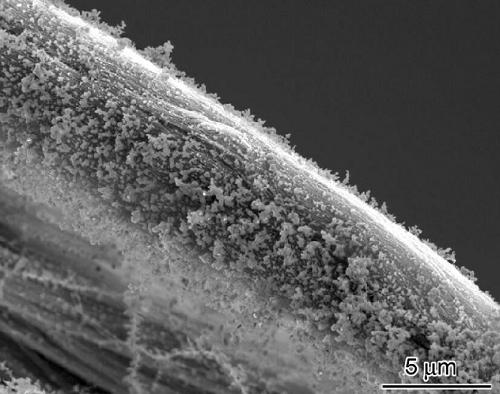

Method for modifying carbon nano tube by using poly3-hexylthiophene and modified carbon nano tube

The invention discloses a method for modifying a carbon nano tube by using poly3-hexylthiophene and a modified carbon nano tube. The method for modifying the carbon nano tube by using the poly3-hexylthiophene comprises the steps of providing a carbon nano tube array and the poly3-hexylthiophene; and placing the poly3-hexylthiophene and the carbon nano tube array in a shielded gas atmosphere to carry out ultraviolet light treatment so that the poly3-hexylthiophene can have graft polymerization with the carbon nano tube array so as to obtain the modified carbon nano tube. The method for modifying the carbon nano tube by using the poly3-hexylthiophene and the modified carbon nano tube, disclosed by the invention, have the advantages that a problem that the stability of the poly3-hexylthiophene cannot be enhanced by using the carbon nano tube because the poly3-hexylthiophene is hard to be combined with the carbon nano tube is solved.

Owner:SHENZHEN XIWAN TECH CO LTD

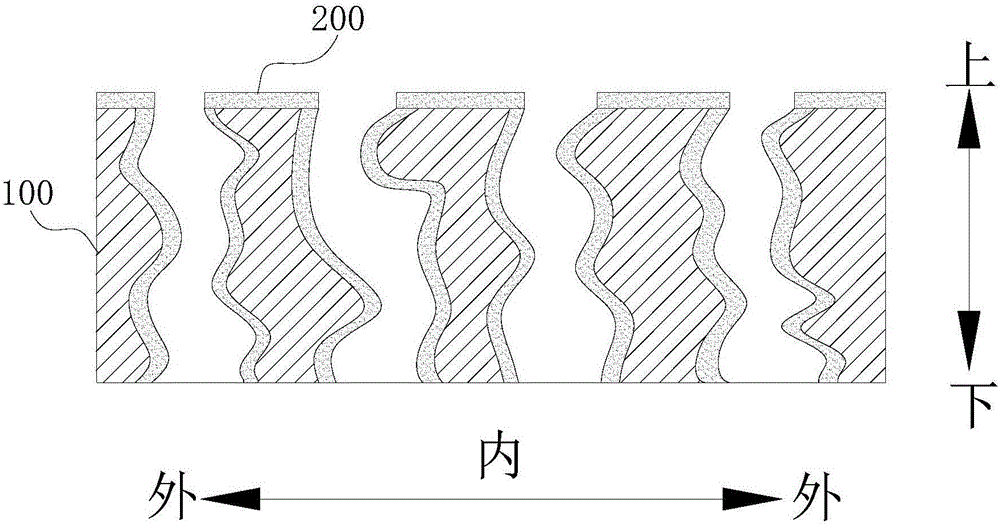

Three-dimensional fused and deposited biological film filler as well as preparation method and application thereof

ActiveCN105753138AIncrease modulusEasy to handleSustainable biological treatmentTreatment with microorganism supports/carriersNanoparticleBiological membrane

The invention discloses a three-dimensional fused and deposited biological film filler as well as a preparation method and application thereof. The method comprises the following steps: (1) adopting polypropylene to form a porous matrix through 3D printing; (2) adopting a nano particle mixture to form sustained release layers on the side wall and upper surface of the porous matrix through 3D printing so as to obtain a sustained release layer-porous matrix composite; and (3) carrying out thermal treatment and ultraviolet-light treatment on the sustained release layer-porous matrix composite in sequence to obtain the biological film filler. The biological film filler prepared by the method can provide trace nutrient substances needed for microbial growth in a sustained release manner during use, so that the biological film growing speed, growing amount and water treatment efficiency of the filler can be improved.

Owner:TSINGHUA UNIV

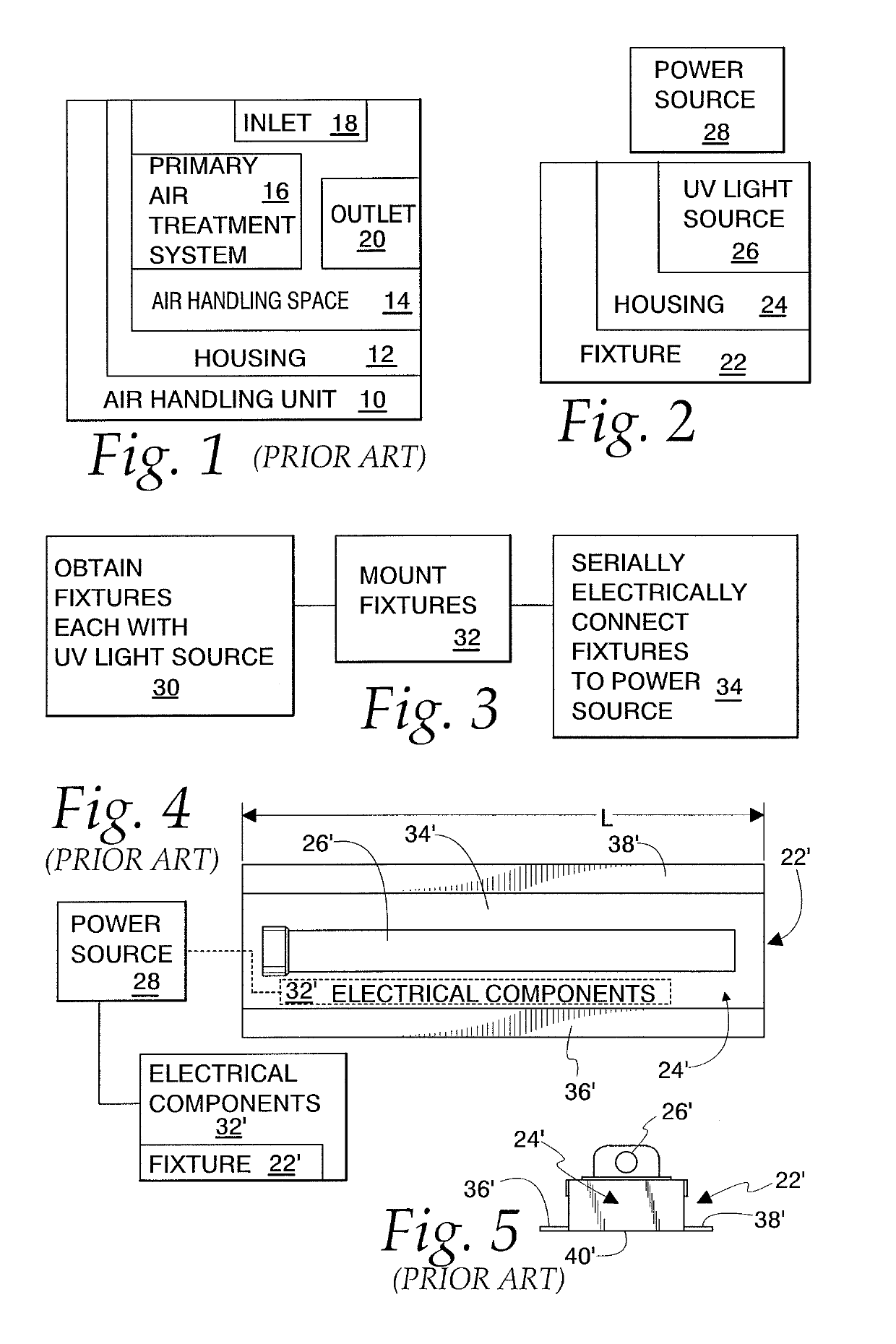

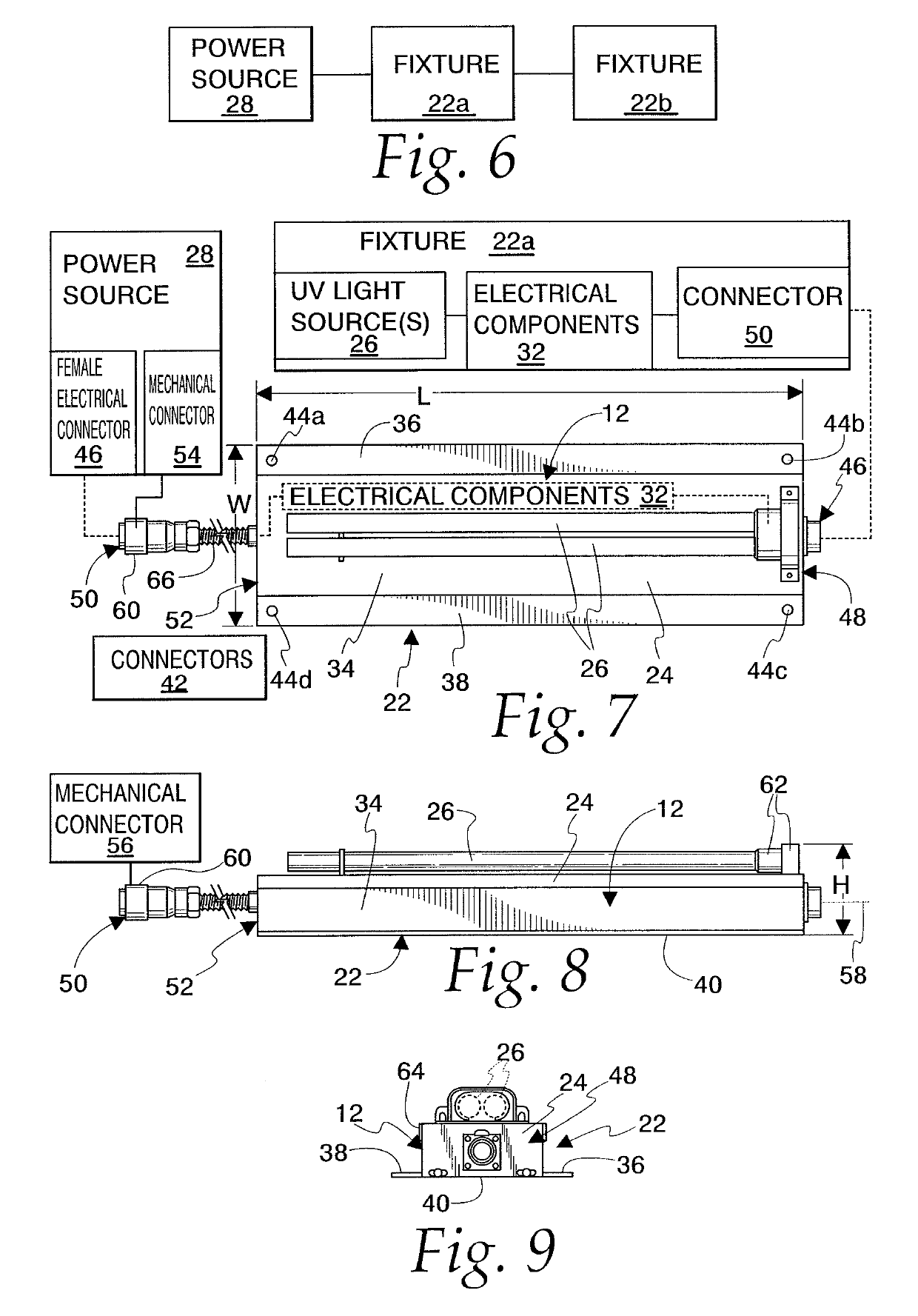

Method of treating air passing through an air handling unit

ActiveUS20190275189A1Electric circuit arrangementsLighting elementsAir treatmentEnvironmental engineering

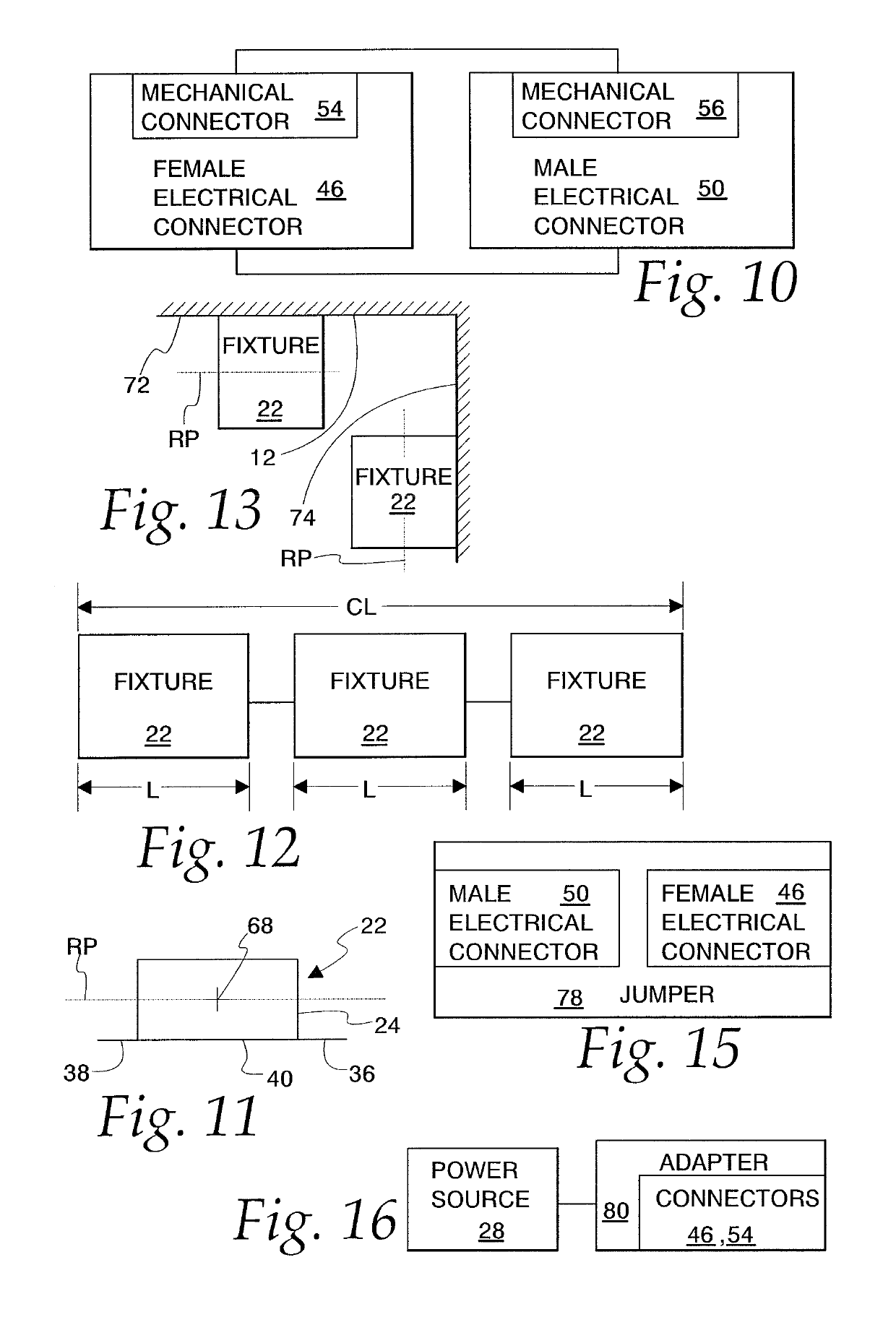

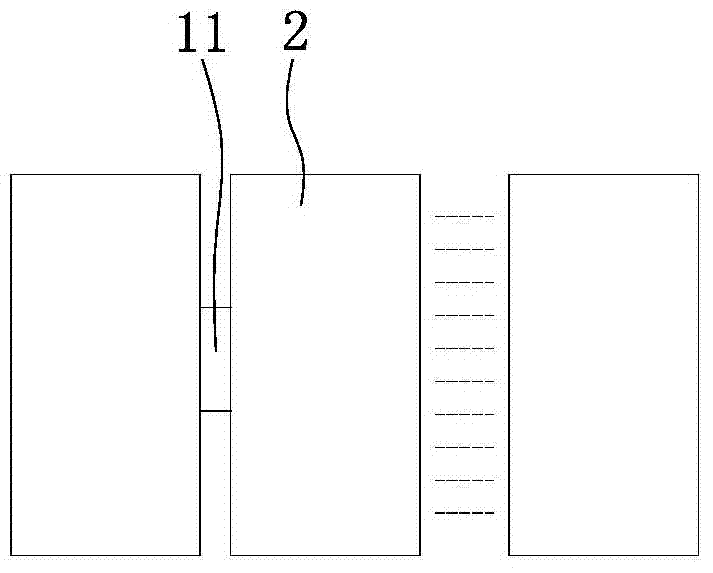

A method of treating air passing through an air handling unit having a housing extending around an air handling space and a primary air treatment system that treats air as the air passes through the air handling unit between air inlet and outlet locations on the air handling unit. First and second fixtures are obtained, each having a housing and a UV light source. The first and second fixtures are strategically mounted to the air handling unit so that UV light from each of the UV light sources on the first and second fixtures treats air moving through the air handling unit with the UV light sources on the first and second fixtures energized. The first and second fixtures are serially electrically connected to a power source to thereby cause the UV light sources on the first and second fixtures to be energized through the power source.

Owner:PETAIRAPY LLC

Ultraviolet-light treatment instrument

ActiveCN103611220ASolve problemsImprove power stabilityLight therapyEngineeringVolumetric Mass Density

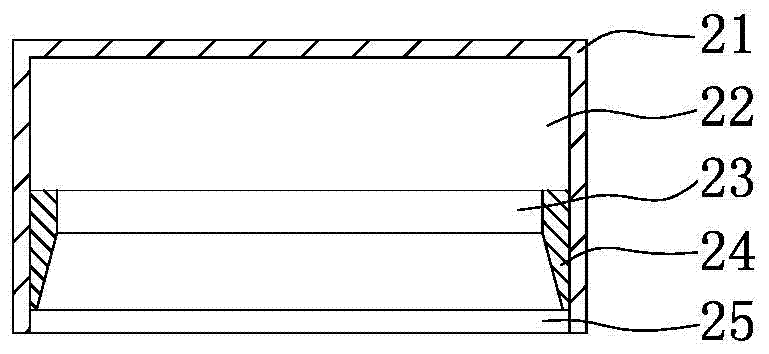

The invention discloses an ultraviolet-light treatment instrument. The ultraviolet-light treatment instrument comprises a main machine (1) and a treatment cover (2). A shell (21) of the treatment cover (2) is of a cover body structure, wherein the upper end of the cover body structure is closed and the lower end of the cover body structure is open. A protection cover (25) is installed on the opening portion of the lower end of the shell (21). A radiator (22) is installed on the upper portion of an inner cavity of the shell (21), annular reflection lenses (24) are arranged on the lower portion of the inner cavity of the shell (21), are close to one another and are fixed to the inner wall of the shell (21), and an integrated circuit board (23) is arranged in the annular reflection lenses (24) and is evenly provided with a plurality of LEDs connected sequentially in series. The novel light sources adopted in the ultraviolet-light treatment instrument have the advantages that not so many materials are consumed, the service life is long, power stability is high and the spectral region is narrow. By means of controlling the distribution density of the LED light sources, the problem that light sensitivity obviously differs because of different treatment regions is also solved, and insufficient treatments or excessive treatments are effectively avoided.

Owner:CHONGQING DEMA PHOTOELECTRIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com