Method for manufacturing high-k dielectric layer water-based indium oxide thin film transistors

A technology of thin film transistors and dielectric layers, which is applied in the manufacture of transistors, semiconductor/solid-state devices, circuits, etc., to reduce costs, avoid high-temperature impurity phases, and realize large-area industrial preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

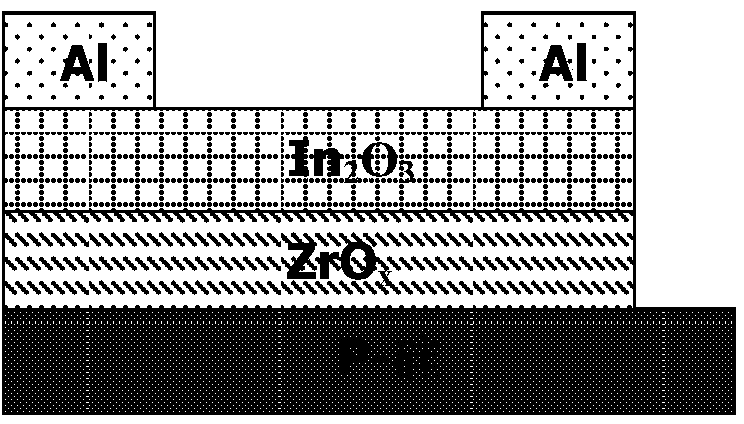

[0019] Zirconium acetylacetonate and indium nitrate powder, dimethylformamide, and ethanolamine organic solvent in this example were all purchased from Aladdin Company, and the purity was greater than 98%; the bottom gate structure was made of ultra-thin zirconia (ZrO x ) is a high-k dielectric layer and water-based indium oxide (In 2 o 3 ) thin film is the preparation process of the thin film transistor of channel layer:

[0020] (1) Ultrathin ZrO was first prepared by sol-gel technique x High-k dielectric films:

[0021] Step 1: Select commercially purchased single-sided polished low-resistance silicon as the substrate (ρ<0.0015Ω·cm) and the gate electrode, and the low-resistance silicon substrate is ultrasonically cleaned with hydrofluoric acid, acetone, and alcohol for 10 minutes each. After repeated washing with deionized water, blow dry with high-purity nitrogen;

[0022] Step 2: Prepare a mixed solution of dimethylformamide and ethanolamine at a molar ratio of 2:1, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com