Method used for preparing TiO2/Cu2O nano heterojunction by composite mask method

A composite mask and heterojunction technology, which is applied in the field of TiO2/Cu2O nano-heterojunction prepared by the composite mask method, can solve the problems of complicated process, uneven distribution and agglomeration, difficult control, etc., and achieve excellent photoelectric performance and smooth surface , size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] ①、TiO2 2 Fabrication of Nanotube Array Thin Films

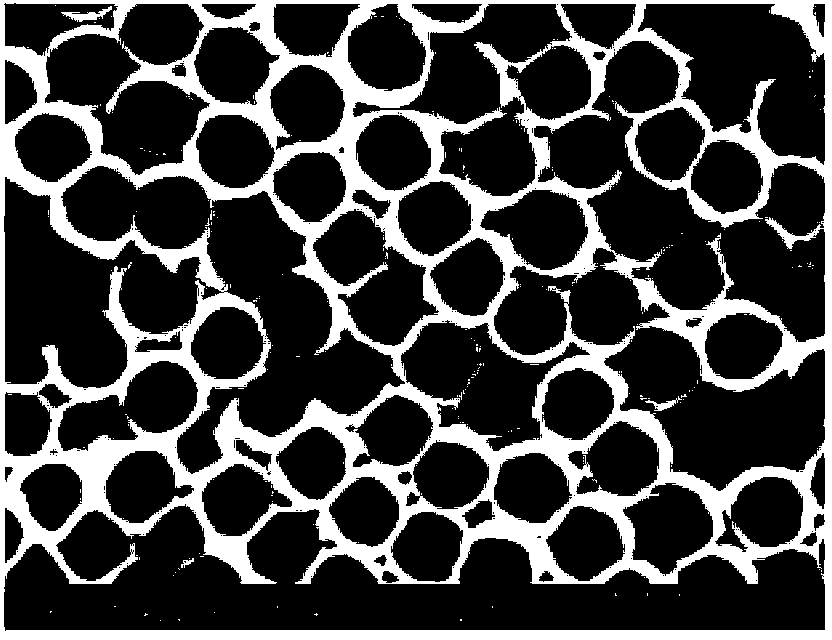

[0034] 0.5g NH 4 Dissolve F in 1mL water, stir well and add it into 49mL ethylene glycol and mix evenly to prepare bath A. Add the bath solution A into the electrolytic cell, use the cleaned titanium sheet as the anode, and the graphite electrode as the cathode, use a constant current stabilized power supply to apply a voltage of 20V to anodize for 0.5h, and then apply a voltage of 60V to anodize for 6h. Take it out and anneal it in a tube furnace at 500°C for 2h. Prepared TiO 2 nanotube array films, see figure 2 and 3 , it can be seen that the tube diameter is 100-150nm, the tube length is 4-80um, and the surface is smooth and highly ordered.

[0035] ②、TiO2 2 Fabrication of Nanotube Array Thin Film Mask

[0036] Dissolve 0.5ml of phenyltriethoxysilane into 48ml of methanol solution, slowly add 1.5ml of deionized water dropwise under slow stirring conditions, and continue stirring for 1h to prepare a phenyltr...

Embodiment 2

[0040] ①、TiO2 2 Fabrication of Nanotube Array Thin Films

[0041] 0.5g NH 4 Dissolve F in 1mL water, stir well and add it into 49mL ethylene glycol and mix evenly to prepare bath A. Add the bath solution A into the electrolytic cell, use the cleaned titanium sheet as the anode, and the graphite electrode as the cathode, use a constant current stabilized power supply to apply a voltage of 25V to anodize for 0.5h, and then apply a voltage of 70V to anodize for 5h. Take it out and anneal it in a tube furnace at 500°C for 2h.

[0042] ②、TiO2 2 Fabrication of Nanotube Array Thin Film Mask

[0043] Dissolve 0.5ml of phenyltriethoxysilane into 48ml of methanol solution, slowly add 1.5ml of deionized water dropwise under slow stirring conditions, and continue stirring for 2h to prepare a phenyltriethoxysilane-methanol composite solution. TiO prepared in step ① 2 The nanotube array thin film was put into the composite solution of phenyltriethoxysilane and methanol, and stirred sl...

Embodiment 3

[0047] ①、TiO2 2 Fabrication of Nanotube Array Thin Films

[0048] 0.6g NH 4 Dissolve F in 1mL water, stir well and add it into 49mL ethylene glycol and mix evenly to prepare bath A. Add the bath solution A into the electrolytic cell, use the cleaned titanium sheet as the anode, and the graphite electrode as the cathode, use a constant-current stabilized power supply to apply a voltage of 30V for anodization for 1h, and then apply a voltage of 80V for anodization for 4h. Take it out and anneal it in a tube furnace at 500°C for 2h.

[0049] ②、TiO2 2 Fabrication of Nanotube Array Thin Film Mask

[0050] Dissolve 0.5ml of phenyltriethoxysilane into 48ml of methanol solution, slowly add 1.5ml of deionized water dropwise under slow stirring conditions, and continue stirring for 2h to prepare a phenyltriethoxysilane-methanol composite solution. TiO prepared in step ① 2 The nanotube array thin film was put into the composite solution of phenyltriethoxysilane and methanol, and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com