Three-dimensional fused and deposited biological film filler as well as preparation method and application thereof

A biofilm and mixture technology, applied in the field of materials, can solve the problems of difficulty in timely replenishment and real-time control of micronutrient elements, and achieve the effect of improving water treatment effect, easy to hang film, and difficult to block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] In one aspect of the present invention, the present invention provides a method for preparing a biofilm filler. According to an embodiment of the present invention, the biofilm filler prepared by the method has the function of sustained release of metal elements, and the preparation method has simple process, readily available materials, low cost and short cycle. Specifically, the method includes:

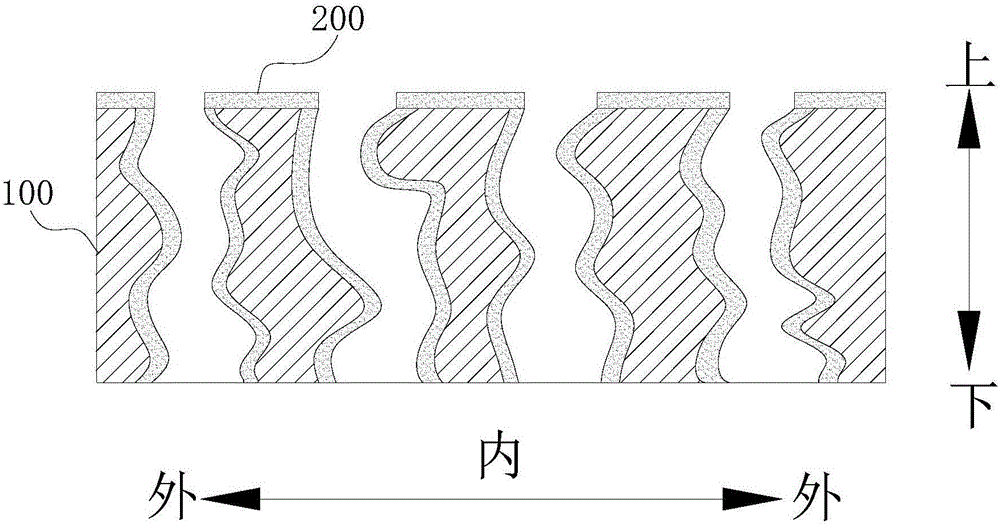

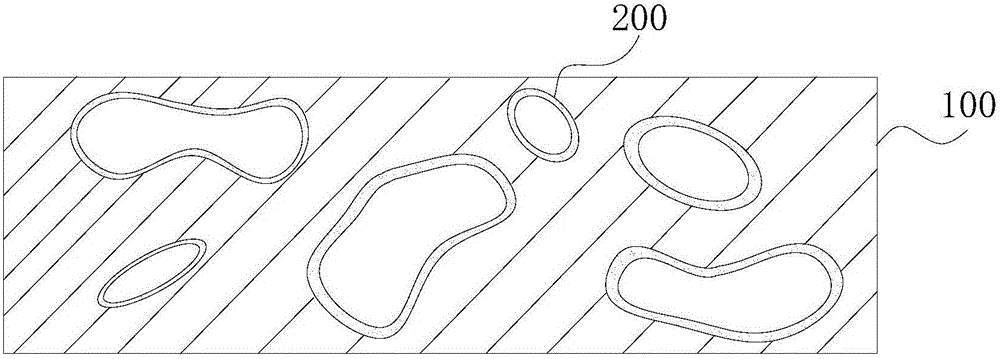

[0027] S100: forming a porous matrix

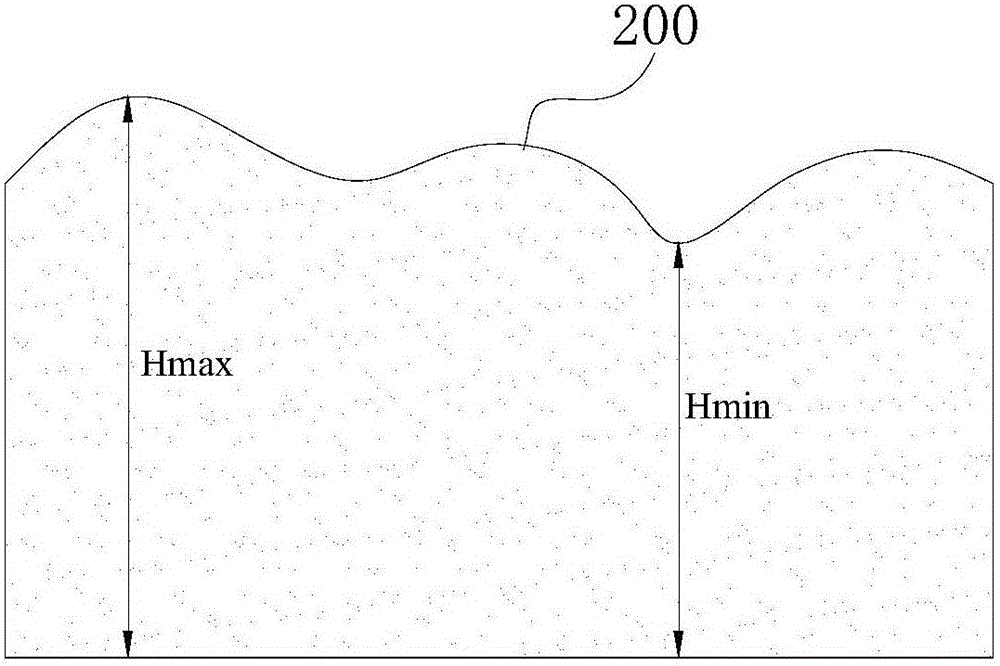

[0028]According to an embodiment of the present invention, in this step, polypropylene is used to form a porous matrix by 3D printing. Specifically, in this step, by setting the relevant parameters in the 3D printing step, for example, by designing parameters such as the thickness, shape, and printing accuracy of the porous matrix according to the CAD digital model software, it is possible to use polypropylene to form a matrix with a porous structure. . The specific surface area of the porous matrix is 260-300m 2 / m 3 . When t...

Embodiment 1

[0056] The FANTASYPro dual-nozzle three-dimensional fusion rapid prototyping (3D printing) machine (EcubMaker) was used for the preparation of biological fillers. First, according to the CAD digital model software, it is designed into a shape of multi-vacant columnar packing, and the temperature is set at 210 degrees Celsius. Polypropylene is fused deposited through a spray head to form a porous matrix.

[0057] Then, according to the designed 2mm slow-release layer thickness, use another nozzle in the FANTASYPro molding machine to deposit the nanoparticle mixture slow-release layer on the inner side and upper surface of the porous matrix. The temperature is set at 220 degrees Celsius, and the nanoparticle mixture includes polypropylene, polyethylene glycol, maleic anhydride, antioxidant 1010, polylactic acid and zinc oxide nanoparticles, and the mass ratio is 74.41:3.68:1.16:18.4:2.32:0.97. The obtained packing density is 0.92g / cm 3 .

[0058] Then heat-treat the biologica...

Embodiment 2

[0060] The biofilm filler prepared in Example 1 was used for wastewater treatment. The target wastewater to be treated is printing and dyeing wastewater of knitted fabrics, in which the pH value of the wastewater is 10, the chroma is 250 times, the BOD value is 220mg / L, the COD value is 800mg / L, and the suspended matter is 200mg / L. The activated sludge is taken from a sewage treatment plant, and it is cultivated and domesticated so that it can stably treat printing and dyeing wastewater. The activated sludge system is added to the ordinary biofilm filler and the new type of trace metal element slow-release suspended biofilm filler respectively. In the waste water, the MLSS in the waste water is 4000mg / L, the sludge load is 0.2kgCOD / kgMLSS·d, the filling rate of the filler is 40%, and the uninterrupted air compressor is used for aeration operation, accompanied by stirring, and the dissolved oxygen is maintained at 2.8g / L about. After three days of continuous treatment, the COD...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com