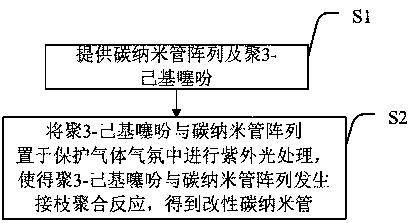

Method for modifying carbon nano tube by using poly3-hexylthiophene and modified carbon nano tube

A technology of hexylthiophene and carbon nanotubes, applied in the field of carbon nanotubes, can solve the problems of difficult bonding and inability of carbon nanotubes to enhance the stability of poly-3-hexylthiophene, and achieve the effect of reducing difficulty and enhancing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 3-Dodecylthiophene (19.34 g, 77.70 mmol) was dissolved in 100 mL of THF, after which N-bromosuccinimide (27.92 g, 161 mmol) was slowly added to the above solution over 5 minutes to give 2 , 5-dibromo-3-dodecylthiophene solution, the solution was stirred at room temperature for 2 hours, and the THF solvent was removed by distillation under reduced pressure once; then 250 mL of hexane was added to precipitate all the succinimide, Then, the hexane solvent was removed by distillation under reduced pressure twice; then, Kugelrohr distillation was used to distill at 120°C and 0.016T to obtain 2,5-dibromo-3-dodecylthiophene as a colorless transparent oil ;

[0039] Dissolve the above 2,5-dibromo-3-dodecylthiophene (1.23 g, 3.08 mmol) in 18 mL of THF, then add 3.05 mL of CH dissolved in butyl ether 3 MgBr, reflux at 120~150°C for 1 hour, add catalyst Ni(dppp)Cl 2 (16.5mg, 1mol%), reflux and stir for 2 hours to carry out catalytic reaction; after the reaction, inject the mixed s...

Embodiment 2

[0041] (1) Preparation of carbon nanotube powder: Deposit a catalyst layer on the substrate, place it in a chemical vapor deposition reactor and pass through a protective gas, raise the temperature to 650°C, and then pass in a carbon source gas, the flow rate is controlled at 2L / min, and the reaction is 25min , thereby generating carbon nanotube arrays on the substrate. Among them, the carbon nanotube array is a multi-walled nanotube array, the average length of the number is 760 μm, and the diameter of the carbon nanotube is 10-15 nm;

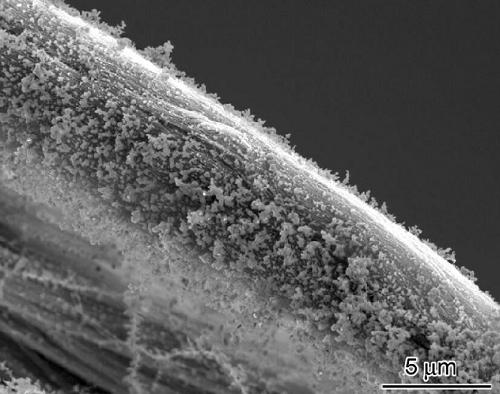

[0042] (2) Preparation of multi-walled carbon nanotube-poly(3-hexylthiophene) nano-compounds (i.e. modified carbon nanotubes): prepare the prepared carbon nanotube array together with the substrate; prepare another substrate, and prepare The film-like poly(3-hexylthiophene) was placed on the substrate, keeping the thickness of the film within the range of 1-3mm; two substrates were placed parallel and side by side under a high-energy ultraviol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com