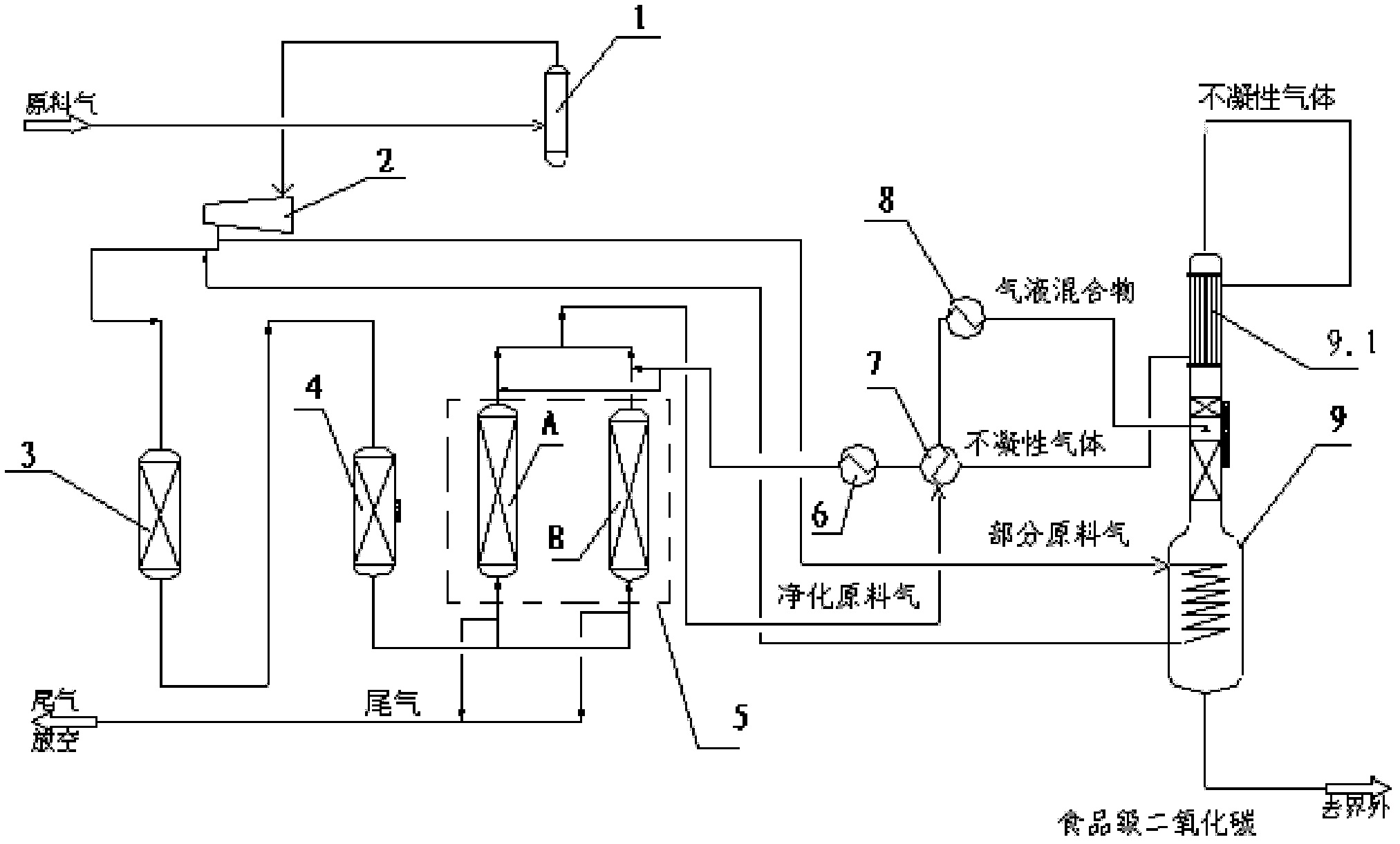

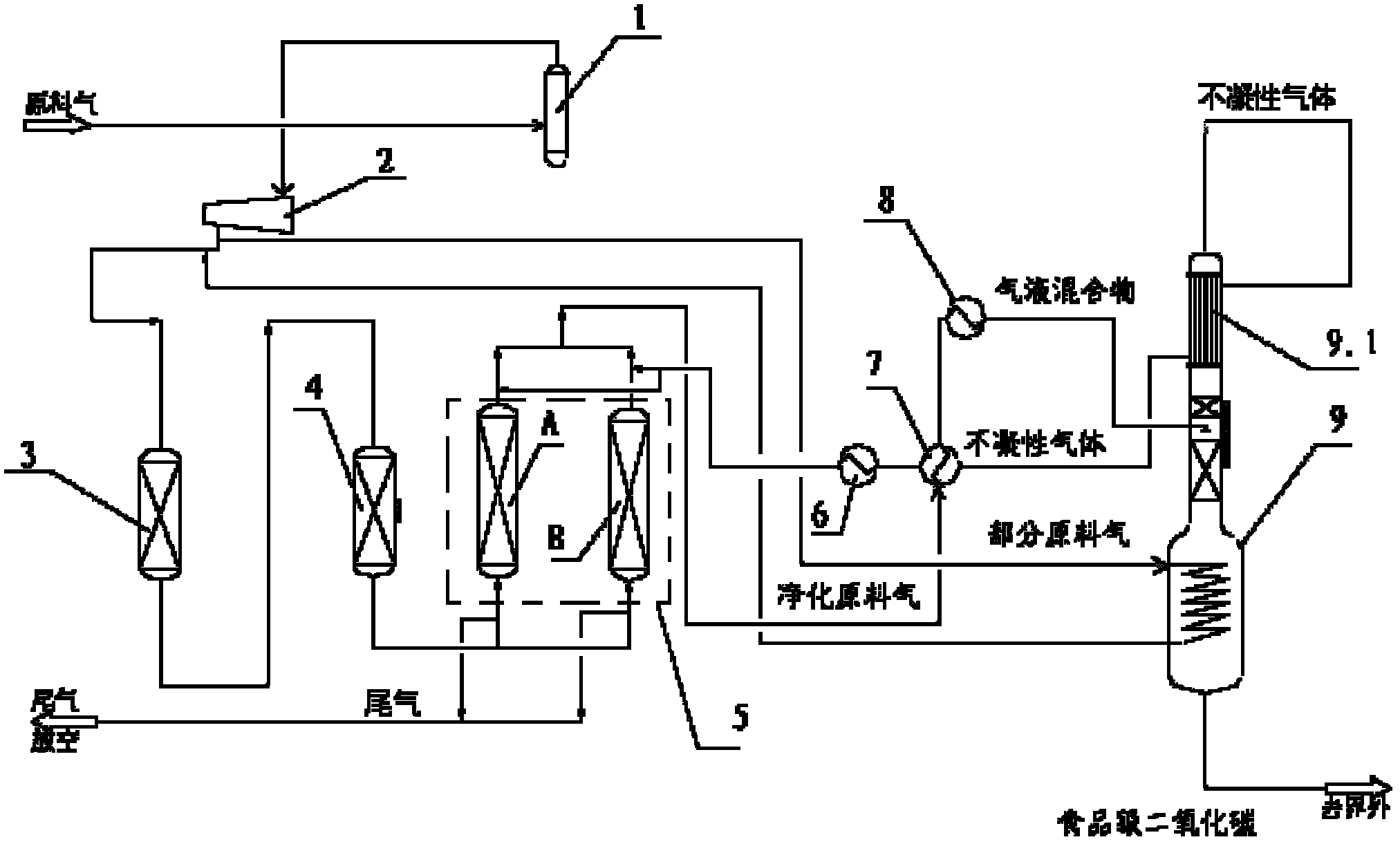

Technological method for preparing food-grade CO2 based on high-concentration carbon dioxide exhaust gas

A process method, carbon dioxide technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as high pressure resistance requirements, high compressor power consumption, and large energy loss, etc., to achieve equipment pressure resistance or resistance. Low temperature requirements, reduced investment and operating costs, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] According to 100,000 tons / year of food grade CO 2 Design, the raw material gas is the high-concentration carbon dioxide emission gas by-product of the ammonia synthesis plant, and its specific specifications are shown in Table 1:

[0025] Table 1 Raw gas technical specifications

[0026] serial number

name

Specification (mol%)

Remark

1

CO 2

88.8

2

CO

40ppm

3

H 2

0.2

4

N 2

10.9

5

h 2 S

3ppm

6

CH 4 o

130pm

7

CH 4

15ppm

8

Ar

15ppm

9

temperature, ℃

25

10

Pressure, MPaG

0.04

[0027] The specific process flow is:

[0028] Containing high concentrations of CO from outside the boundary 2 After the discharge gas is stabilized by the buffer tank 1, it enters the raw material gas compressor 2 to compress the raw material gas. Af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com