Center body of flame tube for radial staged combustion chamber

A technology of center body and flame tube, applied in the field of gas turbine engine, achieves the effect of good cooling effect, high reliability, and satisfying expansion requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039]At present, staged combustion technology has been widely used in aero-engines and gas turbine engines. As far as the structure of the combustion chamber formed by staged combustion technology is concerned, it can be divided into axially staged combustion chamber and radially staged combustion chamber. Compared with Below, because the radially staged combustion chamber structure has a more compact structure and a lighter structure, it has a wider application range. In the radially staged combustion chamber, in order to realize the staged and partitioned combustion between the duty flame and the main combustion stage flame, a central body structure is usually set between the duty flame head and the main combustion stage flame head, and produces Isolate the gas film to separate the duty flame and the main combustion stage flame to avoid mutual interference between the two.

[0040] However, the cooling structure of the existing central body is complex, the cooling effect is...

Embodiment 2

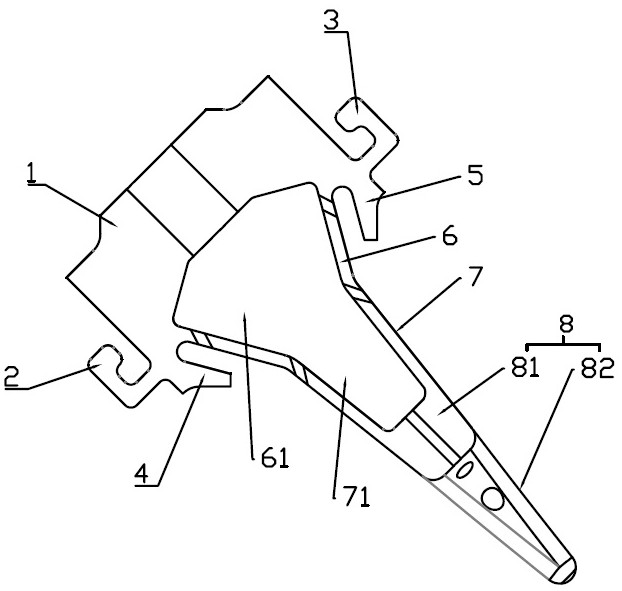

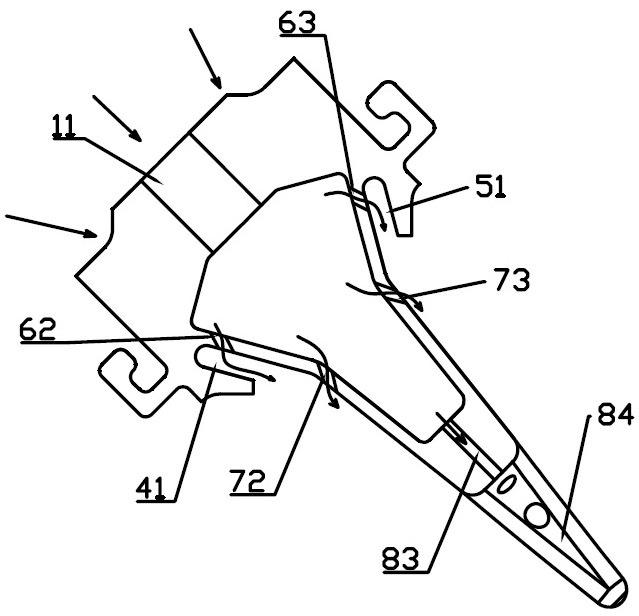

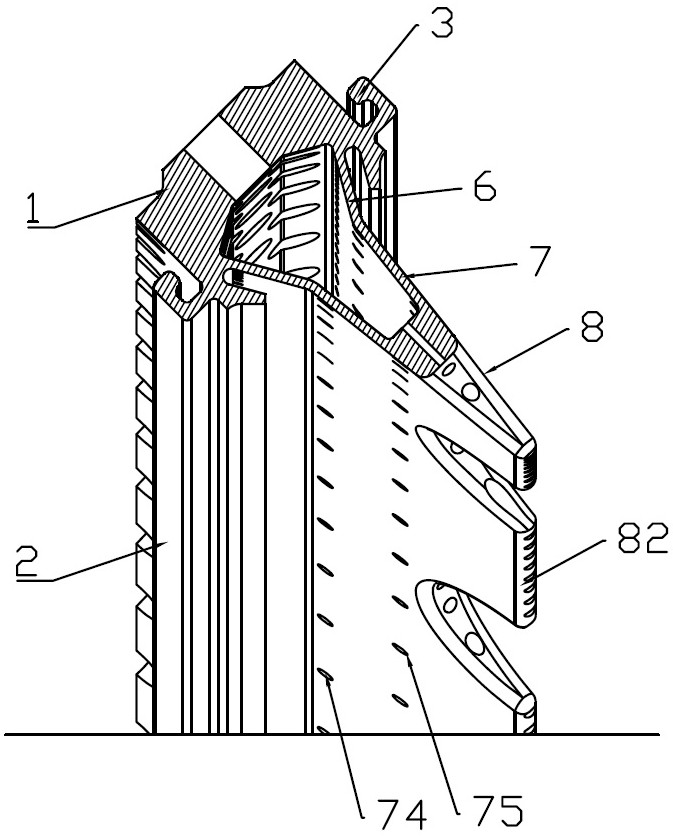

[0043] like Figure 1 to Figure 5 As shown, on the basis of the structure of Embodiment 1, in order to effectively avoid the ablation of the central body and improve the cooling effect of the central body, the cooling structure of this embodiment is designed.

[0044] The mixed flow cavity 61 and the pressure accumulating cavity 71 together form a ring cavity located in the central body. The annular cavity has the effect of annular pressure equalization. The holes lead the air flow in the annular cavity out of the center body, and respectively form cooling air films on the inner ring side and the outer ring side of the center body. The cooling gas film can not only isolate the heat from the main combustion stage flame and the duty stage flame to the central body, but also cool the central body, thereby taking away the heat of the central body.

[0045] The pressure-gathering cavity 71 located in the pressure-gathering section 7 is a part of the ring cavity, and the plurality ...

Embodiment 3

[0053] like Figure 1 to Figure 5 As shown, on the basis of the structure of Embodiment 1 or Embodiment 2, the jet section 8 with several central holes can be divided into a jet front section 81 and a jet rear section 82 along the jet direction, and the jet rear section 82 can be distributed with several The flame grooves 84 and the cross-fire grooves 84 can be semicircular grooves or arc grooves.

[0054] Since the input quantity of the flame head of the main combustion stage is not the same under different working conditions of the gas turbine engine, when switching between different working conditions, the on-duty flame is often required to carry out the operation of the oil and gas mixture ejected from the flame head of the main combustion stage. In the conventional structure, the taper of the jet section 8 and the injection direction of the central hole are changed to ensure the ignition effect; however, this method greatly changes the overall structure of the central bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com