The pcba processing method and pcba board based on the combination of plug-in component technology and patch technology

A technology of PCB board and processing method is applied in the field of circuit board processing to achieve the effect of saving labor costs and material costs, good economic and social benefits, and reducing temperature resistance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

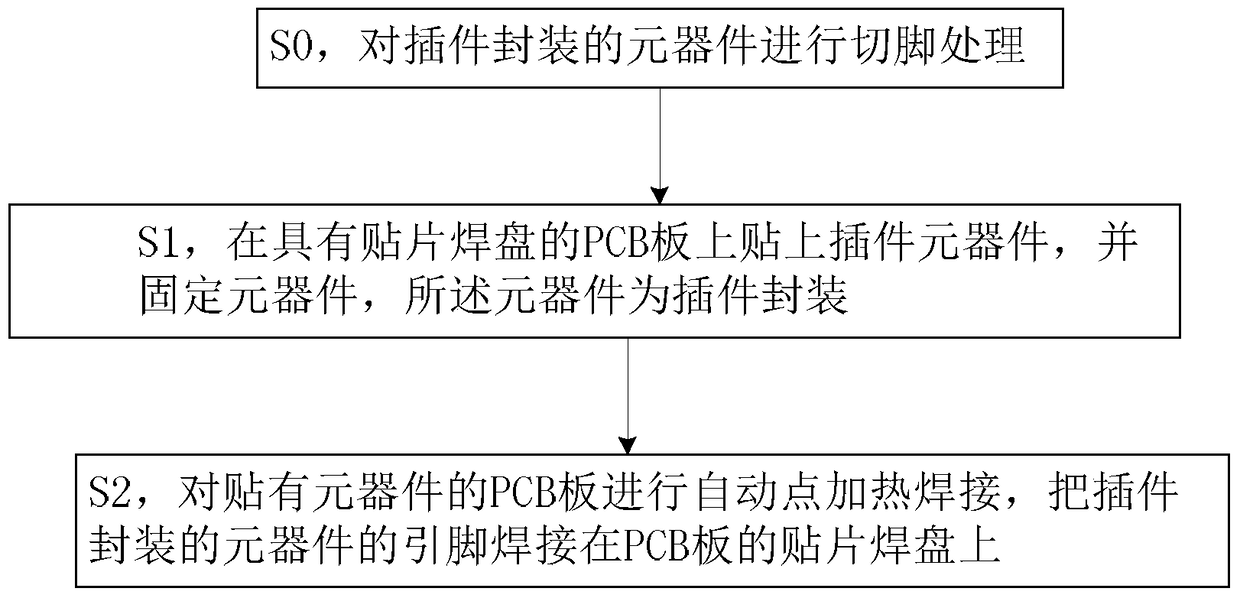

[0031] Such as figure 1 As shown, a PCBA processing method based on the combination of plug-in component technology and patch technology is characterized in that it includes the step: S1, attaching plug-in components on a PCB with patch pads, and fixing the components, The components are plug-in packages; S2, performing automatic spot heating and welding on the PCB with the components attached, and welding the pins of the components in the plug-in package to the patch pads of the PCB. The automatic heating soldering is a non-reflow soldering process, such as using an automatic positioning soldering machine to separately heat and solder the pins of the components in the plug-in package.

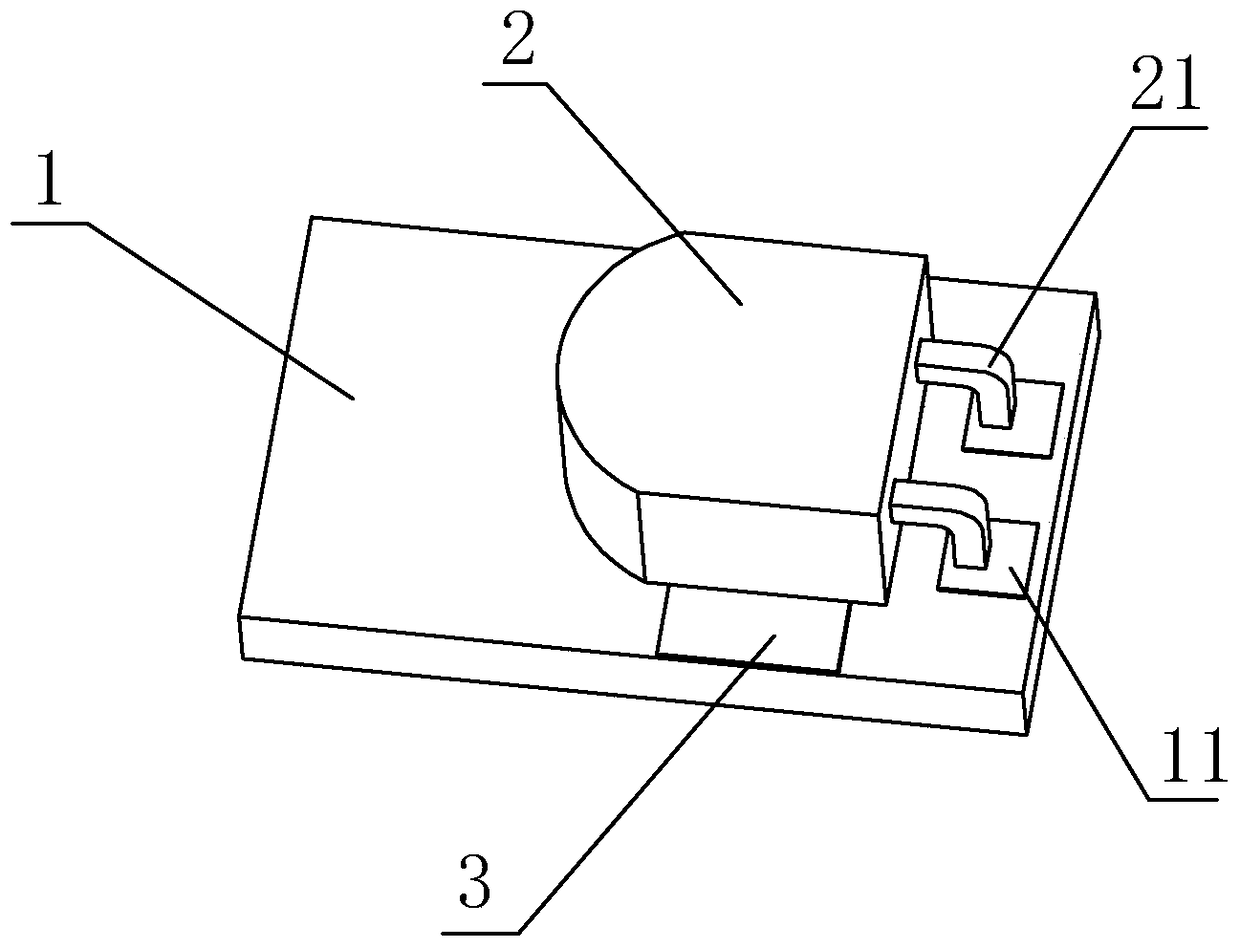

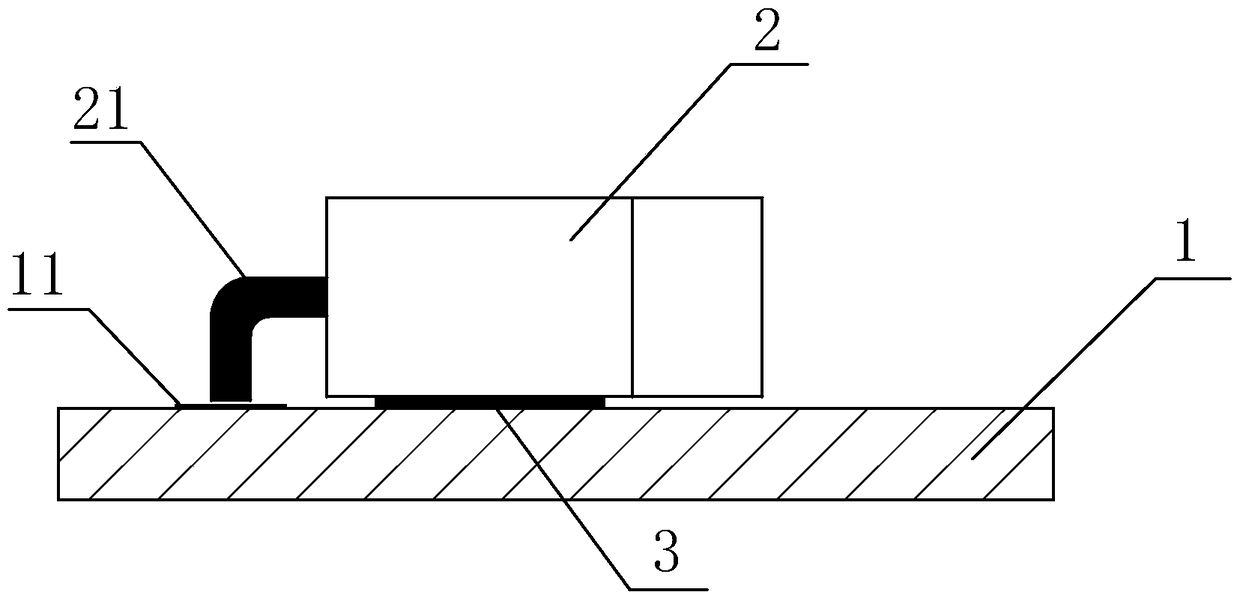

[0032] Such as Figure 2 to Figure 4 As shown, the step S1 specifically includes sub-steps: S11, first paste the adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com