Device and method for preparing fuel salt of molten salt reactor

A molten salt reactor and fuel salt technology, which is applied in the manufacture of reactors, reactors, and greenhouse gas reduction, etc., can solve the problem of high fuel salt cost, and achieve the effects of saving energy, saving raw material costs, and reducing raw material costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

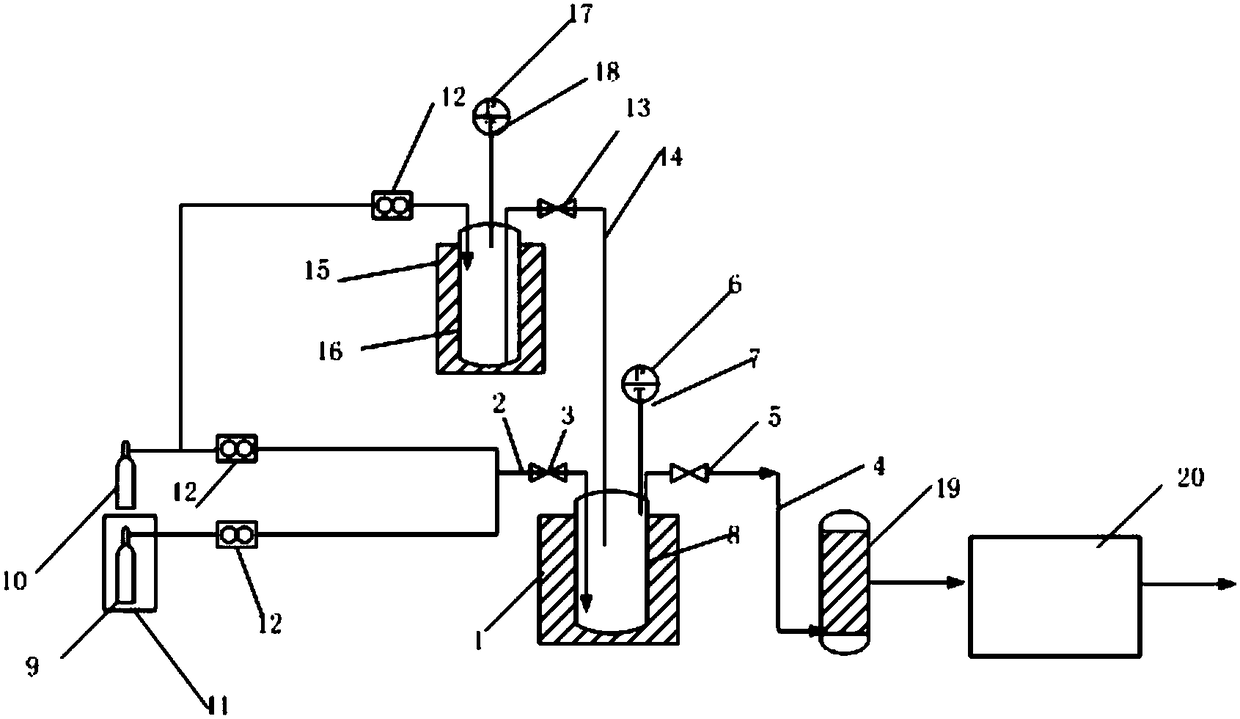

[0035] The method for preparing molten salt reactor fuel salt according to a preferred embodiment of the present invention includes step S1, placing solid fluorine salt and reducing metal in the reactor 8 of the reaction system, placing the inert gas storage tank 10 of the gas supply system, The inert gas in 10' is passed into the device to remove air and water in the device. It should be understood that the solid fluorine salt can also be placed in the molten salt storage tank 16 of the molten salt supply system, and the reducing metal can be placed in the reactor 8 of the reaction system, and the inert gas storage tanks 10, 10 of the gas supply system 'The inert gas in the device is passed into the device to remove the air and water in the device. At this time, the molten salt storage tank 16 is heated by the molten salt heating furnace 15 , so that the heated and melted liquid fluorine salt is sent to the reaction kettle 8 under pressure.

[0036] The fluoride salt is a fl...

example 1

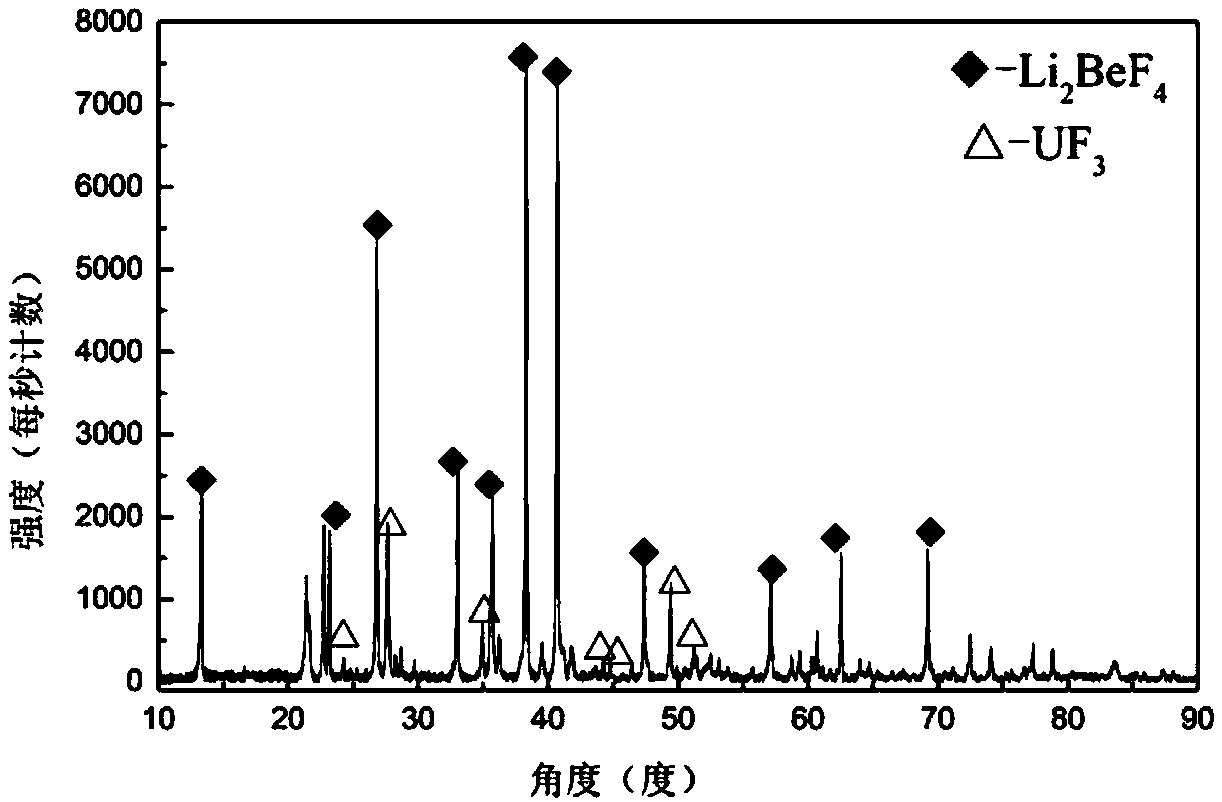

[0048] 400g solid fluoride salt LiF-BeF 2 (67-33mol%) is placed in the molten salt storage tank 16, the tank cover is covered, and the atmosphere in the molten salt storage tank is replaced with pure argon. Heating the molten salt storage tank 16 to raise the temperature from room temperature to 200°C, then keep it warm for 2 hours; replace the atmosphere in the molten salt storage tank with pure argon at the end of the heat preservation; heat the molten salt storage tank 16 again to raise the temperature from 200°C to After 400°C, keep warm for 2 hours; at the end of the keep warm, replace the atmosphere in the molten salt storage tank with pure argon to remove the water produced during the heating process. Heat the molten salt storage tank 16 again to make the temperature reach 550° C.; keep it warm for 4 hours until the fluoride salt is completely melted.

[0049] 12g of reducing metal Be flakes were placed in the reaction kettle 8, the lid of the kettle was covered, and t...

example 2

[0052] 450g solid fluorine salt KF-ZrF 4 (58-42mol%) and 68g reducing metallic nickel wire are placed in the reactor 8, the lid of the kettle is covered, and the atmosphere in the reactor is replaced with pure nitrogen. Heat the reaction kettle 8 to raise the temperature from room temperature to 200°C, then keep it warm for 2 hours; replace the atmosphere in the reaction kettle with pure nitrogen at the end of the heat preservation; heat the reaction kettle 8 again to raise the temperature from 200°C to 400°C, and keep it warm for 2 hours; At the end of the heat preservation, the atmosphere in the reactor was replaced with pure nitrogen to remove the water generated during the heating process.

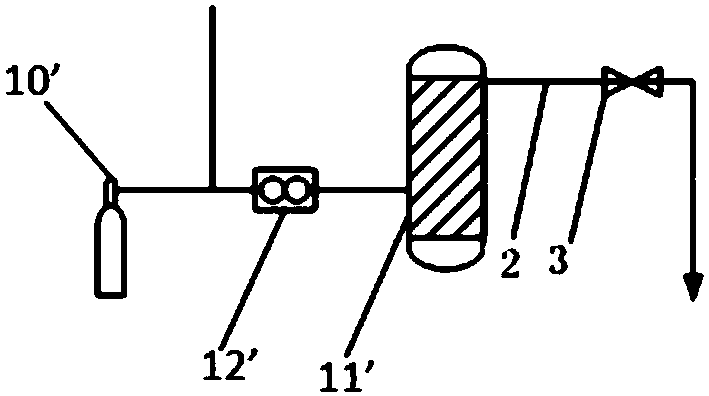

[0053] Continue to heat the reactor 8 to make the temperature reach 500°C; keep it warm for 6 hours until the molten salt is completely melted. Adsorbed with UF 6 The NaF adsorption column 11' is heated to 400°C for desorption, and carried by nitrogen gas with a flow rate of 1L / min. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com