Patents

Literature

98results about How to "Save productivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

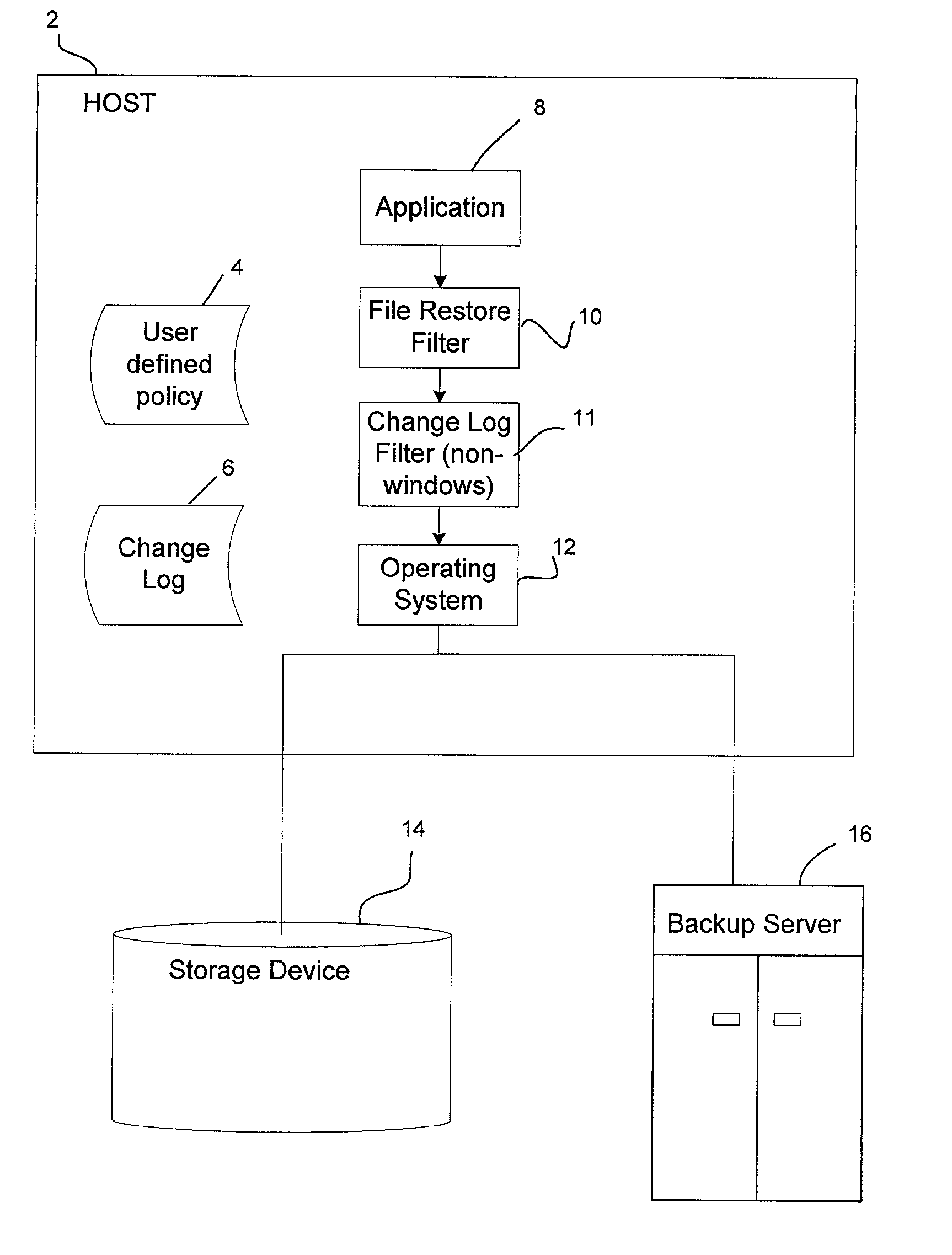

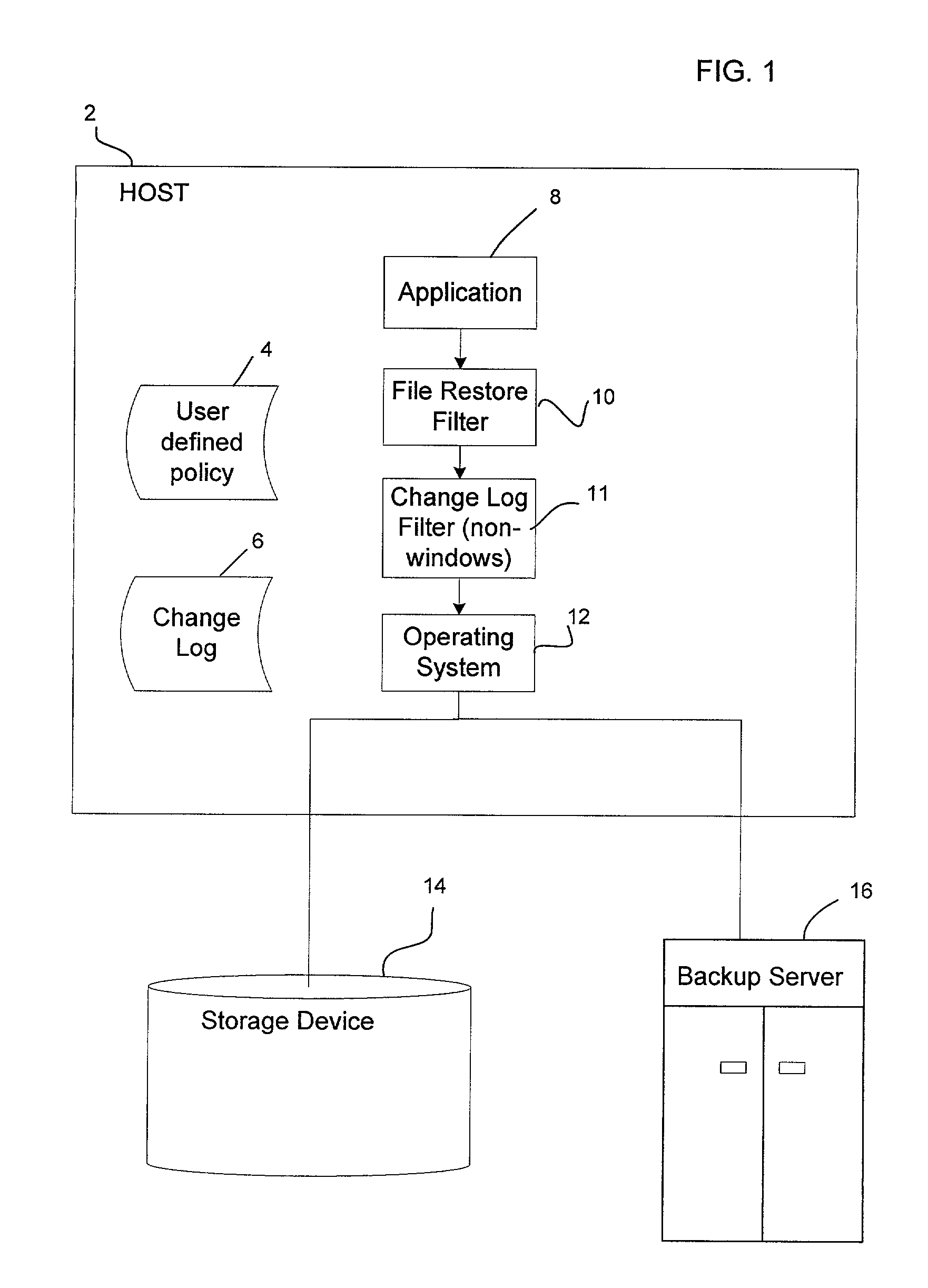

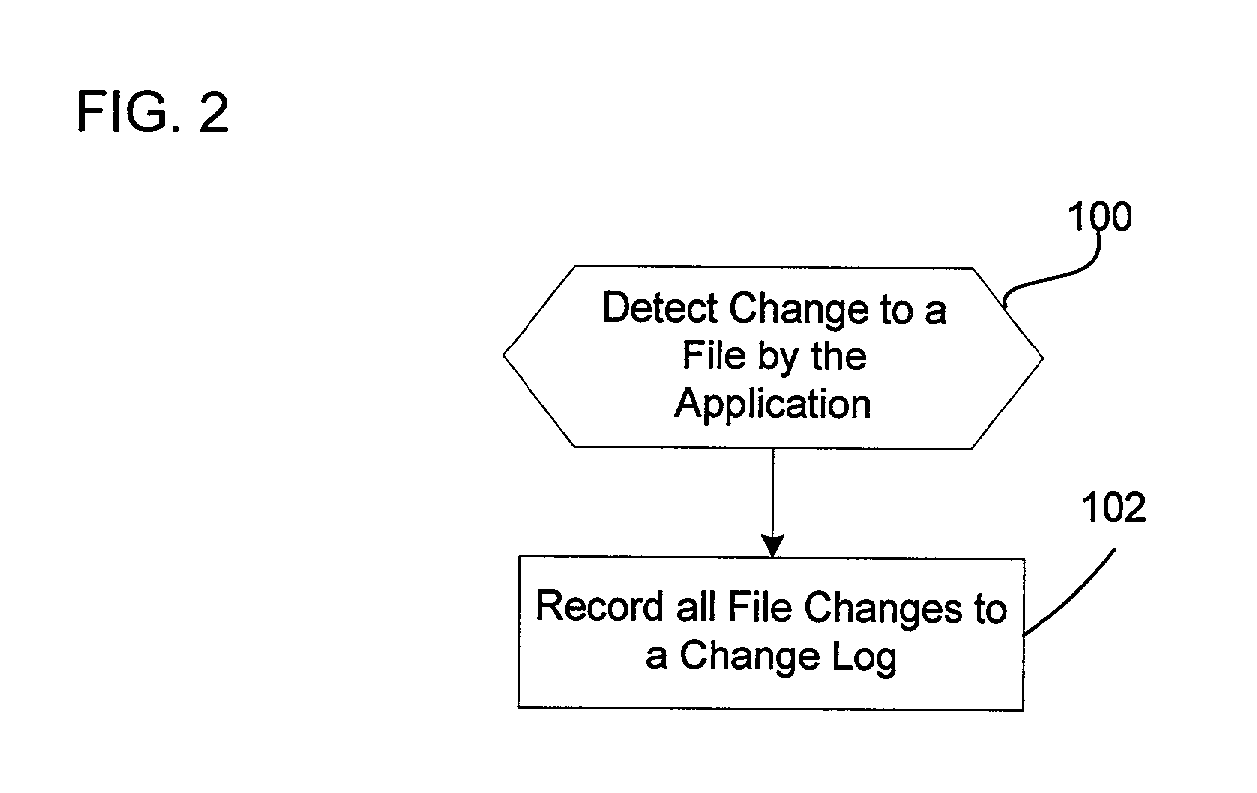

Method, system, and program for a transparent file restore

InactiveUS20030177145A1Low costSave productivityData processing applicationsNon-redundant fault processingApplication softwareOperating system

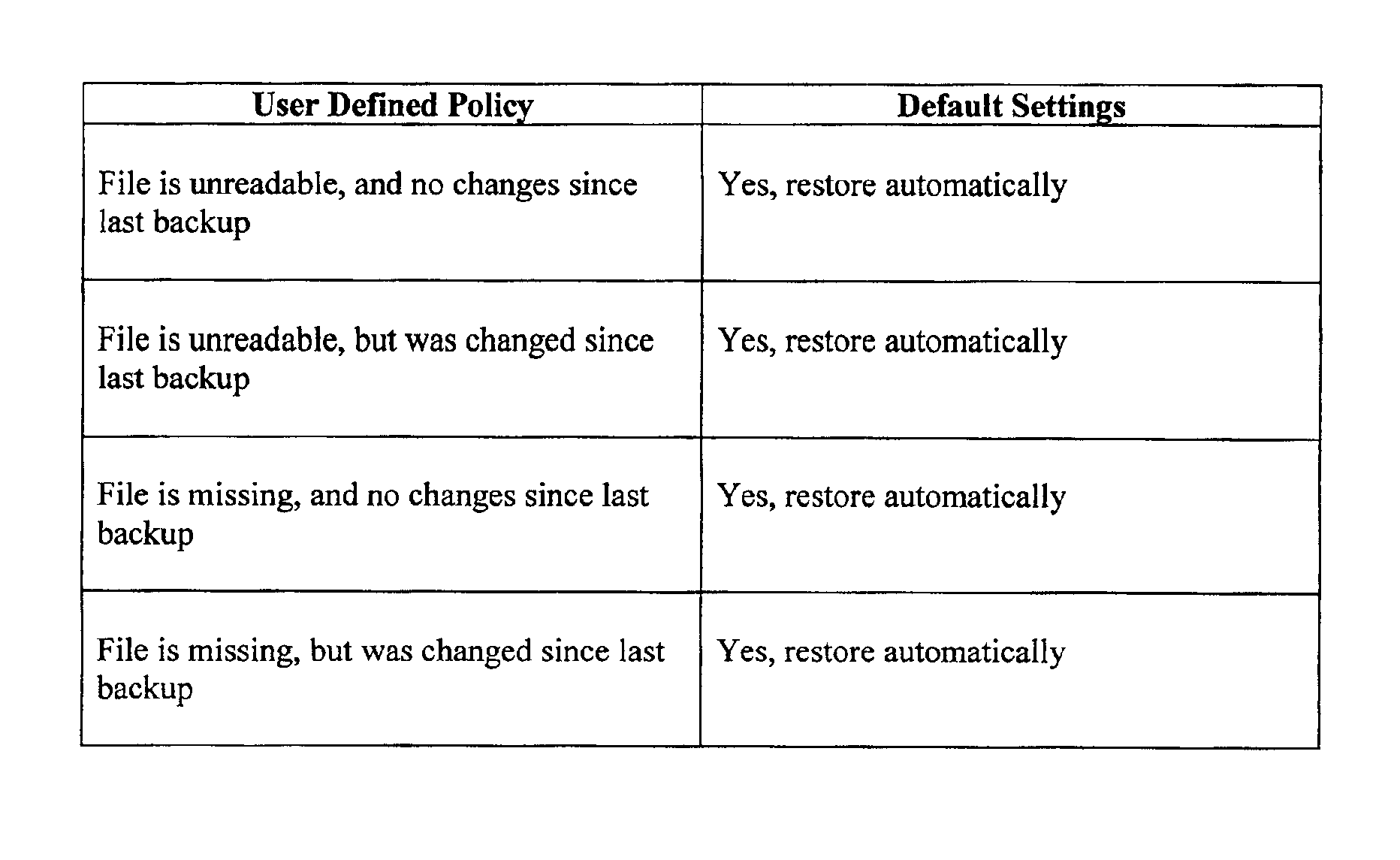

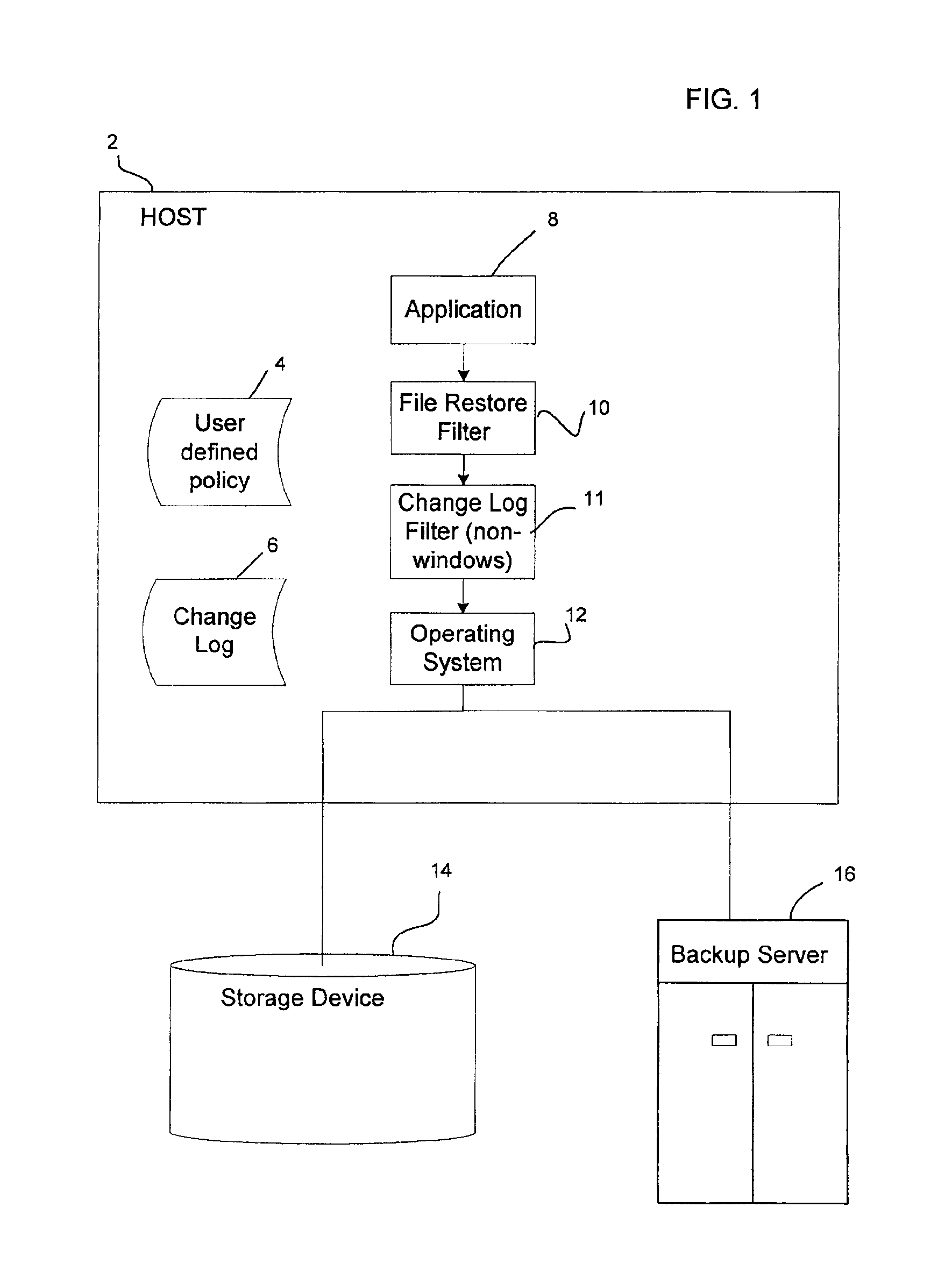

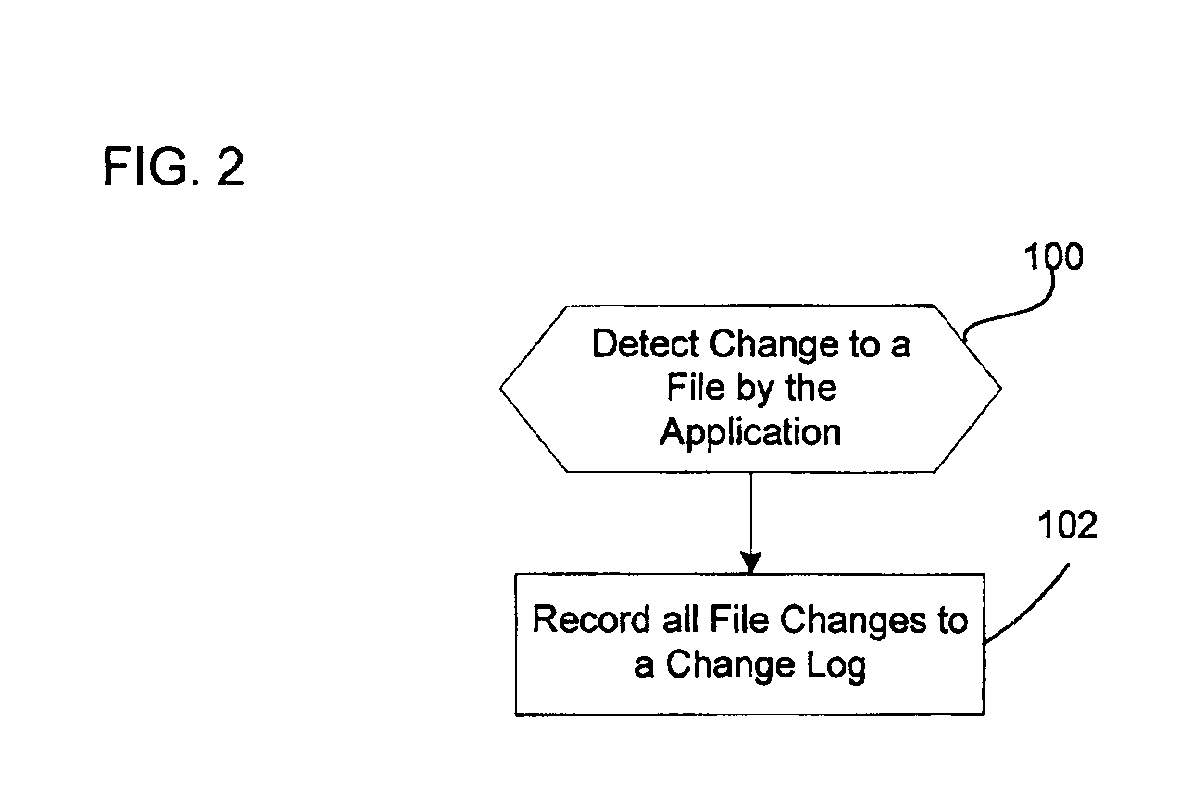

Provided is a method, system, and program for automatically handling an error when retrieving a file for an application. An error is detected while the application retrieves a file from the storage device. A user defined policy is checked to determine whether a backup copy should be restored, and the file is restored from the backup copy if the user defined policy indicates that the backup copy should be used.

Owner:MAPLEBEAR INC

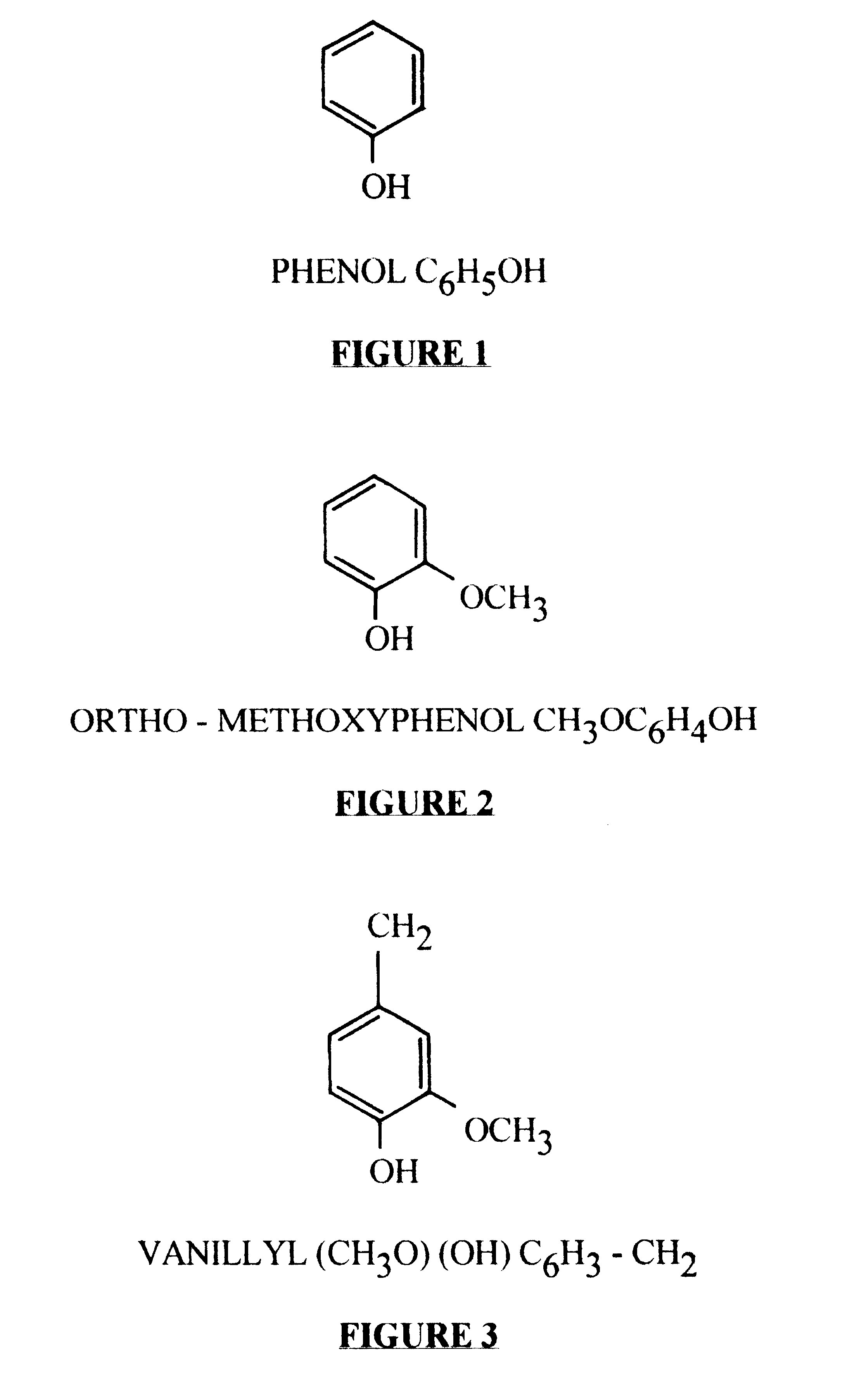

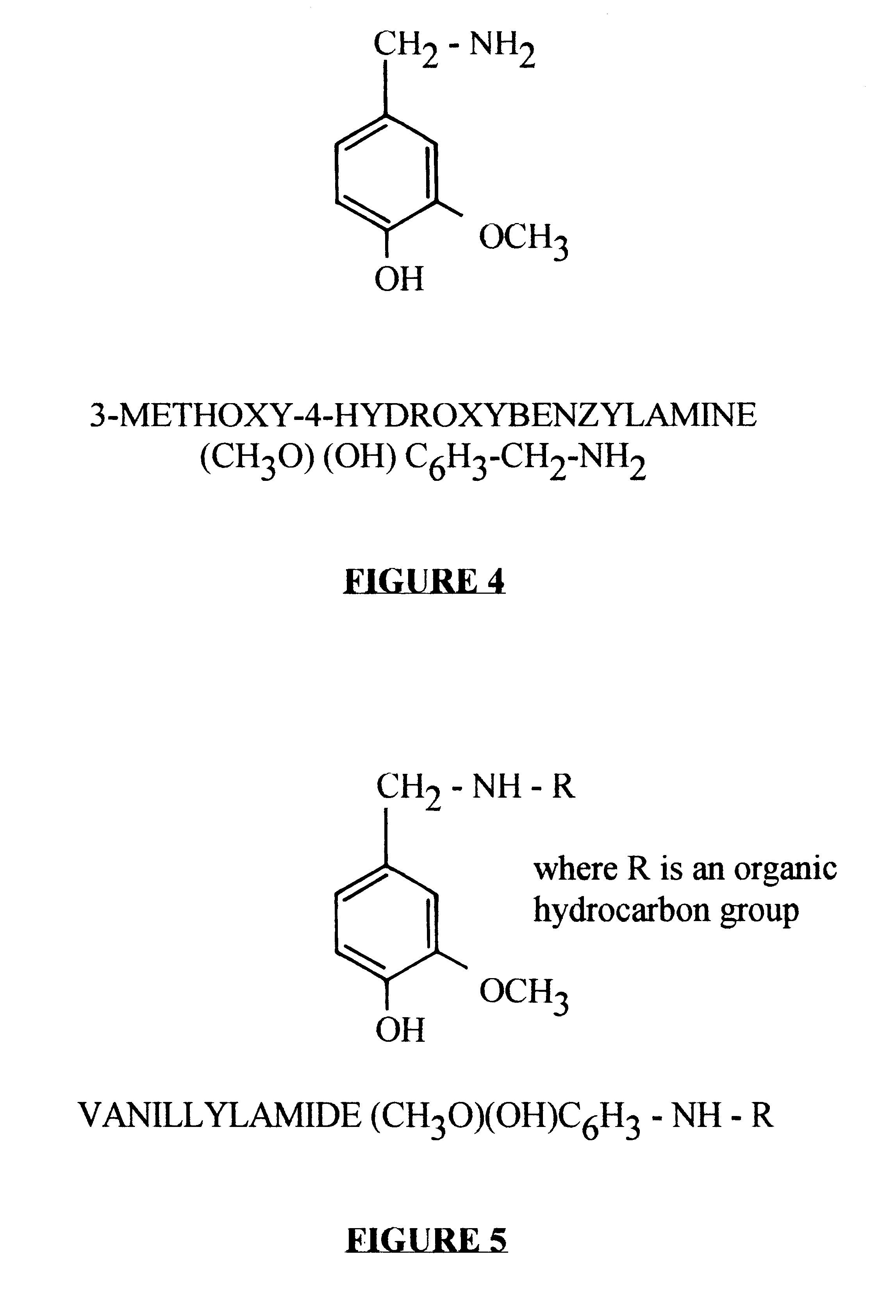

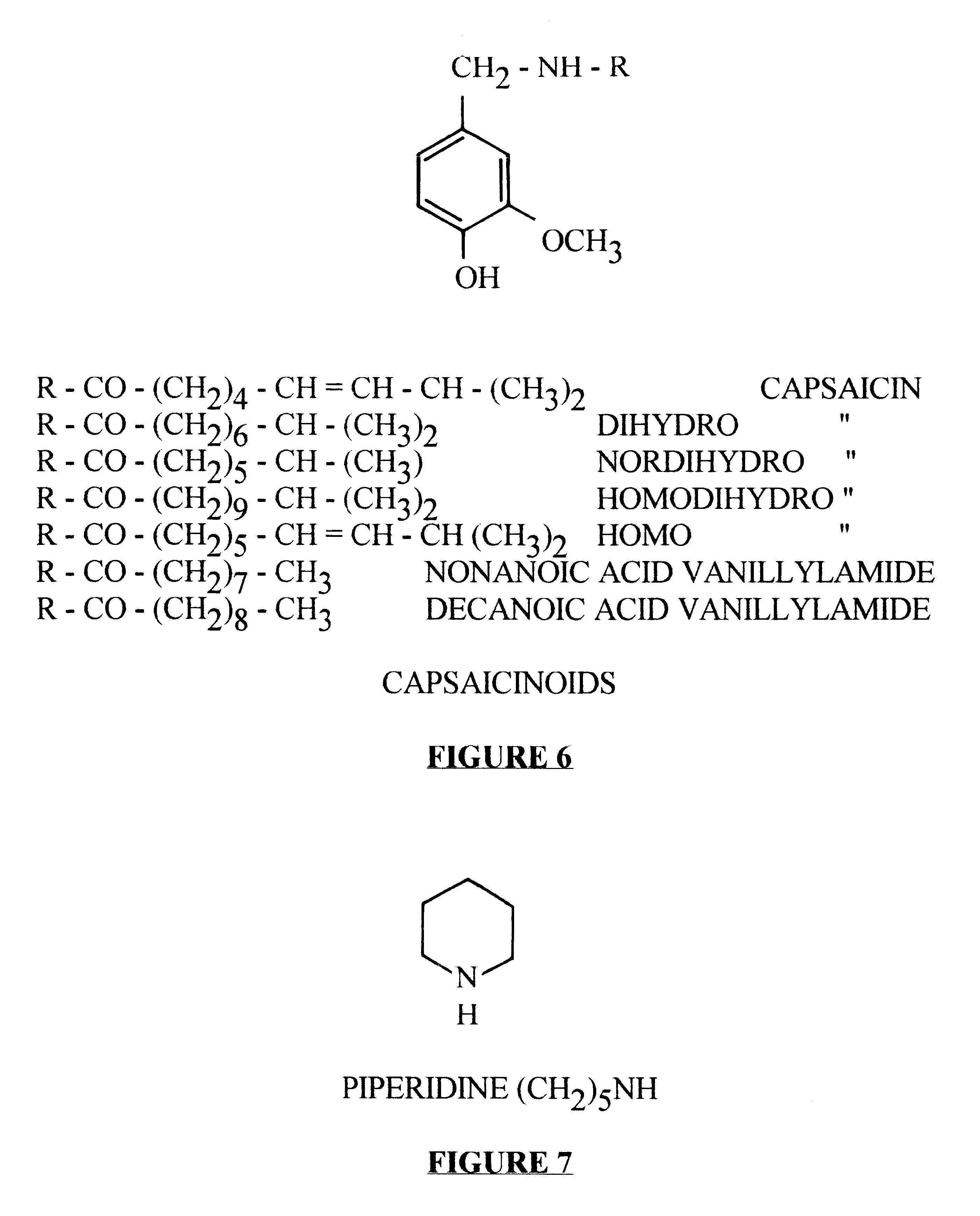

Treatment for wart and related disorders

InactiveUS6593371B1Convenient treatmentUnparalleled effectivenessBiocideCarbohydrate active ingredientsDiseaseCapsicum extract

A novel treatment for wart and related disorders such as papillomas derived from extracts of pepper, ginger, and related plant species containing vanillyl (FIG. 3), and piperidine (FIG. 7) ring structures typical of the pungent principals found in pepper, and ginger. The pepper extracts, which also possess antifungal properties are demonstrated in the topical treatment of warts.

Owner:STAGGS JEFF J

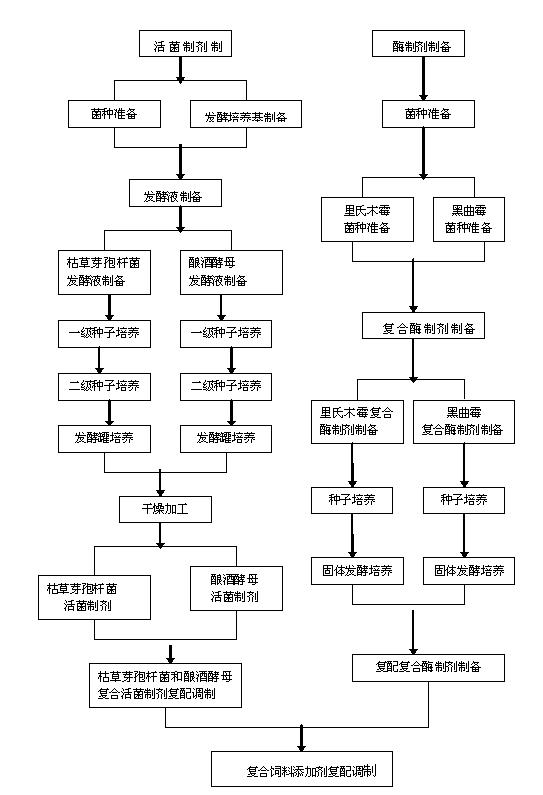

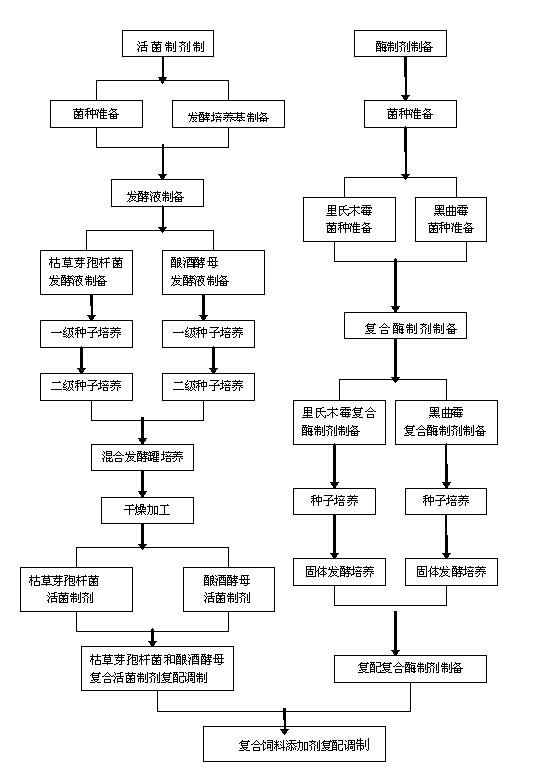

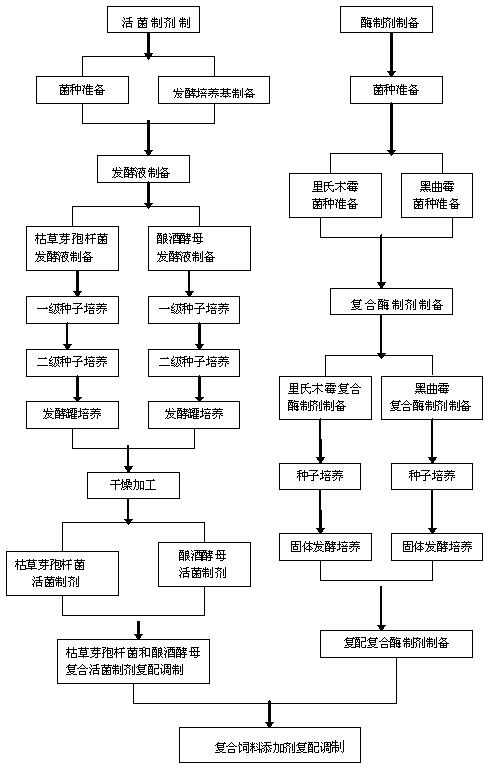

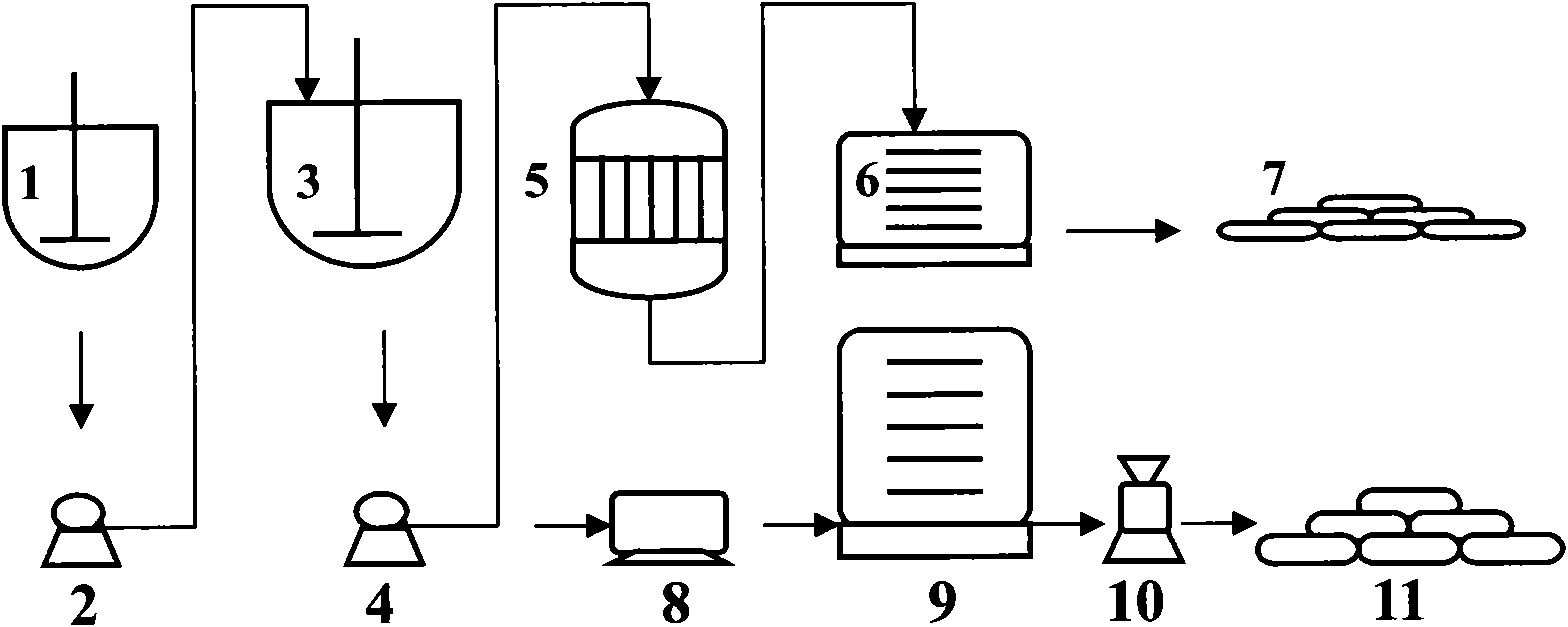

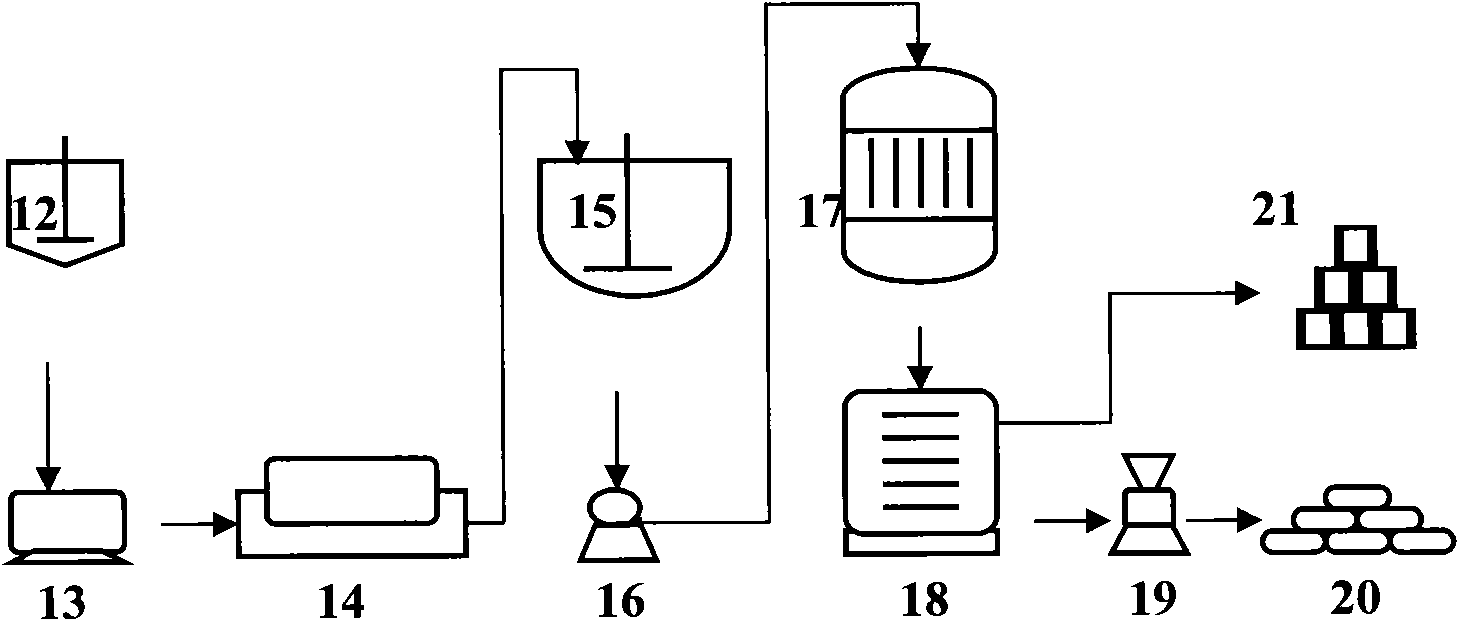

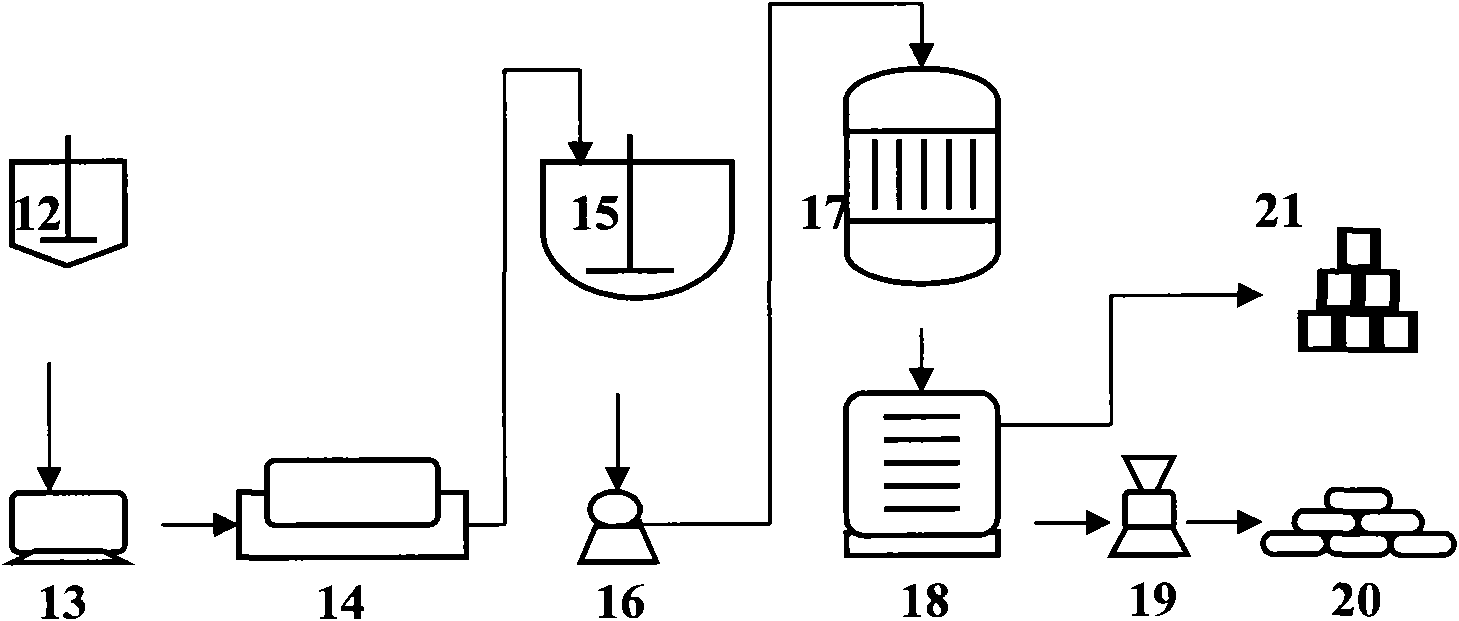

Bio-enzyme and microorganism containing compound feed additive and preparation process thereof

InactiveCN102599351AImprove feed utilizationIncrease production capacityAnimal feeding stuffAmylaseTrichoderma reesei

The invention discloses a bio-enzyme and microorganism containing compound feed additive and a preparation process thereof, which solve the problems of high production cost and less viable count of beneficial microorganisms in the prior art. The bio-enzyme and microorganism containing compound feed additive is characterized in that the additive is prepared by compounding a viable organism preparation (prepared by carrying out liquid fermentation and low-temperature drying on bacillus subtilis and brewer's yeast) with an enzyme preparation (prepared by carrying out solid fermentation and drying on trichoderma reesei and Aspergillus niger); and the viable count of beneficial microorganisms in each gram of the product is greater than 8*10<9> cfu / g, the cellulase activity (refer to the quantity of cellulose degraded by each gram of the product per minute) is greater than 500 mg, the alpha-amylase activity (refer to the quantity of starch hydrolyzed by each gram of the product per minute) is greater than 3000 mg, and the protease activity (refer to the mount of an amino acid generated by caseins hydrolyzed by each gram of the product per minute) is greater than 400 mg. The bio-enzyme and microorganism containing compound feed additive disclosed by the invention has the advantages that: the feed utilization rate of livestock can be improved in a short term, the intestinal digestive flora of livestock is improved and balanced, the breeding cost is reduced, and the feed conversion rate and the animal production performance are improved; and meanwhile, the additive is simple in preparation process, low in production cost, and suitable for industrialized production.

Owner:LIAONING SHENNONG BIOLOGICAL ENG

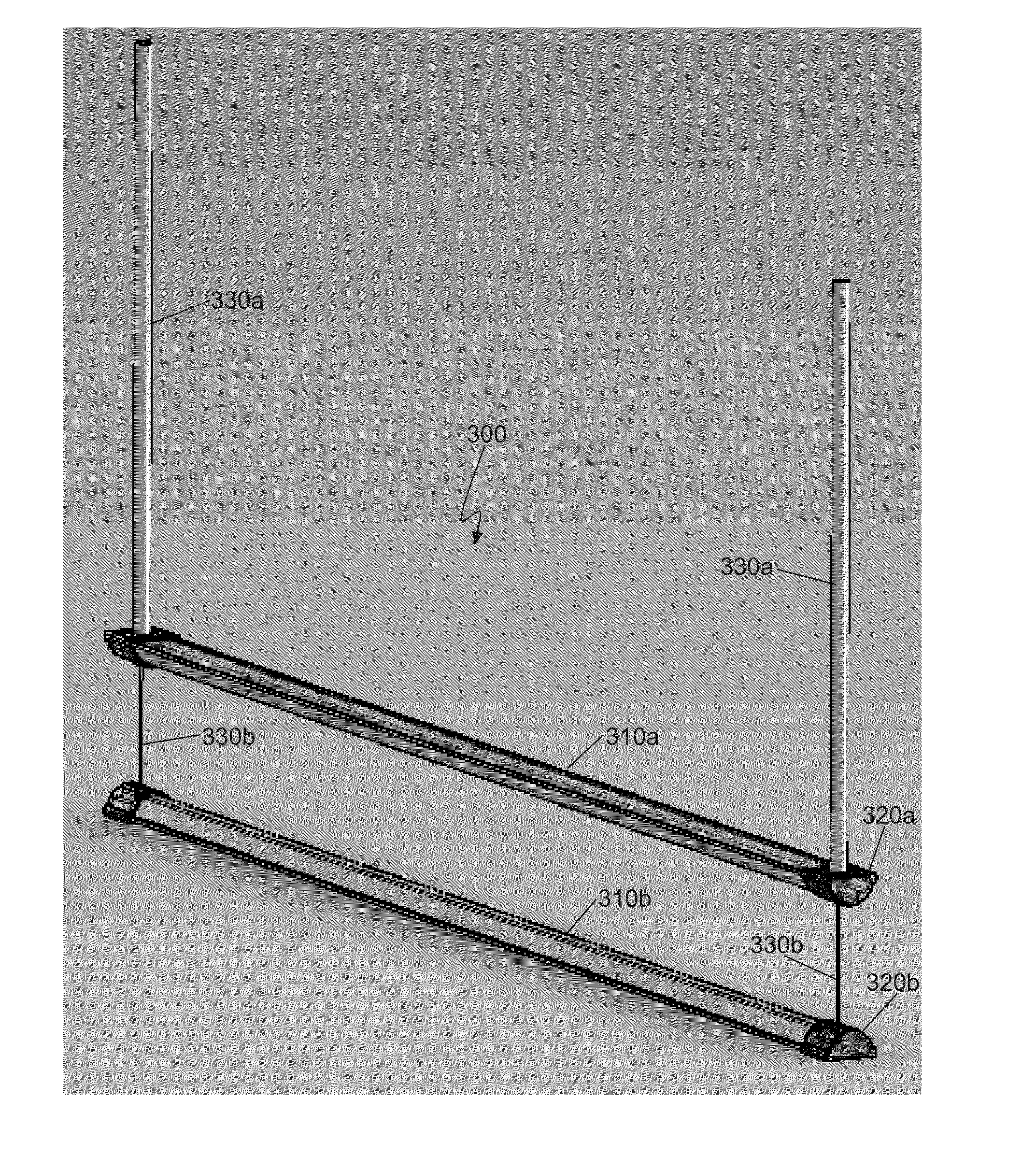

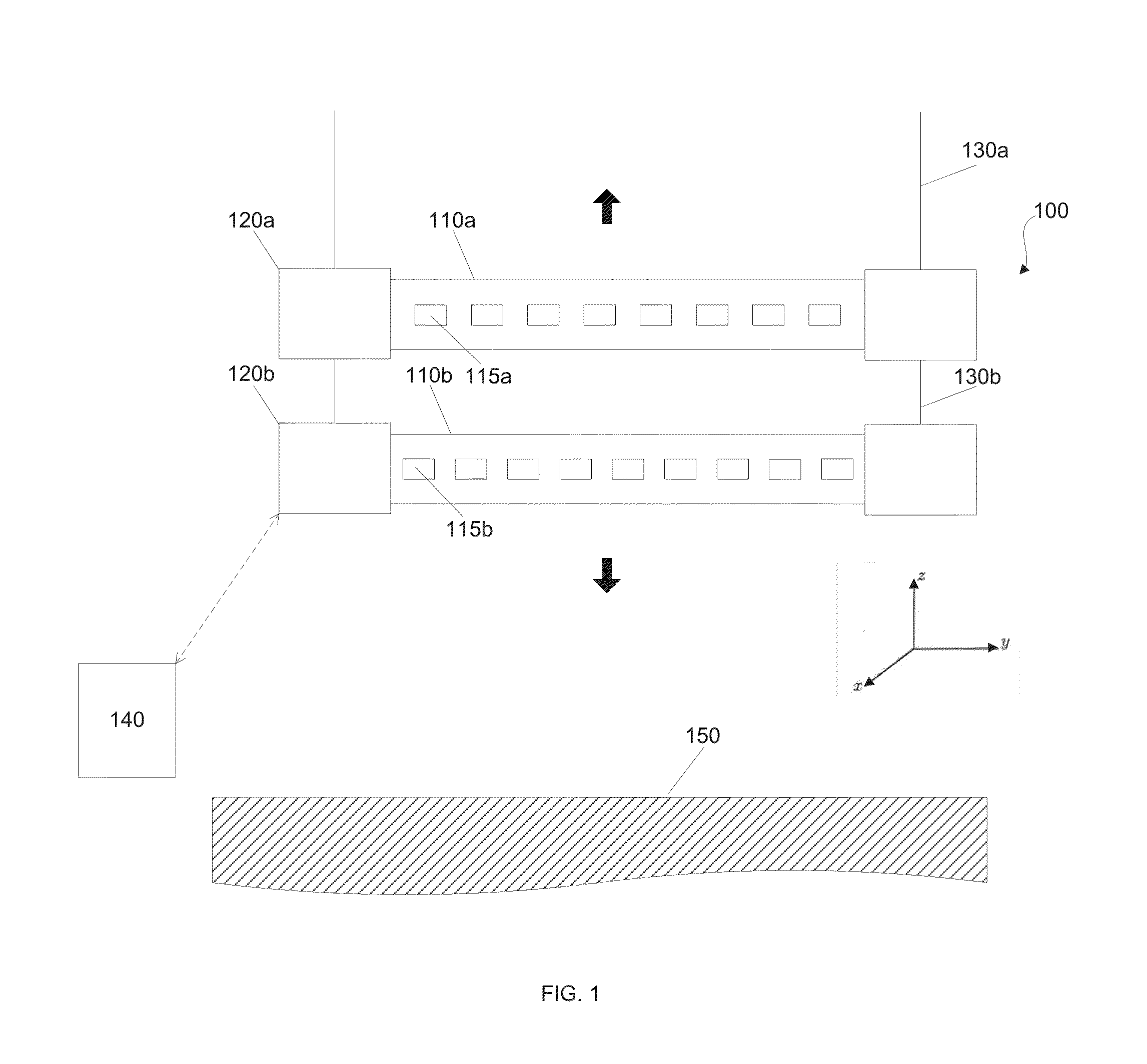

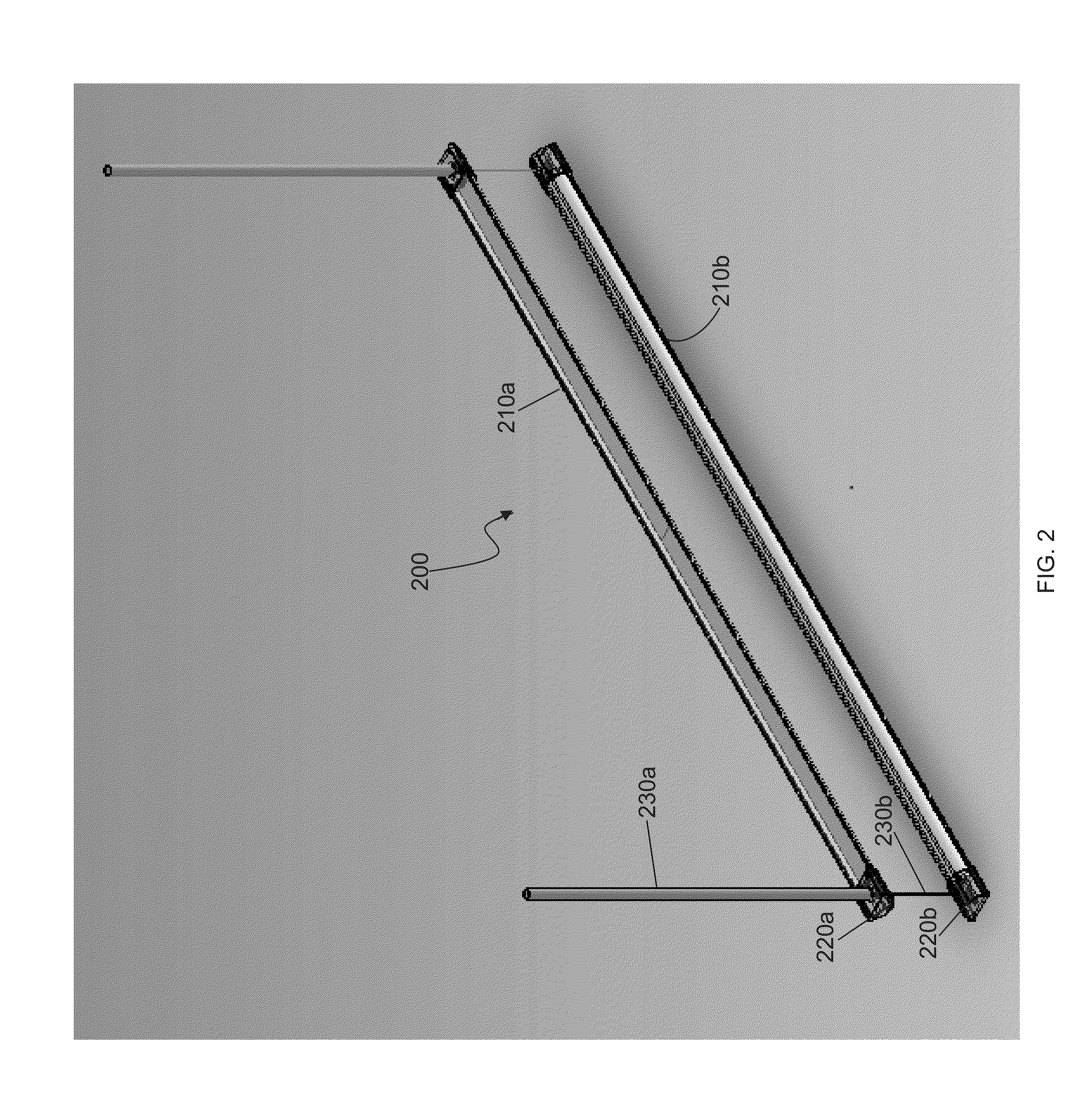

Linear pendant luminaire

InactiveUS20150300617A1Efficiently provideImproved luminairesLighting support devicesElongate light sourcesEngineeringElectrical and Electronics engineering

Owner:NEXT LIGHTING CORP

Method, system, and program for a transparent file restore

InactiveUS6950836B2Low costSave productivityData processing applicationsNon-redundant fault processingApplication softwareOperating system

Provided is a method, system, and program for automatically handling an error when retrieving a file for an application. An error is detected while the application retrieves a file from the storage device. A user defined policy is checked to determine whether a backup copy should be restored, and the file is restored from the backup copy if the user defined policy indicates that the backup copy should be used.

Owner:MAPLEBEAR INC

Processing technique for black tea

The invention relates to a processing technique for black tea and belongs to the field of production of tea. The processing technique comprises the following steps: firstly, screening the tea; secondly, freezing; thirdly, unfreezing and spreading and drying in the air; fourthly, rolling; fifthly, fermenting; sixthly, carrying out enzyme deactivation; seventhly, primarily baking; eighthly, secondarily baking. According to the processing technique disclosed by the invention, a withering technology is omitted, and a freezing technique and a roller enzyme deactivation process are added; simplicity and convenience in operation are realized, a place is saved, production time is shortened, the productivity is greatly improved, and the technique is easy to grasp and popularize; besides, sufficiency in fermentation is realized; prepared finished black tea has the advantages of compact and even shape and strips, black bloom color and luster, orange red and bright soup, sweet and lasting aroma, faint chestnut-like aroma, mellow taste, freshness, no astringency and obvious sweet after taste; in addition, the content of amino acid reaches 2.20 to 2.84 percent, the content of theoflavin reaches 4.01 to 4.93 percent, the content of thearubigin reaches 13.02 to 16.12 percent and is far higher than that of ordinary black tea; the content of theabrownin is controlled at 3.24 to 3.91 percent, and the content of caffeine is controlled at 1.89 to 2.78 percent; aroma, soup color, taste, mouthfeel and a stomach nourishing effect of the black tea are greatly improved.

Owner:XINYANG AGRI & FORESTRY UNIV

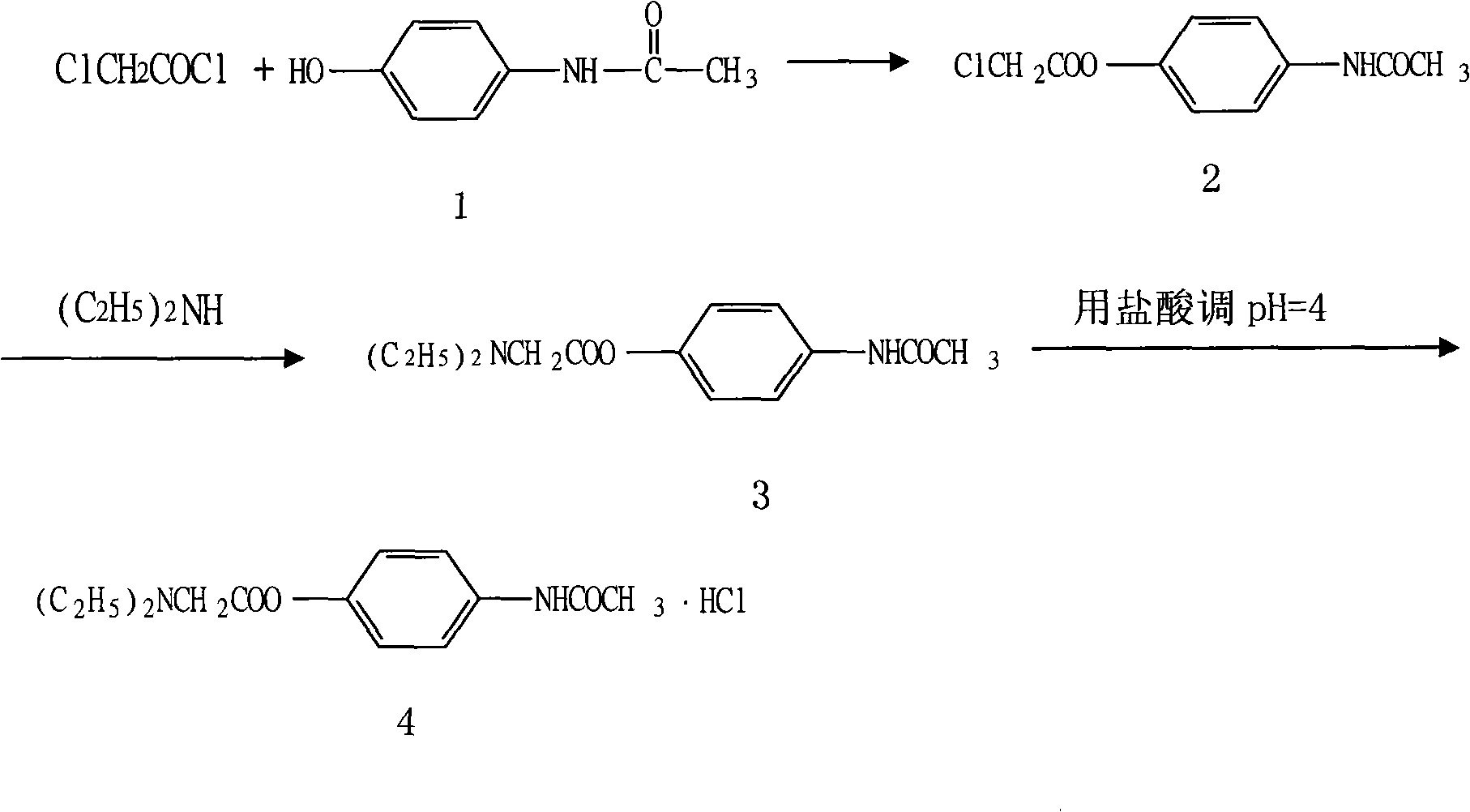

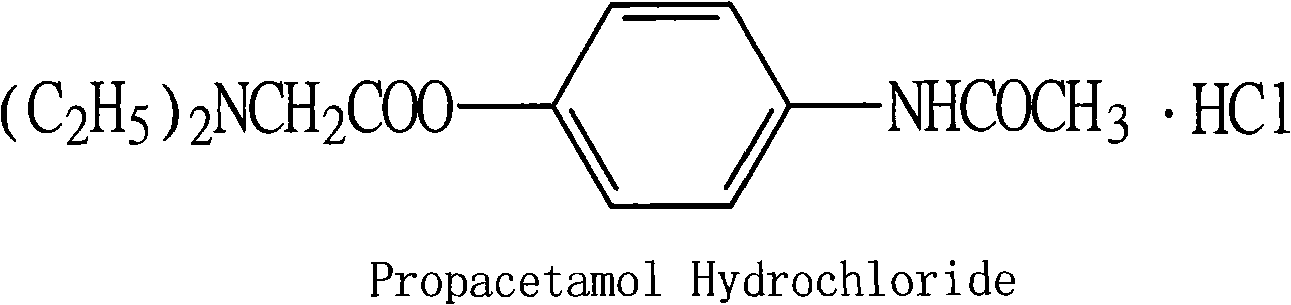

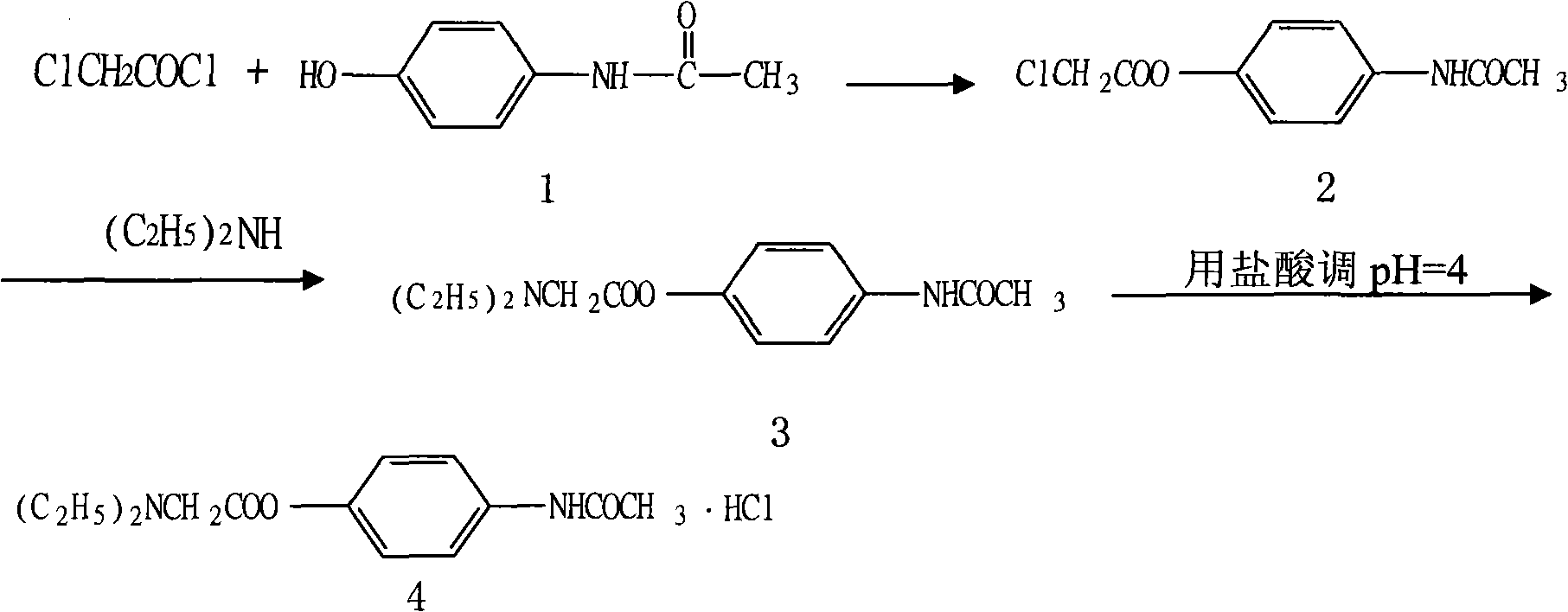

Preparation of propacetamol hydrochloride

InactiveCN101353314ASimplify purification operationsHigh yieldOrganic compound preparationCarboxylic acid amides preparationAcetic acidPropacetamol

The invention provides a preparation method of propacetamol hydrochloride. The preparation method is characterized in that chloracetyl chloride and paracetamol carry out an acetylization chloride reaction in a polar aprotic solvent to obtain chloroactic acid-4-acetylamino phenyl ester which is directly aminated with diethylamine to obtain N, N'-diethylglycine 4-acetylamino phenyl ester, hydrochloric acid is used for adjusting the pH to be 4, and the propacetamol hydrochloride is obtained. The preparation method has the advantages of mild condition, convenient separation and purification, the total product yield is greatly increased, the use of the amount of the reaction solvent is low, and the preparation method reduces industrial pollution, and is applicable to industrialized production.

Owner:ANHUI PIOM PHARMA

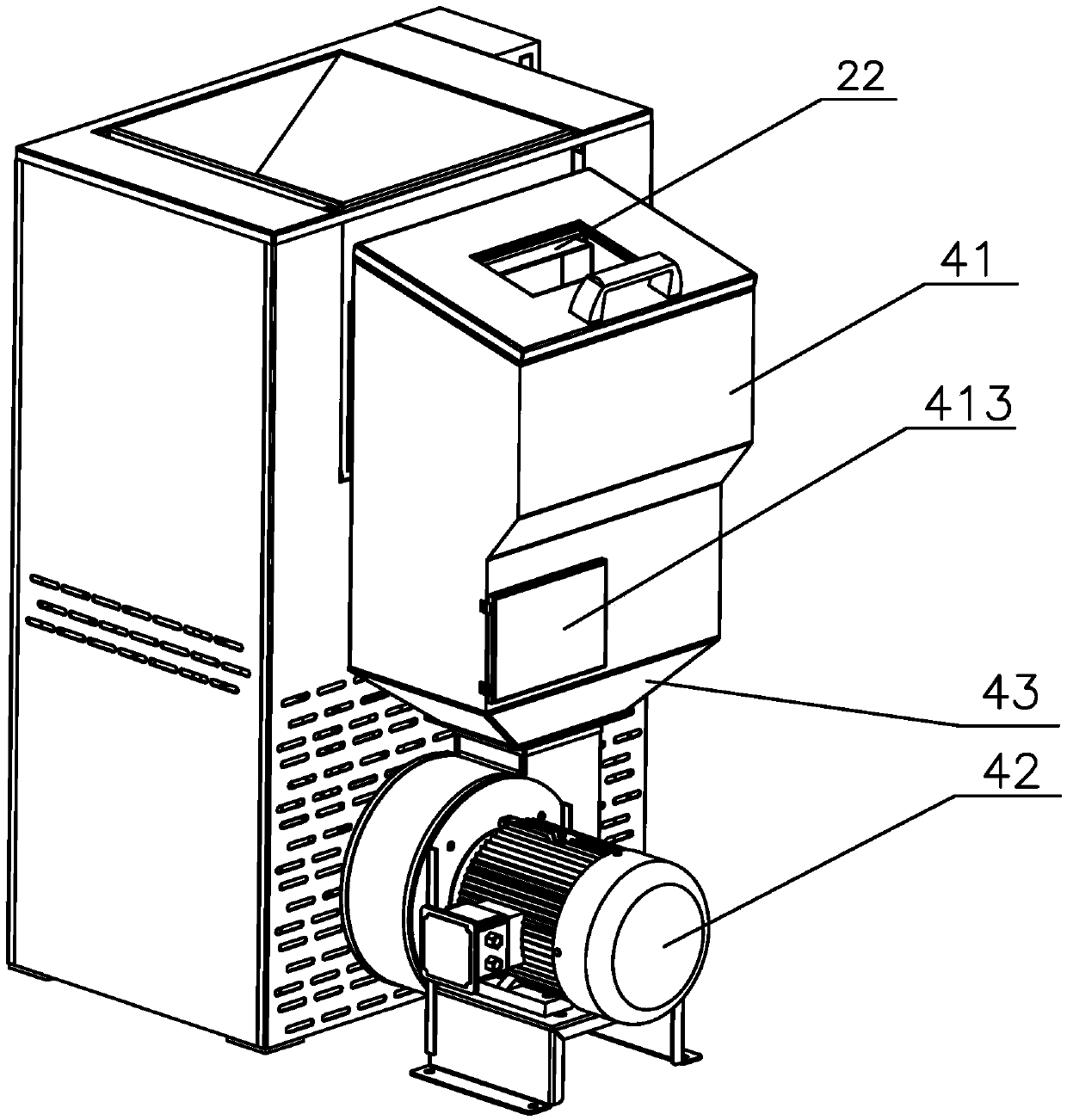

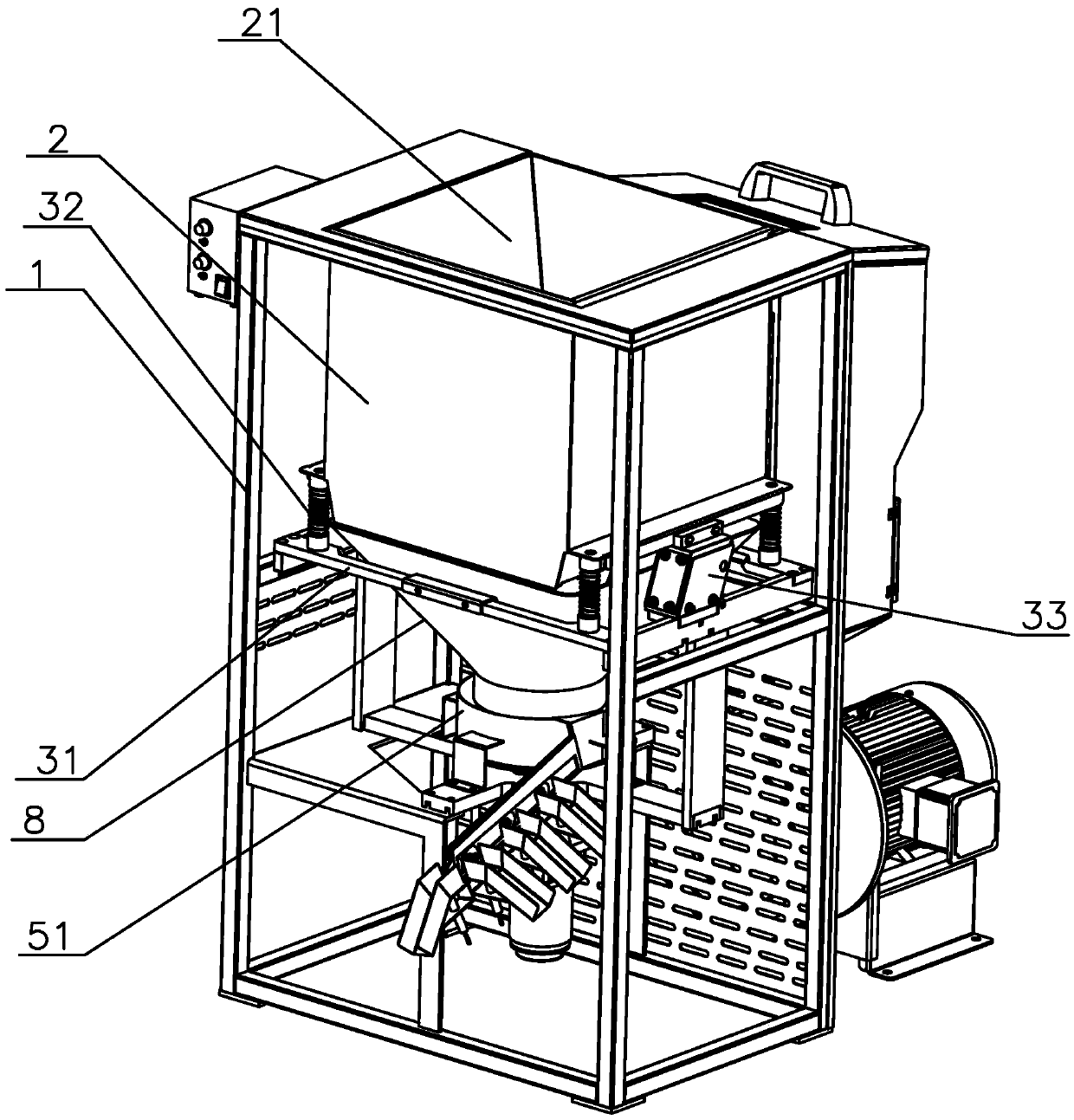

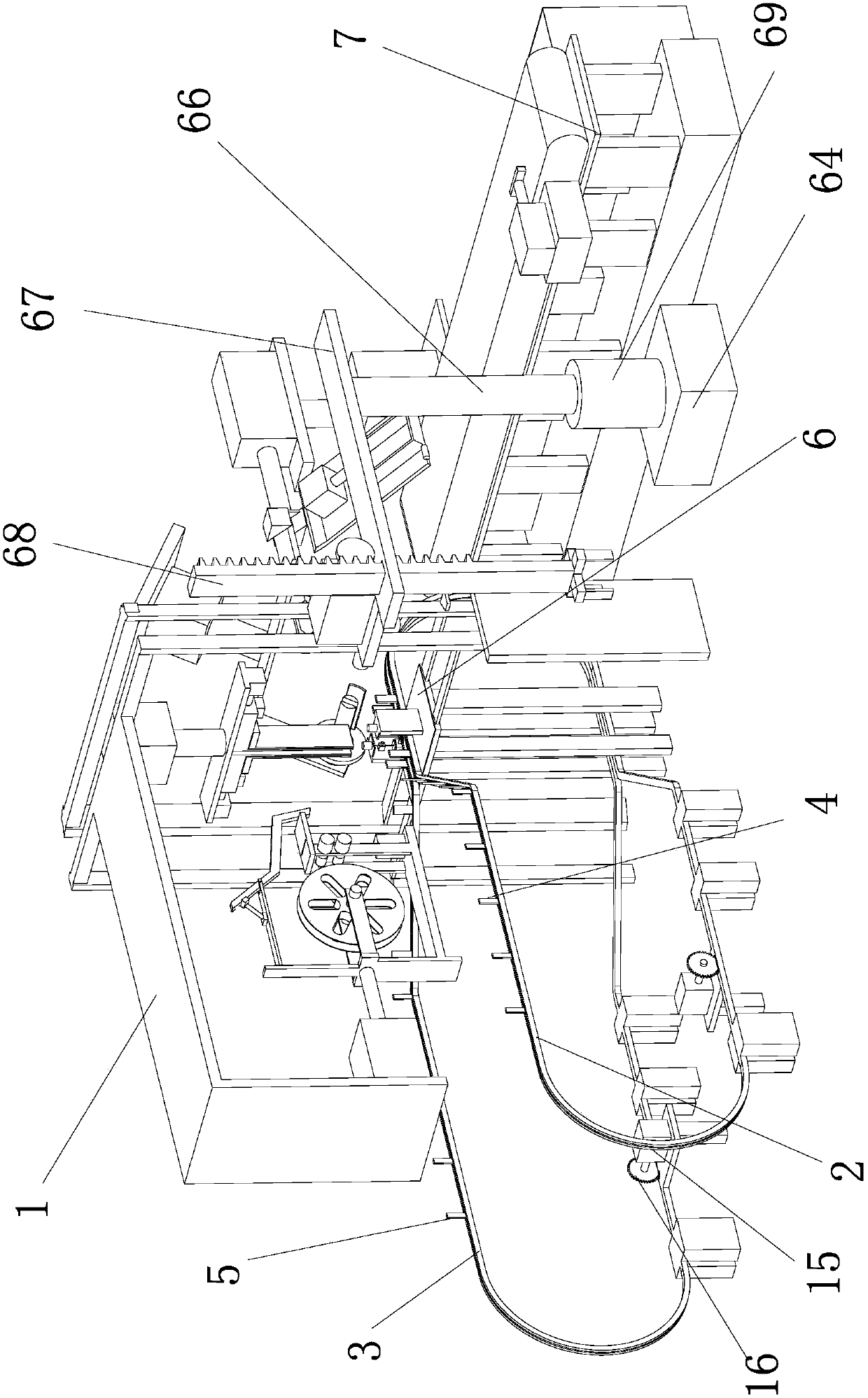

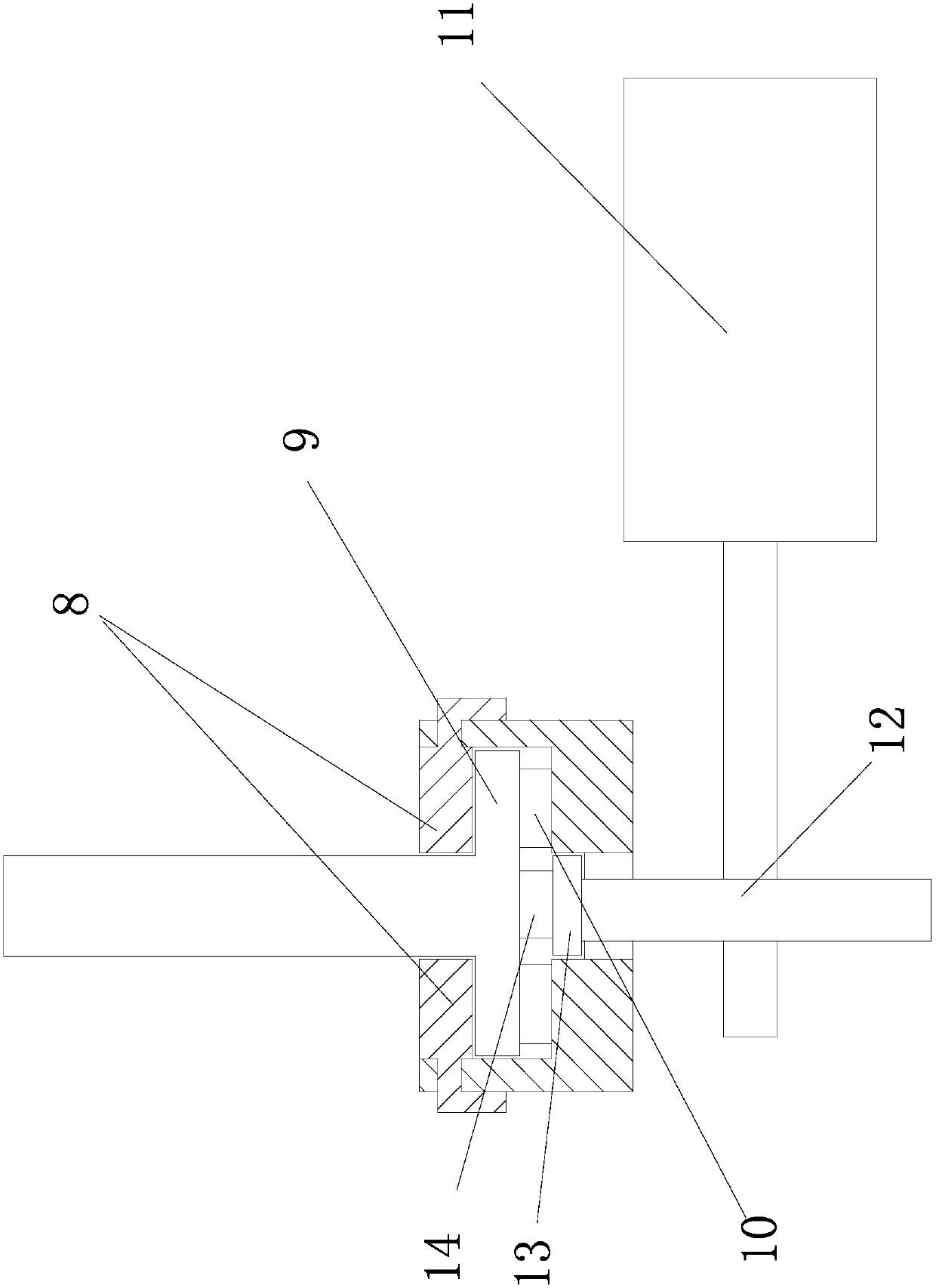

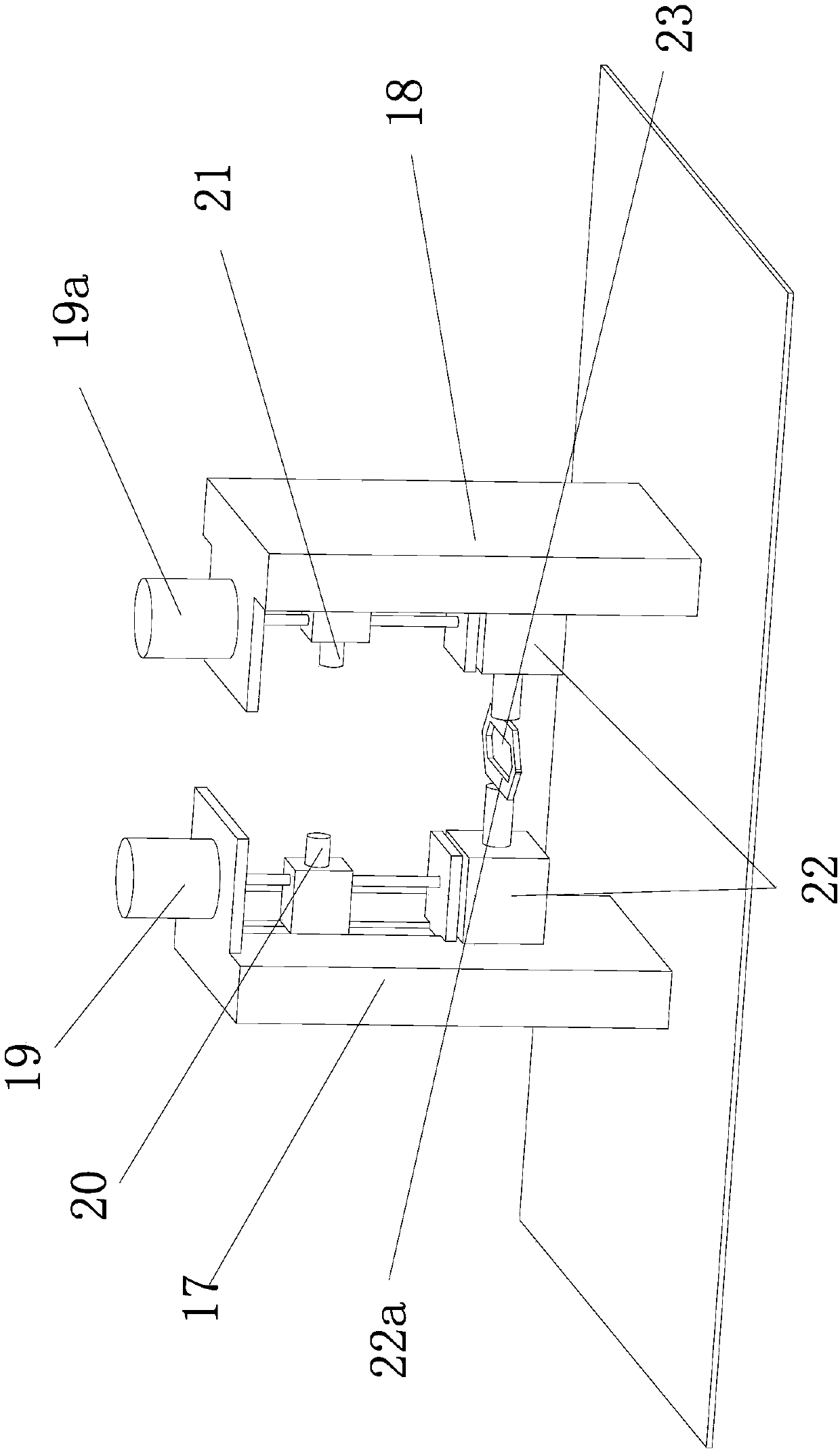

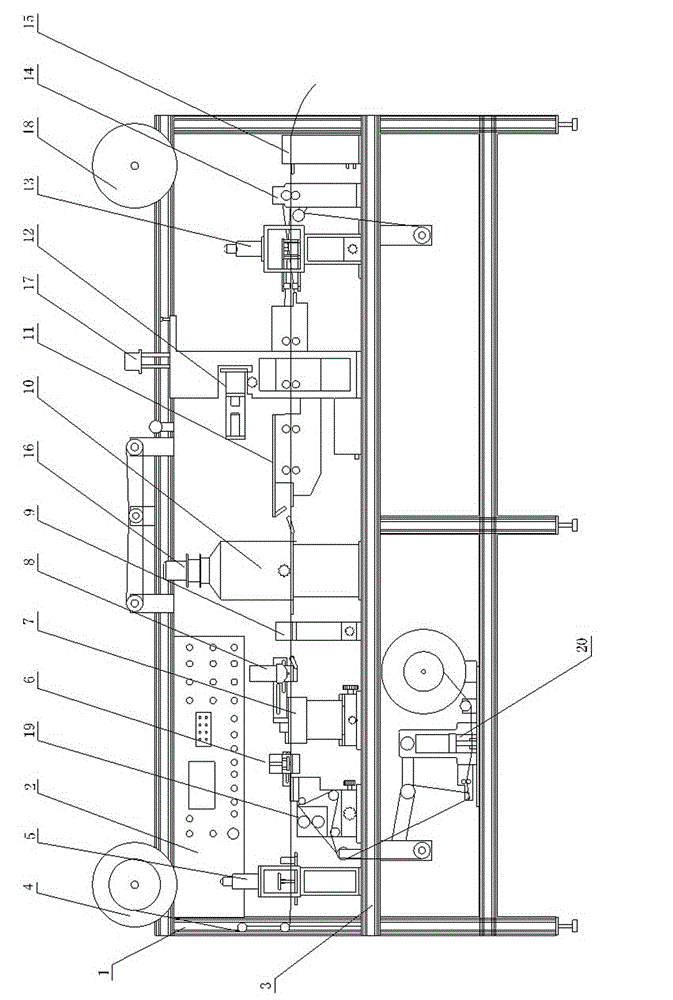

Paper money and coin sorting machine

InactiveCN105513200ASave productivityImprove labor productivityCoin/paper handlersCentrifugationEconomic benefits

The invention relates to the technical field of paper money and coin sorting automation, in particular to a paper money and coin sorting machine. The paper money and coin sorting machine comprises a main rack, a coin feeding part, a paper money sorting part, a coin sorting centrifugation part and a coin sorting guide groove part, wherein the coin feeding part, the paper money sorting part, the coin sorting centrifugation part and the coin sorting guide groove part are installed on the main rack. The paper money sorting part is communicated with the side face of the coin feeding part, the bottom of the coin feeding part is connected with the coin sorting centrifugation part, and the coin sorting centrifugation part is connected with the coin sorting guide groove part. According to the paper money and coin sorting machine, full-automatic design is adopted, paper money and coins can be sorted, the coins of different face values are sorted, previous labor force is changed, productivity is saved, labor productivity is improved, cost is reduced, and great economic benefits are acquired.

Owner:陈金钟

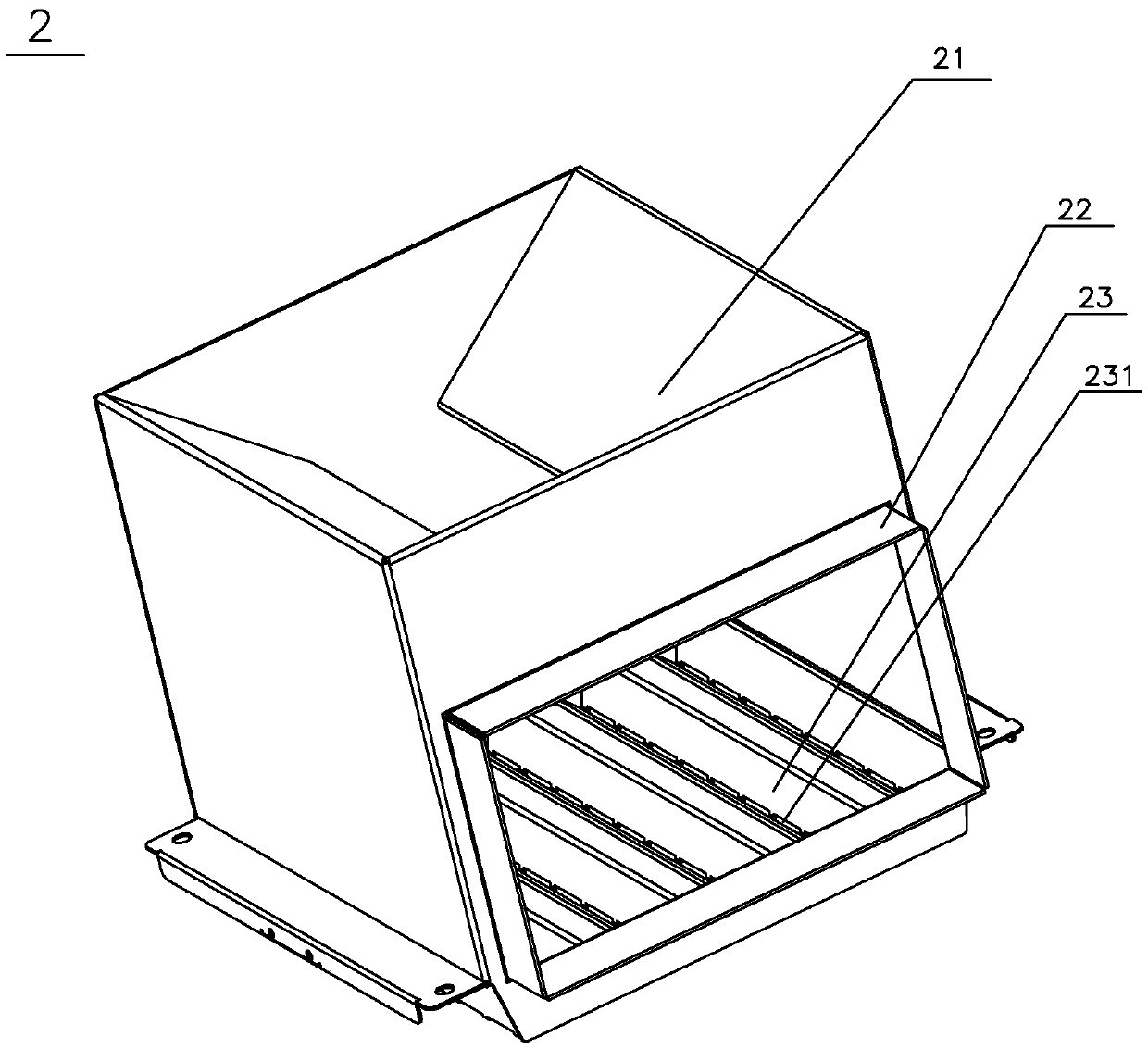

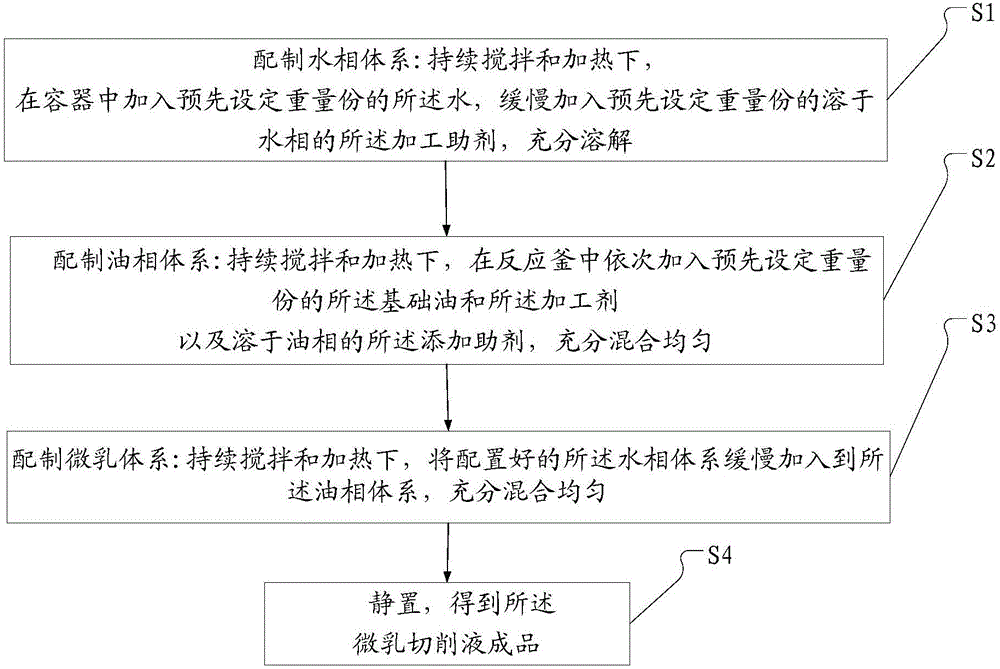

Micro-emulsion cutting fluid and preparation technology thereof

InactiveCN106281630AImprove heat transfer performanceEasy to cleanLubricant compositionProcedure AgentsEngineering

The invention discloses micro-emulsion cutting fluid and a preparation technology thereof. The micro-emulsion cutting fluid is prepared from 35-50 parts of a liquid-phase carrier, 8-15 parts of base oil, additives which include 15-25 parts of an antirust agent, 10-20 parts of a lubricant, 5-8 parts of a non-ionic surface active agent and 0.1-0.2 part of nanometer anti-mildew bactericide and processing aids. The preparation technology of the micro-emulsion cutting fluid comprises the steps of preparing a water phase system, and dissolving water and the processing aids dissolved into a water phase; preparing an oil phase system, and mixing the base oil and the additives and the processing aids dissolved into an oil phase; preparing a micro-emulsion system, slowly adding the prepared water phase system into the oil phase system, and mixing the mixture to be uniform; performing standing, and obtaining the finished micro-emulsion cutting fluid. The micro-emulsion cutting fluid is good in heat transfer performance, good in lubricating performance, not likely to be mildewed or sedimented or layered, and capable of reducing environmental pollution; meanwhile, the preparation method is simple and convenient and low in cost, simplifies production procedures and saves the cost.

Owner:NANTONG KEXING CHEM

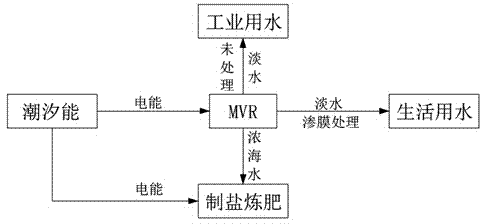

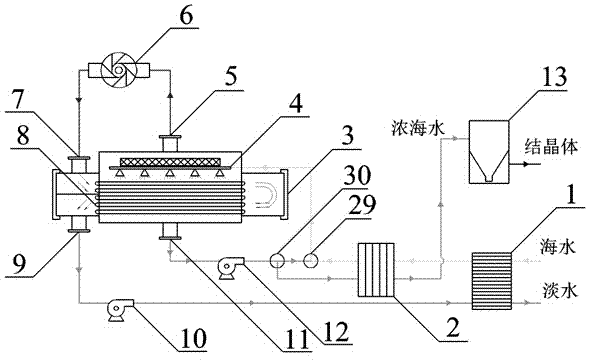

Tidal energy, solar energy, and mechanical vapor recompression integrated seawater desalination system

InactiveCN104773779AReduce electricity consumptionIncrease costGeneral water supply conservationSeawater treatmentThermal energyPower station

The invention belongs to the technical field of seawater desalination, and especially relates to an integrated seawater desalination system, which utilizes the tidal energy and solar energy to generate power to drive a mechanical vapor recompression seawater desalination comprehensive utilization device to produce fresh water and refine salt-containing minerals. The system comprises a tidal energy power generation system, a solar energy power generation system, and an MVR evaporation system. The tidal energy power generation system is a tidal energy power station, which supply power to the system. The solar energy power generation system is a solar plate-type pre-heater, which can absorb the optical energy and convert the optical energy into electric energy and thermal energy, supplies power to the system, and preheats seawater in the pipes of the preheater. The MVR evaporation system is used to condense and desalinate the seawater.

Owner:SHENYANG AEROSPACE UNIVERSITY

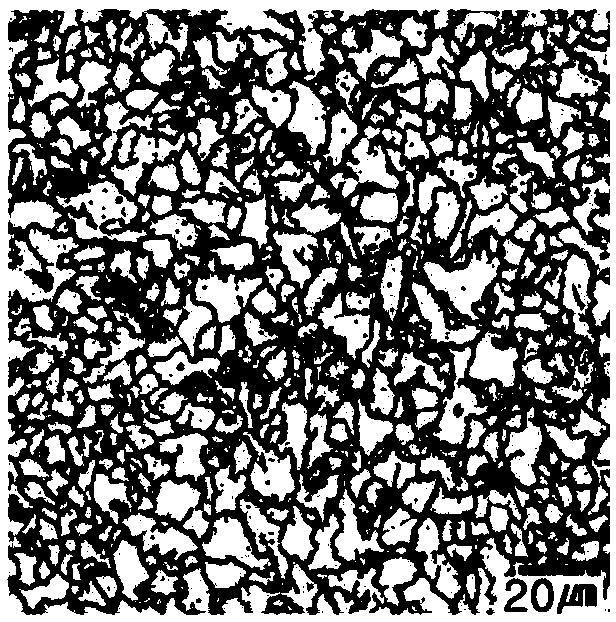

Hot Rolled Steel Plate Which Has Low Errors In Material And Thickness And Has Excellent Resistance Of Electroplating Stripping And The Manufacturing Method Thereof

ActiveCN103882343ASmall materialSmall thicknessHot-dipping/immersion processesFurnace typesProduction rateSheet steel

The present invention relates to a hot rolled steel plate which has low errors in material and thickness and has excellent resistance of electroplating stripping and the manufacturing method thereof. The present invention provides the hot rolled steel plate including the C, Mn, Si, Al, P, S, Cu, Sb, B, N, Ti, Nb foreign element Cr, Ni, Mo, Sn, remainder of Fe and other inevitable impurities, the contents thereof are described in the instruction. The present invention also provides the manufacturing method of the hot rolled steel plate. According to the present invention, scrap iron can be used for making the hot rolled steel plate to improve the reusing resources and to save the energy and productivity, the hot rolled steel plate fused and galvanized can be also used for a molten zinc hot rolled steel plate.

Owner:浦项股份有限公司

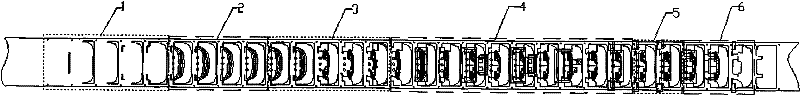

Sock packer

ActiveCN107776944AAvoid violent collisionsSave productivityLabelling deformable materialsSortingSOCKSBiochemical engineering

The invention provides a sock packer, belongs to the technical field of machinery and solves the technical problems of low efficiency and the like in prior sock packing. The sock packer comprises a rack and is characterized in that a first rail and a second rail which are in closed circulation are fixed on the rack, a first gap is formed between one end of the first rail and one end of the secondrail, a second gap is formed between the other end of the first rail and the other end of the second rail, and the second gap is smaller than the first gap; a first guide groove is formed in the firstrail, a first through hole communicated with the first guide groove is formed in the lower part of the first rail, a second guide groove is formed in the second rail, and a second through hole communicated with the second guide groove is formed in the lower part of the second rail. The sock packer has the advantage that socks are packed automatically and efficiently.

Owner:全椒县瑞祥工艺品有限公司

Method for raising fishes in paddy field

InactiveCN105706963AImprove hygieneIncrease incomeClimate change adaptationPisciculture and aquariaWater sourceCommon carp

The invention belongs to the technical field of agricultural ecology and particularly relates to a method for raising fishes in a paddy field. The method comprises the following steps: A, selecting a piece of paddy field: selecting the field with clean water, sufficient water source, convenient irrigation and drainage, good water and fertility retention performance and no drought and flood influence; B, rearranging the piece of paddy field: digging a fish ditch with the depth of 50-80cm and the width of 50-100cm; digging a fish pit with the depth of 1-1.5m and the area accounting for 5-8% of that of the paddy field; connecting the fish ditch with the fish pit; heightening and reinforcing a ridge; forming a water inlet and a water outlet in the corresponding corners of the paddy field; C, raising the fishes: starting to throw fingerlings after rice seedlings turn green 7-15 days after seedling transplantation, wherein the fingerlings are thrown according to a quantity ratio of grass carp to common carp to golden carp of 1 to 1 to 1 and 10-20kg of the fingerlings are thrown per mu; and D, performing raising management. The method is easy to implement and high in fish yield per mu.

Owner:重庆市富友畜禽养殖有限公司

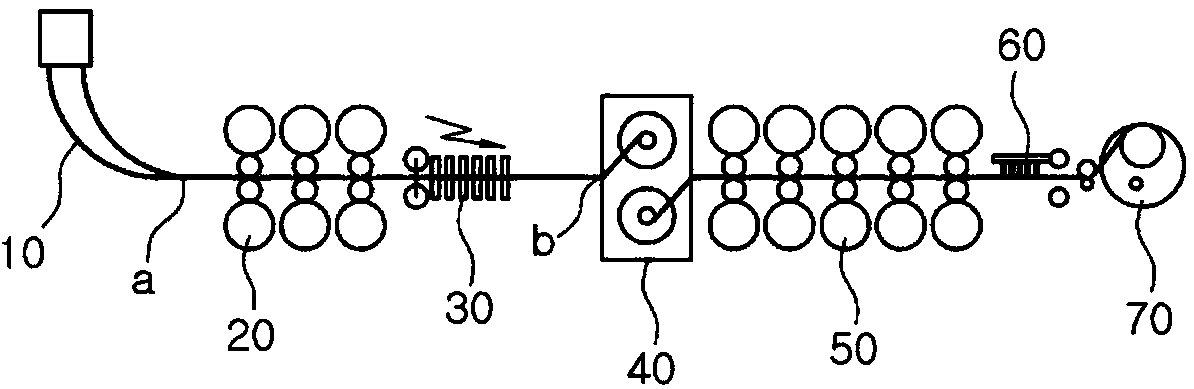

Disposable electrocardio-electrode combining machine

The invention relates to a disposable electrocardio-electrode combining machine. The disposable electrocardio-electrode combining machine is characterized by comprising a frame, a control panel and a working platform, wherein the working platform is positioned in the middle of the frame; a substrate material placing device is arranged at the upper part of one end of the frame; the control panel is arranged on one side of the upper part of the frame; a core punching mechanism a, a trademark combining device, a core punching mechanism b, a button feeding device, an electrifying device, an adhesive dispensing mechanism, an ultraviolet cover shell, a material feeding mechanism, a plastic uptake device, a shape cutting mechanism, a material collecting frame and a cut-off mechanism are arranged on the working platform in sequence from left to right; a fan is arranged at the upper part of the ultraviolet cover shell; a nail rounding mechanism is arranged at the upper part of the plastic uptake device; and a film material placing plate is arranged at the upper part of the other end of the frame. The disposable electrocardio-electrode combining machine provided by the invention has the advantages as follows: the automation degree of the disposable electrocardio-electrode combining machine is high; the combination of the whole disposable electrocardio-electrode sheet can be finished on one production line, so that convenience in operation is realized and the working efficiency is greatly increased; and various disposable electrocardio-electrode sheets with different styles can be made according to needs of customers.

Owner:茅惠杰

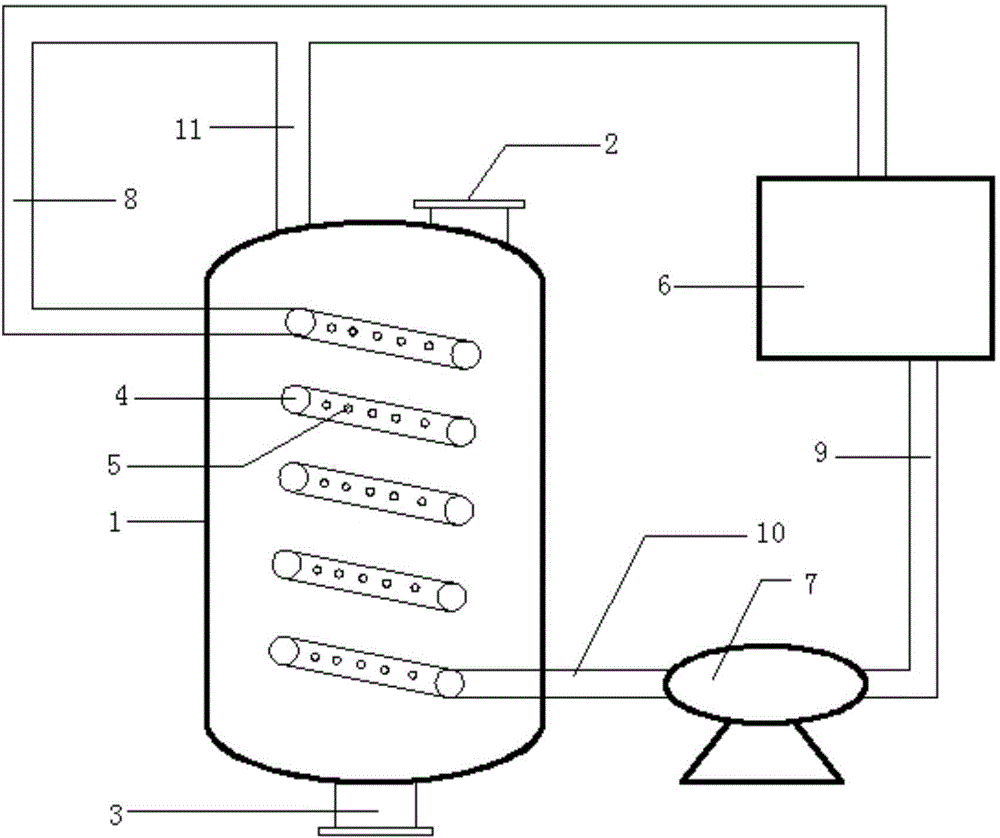

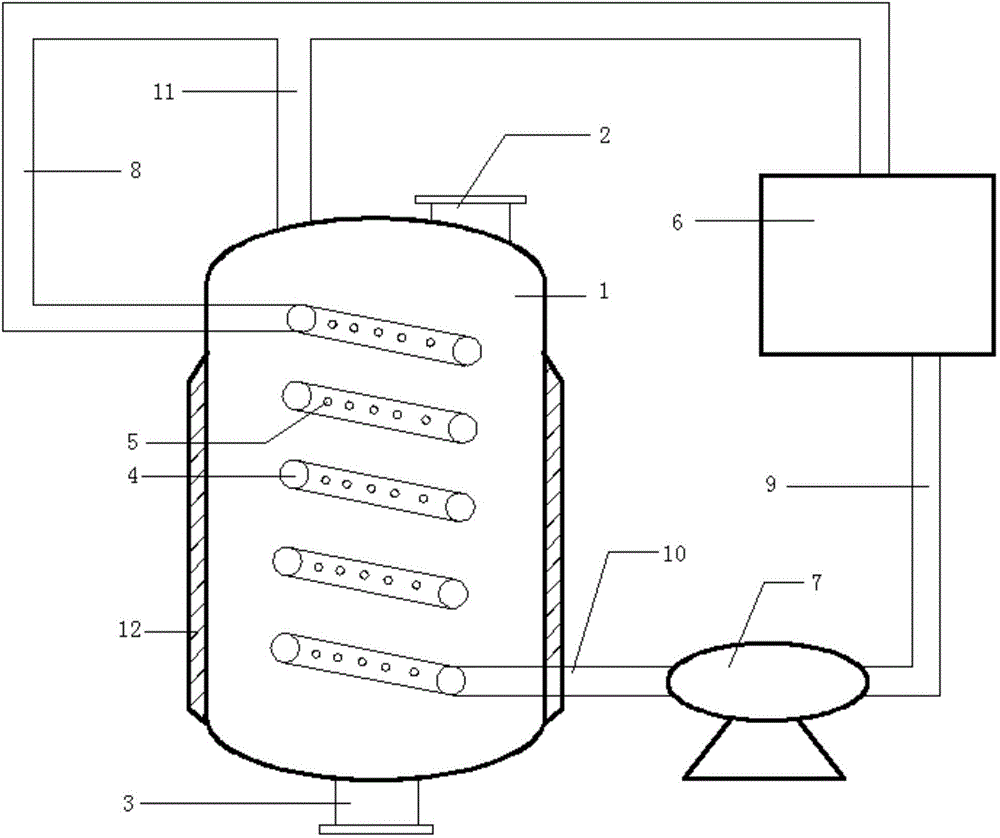

Gas stirring tank easy to heat and stirring method

InactiveCN104525032AEasy to controlRealize intermittent blowingTransportation and packagingMixer accessoriesUnit operationEngineering

The invention relates to a gas stirring tank easy to heat and a stirring method. The gas stirring tank comprises a stirring tank body, a heating furnace, and a blower device for intermittent blowing the stirring tank body; a feed inlet is disposed at the top end of the stirring tank body; a discharge port is disposed at the bottom end of the stirring tank body; a coil pipe is uniformly disposed inside the stirring tank from bottom to top; blowholes are uniformly disposed on the coil pipe; an outlet of the coil pipe is connected with the heating furnace through a first connecting pipe; the heating furnace is connected with the blower device through a second connecting pipe; the blower device is connected with an inlet of the coil pipe through a third connecting pipe; the top end of the stirring tank body is communicated with the first connecting pipe through a fourth connecting pipe. The gas stirring tank of the invention realizes stirring and heating processes simultaneously, saves unit operation, and saves production land occupation and production equipment; the gas stirring tank has a simple structure, needs no stirring motor or stirring paddle, and is convenient to operate.

Owner:SHANDONG JIN ZELI ENERGY TECH

Preparation method for 2-chloro-4-nitroaniline

ActiveCN101343232AImprove qualityLow costOrganic compound preparationAmino compound preparationWastewaterP-Nitroaniline

The invention relates to a preparation method of o-chloro-p-nitroaniline, which takes p-nitroaniline as a raw material, and prepares the o-chloro-p-nitroaniline by directly inputting chlorine gas for implementing the chlorination reaction in a diluted hydrochloric acid medium with a temperature of between -20 and 10 DEG C, wherein, the p-nitroaniline and the input chlorine gas are present in a molar ratio of 1:1-1.1. The preparation method can prepare the o-chloro-p-nitroaniline with best quality, and has advantages of simple process, high yield, low production cost and non wastewater discharge.

Owner:苏州市罗森助剂有限公司

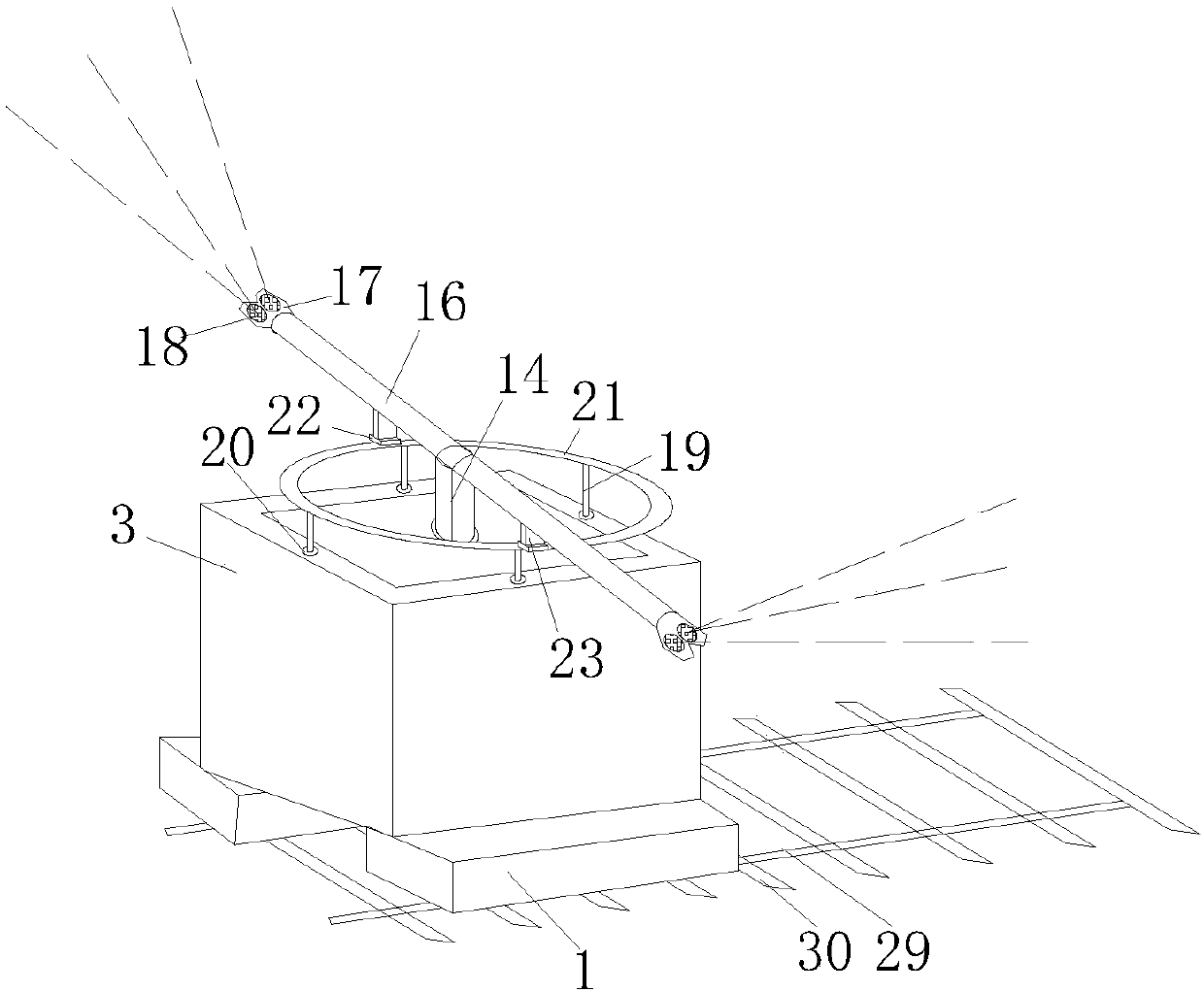

Rail walking type agricultural irrigation device

InactiveCN107736236ASave productivityImprove irrigation efficiencyWatering devicesCultivating equipmentsFixed bearingAgricultural irrigation

The invention discloses a rail walking type agricultural irrigation device. The device comprises a base, wherein rollers are arranged on two sides of the base, an irrigation work box is arranged on the base, a motor supporting plate is arranged on the right side wall of the irrigation work box, the motor supporting plate is welded to the right side wall of a first fixed bearing, and a motor is arranged on the motor supporting plate; the output end of the upper side of the motor is coaxially connected with a first gear, the first gear is meshed with a second gear arranged on the left side of the first gear, the lower end of the second gear is coaxially connected with a connection shaft, the connection shaft penetrates through the first fixed bearing and a second fixed bearing on the bottomwall of the irrigation work box, and the bottom of the connection shaft extends into the base and is connected with a driving device in the base. Full-automatic irrigation can be carried out through the irrigation device without manual operation, unnecessary productivity is saved, and the irrigation efficiency is improved.

Owner:佛山杰致信息科技有限公司

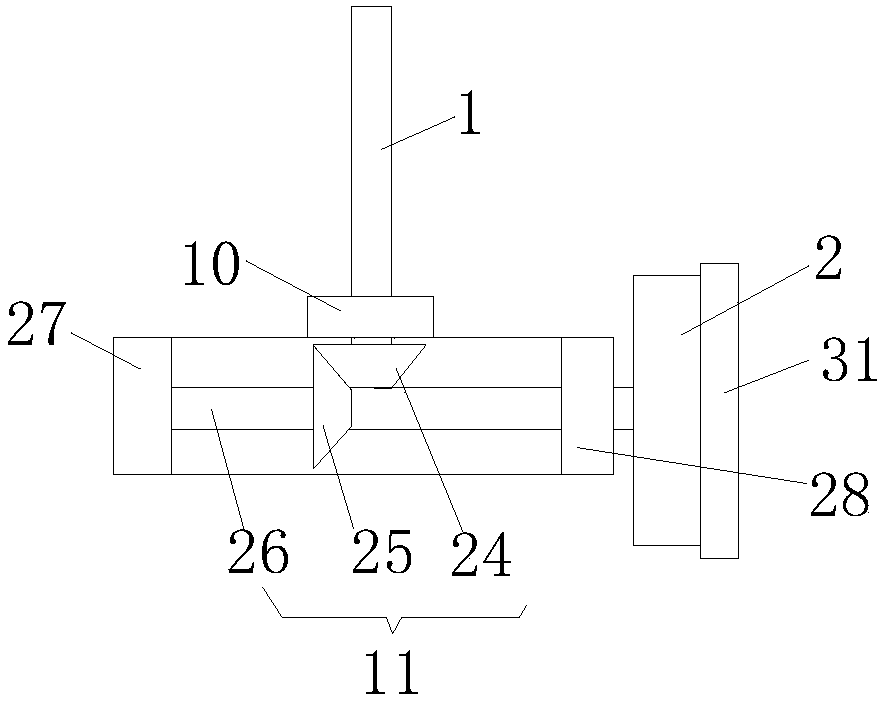

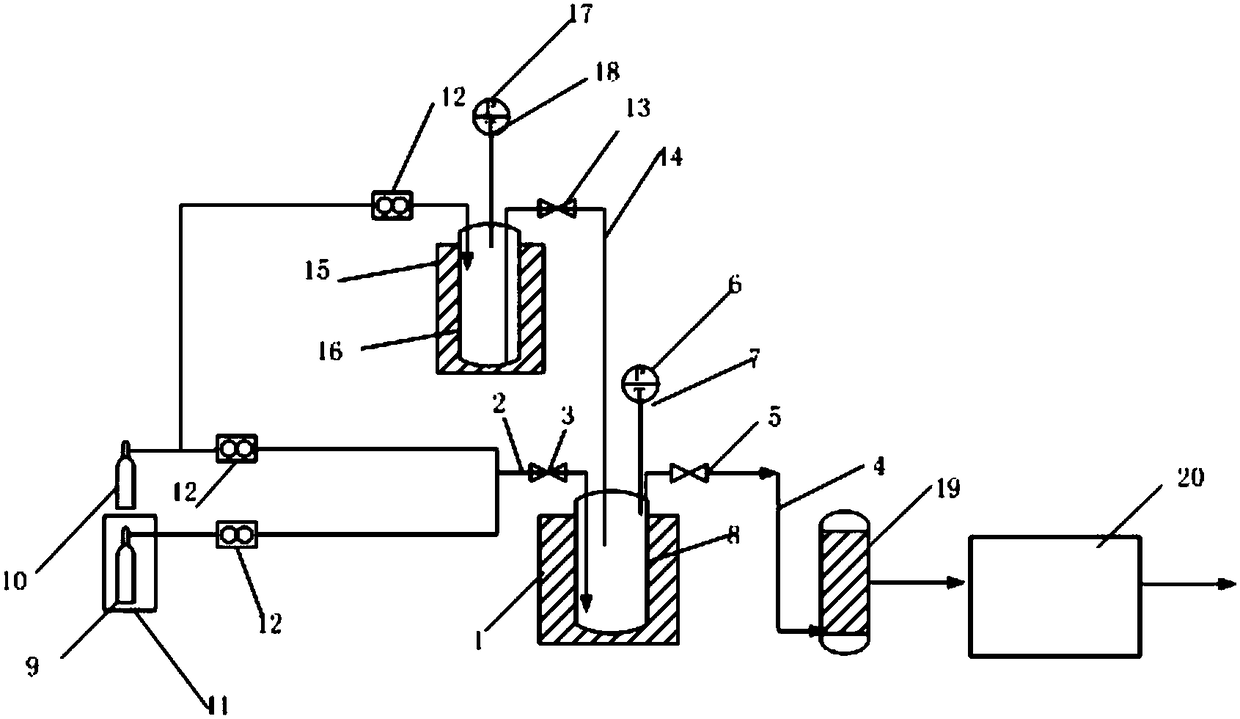

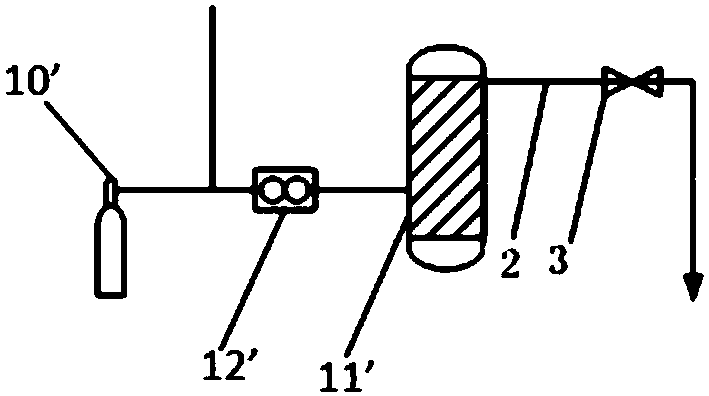

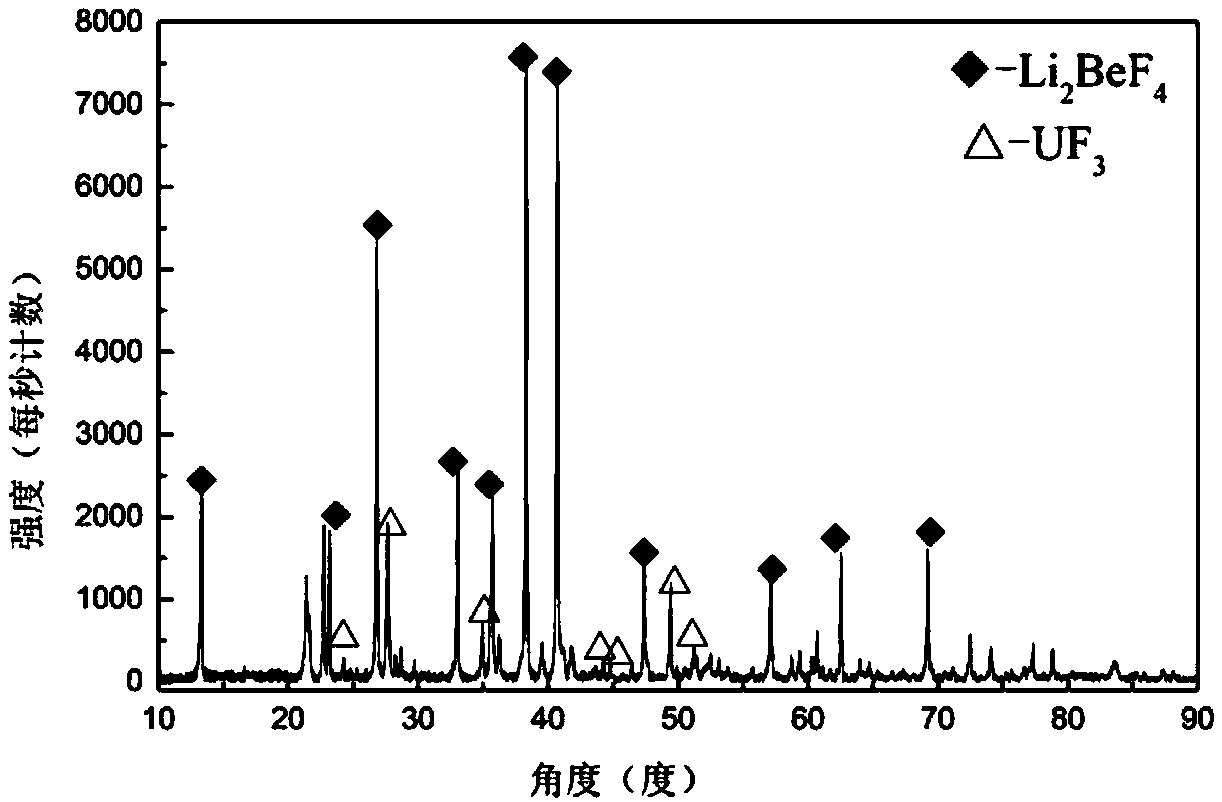

Device and method for preparing fuel salt of molten salt reactor

ActiveCN108109710AEasy to produceSimple processNuclear energy generationReactors manufactureGas supply equipmentEngineering

The invention relates to a device for preparing fuel salt of a molten salt reactor. The device comprises a gas supply system and a tail gas treatment system which are connected with a reaction system,wherein the reaction system comprises a reaction kettle containing reducing metal and a reaction heating furnace used for heating the reaction kettle; the gas supply system comprises gas supply equipment supplying inert gas and / or UF6gas into the reaction kettle; and the tail gas treatment system comprises treatment equipment for absorbing excess UF6 gas and tail gas in the reaction kettle. The invention further provides a method for preparing fuel salt of the molten salt reactor through the device. The device directly reduces UF6 in molten salt to prepare UF3 and / or UF4 to obtain fuel salt,simplifies the production process of molten salt, and has the advantages of short technical process, simple and flexible operation, no radioactive powder operation, material cost saving and energy saving.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

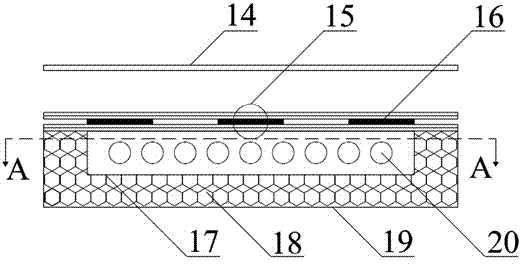

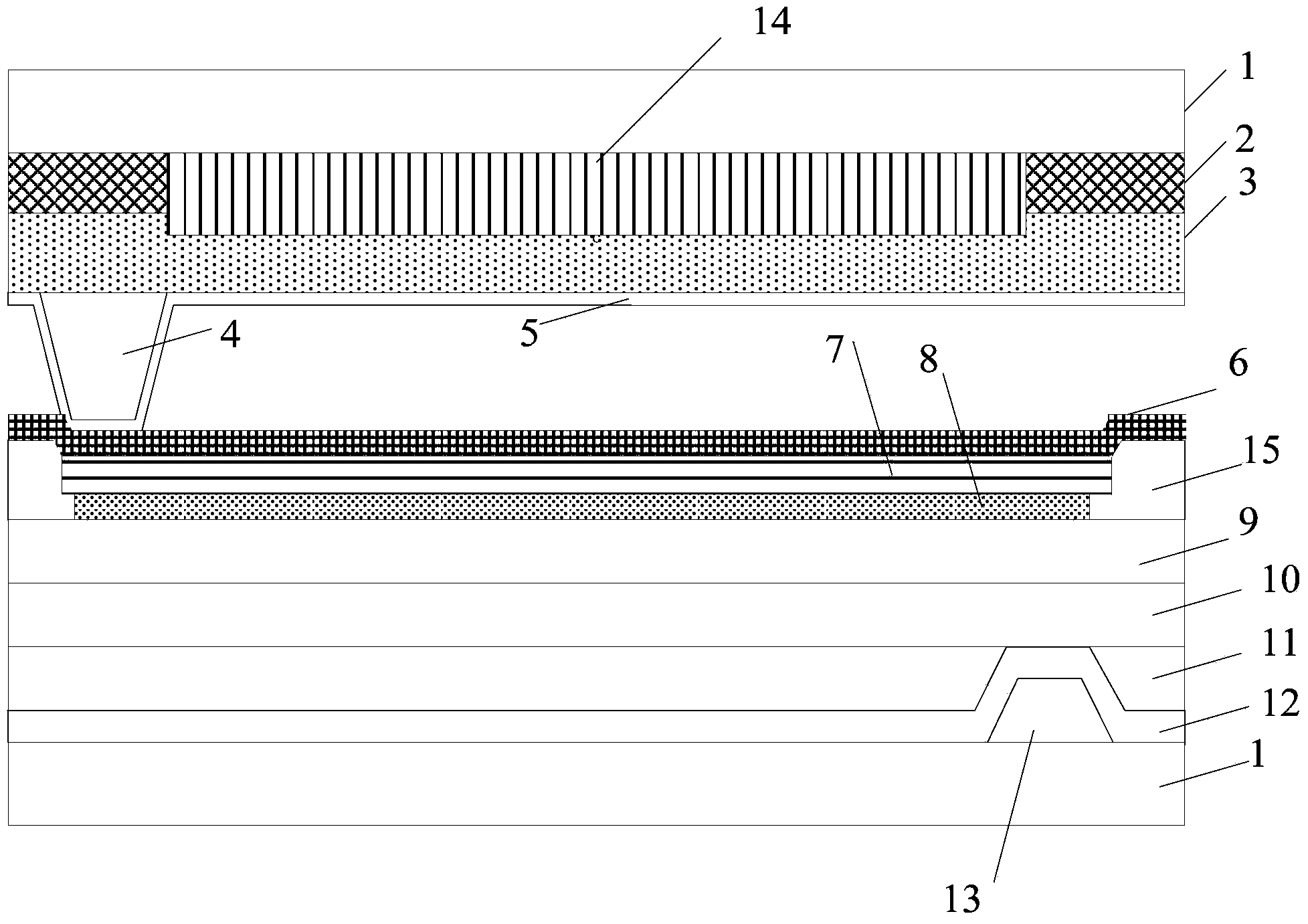

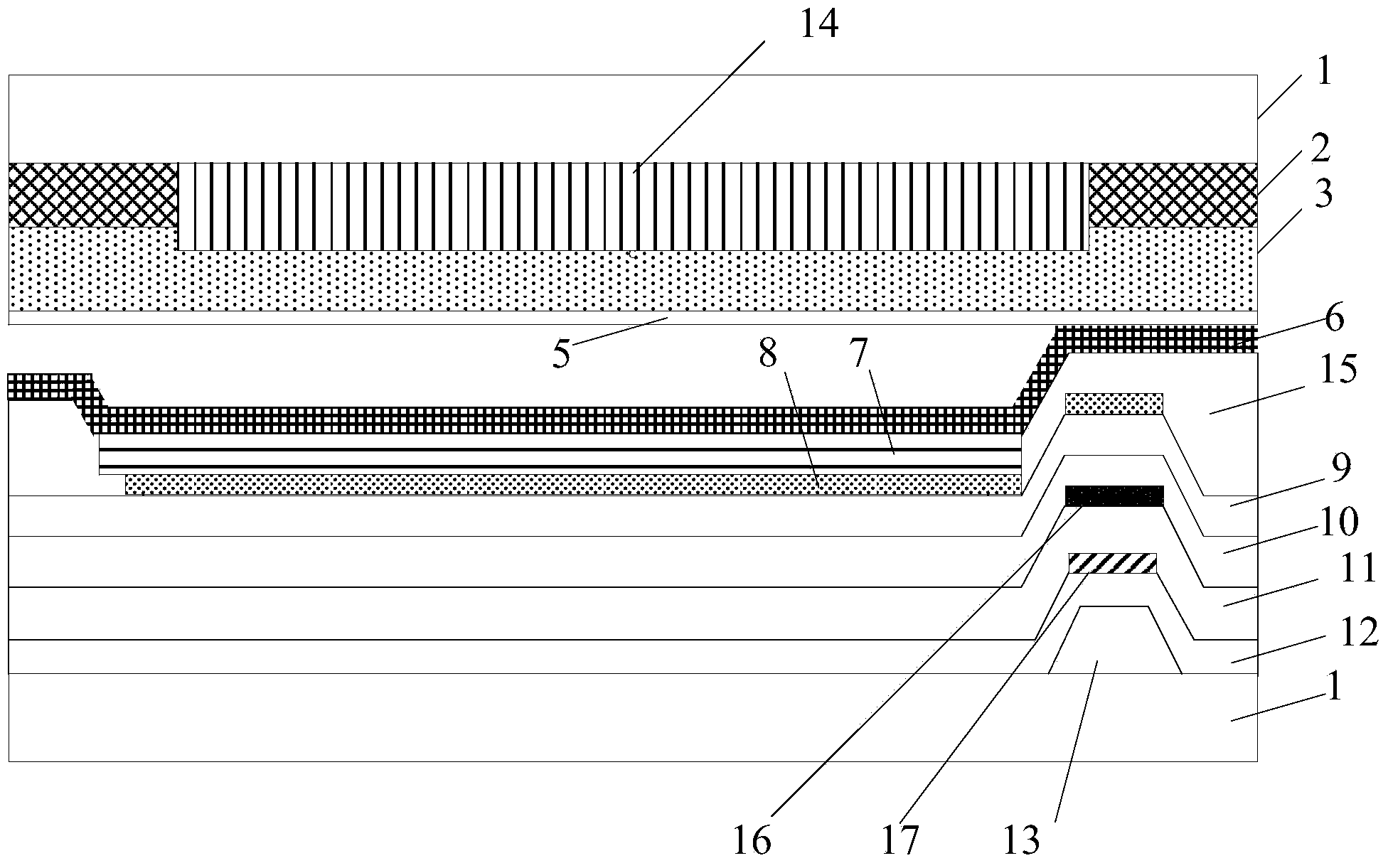

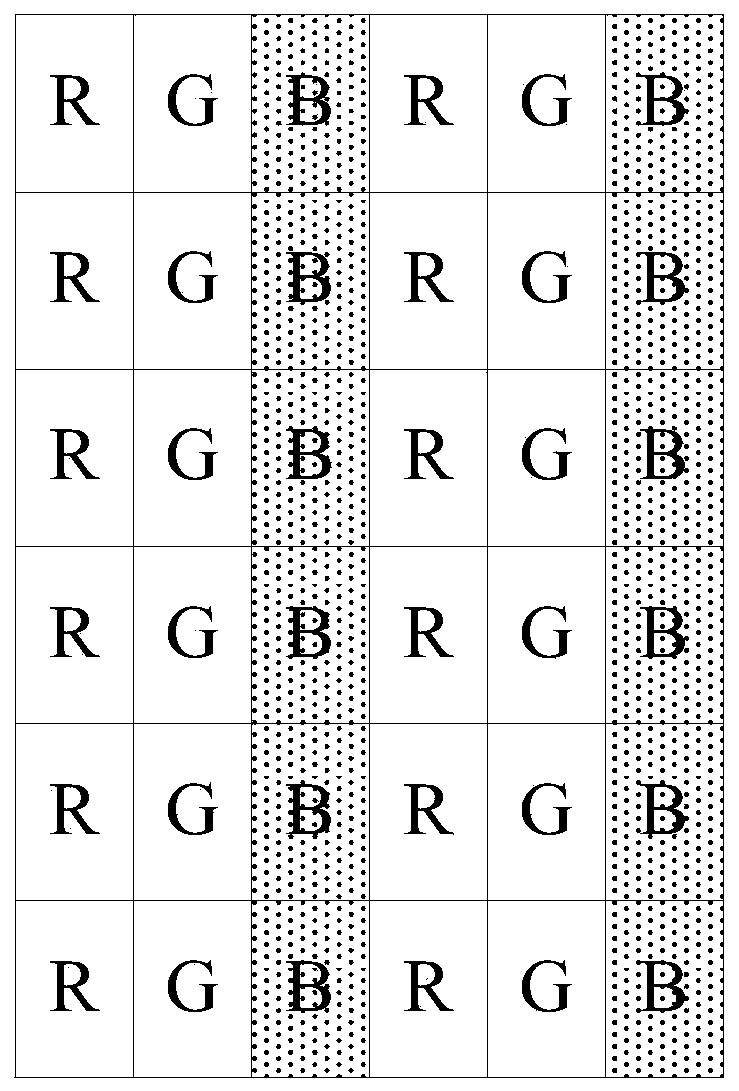

Display panel, manufacturing method thereof and display device

ActiveCN103681765ASave production timeSave productivitySolid-state devicesSemiconductor/solid-state device manufacturingManufacturing technologyDisplay device

The invention provides a display panel, a manufacturing method thereof and a display device, and belongs to the display field. The display panel comprises a colored film substrate and an array substrate opposite to the colored film substrate, wherein the colored film substrate is not provided with a spacer used for supporting the box thickness of the display panel. Protrusions used for supporting the box thickness of the display panel are arranged on the face, opposite to the colored film substrate, of the array substrate. According to the technical scheme, the manufacturing technology of the columnar spacer can be omitted, so that the production time and the production material of the display panel are saved, and the production cost of the display panel is lowered.

Owner:BOE TECH GRP CO LTD

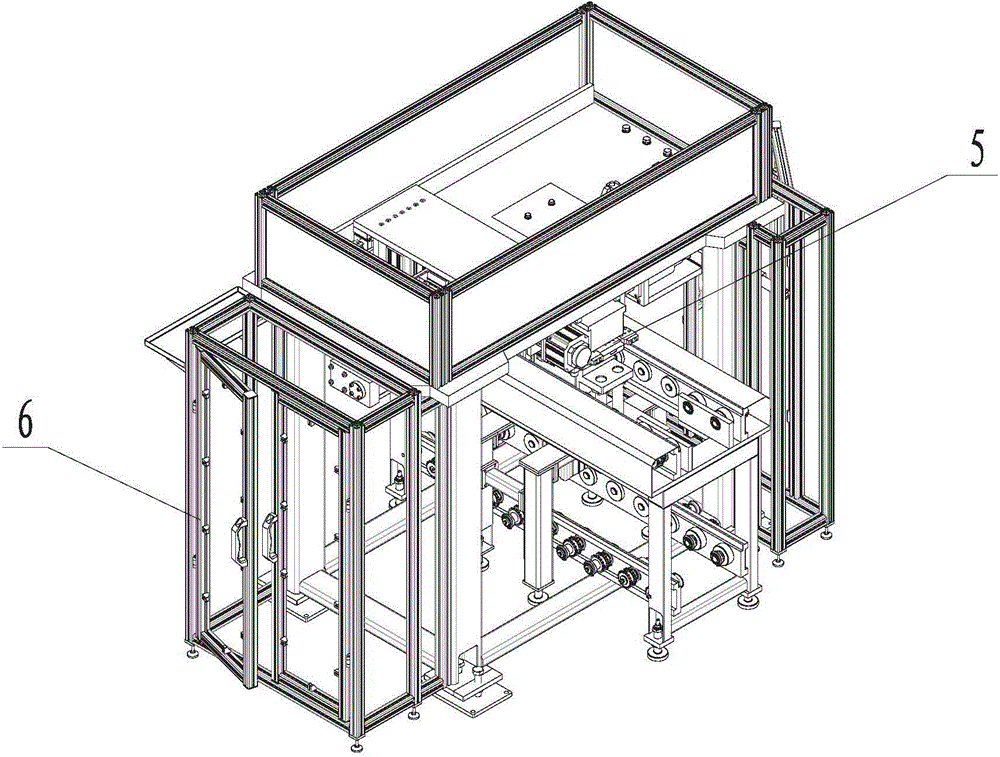

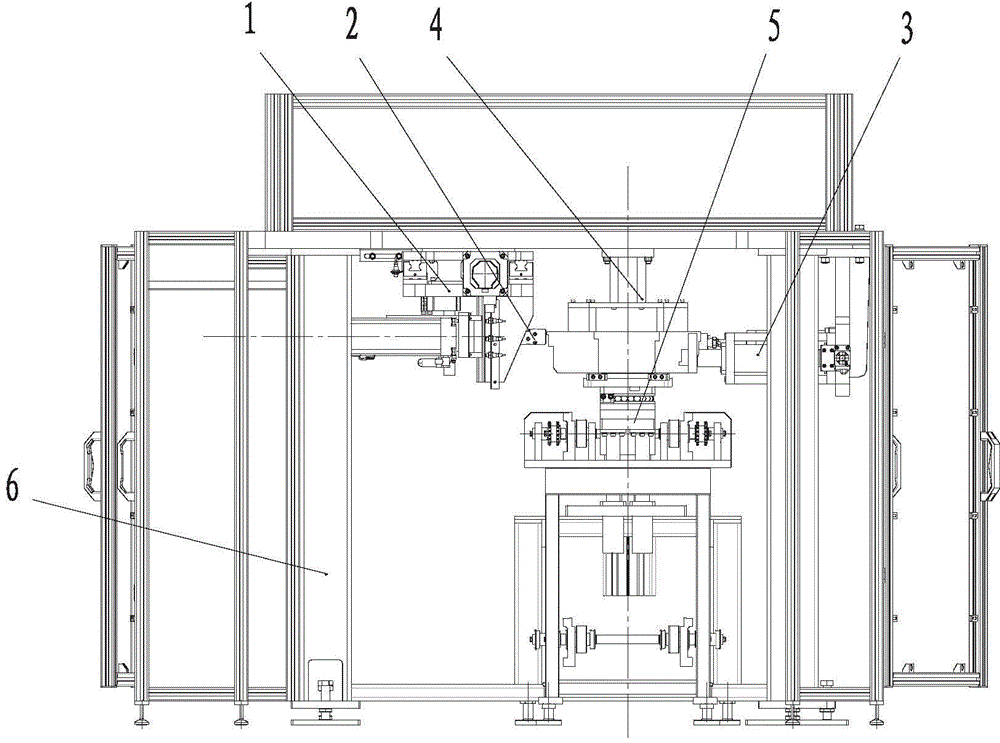

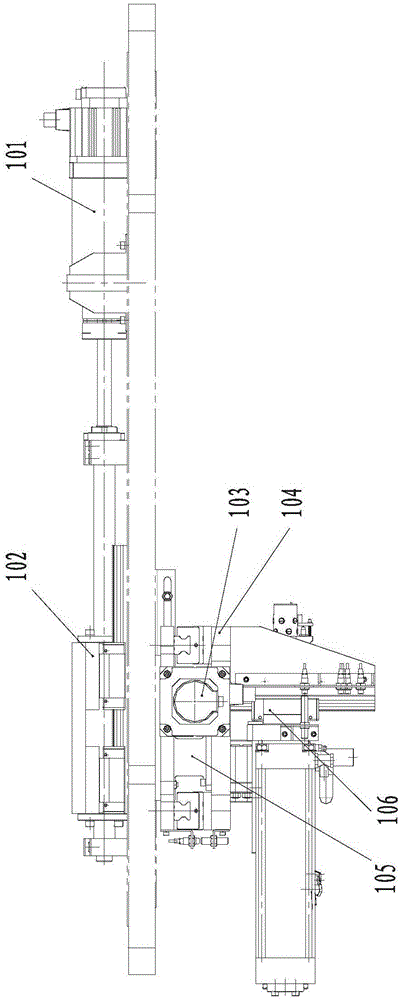

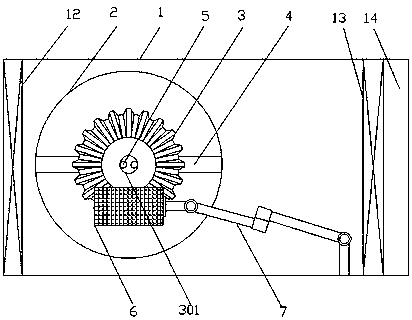

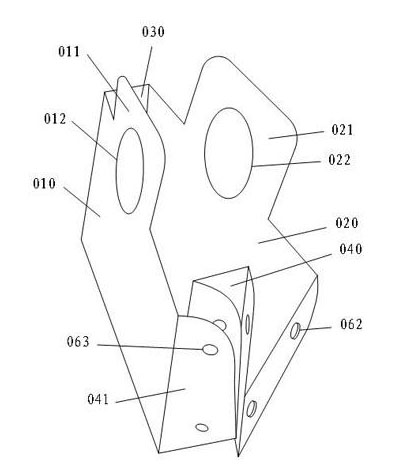

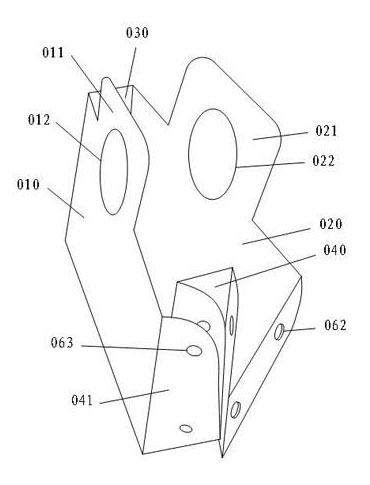

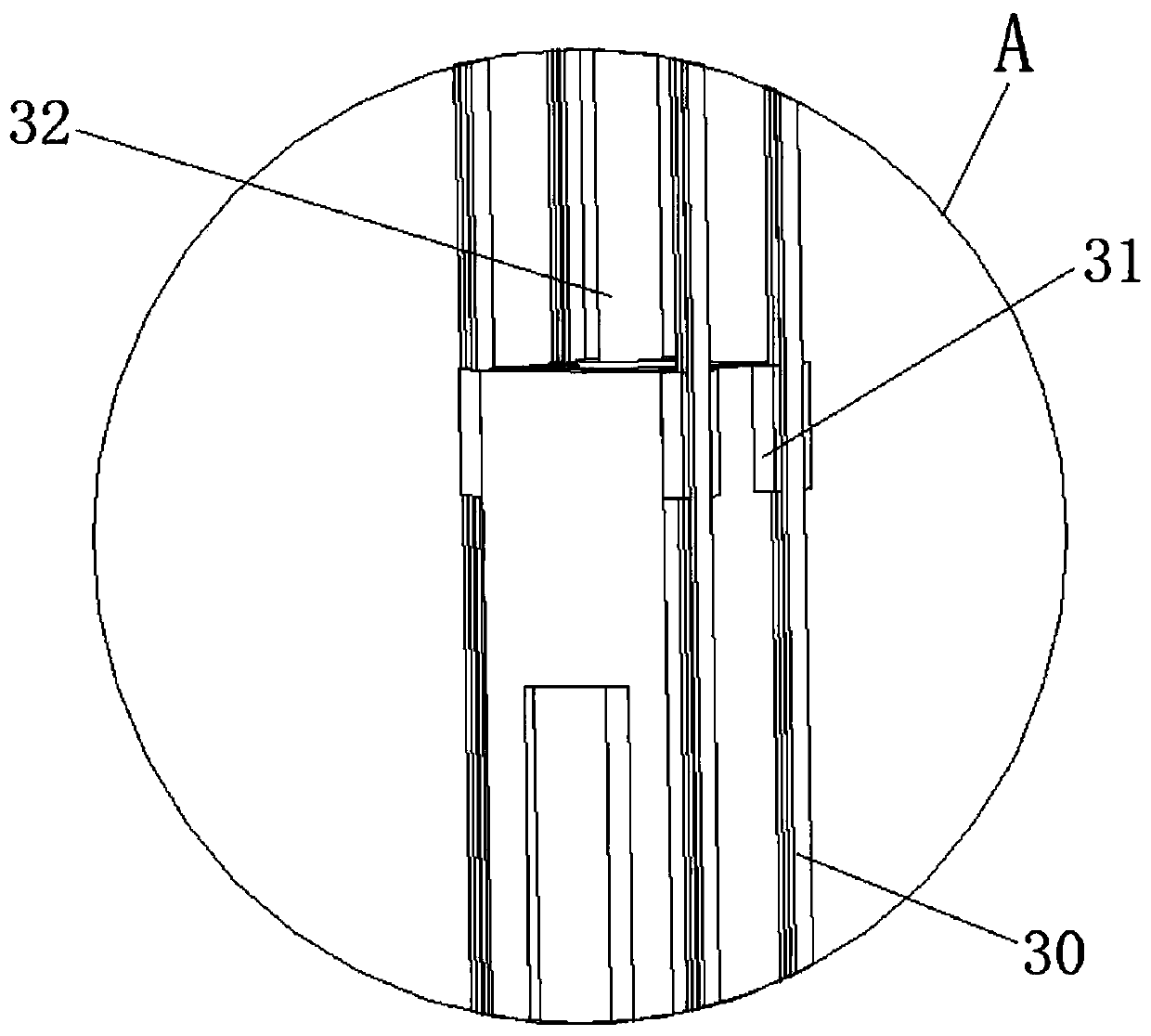

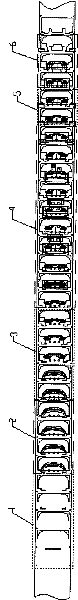

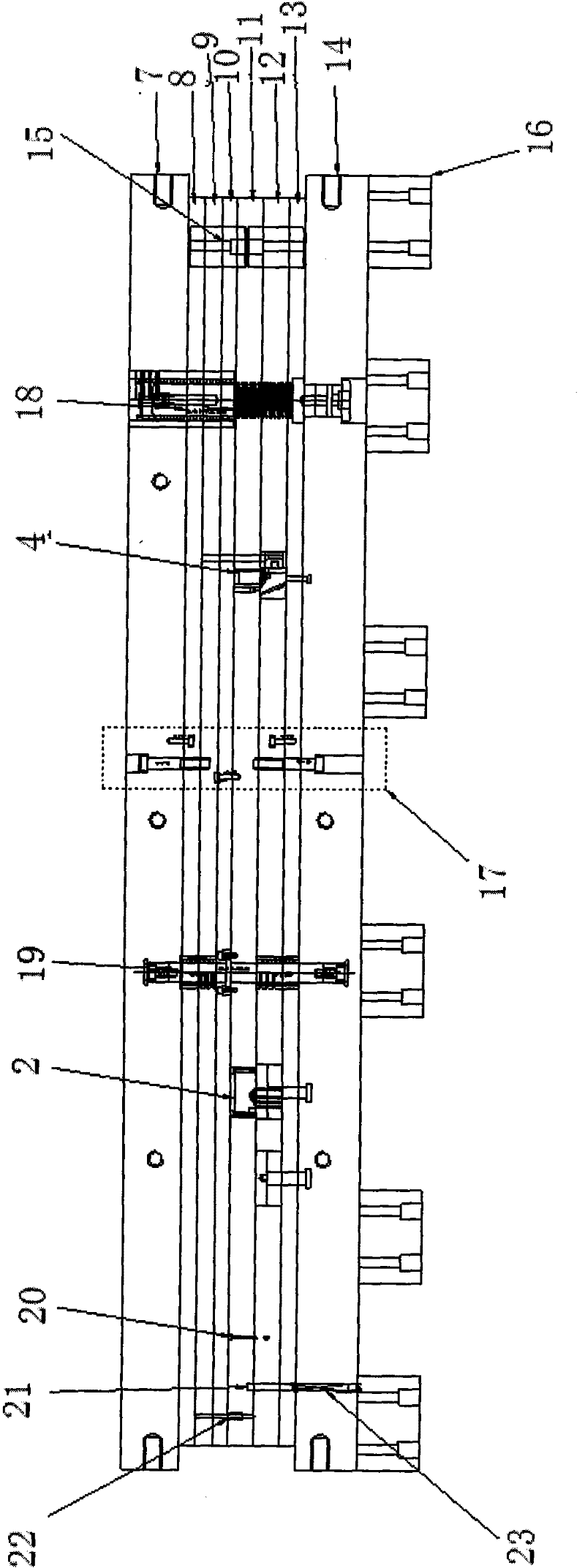

Integrated three-axis linked compound automatic pressing machine for adapter tubes

ActiveCN105583604ASolve mechanical effectsSolve take timeMetal working apparatusEngineeringPositioning system

The invention belongs to the technical field of automobile engine manufacturing, and particularly relates to an integrated three-axis linked compound automatic pressing machine for adapter tubes. The integrated three-axis linked compound automatic pressing machine comprises a machine body, and a horizontal positioning system and a vertical positioning system arranged on the machine body. The horizontal positioning system comprises an integrated three-axis positioning structure and a reverse thrust executing structure arranged on two sides of the machine body respectively. A pressing executing structure, corresponding to the reverse thrust executing structure, is arranged on the integrated three-axis positioning structure. The vertical positioning system comprises an upper limiting structure and a line body lifting structure, which are arranged at the top and bottom of the machine body respectively and correspond to each other. A workpiece to be pressed is placed on the line body lifting structure, and is lifted up by the line body lifting structure to be in contact with the upper limiting structure. The workpiece to be pressed is horizontally positioned by the integrated three-axis lined positioning structure and the reverse thrust executing structure. The integrated three-axis linked compound automatic pressing machine, provided by the invention, is a complete machine of which an integrated X, Y and Z space coordinates positioning device and a pressing mechanism work synchronously, is applicable to two straight adapter tubes and two special-shaped adapter tubes, and can complete compound pressing quickly and effectively.

Owner:中国科学院沈阳计算技术研究所有限公司

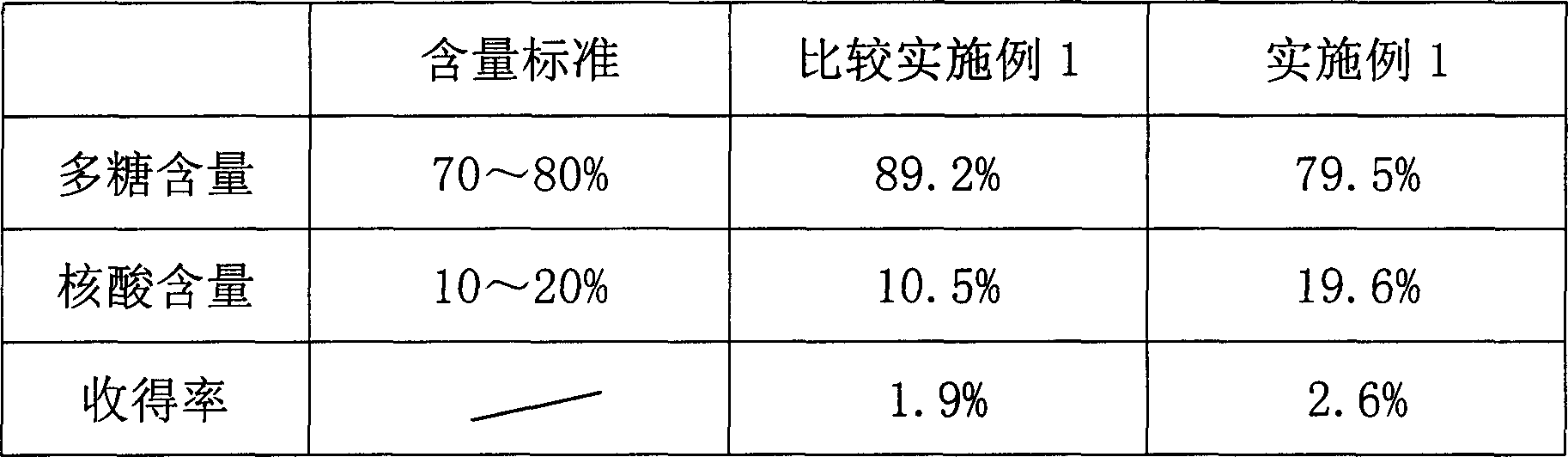

Bacterial-breaking process druing procedure of BCG acid powder polysaccharide and nucleic

ActiveCN1817910AFully contactedBacteria thoroughlySugar derivativesFermentationPolysaccharideNucleic acid

Bacterium-breaking process in preparing of Calmette-Guerin bacterium and nucleic acid primitive powder is carried out by shearing, dispersing and emulsifying. It costs low, has more nucleic acid content and better quality.

Owner:ZHEJIANG WAN SHENG PHARMA CO LTD

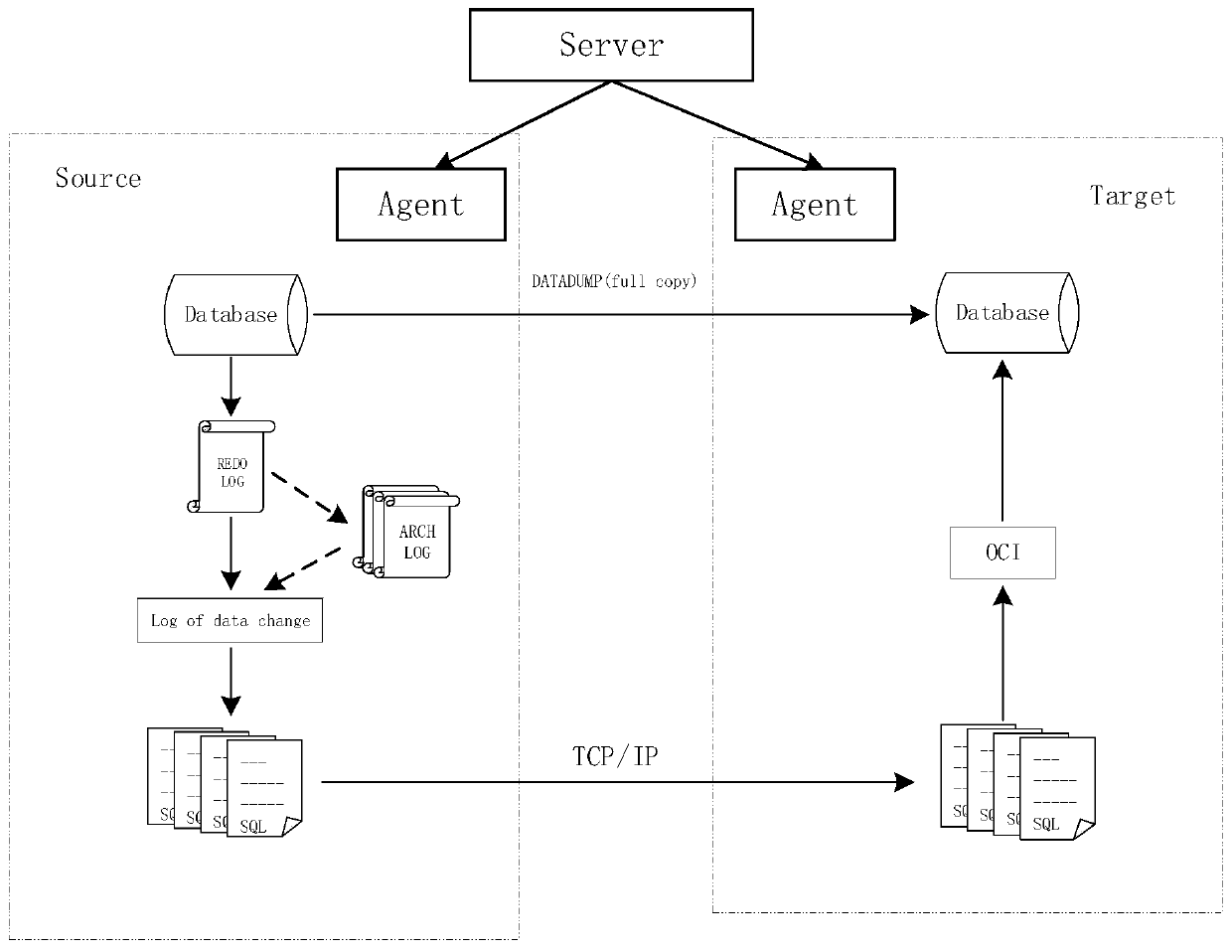

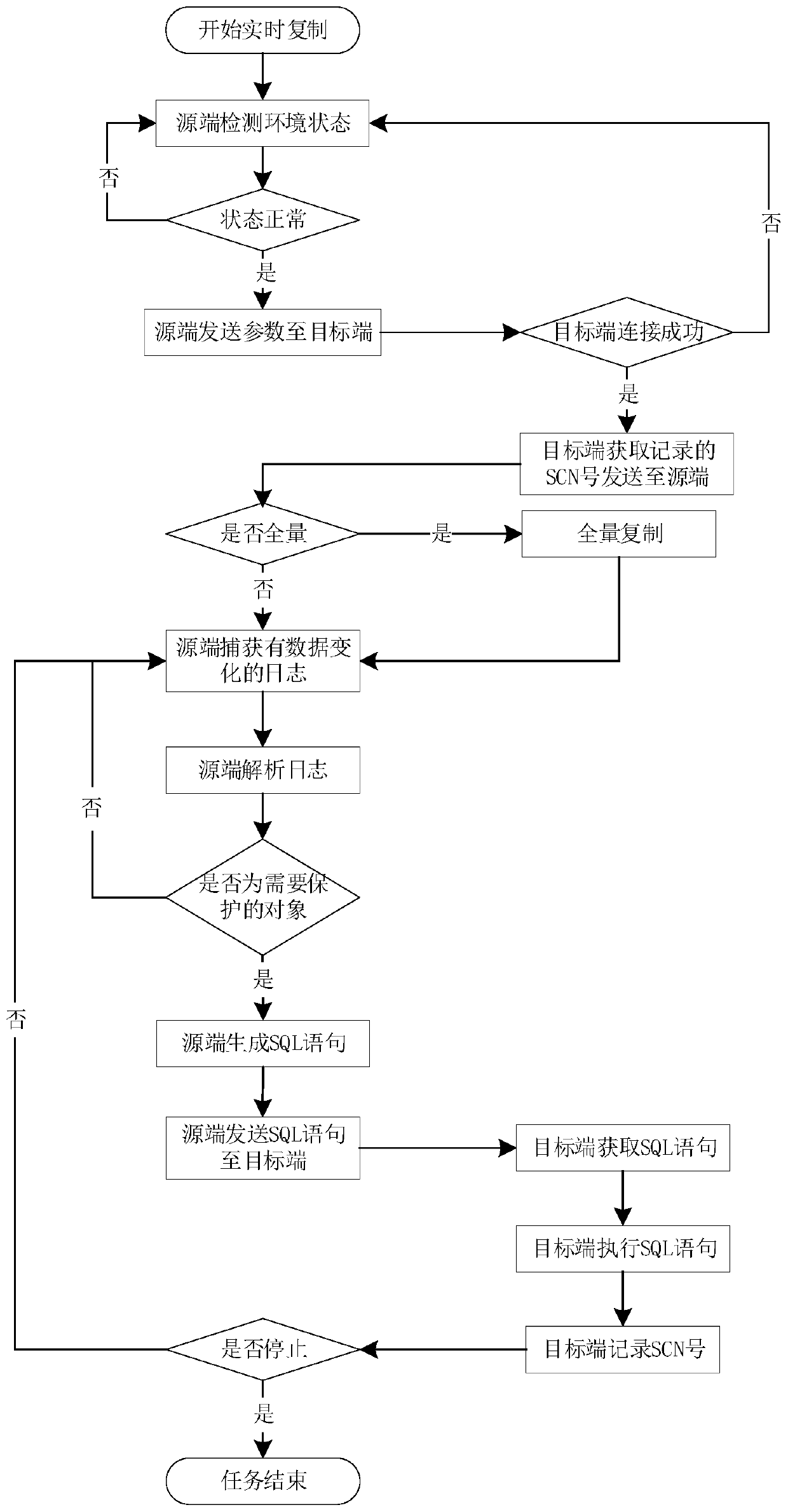

Continuous data protection system and method based on Oracle log analysis

InactiveCN111427898AEnsure consistencyGuaranteed availabilityDatabase updatingDatabase distribution/replicationLogfileOracle database

The invention relates to a continuous data protection system and method based on Oracle log analysis, which are used for protecting Oracle data and meeting the requirement scene that low RPO of a client is consistent with that of a database, and the system comprises a server and a console used as real-time copying software; the client Agent is used as an agent client for copying the software at the source end and the target end in real time; the source end Source is used as a production environment end of the user; the target end Target is used as a disaster recovery backup environment end ofthe user; the Database is used for storing the actual data of the source end Source database and the target end Target database; and the Redo log file or archived log is used for storing all operationrecords and changed data of database change. Compared with the prior art, the method has the advantages that the RPO and the RTO are close to 0, and the real-time consistency and availability of Oracle database data are guaranteed.

Owner:EISOO SOFTWARE

Method for preparing calcium carbonate from yellow phosphorus furnace slag to co-produce industrial salt and silicon gel

InactiveCN101844791AHigh market demandPollution controlCalcium/strontium/barium carbonatesSilicaSlagSilica gel

The invention relates to the technical field of chemical engineering three-waste control and utilization, in particular to a method for preparing calcium carbonate from yellow phosphorus furnace slag to co-produce industrial salt and silicon gel. The method comprises the following steps: generating calcium chloride through reaction between hydrochloric acid and calcium oxide in the yellow phosphorus furnace slag; then, carrying out reaction with sodium carbonate to obtain clear sodium chloride solution and calcium carbonate filter cake through suction filtration; obtaining the sodium silicate through the reaction between the rest silicon dioxide of the yellow phosphorus furnace slag and the sodium carbonate; and obtaining the silicon gel and the sodium chloride products through the reaction between the sodium silicate and the hydrochloric acid. The invention has the advantages of low production cost, high benefits, large market requiring amount and simple process and production equipment, and belongs to a practical treatment and utilization method. The method eliminates the chemical waste slag, controls the environment pollution, and can also create considerable economic value.

Owner:南通欣宇光肠衣有限公司

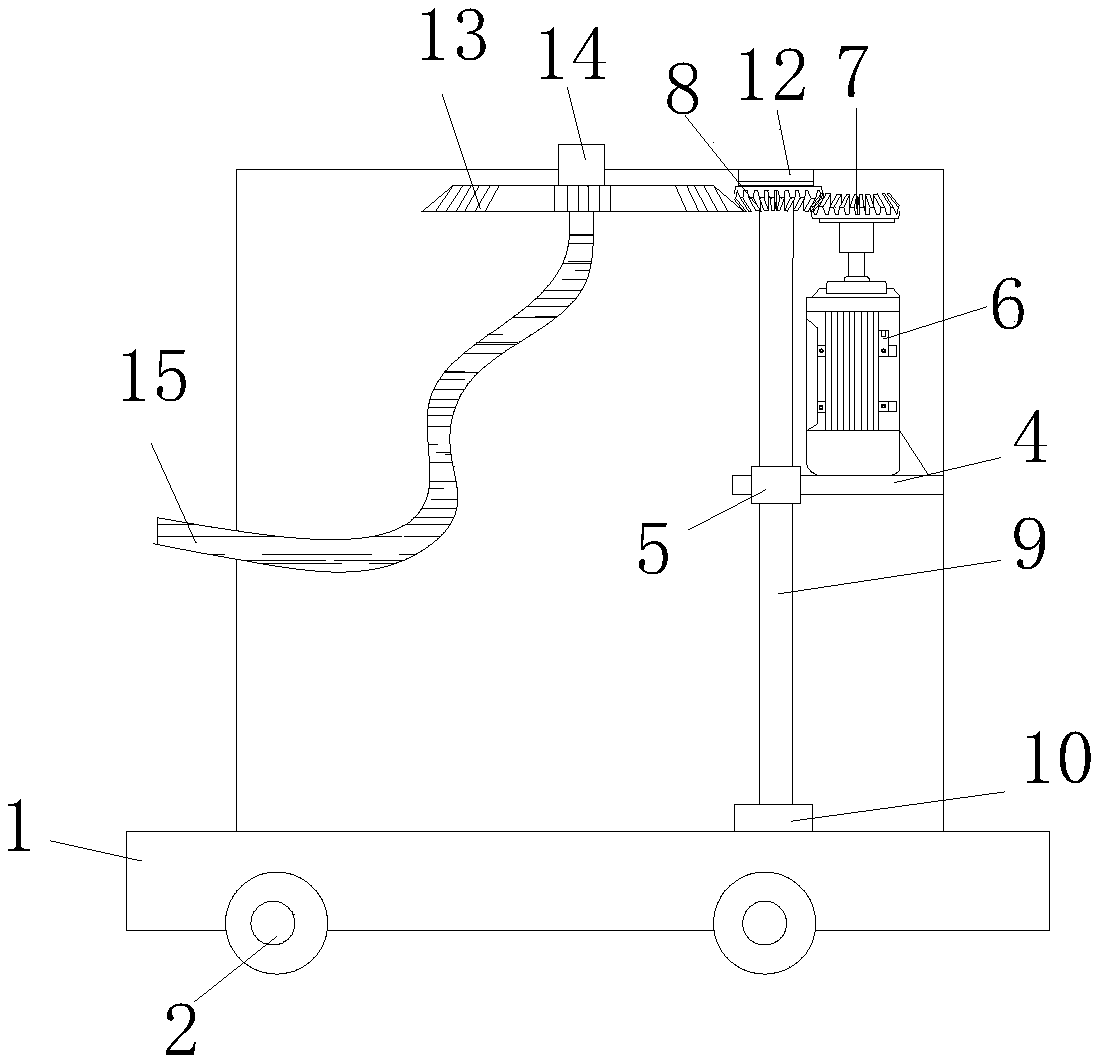

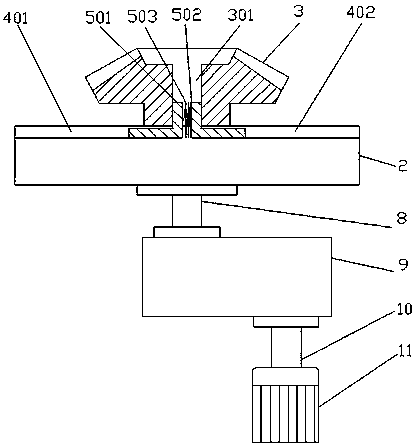

Device for deburring teeth of bevel gear

The invention discloses a device for deburring teeth of a bevel gear, and belongs to the field of machining equipment. Main technical points in the invention are as follows: the teeth of the bevel gear are deburred by rotation of an electric hairbrush fixed on a universal adjustment frame; the bevel gear is fixed on a turntable in the device through a fixing assembly; the turntable drives the bevel gear to rotate slowly; and thus, teeth around the bevel gear are completely deburred by the electric hairbrush. Each tooth does not need to be artificially polished one by one; therefore, the productivity is saved; and the structure is simple.

Owner:付志青

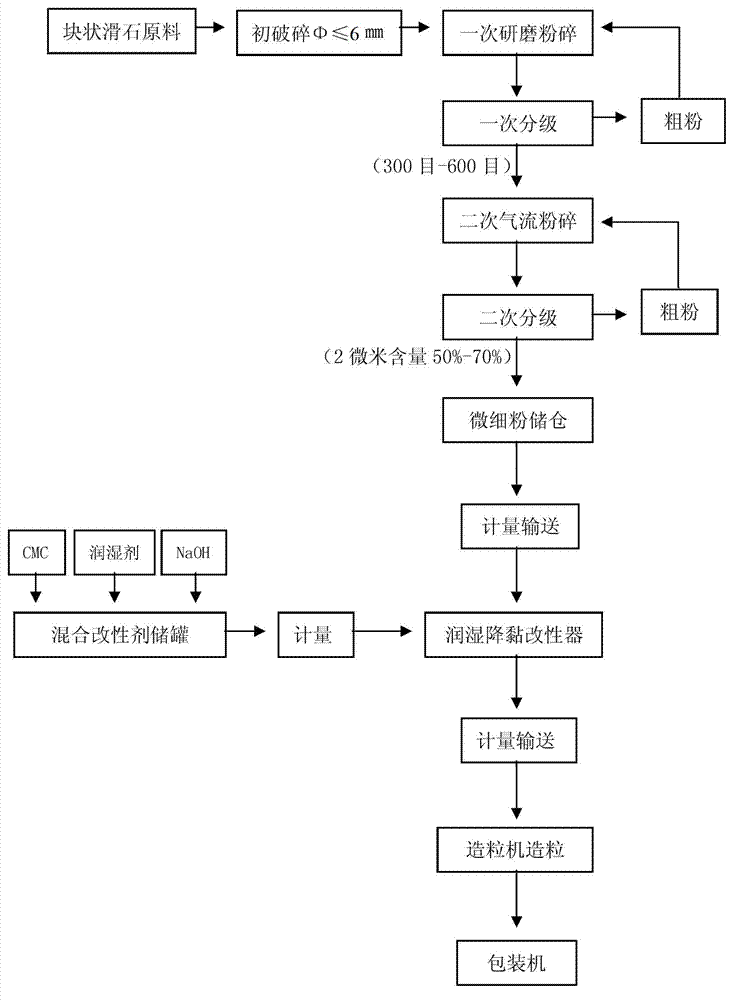

Modified talcum for papermaking coating and preparation method thereof

The invention relates to a modified talcum for a papermaking coating. The product is a white cylindrical granular talcum having a whiteness being not less than 88% and comprises the following main ingredients in percentage by mass: not less than 60% of natural talcum in the shape of a sheet-shaped particle, 0.3-0.8% of anion-type polyacrylic acid-acrylate-sulfonate copolymer, 0.2-0.5% of sodium carboxymethylcellulose, 0.02-0.1% of industrial-grade NaOH, and 5.0-10.0% of water. Compared with the prior art, the invention has the beneficial effects that the high-performance modified talcum product is prepared by the preparation method disclosed by the invention, and the product has high hydrophily, is easy to disperse in water phase; moreover, a pigment dispersoid is low in viscosity, good in the mobility, stable in the suspension property, and not easy to precipitate, so that the quality of paper is effectively improved.

Owner:辽宁艾海滑石有限公司

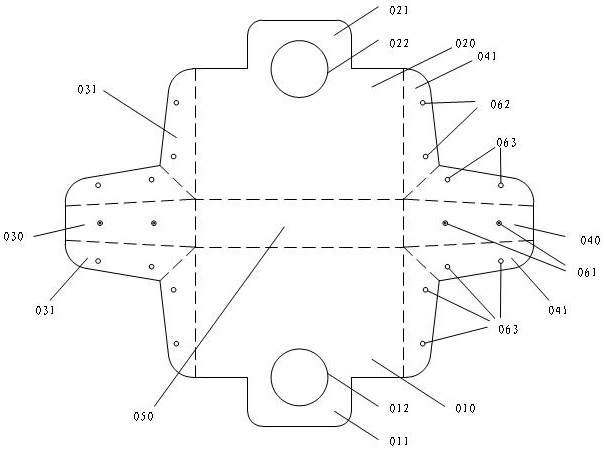

Paper bag

The invention discloses a paper bag which is formed by folding paper plates for box making. An unfolding plane can be a bottom plate, a front panel and a back panel, a left panel and a right panel, wherein the bottom plate is formed by segmenting creases; the front panel and the back panel are respectively connected with the creases at the two long sides of the bottom plate; the left panel and the right panel are respectively connected with the creases at the two short sides of the bottom plate; the left panel and the right panel are respectively provided with symmetric folding edges connected with the two creases between the front panel and the back panel; the folding edges at one side of the left panel is sequentially overlapped on the left panel; the left side plate and the folding edge overlapped at the outermost layer of the left panel are provided with snap fasteners correspondingly connected with each other; the folding edges at one side of the right panel are sequentially overlapped on the right panel; and the right side plate and the folding edge overlapped at the outermost layer of the right panel are provided with snap fasteners correspondingly connected with each other. Four side plates and the bottom plate are connected to form an integral paper bag, and therefore, the paper bag is firm in structure and saves the production and transportation costs. When the paper bag is not used, the snap fasteners are released and a plurality of unfolded paper bags can be placed in an overlapping way, so that the paper bag is convenient to accommodate.

Owner:SHANGHAI MAXIM GARMENT ACCESSORIES

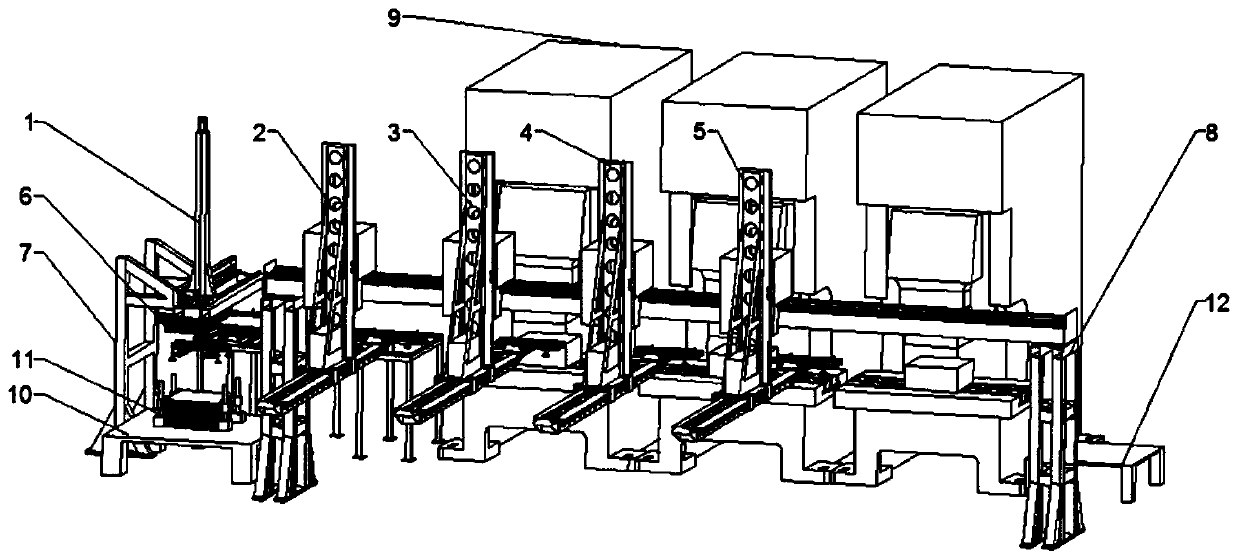

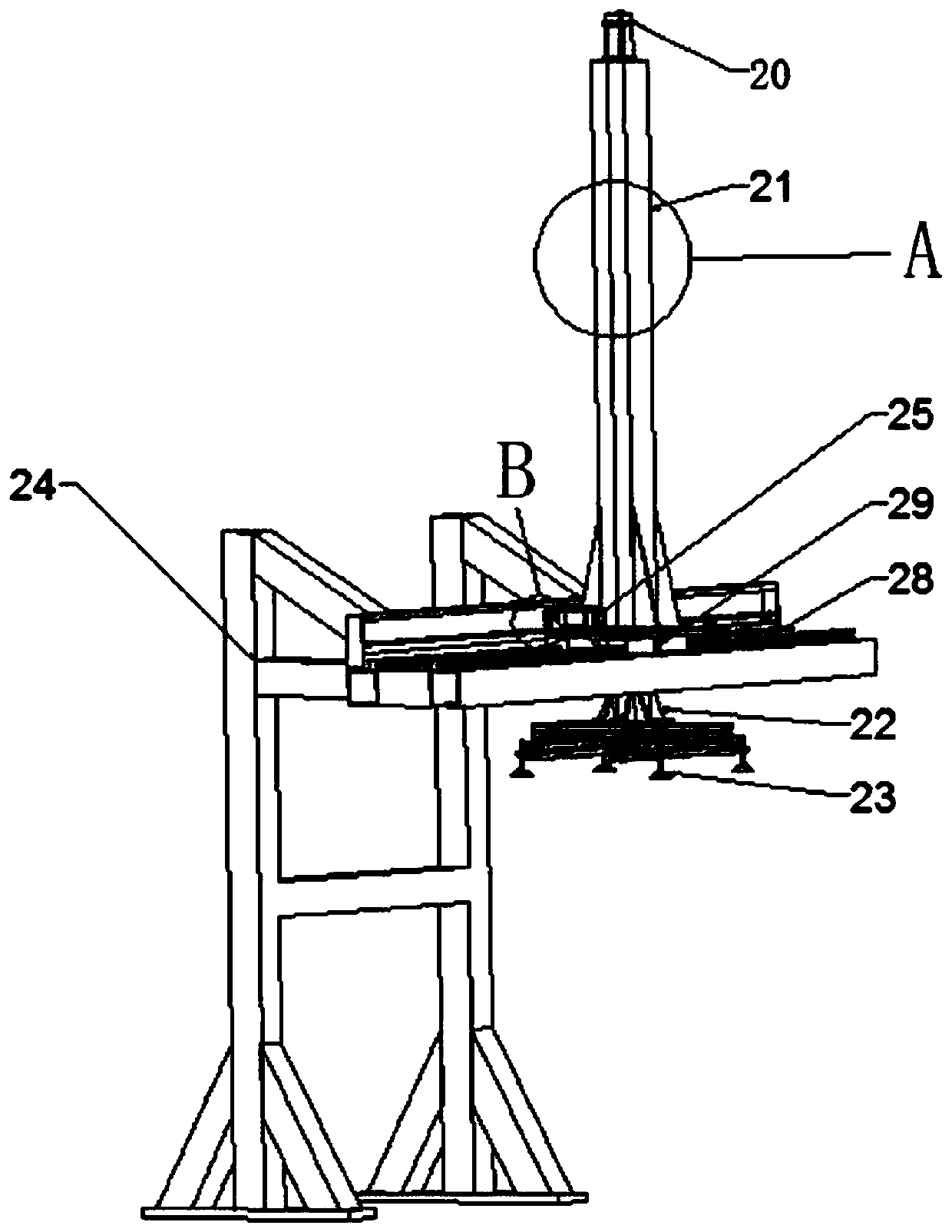

Line connection type automatic loading and unloading system of open press machine and application thereof

ActiveCN110817403AMeet the requirements of efficient and safe productionLow costConveyor partsRobot handWorking environment

The invention relates to a line connection type automatic loading and unloading system of an open type press machine and application thereof. The line connection type automatic loading and unloading system of the open type press machine comprises a material taking mechanical arm, wherein the material taking mechanical arm comprises a material taking mechanical arm support, a sliding device and a lifting device; the sliding device is arranged on the material taking mechanical arm support; the lifting device is arranged on the sliding device; a grabber is arranged at the bottom end of the lifting device; a centering platform comprises a centering platform support, a centering platform frame and a centering device; the centering platform frame is moved on the centering platform support through a driving device; the centering device is arranged on the centering platform frame to achieve centering adjustment on a workpiece; and a loading and unloading mechanical arm comprises a mechanical arm truss and at least two mechanical arms, and the mechanical arms are arranged on the mechanical truss and used for loading or unloading the open type press machine. According to line connection typeautomatic loading and unloading system of the open type press machine, continuous loading and unloading operation without stopping can be achieved corresponding to a multi-process open type press machine, and a line connection type mechanical arm replaces a traditional manual loading and unloading, so that the cost is saved, the working environment is improved, the labor and time are saved, the production efficiency is improved, and the safety requirement is met.

Owner:SHANDONG UNIV OF SCI & TECH

Manufacturing method of bobbin paper

InactiveCN106555360AQuality improvementSave raw materialsWater-repelling agents additionReinforcing agents additionSocial benefitsBobbin

The invention relates to a method for manufacturing paper by recycled paper, in particular to a manufacturing method of bobbin paper. The manufacturing method of the bobbin paper comprises the steps of fermenting, cleaning and dehydrating vinasse residue and corn straws separately, removing impurities, retaining plant fibers, mixing with waste paper according to a ratio being (2-4):(6-8), adding paper-making aids properly and producing the bobbin paper. According to the method, the production waste, such as the vinasse residue, the corn straws and the waste paper pulp, are completely utilized to produce the bobbin paper, so the method is low in cost, simple and convenient to operate and high in product stability; the vinasse residue and the waste paper pulp are used to realize waste utilization and the corn straw are used to prolong the value chain of corn, so good social benefit and environmentally-friendly benefit are achieved.

Owner:怀宁县天元纸业有限公司

Saccharifying method for producing malt syrup through extruded enzyme-containing syrup raw materials

ActiveCN103382495ASolve the problem of easy clogging and dumping of the pumpSolve the plumbing problemFermentationStarch productionEnzyme

The invention belongs to the technical field of saccharifying methods for extruded materials of extruded syrup raw materials with enzymic preparations added in malt syrup production processes and provides a saccharifying method for the extruded materials of the extruded syrup raw materials with the enzymic preparations added for producing malt syrup. According to the saccharifying method, syrup mixing and high-temperature (128 DEG C-145 DEG C) enzyme deactivation in the prior art are omitted, and the extruded syrup raw materials with the enzymic preparations added are liquefied and saccharified directly. The problems that powder materials in material liquids are deposited on tank bottoms easily during the syrup mixing of particles of the extruded materials of the extruded syrup raw materials which contain the enzymic preparations and are used for producing the malt syrup and the particles in the material liquids block pipelines and material pouring pumps easily when the material liquids of syrup mixing tanks are poured into and liquefied in a jetting mode in liquidation tanks in the prior art are solved. Compared with existing saccharifying processes for producing the malt syrup through traditional enzymic methods, the saccharifying method has the advantages that jetting liquidation processes and devices are omitted, starch production processes and devices are omitted and environmental pollution caused by the saccharifying method is avoided.

Owner:ZIBOHUICHUANG BIOLOGICAL SCI TECH LTD +1

Precise punching mould

The invention discloses a precise punching mould which comprises a plurality of working units, wherein each working unit comprises a first punching unit, a first bending forming unit, a second punching unit, a second bending forming unit, a punching bending compound unit and a blanking end-product unit; the first punching unit is used for punching an outline on a material; the first bending forming unit is used for primarily bending and forming the material; the second punching unit is used for punching a hole or slot on a primarily bent and formed part; the second bending forming unit is used for finally bending and forming the material; the punching bending compound unit is used for punching the hole or slot on a final bent and formed part and bending the protection pins of a product; and the blanking end-product unit is used for respectively punching and blanking an end-product and the wastes. Compared with the prior art, the precise punching mould has the advantages of (1) high production efficiency, (2) safety in operation, (3) excellent economical efficiency and (4) high precision.

Owner:KUNSHAN XINTAILI PRECISION COMPONENTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com