Bio-enzyme and microorganism containing compound feed additive and preparation process thereof

A compound feed and bio-enzyme technology, applied in animal feed, animal feed, application, etc., can solve the problems of easy reduction of Bacillus subtilis viable bacteria count, reduced effect of additives, weakened digestion effect of feed additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

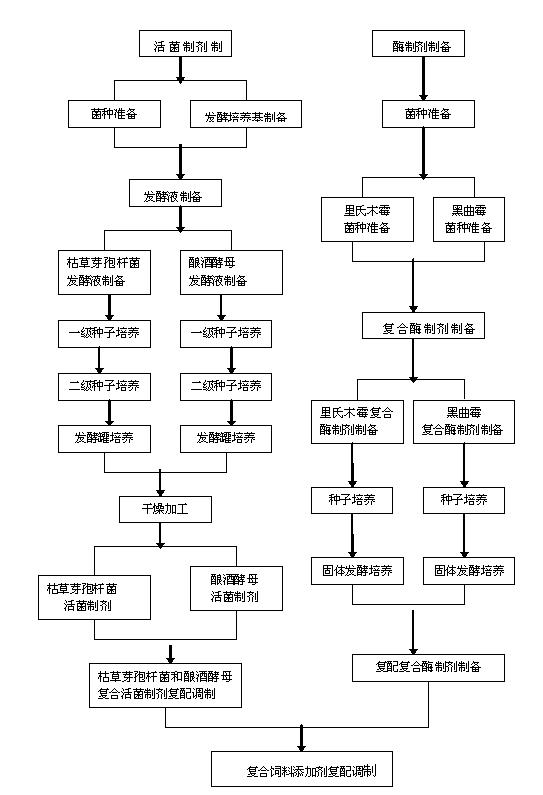

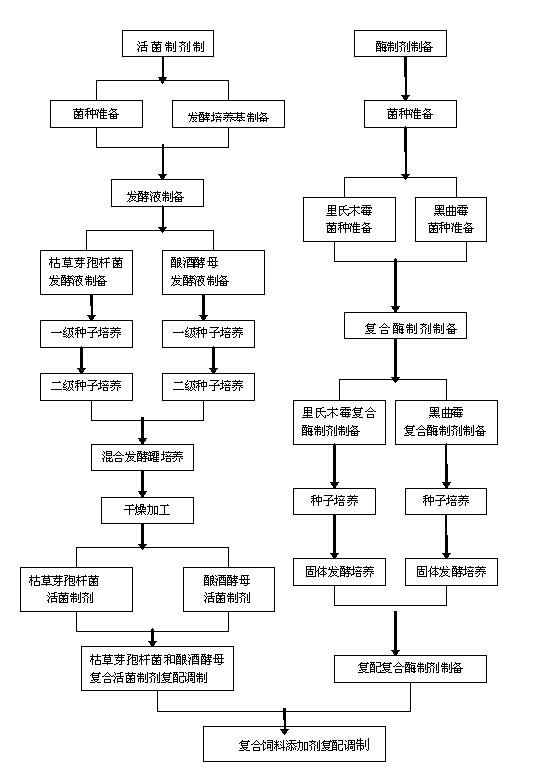

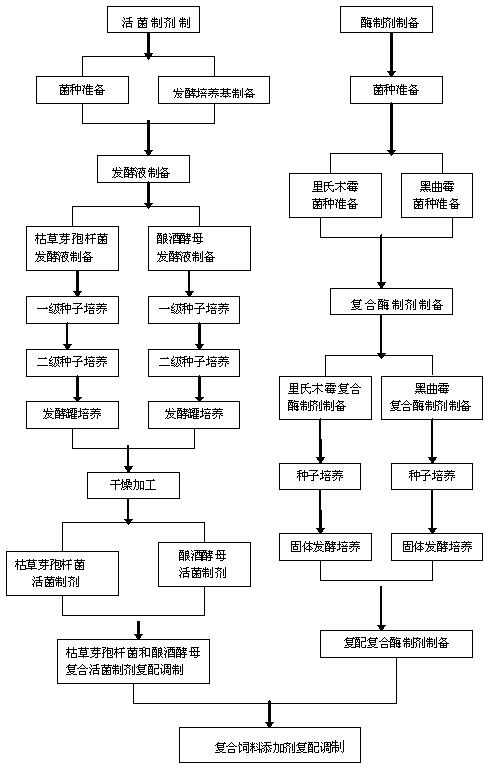

Image

Examples

specific Embodiment approach 1

[0072] A compound feed additive containing biological enzymes and microorganisms proposed by the present invention is composed of beneficial bacteria components and biological enzyme components, and the beneficial bacteria components contain Bacillus subtilis, Saccharomyces cerevisiae, Trichoderma reesei and Aspergillus niger , the biological enzyme component contains cellulase, α-amylase and protease, and the compound feed additive containing biological enzyme and microorganism is made of liquid seeds activated by Bacillus subtilis and Saccharomyces cerevisiae by liquid fermentation and 40-50 The living bacteria preparation prepared by drying at low temperature at ℃ and the enzyme preparation prepared by solid fermentation and drying of liquid seeds activated by Trichoderma reesei and Aspergillus niger are compounded at a ratio of 1:3; this product contains The number of viable microorganisms >8×10 9 cfu, the final cellulase activity is the amount of cellulose degraded per gr...

specific Embodiment approach 2

[0088] A kind of preparation technology of the compound feed additive containing biological enzyme and microorganism of the present invention adopts following steps:

[0089] 1. Preparation of viable bacterial preparations

[0090] 1.1. Strain preparation

[0091] The present invention selects Bacillus subtilis ( Bacillus subtilis ) and Saccharomyces cerevisiae ( Saccharomyces cerevisiae ) as live bacteria preparation strains;

[0092] 1.2. Fermentation medium preparation

[0093] The present invention selects crushed corn and soybean meal, the ratio of corn and soybean meal is 10:1, adds warm water at 40-50°C, the ratio of material to water is 1:2.5-1:3.5, mixes well and heats to 75-85 °C, the time is 40-50 minutes; cook at 130-135 °C, 0.10-0.15 MPa for 80-90 minutes, cool to 60-70 °C, add high-temperature liquefying enzyme and glucoamylase for 3-4 hours to obtain glucose value (DE value) above 65% and 12-14°BX corn and soybean meal enzymatic hydrolysis saccharificatio...

specific Embodiment approach 3

[0142] In the fermentor culture step in the fermented liquid preparation step prepared by the live bacterial agent, the fermentor culture that is carried out separately can be combined into a mixed fermenter culture of Bacillus subtilis and Saccharomyces cerevisiae, that is to say, the liquid seeds of Bacillus subtilis and Saccharomyces cerevisiae are respectively pressed 3% to 5% are co-inoculated into corn and soybean meal enzymatic saccharification liquid for mixed culture, 10L automatic seed fermentation tank is filled with 5L seed fermentation medium, and cultivated at 28-32°C, 180-200rpm (rev / min) for 20 hours , other steps are with embodiment 2. Adopting this implementation mode can save materials and energy consumption in fermentation tanks and production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com