Liquid compound acidifier with strong buffer capacity and preparation technology thereof

A technology of compound acidifier and buffering capacity, which is applied in the direction of medical preparations containing active ingredients, digestive system, drug combination, etc., can solve the hidden dangers of antibiotic public health safety, accelerate drug-resistant strains, antibiotic residues and other problems, and achieve the improvement of feed Utilization and conversion rate, reduction of mucosal irritation, effect of small change in acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The liquid composite acidulant with strong buffer capacity described in this embodiment is formulated by adopting ammonium formate, formic acid, acetic acid, lactic acid, copper sulfate and purified water; every 100L of said composite acidifier contains: ammonium formate 18kg, formic acid 30kg, acetic acid 8kg, lactic acid 25kg, copper sulfate 25kg, and the balance is purified water.

[0022] The ammonium formate, formic acid, acetic acid and lactic acid are all food grade; the copper sulfate is reagent grade.

[0023] The preparation process of the liquid composite acidulant with strong buffer capacity described in this embodiment comprises the following steps:

[0024] 1. Take 10kg of purified water, heat it to 40-45°C, then add 18kg of ammonium formate, stir and dissolve to obtain solution A;

[0025] 2. Weigh 30kg of formic acid, add it into the solution A prepared in step 1, stir evenly, and prepare solution B;

[0026] 3. Weigh 8 kg of acetic acid, add it into t...

Embodiment 2

[0031] The liquid compound acidulant with strong buffer capacity described in this embodiment is formulated by adopting ammonium formate, formic acid, acetic acid, lactic acid, copper sulfate and purified water; every 100L of said compound acidulant contains: ammonium formate 20kg, formic acid 25kg, acetic acid 10kg, lactic acid 26kg, copper sulfate 23kg, and the balance is purified water.

[0032] The ammonium formate, formic acid, acetic acid and lactic acid are all food grade; the copper sulfate is reagent grade.

[0033] The preparation process of the liquid composite acidulant with strong buffer capacity described in this embodiment comprises the following steps:

[0034] 1. Take 25kg of purified water, heat it to 40-45°C, then add 20kg of ammonium formate, stir and dissolve to obtain solution A;

[0035] 2. Weigh 25kg of formic acid, add it into the solution A prepared in step 1, stir evenly, and prepare solution B;

[0036] 3. Weigh 10 kg of acetic acid, add it to the...

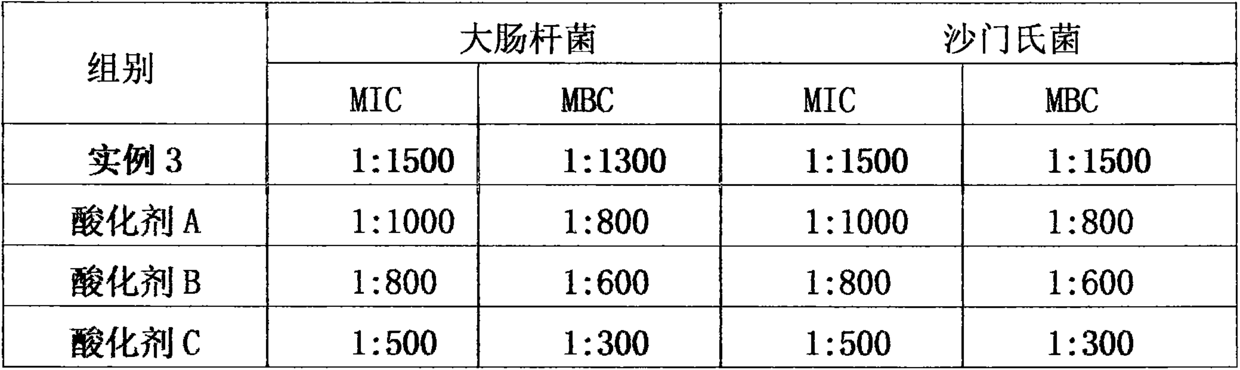

Embodiment 3

[0041] The liquid compound acidulant with strong buffer capacity described in this embodiment is formulated by adopting ammonium formate, formic acid, acetic acid, lactic acid, copper sulfate and purified water; every 100L of said compound acidulant contains: ammonium formate 23kg, formic acid 20kg, acetic acid 10kg, lactic acid 22kg, copper sulfate 25kg, and the balance is purified water.

[0042] The ammonium formate, formic acid, acetic acid and lactic acid are all food grade; the copper sulfate is reagent grade.

[0043] The preparation process of the liquid composite acidulant with strong buffer capacity described in this embodiment comprises the following steps:

[0044] 1. Take 10kg of purified water, heat it to 40-45°C, then add 23kg of ammonium formate, stir and dissolve to obtain solution A;

[0045] 2. Weigh 20 kg of formic acid, add it into the solution A prepared in step 1, stir evenly, and prepare solution B;

[0046] 3. Weigh 10 kg of acetic acid, add it to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com