Rapid dehydration and fermentation cowpea production line and production and processing technology

A rapid dehydration, production line technology, applied in the preservation of fruits/vegetables with acid, food science and other directions, can solve the problems of high water content of sour cowpea, restrictions on mass production of products, improper storage and easy white film, etc. Variety of colors and rich taste effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

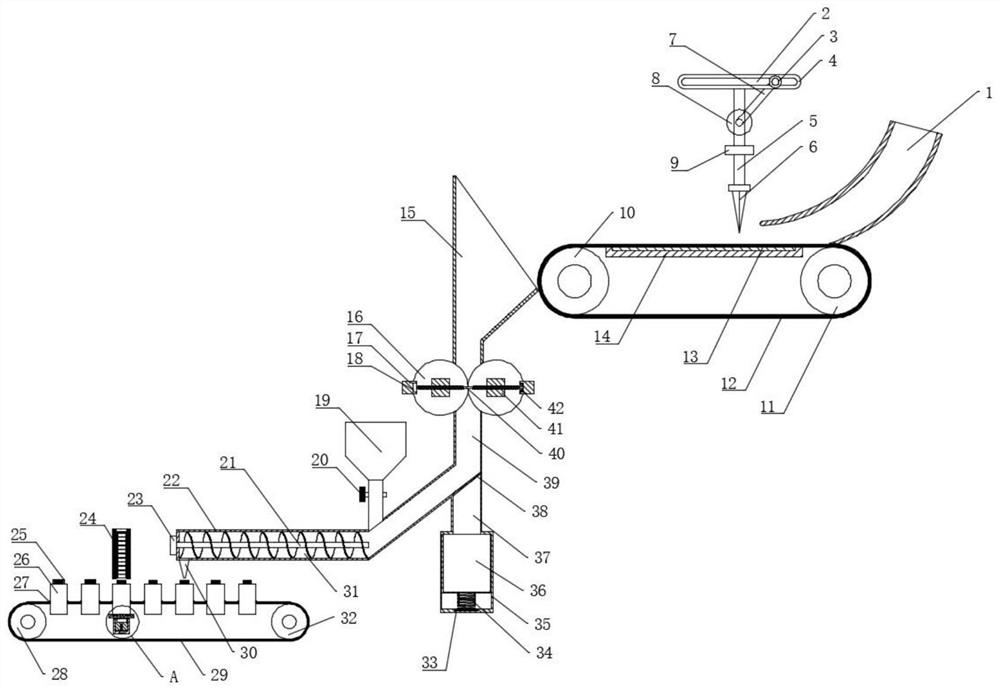

[0043] Embodiment 1: a kind of rapid dehydration fermentation cowpea production line, such as Figure 1 to Figure 8 As shown, it includes a feeding pipe 1, a chopping device, a pressing device, a stirring device and a packaging device. There is a guide pipe 15 between the feeding ends of the squeegee, and a connecting pipe 39 is arranged between the pressing device and the stirring device; the discharge end of the stirring device is located directly above the packaging device; the connecting pipe 39 is a folded Shaped tube, a cowpea liquid collecting device is provided at the bending place of the folded-shaped tube;

[0044] The packaging device includes a conveying device, a rotating device and a bottle cap replenishing device; the rotating device is located in the conveying device, and the bottle cap replenishing device is located just above the conveying device;

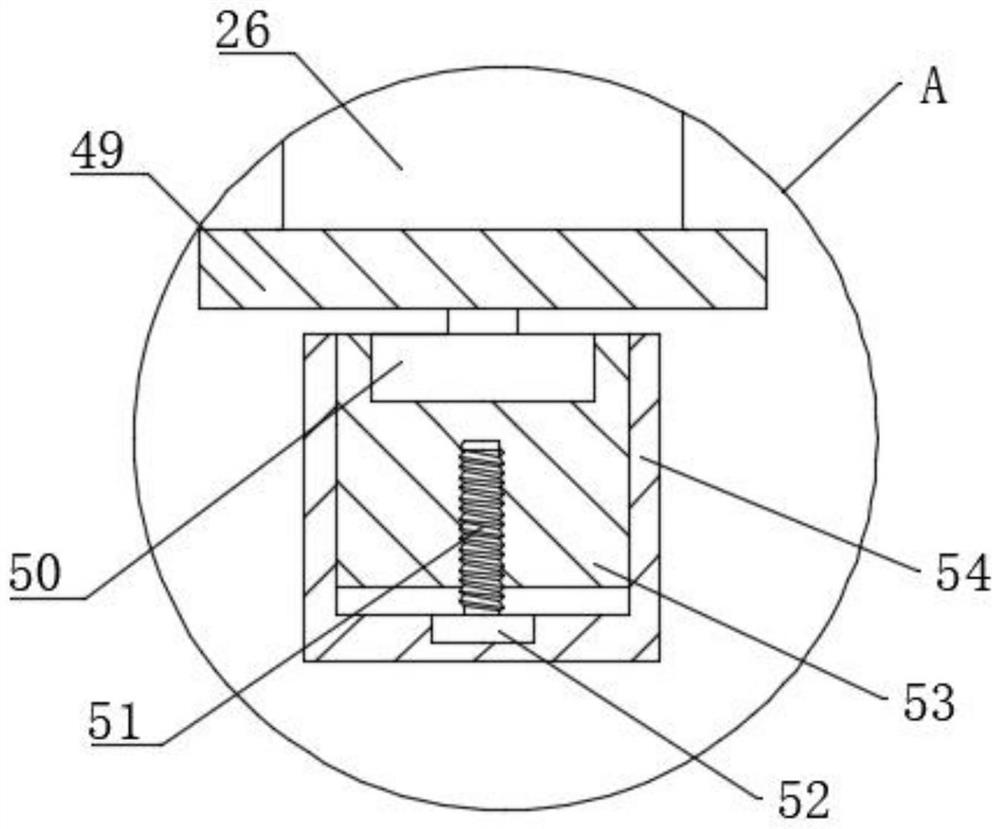

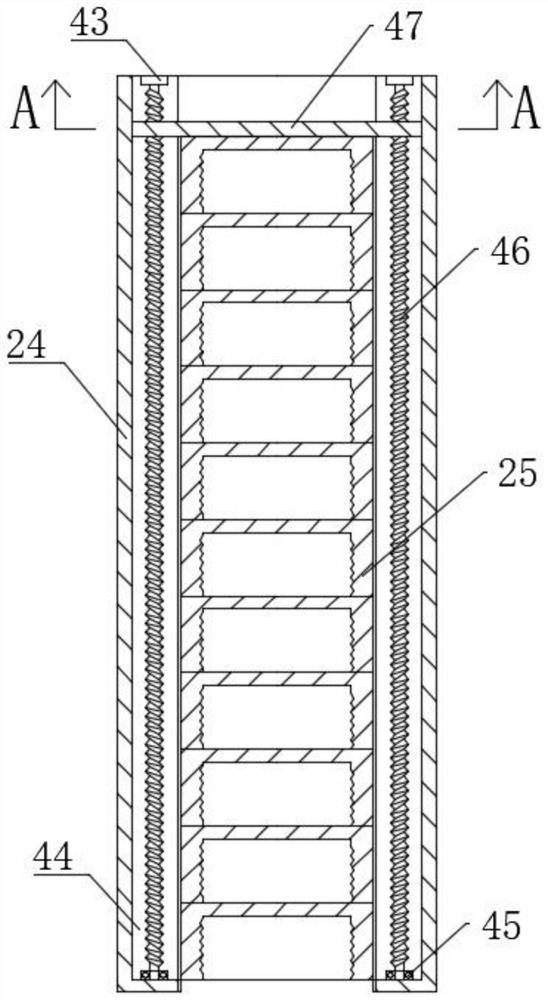

[0045] The conveying device includes a conveyor belt 29, two driving wheels 28, two driven wheels 32, two rota...

Embodiment 2

[0062] Embodiment 2: a kind of processing technology of rapid dehydration and fermentation cowpea, specifically comprises the following steps:

[0063] S1: Collect fresh cowpeas without pesticide residues as raw materials;

[0064] S2: Mix the cleaned cowpea and ginger and chop the mixture;

[0065] S3: Press the chopped mixture to reduce the cowpea moisture to 60%-80%;

[0066] S4: adding the peppers and garlic sprouts that have been fermented by lactic acid bacteria into the cowpea chopped mixture in different proportions;

[0067] S5: bottle and package the chopped mixture, and put the packaged mixture into a fermentation room for temperature-controlled fermentation for 5-7 days to obtain finished sour cowpeas.

[0068] In the described S2, the mixture is chopped in a chopping device; in the S3, the mixture is squeezed in a pressing device; in the S4, adding pepper and garlic sprouts is controlled by the charging cylinder 19 and the solenoid valve 20 The dosage is added ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com