Bacterial-breaking process druing procedure of BCG acid powder polysaccharide and nucleic

A BCG polysaccharide and preparation process technology, which is applied in the field of BCG cell destruction by high-shear dispersion emulsification method, can solve the problems of insufficient contact between the knife and the cell body, and insufficient bacteria destruction, and achieve saving Productivity and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

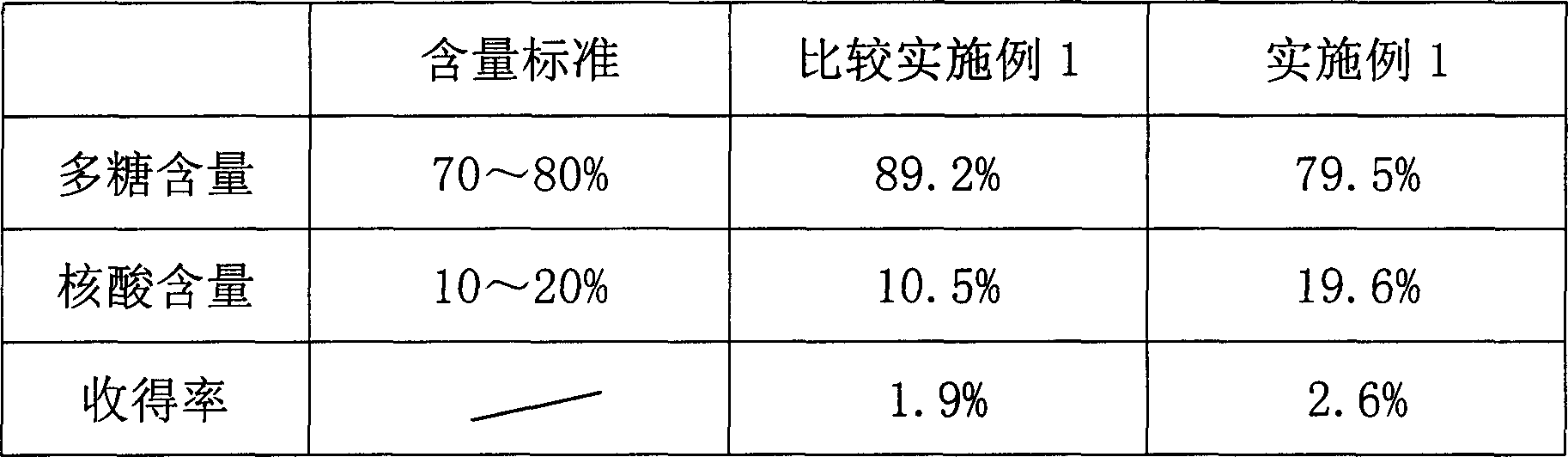

Embodiment 1

[0010] Put 6 kg of bacteria into a 20-liter stainless steel bucket, add 6 liters of water for injection, insert the bactericidal knife into the liquid, the knife is about 5 cm away from the bottom of the bucket, turn on the power, and run continuously (10000 rpm) 3 Hours, the prepared homogenate enters the next process for further extraction, and finally the original powder of BCG polysaccharide and nucleic acid is obtained. Calculate the product yield and detect the component content in the product, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com