Modified talcum for papermaking coating and preparation method thereof

A talc and modified technology, which is applied in paper coating, papermaking, textiles and papermaking, etc., can solve the problems of long dispersion time, difficulty, and large power consumption, and achieve easy dispersion in water phase, high enterprise benefit, and small dust pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

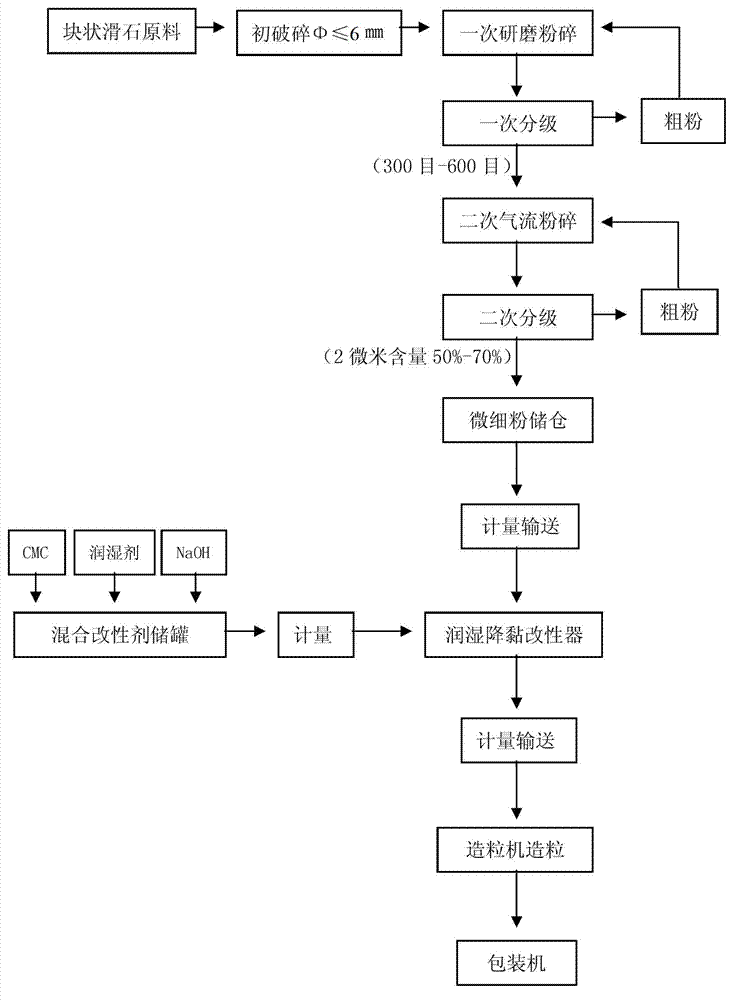

[0018] Such as figure 1 As shown, a kind of talc in flake form whose talc component is 88% pure through X-ray diffraction analysis is selected as raw material, first, block talc raw material is crushed to a diameter of less than 6mm by jaw crusher and hammer crusher, and then conveyed To the Raymond mill, grind and pulverize to 325 mesh fine powder, and then transport it to the airflow pulverizer with powder classification system through negative pressure airflow to continue grinding and pulverization, and use the closed-circuit classification process to classify the ultrafine powder with a content of 2 microns and 50.3%. The fine talc powder is conveyed to the fine powder storage bin through negative pressure airflow, and the ultrafine talc powder in the fine powder storage bin is continuously and quantitatively conveyed to the screw mixer by a screw conveyor with a metering device for full mixing Dissociate by rubbing, and at the same time, spray the pre-prepared modifier mi...

Embodiment 2

[0023] Such as figure 1 As shown, a kind of talc in flake form whose talc component is 88% pure through X-ray diffraction analysis is selected as raw material, first, block talc raw material is crushed to a diameter of less than 6mm by jaw crusher and hammer crusher, and then conveyed To the Raymond mill, grind and pulverize to 325 mesh fine powder, and then transport it to the jet pulverizer with powder classification system through negative pressure airflow to continue grinding and pulverization, and use the closed-circuit classification process to classify the ultrafine powder with a content of 64.8% in 2 microns. The fine talc powder is conveyed to the fine powder storage bin by negative pressure airflow; the ultrafine talc powder in the fine powder storage bin is continuously and quantitatively conveyed to the spiral mixer through a screw conveyor with a metering device and fully stirred Dissociate by rubbing, and at the same time, spray the pre-prepared modifier mixture ...

Embodiment 3

[0027] Such as figure 1 As shown, a kind of talc in flake form whose talc component is 88% pure through X-ray diffraction analysis is selected as raw material, first, block talc raw material is crushed to a diameter of less than 6mm by jaw crusher and hammer crusher, and then conveyed To the Raymond mill, grind and pulverize to 325 mesh fine powder, and then transport it to the airflow pulverizer with powder classification system through negative pressure airflow to continue grinding and pulverization, and use the closed-circuit classification process to classify the ultrafine powder with a content of 2 microns and 67.5%. The fine talc powder is conveyed to the fine powder storage bin by negative pressure airflow; the ultrafine talc powder in the fine powder storage bin is continuously and quantitatively conveyed to the spiral mixer through a screw conveyor with a metering device and fully stirred Dissociate by rubbing, and at the same time, spray the pre-prepared modifier mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com