Micro-emulsion cutting fluid and preparation technology thereof

A cutting fluid and microemulsion technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of poor heat transfer effect, decomposition and deterioration of water-based products, etc., and achieve the effects of reducing discharge, fast separation, good mildew resistance and sterilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

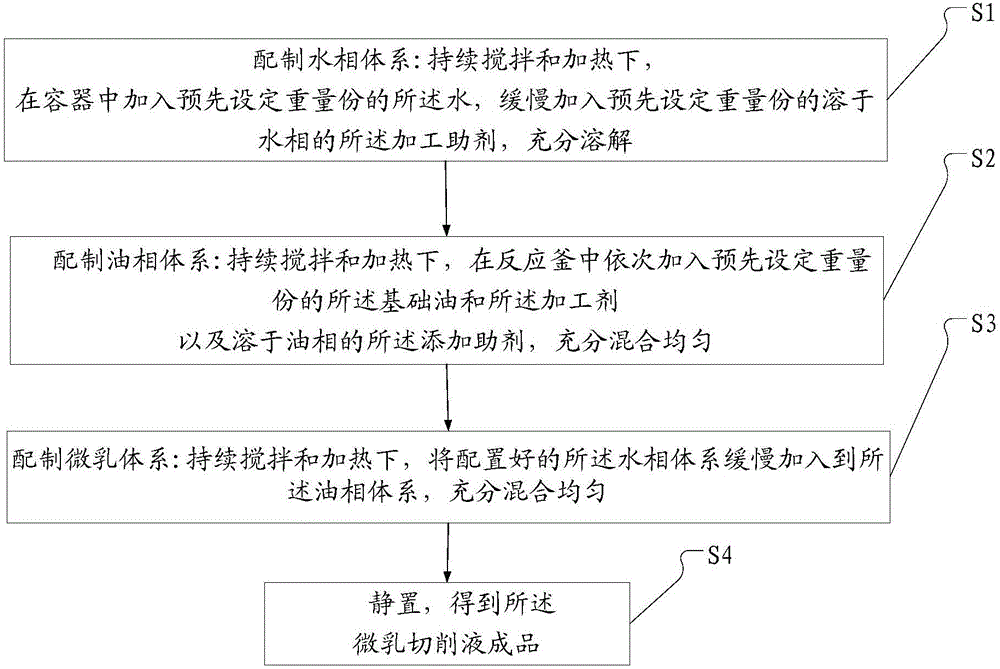

[0044] The preparation process of the microemulsion cutting fluid of the present invention comprises:

[0045] S1: Prepare the water phase system, under continuous heating and stirring, add the preset weight part of water into the container, slowly add the preset weight part of the processing aid soluble in the water phase, and fully dissolve;

[0046] S2: Prepare the oil phase system, under continuous stirring and heating, add the base oil, additives and processing aids soluble in the oil phase in sequence in the reaction kettle, and mix well;

[0047] S3: Prepare the microemulsion system, under continuous stirring and heating, slowly add the prepared water phase system to the oil phase system, and mix well;

[0048] S4: standing still to obtain the finished microemulsion cutting fluid. Each process step is described below:

[0049] Before the preparation process, it is necessary to set the types of processing aids and the weight of each component. According to the nature a...

Embodiment 1

[0056] Before carrying out the preparation process, set the parts by weight of each component, liquid phase carrier: adopt 45 parts of water, adopt 6 parts of base oil; 1 part of high fatty alcohol polyoxyethylene ether, 0.1 part of nano-silver particles for nano anti-mold and antibacterial agent, 6 parts of Span-80 for non-ionic surfactant;

[0057] S1: Prepare a water phase system, add 45 parts of water into the container under continuous heating and stirring, and fully dissolve;

[0058] S2: Prepare the oil phase system, under continuous stirring and heating, add 12 parts of base oil (purchased from PetroChina) and 21 parts of 2-aminoethanol borate, 16 parts of high fatty alcohol polyoxyethylene ether in the reactor , 0.1 part of nano-silver particles, 6 parts of Span-80 (purchased by BASF AG) are fully mixed;

[0059] S3: Prepare the microemulsion system, under continuous stirring and heating, slowly add the prepared water phase system to the oil phase system, and mix wel...

Embodiment 2

[0063] Before carrying out the preparation process, set the parts by weight of each component, liquid phase carrier: adopt 42 parts of water, adopt 10 parts of base oil; 1 part of high fatty alcohol polyoxyethylene ether, 0.2 part of nano-silver particles for nano anti-mold and antibacterial agent, 5 parts of Span-80 for non-ionic surfactant;

[0064] S1: Prepare a water phase system, add 42 parts of water to the container under continuous heating and stirring;

[0065] S2: Prepare the oil phase system, under continuous stirring and heating, add 10 parts of base oil (purchased from PetroChina) and 23 parts of 2-aminoethanol borate, 18 parts of high fatty alcohol polyoxyethylene ether in the reactor , 0.2 parts of nano-silver particles, 5 parts of Span-80 (purchased by BASF AG) are fully mixed;

[0066] S3: Prepare the microemulsion system, under continuous stirring and heating, slowly add the prepared water phase system to the oil phase system, and mix well;

[0067] S4: sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com