Gas stirring tank easy to heat and stirring method

A technology of gas stirring and stirring tank, which is applied in the direction of mixer accessories, chemical instruments and methods, dissolution, etc., can solve the problems of no heating device, uneven stirring, and inability to heat materials, so as to save production equipment, improve heating efficiency, The effect of saving production space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

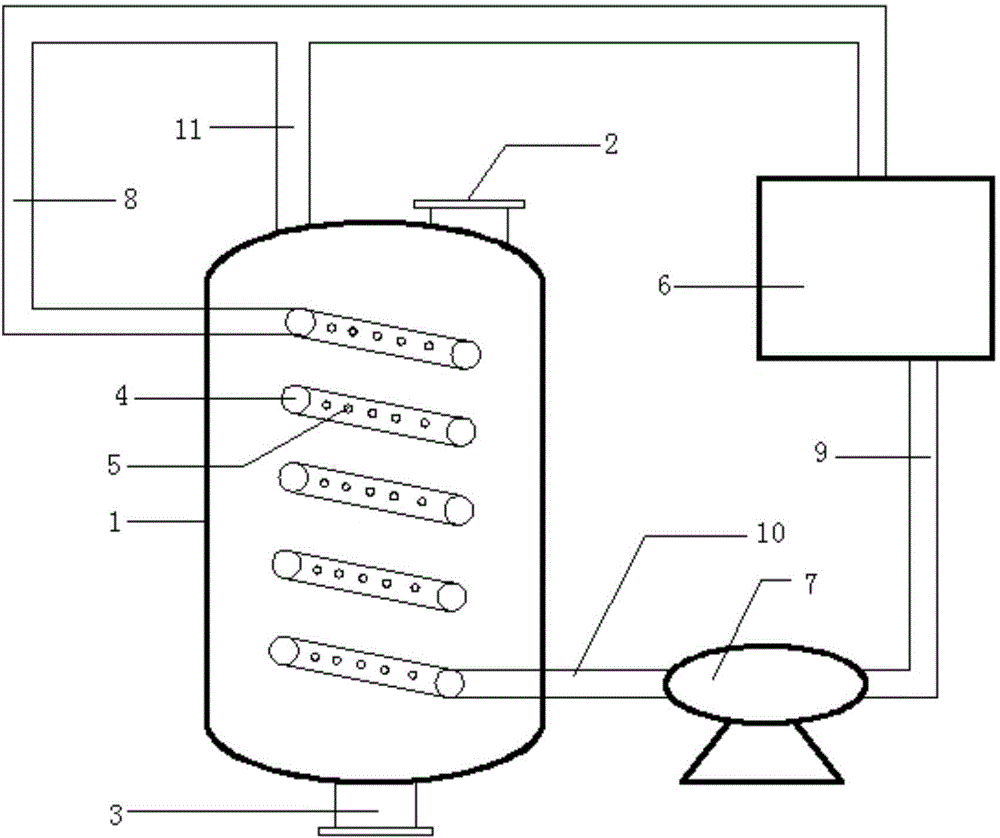

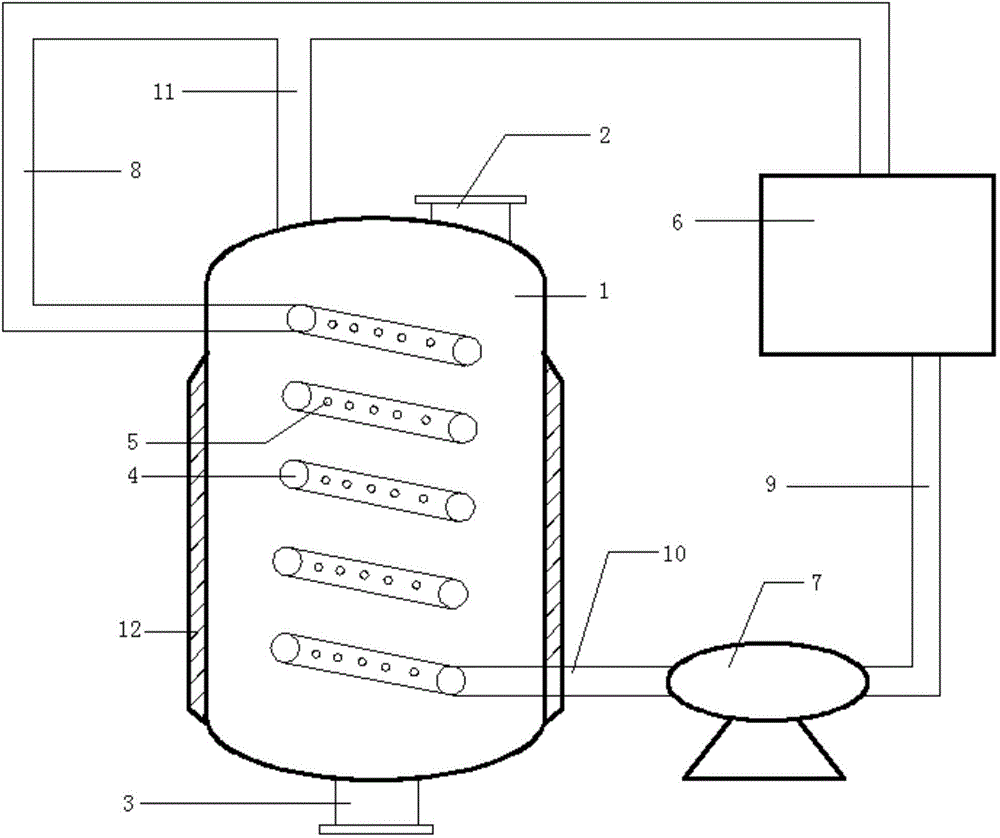

[0024] A gas stirred tank that is easy to heat includes a stirred tank body 1, a heating furnace 6 and an air blowing device 7 for intermittently blasting the stirred tank body 1. The top of the stirred tank body 1 is provided with a feed port 2, The bottom of the stirred tank body 1 is provided with a discharge port 3, and the inside of the stirred tank body 1 is uniformly provided with a coil 4 from the bottom end to the top, and the coil 4 is uniformly provided with an air injection hole 5 The outlet of the coiled pipe 4 is connected to the heating furnace 6 through the first connecting pipe 8, and the heating furnace 6 is connected to the blowing device 7 through the second connecting pipe 9, and the described blowing device 7 is passed through the third The connecting pipe 10 is connected to the inlet of the coil pipe 4 ; the top of the stirred tank body 1 communicates with the first connecting pipe 8 through the fourth connecting pipe 11 .

[0025] The blowing device 7 d...

Embodiment 2

[0029] Easy-to-heat gas stirred tank as described in Example 1, the difference is that the outside of the stirred tank body 1 is provided with a jacket 12;

[0030] The blast device 7 is a compressor, and the duration of each blast is 2 minutes, and the time interval between two adjacent blasts is 30 seconds.

[0031] Since the jacket 12 is provided, the stirred tank has the function of heat preservation, and the heating efficiency is improved.

Embodiment 3

[0033] A kind of method that material is stirred, comprises using the easy-to-heat gas stirred tank described in embodiment 1, and step is as follows:

[0034] Put the material into the stirring tank body 1, turn on the heating furnace 6 and the blower device 7, the heating furnace 6 heats the air and blows the heated air into the coil 4 through the blower device 7, and the heated air passes through the coil The air injection hole 5 set on the pipe 4 is sprayed into the stirring tank body 1 to heat the material; the blower device 7 performs intermittent blasting, and the material spirally rises under the action of the heated air sprayed from the air injection hole 5 to form Vortex, and then realize the stirring effect on the material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com