System and method for monitoring high-temperature corrosive atmosphere of water cooling wall of boiler

A high-temperature corrosion and monitoring system technology, applied in measuring devices, analyzing gas mixtures, instruments, etc., can solve the problems of complex flue gas sampling and analysis systems, valves are easily affected by dust, and low reliability, and meet air tightness requirements The effect of reducing, maintenance-free, and ensuring operational reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

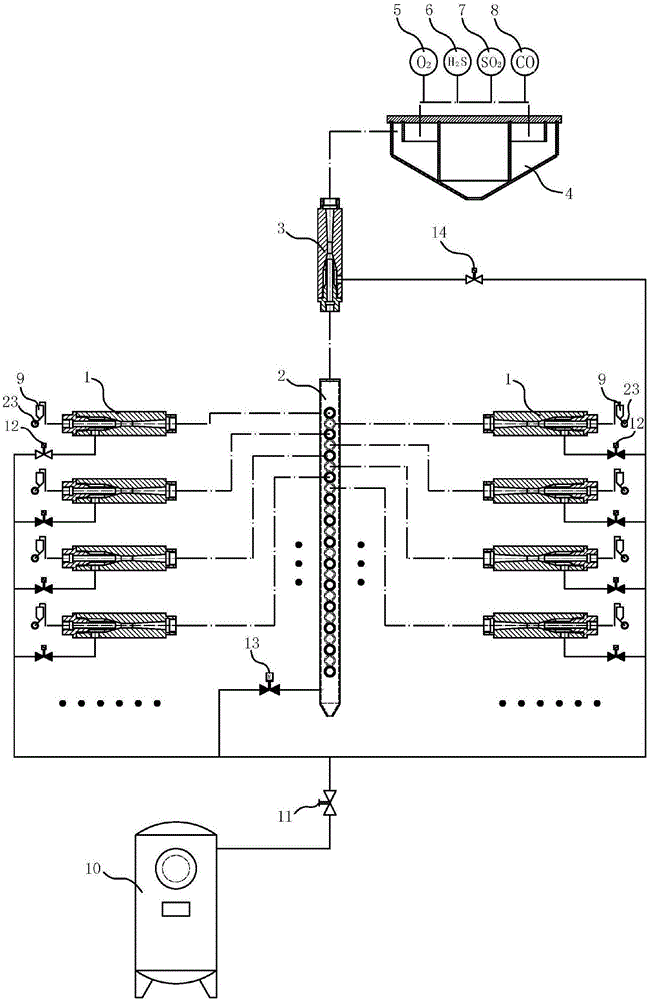

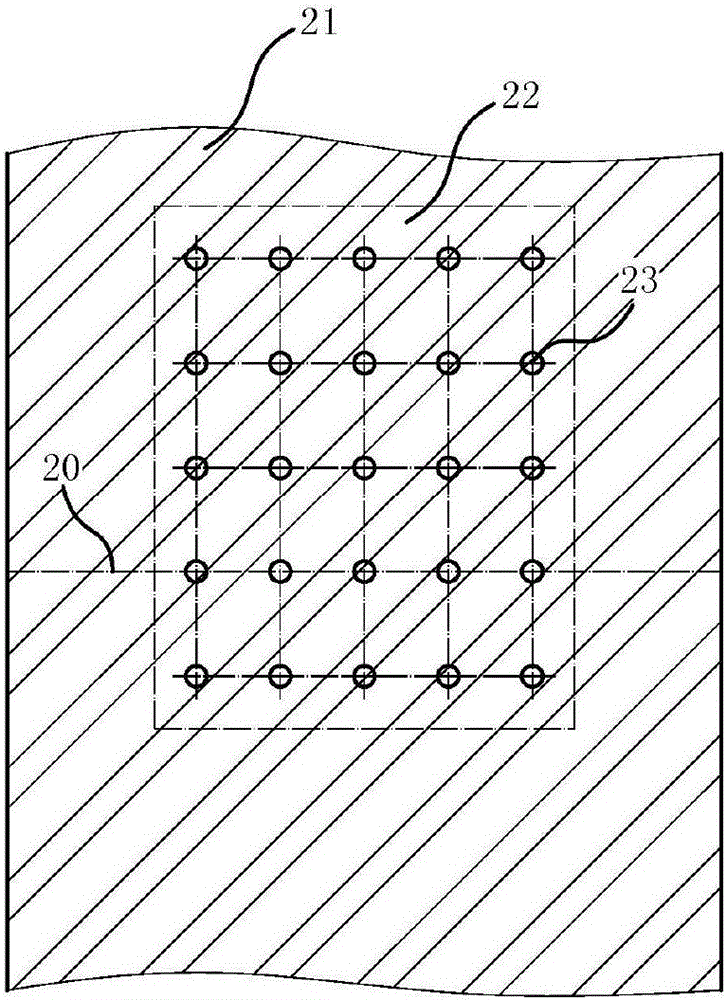

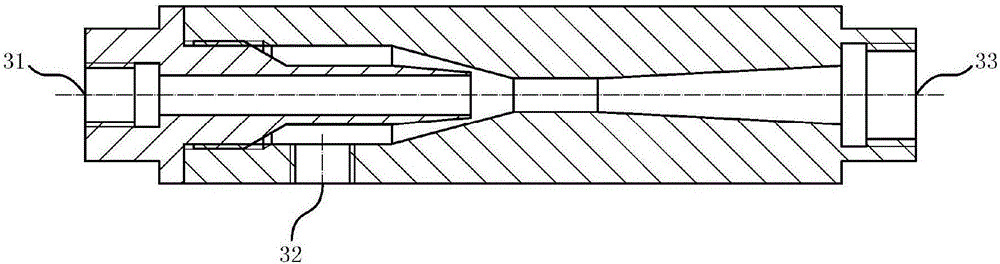

[0054] The 660MW ultra-supercritical coal-fired unit boiler adopts the combustion method of front and rear walls opposed to each other. High temperature corrosion is prone to occur in the middle part of both sides of the wall, near the elevation position of the center line of the out-of-fire air, and within 6 meters above it. The water wall tube thinning rate is up to 2mm / Year, seriously threatening the safe operation of the unit. According to the inspection during the maintenance period, the areas prone to high temperature corrosion on both sides of the wall are delineated, the total width is 10 meters, the total height is 12.5 meters, and the walls on both sides are symmetrical. In order to shorten the connecting pipeline and shorten the inspection cycle, each side wall is equipped with a set of boiler water wall high temperature corrosion atmosphere monitoring system of the present invention; each side wall is arranged with 25 flue gas sampling points, the horizontal distanc...

Embodiment 2

[0060] This embodiment is similar to embodiment 1, except that it is installed in a 300MW subcritical coal-fired unit. The boiler adopts a four-corner tangential combustion method. The four walls of the water wall are equipped with flue gas sampling points. Two sets of boilers of the present invention are installed diagonally. Monitoring system for high temperature corrosion atmosphere of water wall.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com