Full-automatic high-temperature-melt release mechanism and control method thereof

A technology of high temperature melting and releasing mechanism, applied in chemical instruments and methods, laboratory utensils, reagent containers, etc., can solve the problems of damage to the melting furnace, the valve cannot be moved, and the pressure is not adjustable, so as to meet the requirements of reducing temperature resistance. , Excellent thermal shock resistance, avoid high temperature failure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

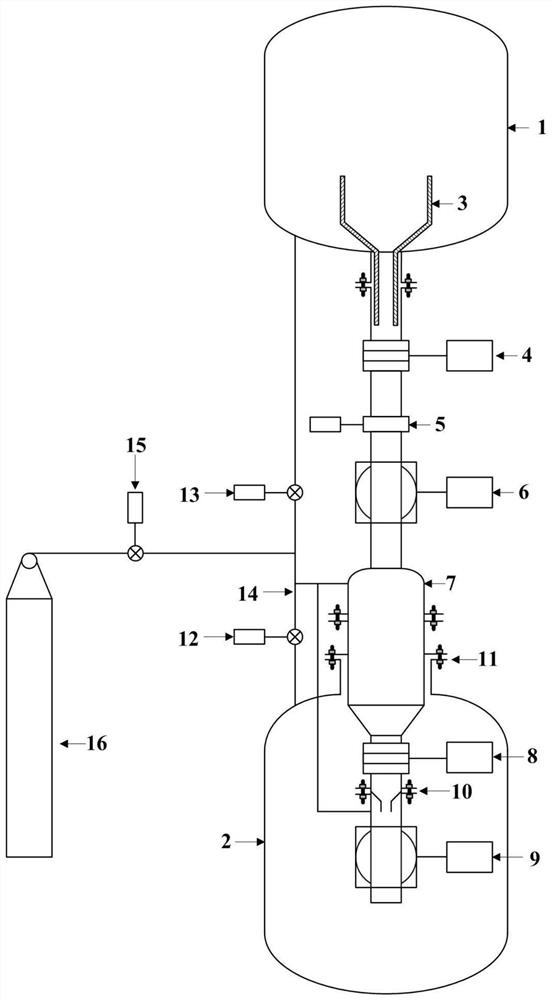

[0046] In view of the background of the difficulty in transferring high-temperature molten matter from a low-pressure environment to a high-pressure environment and the inadequacy of existing experimental techniques to deal with such problems, this embodiment proposes a fully automatic release mechanism for high-temperature molten matter. A temporary storage container is set between the atmospheric pressure container of the top smelting furnace and the bottom experimental container, and the transfer of the melt from the low pressure space to the high pressure space is realized by means of two-stage transfer.

[0047] In this embodiment, the isolation valves placed upstream and downstream of the temporary storage container are separated by a pair of valves to block the high-temperature molten material and to separate the pressure sealing function; the top valve adopts the valve body structure of the gate valve to block the molten material. The valve body is made of steel core wr...

Embodiment 2

[0059] This embodiment proposes a control method for the automatic release mechanism of the high-temperature molten material as proposed in the above-mentioned embodiment 1. This embodiment takes the experimental research of releasing the high-temperature molten material into a pressure vessel with a system pressure of 2 MPa in the form of a jet as an example. To describe, the specific process is as follows:

[0060] Close the melt release valve 8 downstream of the temporary storage container 7, the downstream main sealing valve 9, and the first electric pressure balance valve 12 on the pressure balance pipeline between the temporary storage container 7 and the bottom high-pressure container 2, and fill the bottom high-pressure container 2 The pressure reaches 2MPa;

[0061] Open the protective gate valve 4 upstream of the temporary storage container 7, the upstream sealing valve 6, and the second electric pressure balance valve 13 on the pressure balance line between the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com