Pressure resisting airtight cold plate vacuum brazing universal tool

A tooling and cold plate technology, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of small pressure, difficult to correct parts, deformation, etc., to reduce heat absorption and prevent product deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and examples.

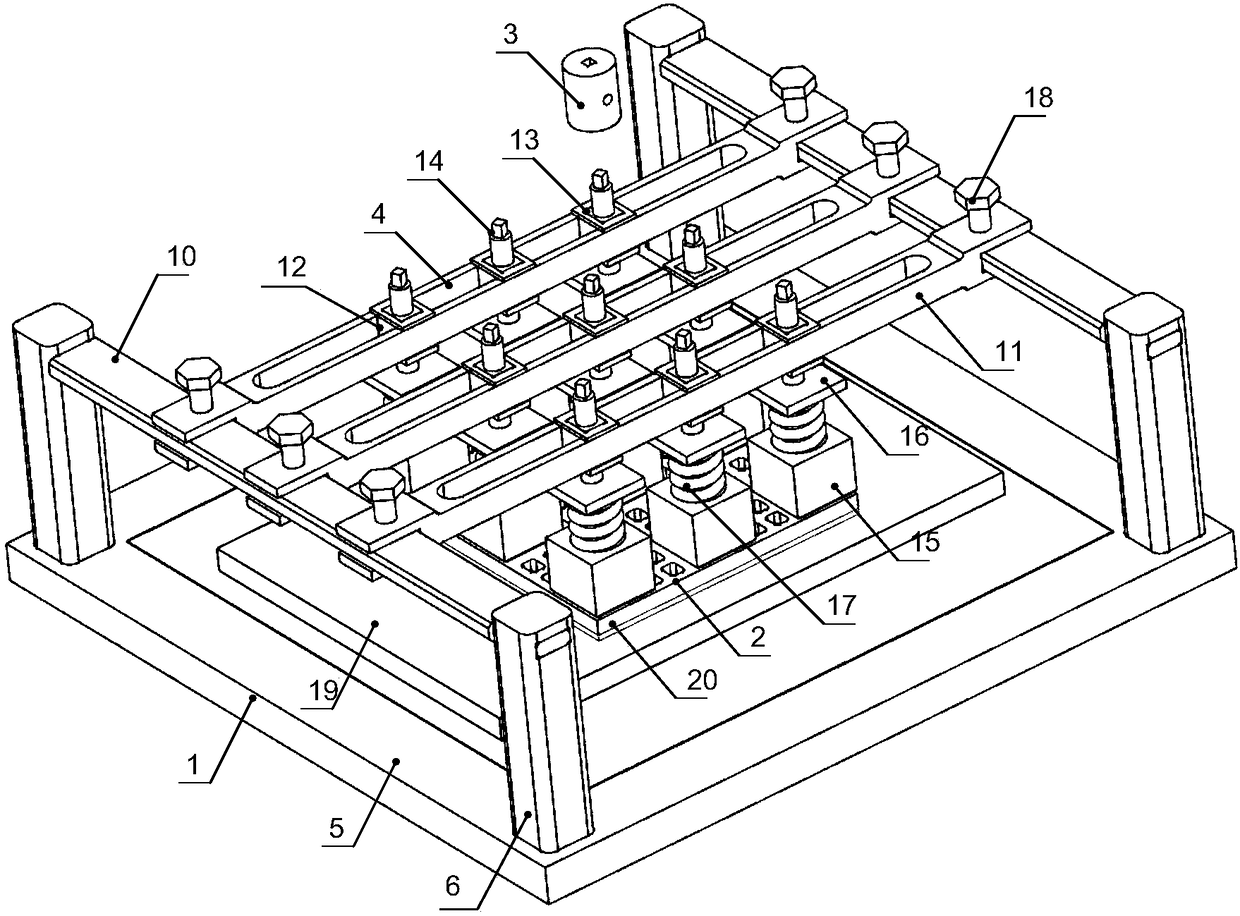

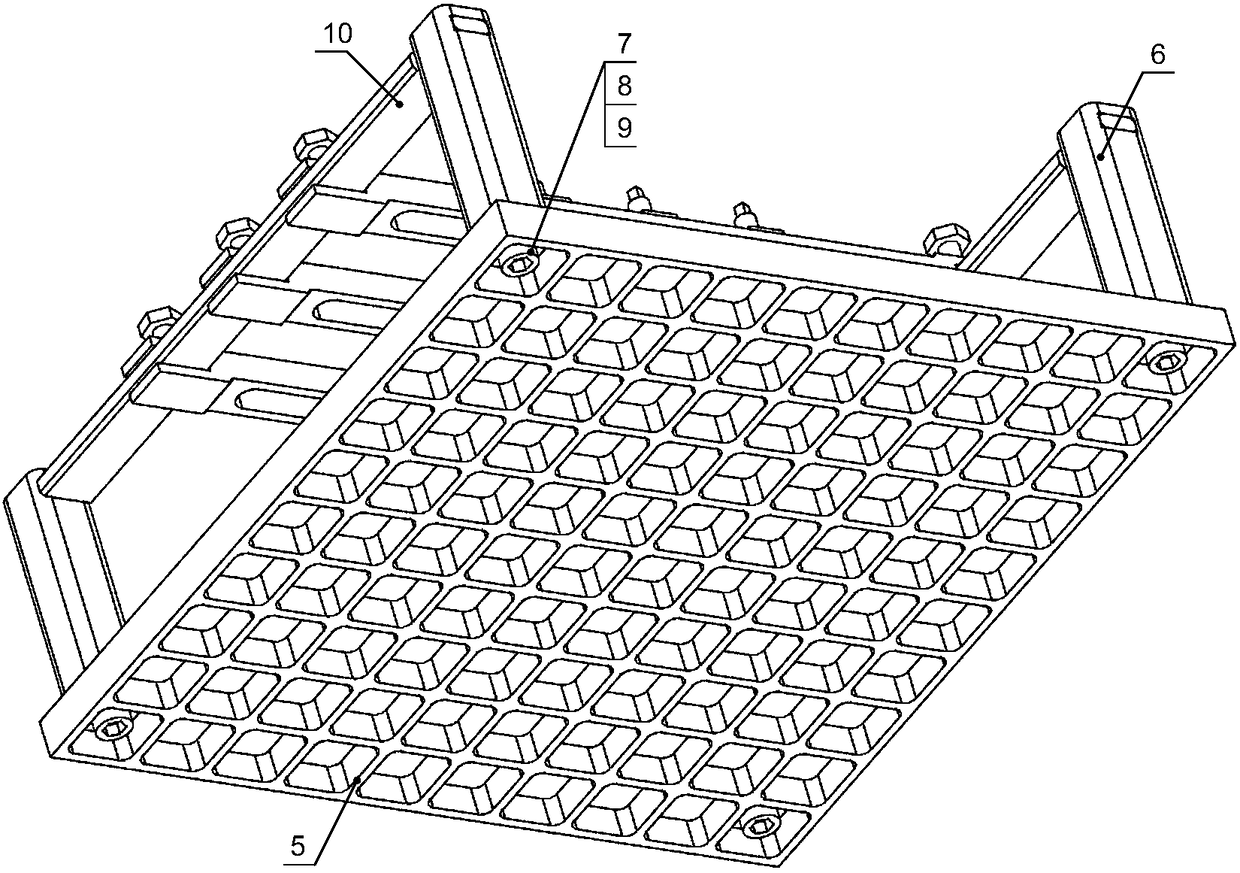

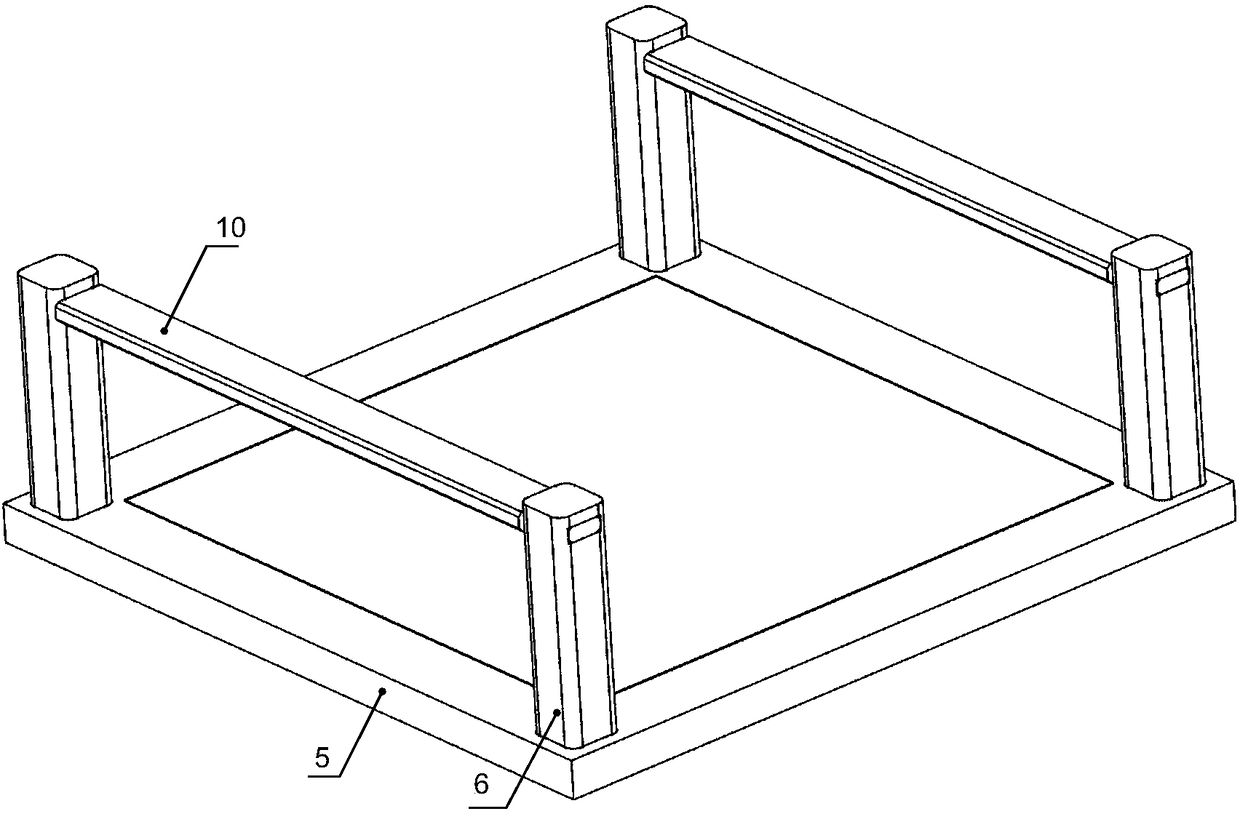

[0042] Such as Figure 1 to Figure 4 As shown, a pressure-resistant airtight cold plate vacuum brazing universal tooling, the universal tooling includes a mother board 2 with square grooves arranged in a square array and a base plate 5 with square grooves on the back; the cold plate is placed on the foundation On the front side of the board 5, the sub-motherboard 2 is located on the other side of the cold plate, and the general tooling compresses the cold plate by pressing the sub-motherboard 2. The invention can greatly reduce the heat absorbed by the tooling during the brazing process through the design of the square groove on the mother board and the base plate, ensure the brazing effect of the parts, and at the same time ensure the flatness of the parts brazing; the existing tooling directly passes through Pressing the parts with a briquetting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com