Short fiber-reinforced high temperature-resistant rubber roll, rubber roll rubber material and preparation methods thereof

A technology of short fiber reinforcement and manufacturing method, which is applied in the field of high temperature resistant rubber rollers, can solve the problems of rubber thermal oxidative aging damage, etc., and achieve the effects of small compression set, high material distribution consistency, and superior price competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

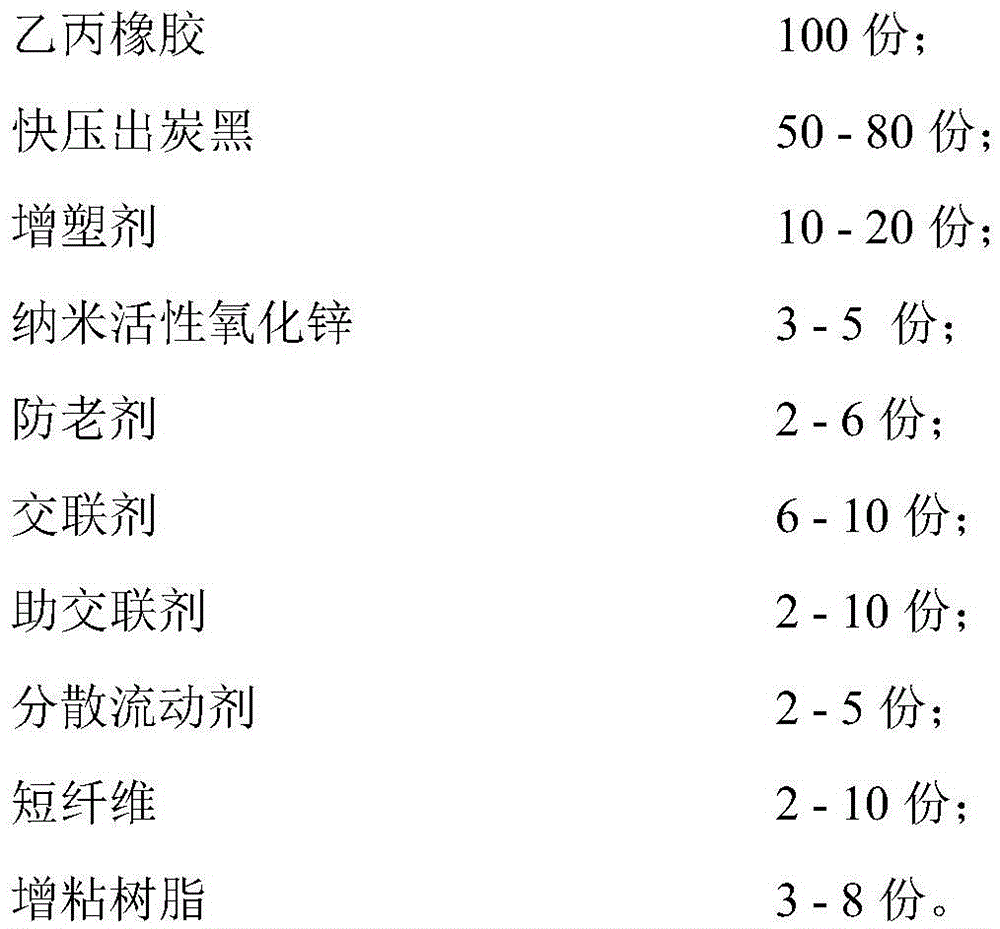

[0036] A short-fiber reinforced high-temperature-resistant rubber roller in this embodiment has a specification of Φ560×Φ520×1600, and the components and parts by weight of the rubber used are:

[0037]

[0038]

[0039] According to the formula design requirements, the ethylene-propylene rubber is 6160D EPDM rubber produced by LANXESS, and the content of the third monomer in EPDM rubber is 1.2%; the fast-extrusion carbon black is the fast-extrusion carbon black produced by Cabot Carbon black N550; Plasticizer is the PW-380 paraffin oil produced by Shanghai Jinhai Special Lubricating Oil Factory; Nano-active zinc oxide is produced by Lanxess; They are composed of agent ZMB2 / C-5, which are produced by Jiangsu Huada Chemical Group Co., Ltd. and Lanxess; the cross-linking agent is dicumyl peroxide, which is produced by Aksu; Methyl methacrylate is produced by Sartomer; the dispersion flow agent is WB42, produced by Jiatuo; the short fiber is P91-40 / EPDM produced by Rhine, w...

Embodiment 2

[0052] A short-fiber reinforced high-temperature-resistant rubber roller in this embodiment has a specification of Φ330×Φ290×1900, and the components and parts by weight of the rubber used are:

[0053]

[0054]

[0055] According to the formula design requirements, the ethylene-propylene rubber is 6160D EPDM rubber produced by LANXESS, and the content of the third monomer in EPDM rubber is 1.2%; the fast-extrusion carbon black is the fast-extrusion carbon black produced by Cabot Carbon black N550; Plasticizer is the PW-380 paraffin oil produced by Shanghai Jinhai Special Lubricating Oil Factory; Nano active zinc oxide is produced by Lanxess; They are composed of agent ZMB2 / C-5, which are produced by Jiangsu Huada Chemical Group Co., Ltd. and Lanxess; the cross-linking agent is dicumyl peroxide, which is produced by Aksu; Methyl methacrylate is produced by Sartomer; the dispersion flow agent is WB42, produced by Jiatuo; the short fiber is P91-40 / EPDM produced by Rhine, w...

Embodiment 3

[0068] A short-fiber-reinforced high-temperature-resistant rubber roller in this example has a specification of Φ200×Φ170×1250, and the components and parts by weight of the rubber used are:

[0069]

[0070]

[0071] According to the formula design requirements, the ethylene-propylene rubber is 6160D EPDM rubber produced by LANXESS, and the content of the third monomer in EPDM rubber is 1.2%; the fast-extrusion carbon black is the fast-extrusion carbon black produced by Cabot Carbon black N550; plasticizer is the PW-380 paraffin oil produced by Shanghai Jinhai Special Lubricating Oil Factory; nano-active zinc oxide is produced by Lanxess; the anti-aging agent is 3 parts by weight of antioxidant 445 and 1 part of anti-aging They are composed of agent ZMB2 / C-5, which are produced by Jiangsu Huada Chemical Group Co., Ltd. and Lanxess; the cross-linking agent is dicumyl peroxide, which is produced by Aksu; Methyl methacrylate is produced by Sartomer; the dispersion flow age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com