Patents

Literature

75results about How to "Stop crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

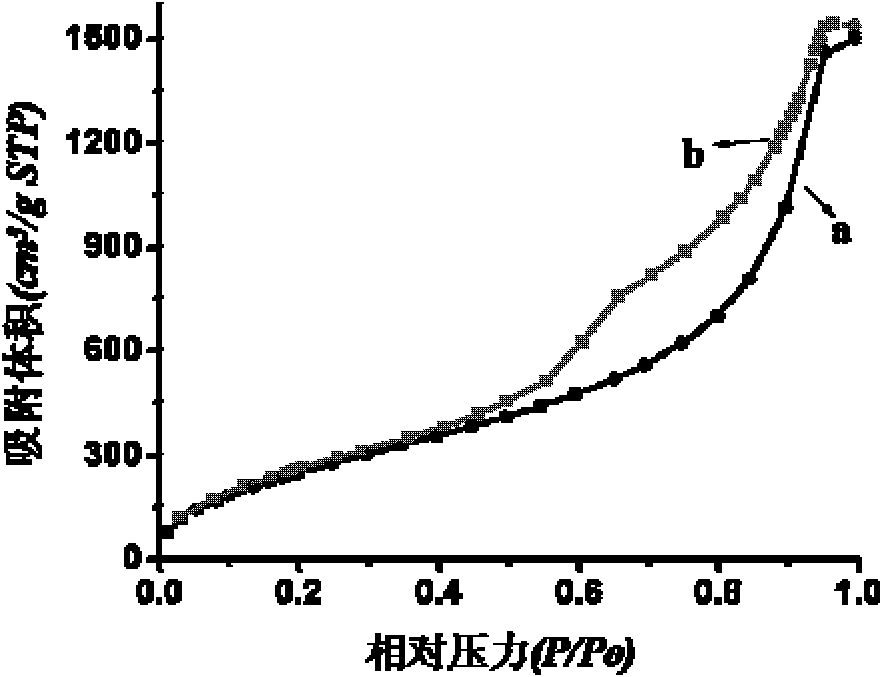

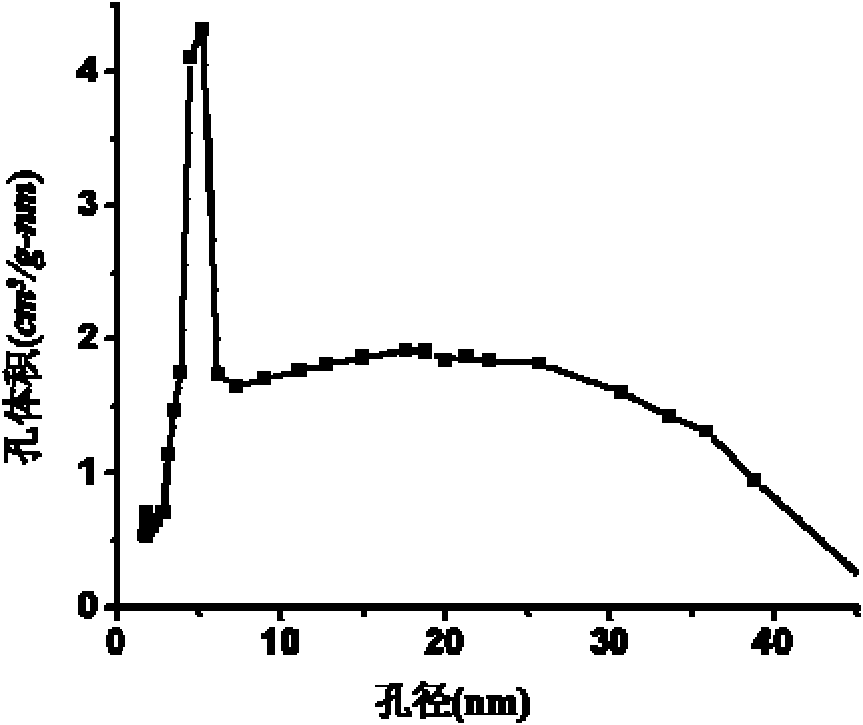

Method for preparing foam material reinforced silica aerogel composite material

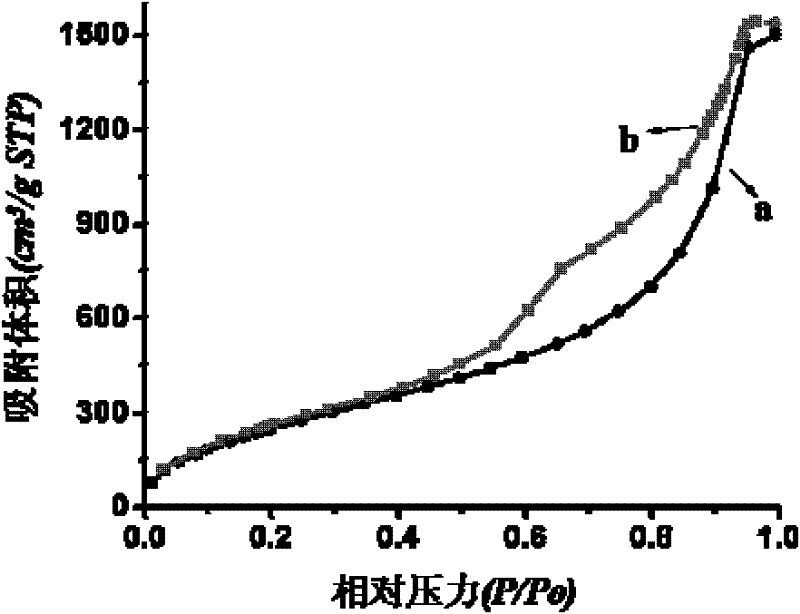

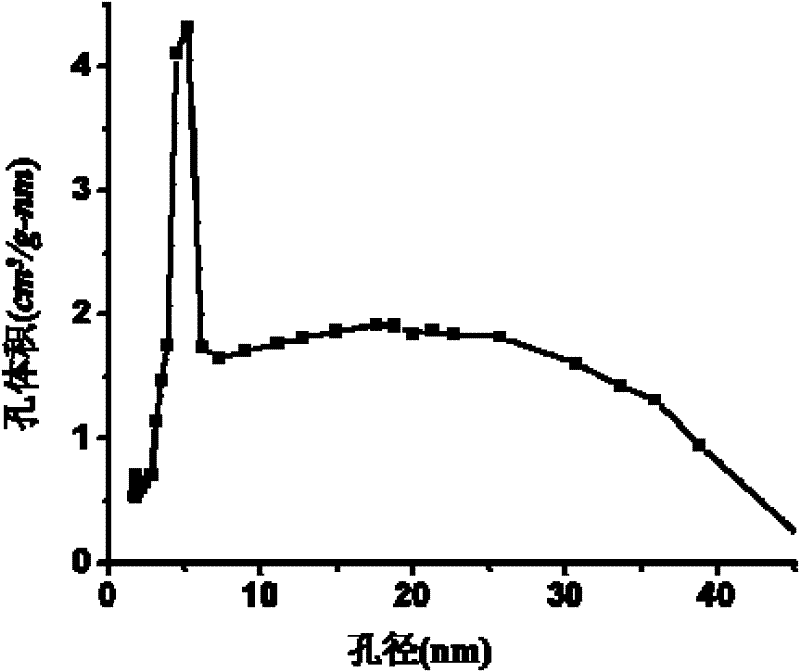

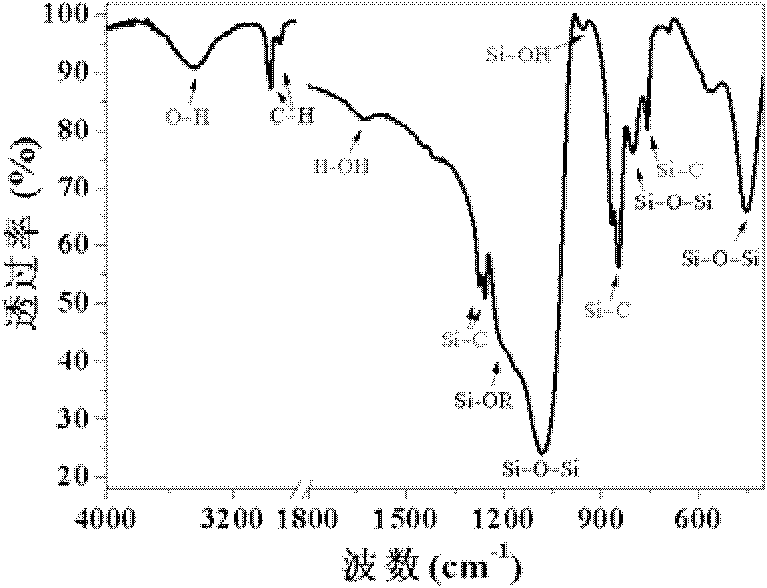

The invention discloses a method for preparing a foam material reinforced silica aerogel composite material and relates to silica aerogel. The method comprises the following steps of: preparing silica plural gel and aging the silica plural gel, modifying and drying. Through test, porosity is 80 t o 95 percent, density is 0.15 to 0.5g / cm<3>, the Brunauer-Emmett-Teller (BET) specific surface area is 600 to 1,100m<2> / g, and a water contact angle is 130 to 160 degrees; the foam material reinforced silica aerogel composite material is super hydrophobic; aerogel pore size distribution is relativelycentralized and the pore size of the aerogel is 2 to 50nm; and coefficient of heat conductivity is 0.01 to 0.035 W / (m.K), compression strength is 0.3 to 2Mpa (2 percent deformation), and elastic modulus is 1 to 5 Mpa. Meanwhile, the foam material reinforced silica aerogel composite material has good heat insulation performance, and adsorption performance, environment-friendliness and the other excellent performance. The method is simple, is short in a cycle, low in cost, and high in safety, and contributes to large-scale production; and by the method, excellent performance of the aerogel can be kept and the mechanical property of aerogel can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

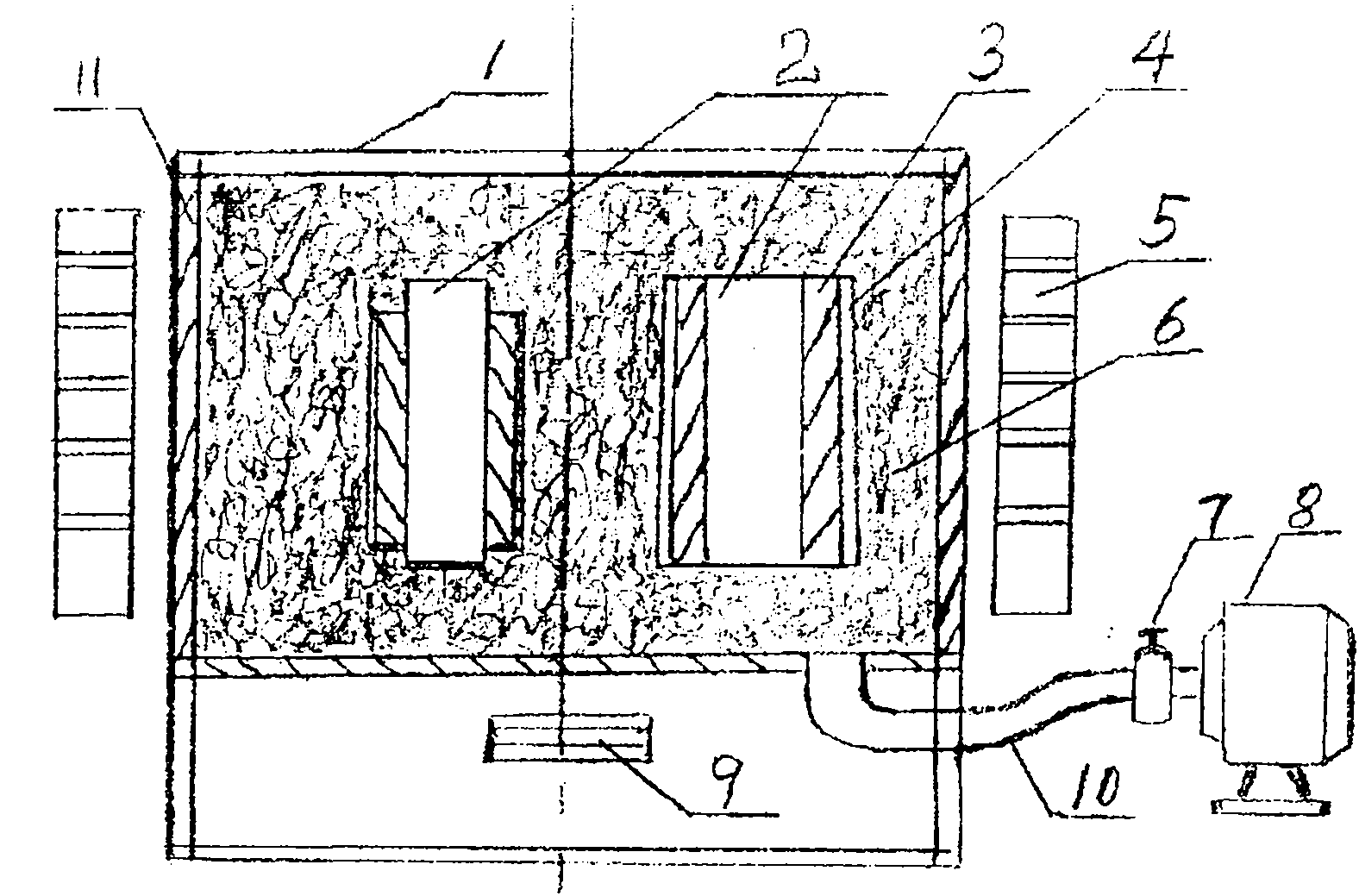

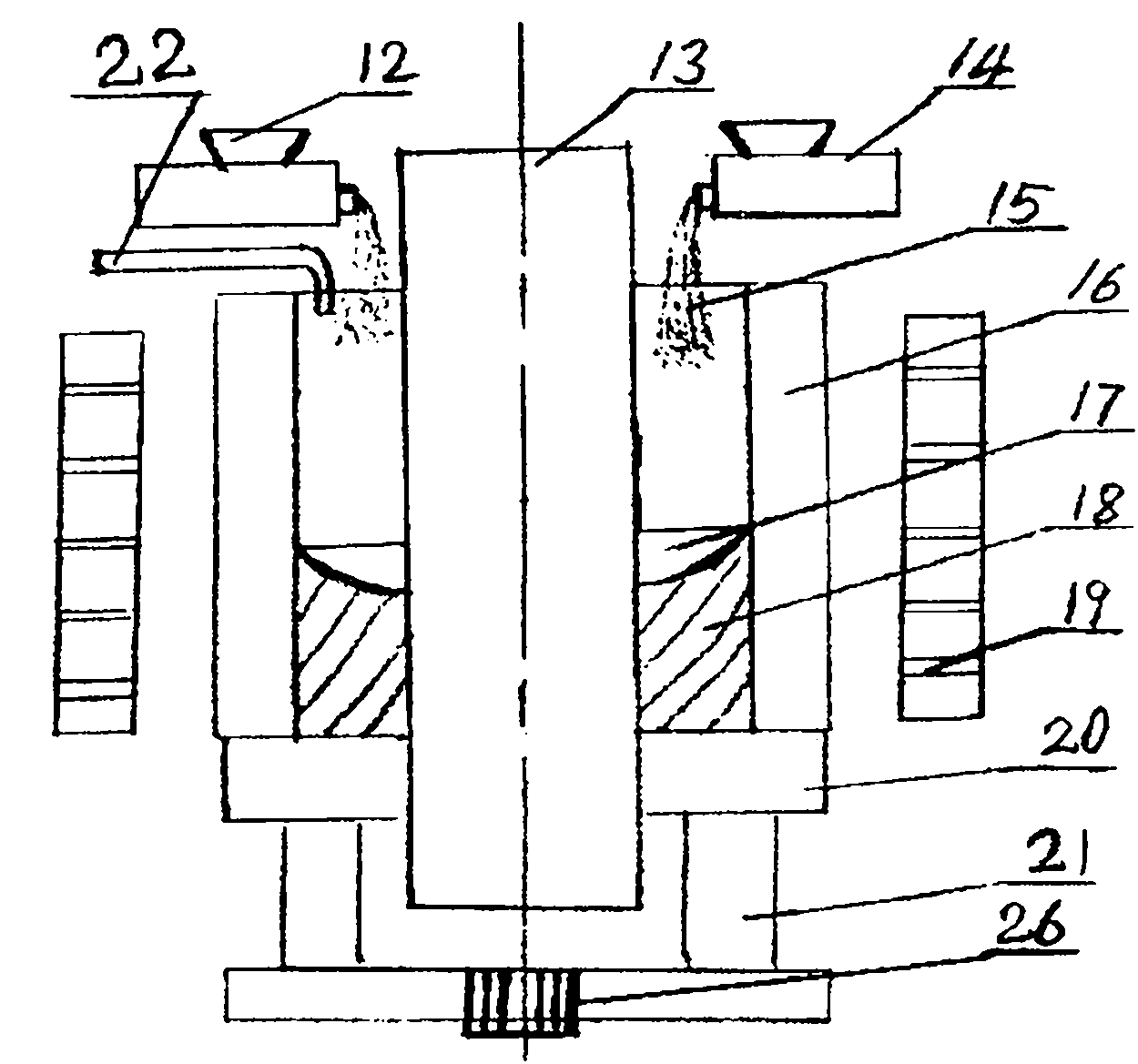

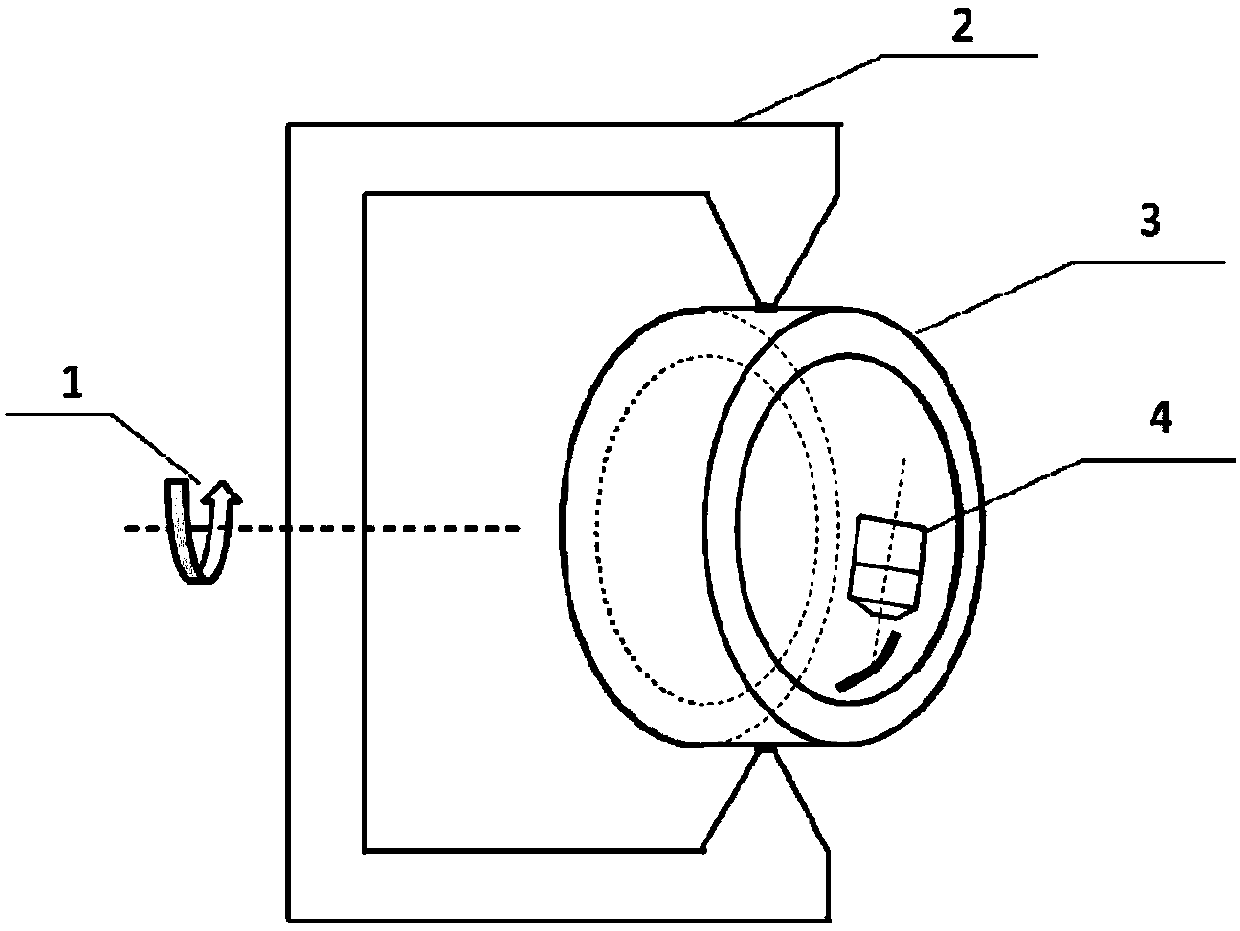

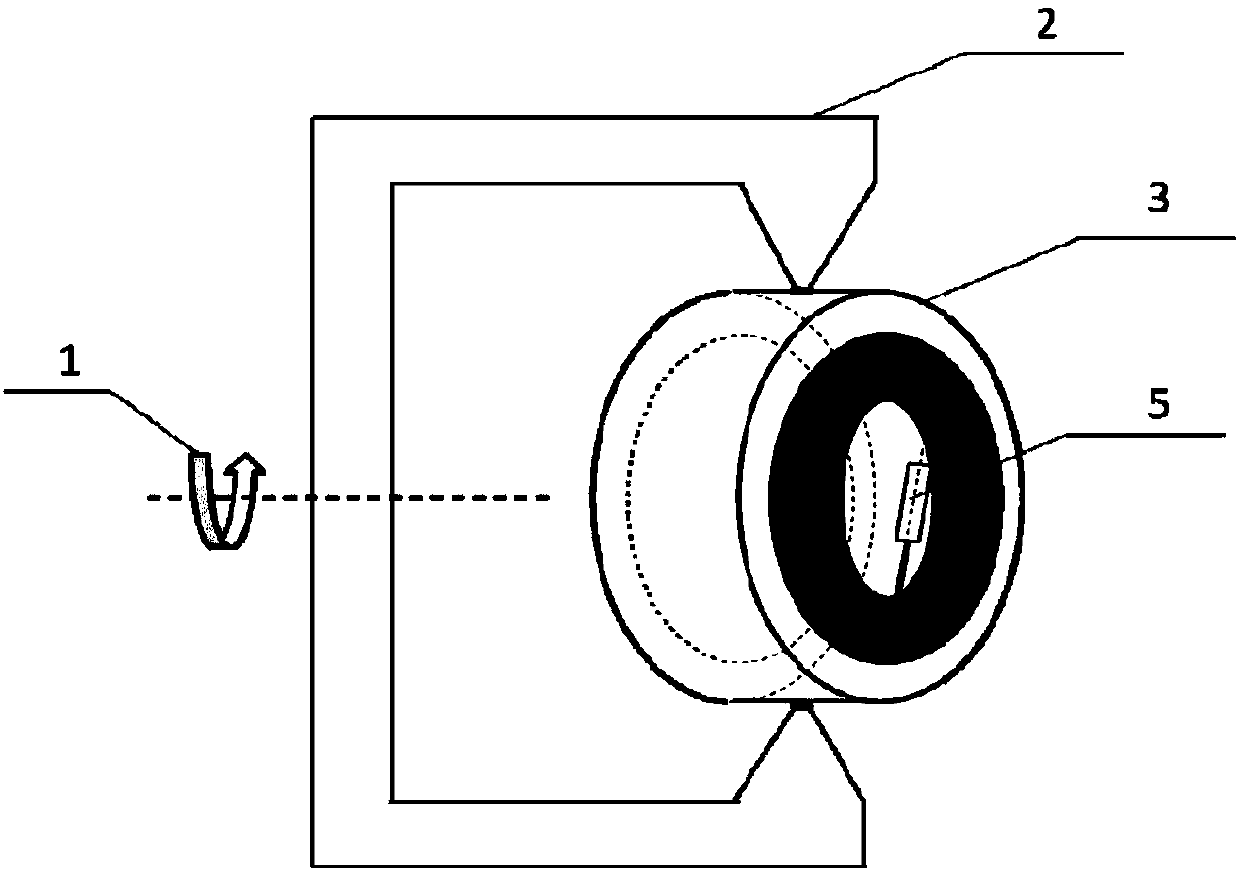

Preparation process and device of nano-particle reinforced bimetal composite

InactiveCN101914767ALow melting pointImprove toughnessMetallic material coating processesCorrosionBonding strength

The invention relates to a preparation process and a device of a nano-particle reinforced bimetal composite, the nano-particle reinforced bimetal composite comprises the following chemical components by weight percent: 6-25% of Cr, 4-18% of Ni, 1.0-4% of Mo, 1.0-1.8% of Si, 1.2-3% of Mn, 0.4-2.2% of B, 0.1-1.2% of MgO, 0.2-2% of CaF2, 0.2-0.7% of C, 0.2-0.8% of Nb, not more than 0.9% of one or the combination of CeO2, Y3O2 and La2O3, 0.0-0.8% of Co, and the balance of Fe, and mixed particles of nano-sized carbides, nitrides, borides or carbonitrides are added in alloy powder. The vacuum induction melting and the cladding processes and equipment are adopted for melting and cladding the mixture on a workpiece, the thickness of a cladding layer is 0.1-25mm, the cladding layer contains 1%-50% of nano-reinforcing particles of one or the combination of the carbides, the nitrides, the borides and silicides, and the cladding layer has special performances of wear resistance, corrosion resistance, electrical conductivity, self-lubrication performance and the like. A coating layer and a base material form the metallurgical bonding, thereby having high bonding strength, overcoming the drawbacks in various coating processes at home and abroad, leading the coating layer to avoid the defects of shrinkage cavities, inclusion, cracking, shedding and the like and having the advantages of high heating temperature, fast speed, high production efficiency, small energy consumption, simple preparation process and low cost.

Owner:丁家伟

Aramid fiber enhanced wood-plastic composite material and preparation method thereof

InactiveCN101629022AImprove mechanical propertiesImprove thermal stabilityFibre treatmentChemical LinkageThermoplastic

The invention relates to aramid fiber enhanced wood-plastic composite material and a preparation method thereof, relating to fiber enhanced wood-plastic composite material and the preparation method thereof. The invention solves the problem that the existing wood-plastic composite material has bad comprehensive mechanical property. The wood-plastic composite material comprises thermoplastic, wood fiber material, lubricant, bulking agent and graft modification aramid fiber. The preparation method of the invention is as follows: 1. weighing raw materials; 2. preparing premixing materials; 3. melting, extruding and molding the premixing materials to obtain the fiber enhanced wood-plastic composite material. The preparation method utilizes carbon-carbon double bond and silane alkyl on the surface of modified aramid fiber and polyolefin and wood flour to form chemical bonds so that aramid fiber and polyolefin has good compatibility, and effectively enhances the interface binding force of the composite materials; the aramid fiber enhanced wood-plastic composite material simultaneously has high strength, high tenacity, and good comprehensive mechanical property. The method can be used for producing the wood-plastic composite material with high performances such as structural engineering materials, etc.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

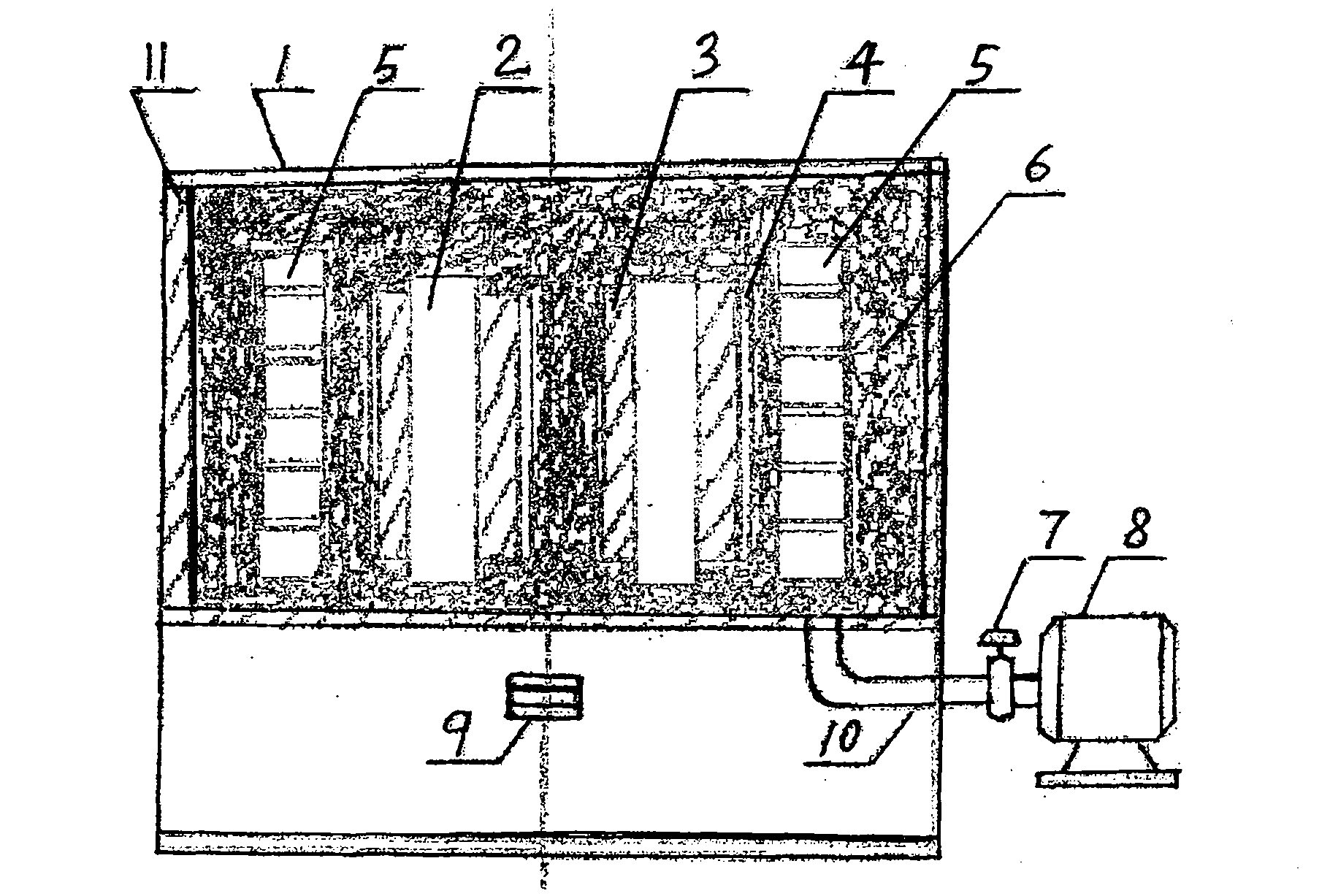

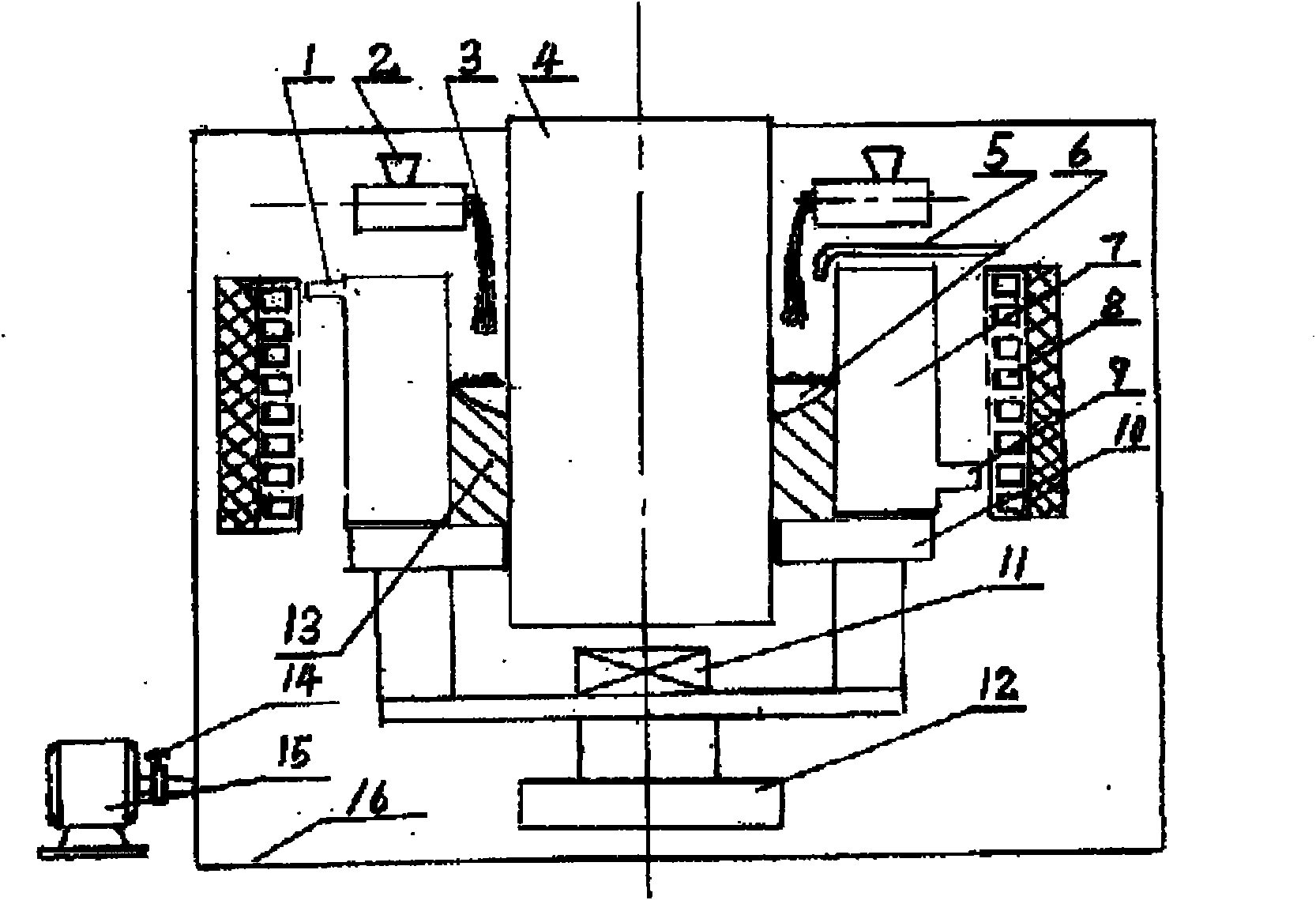

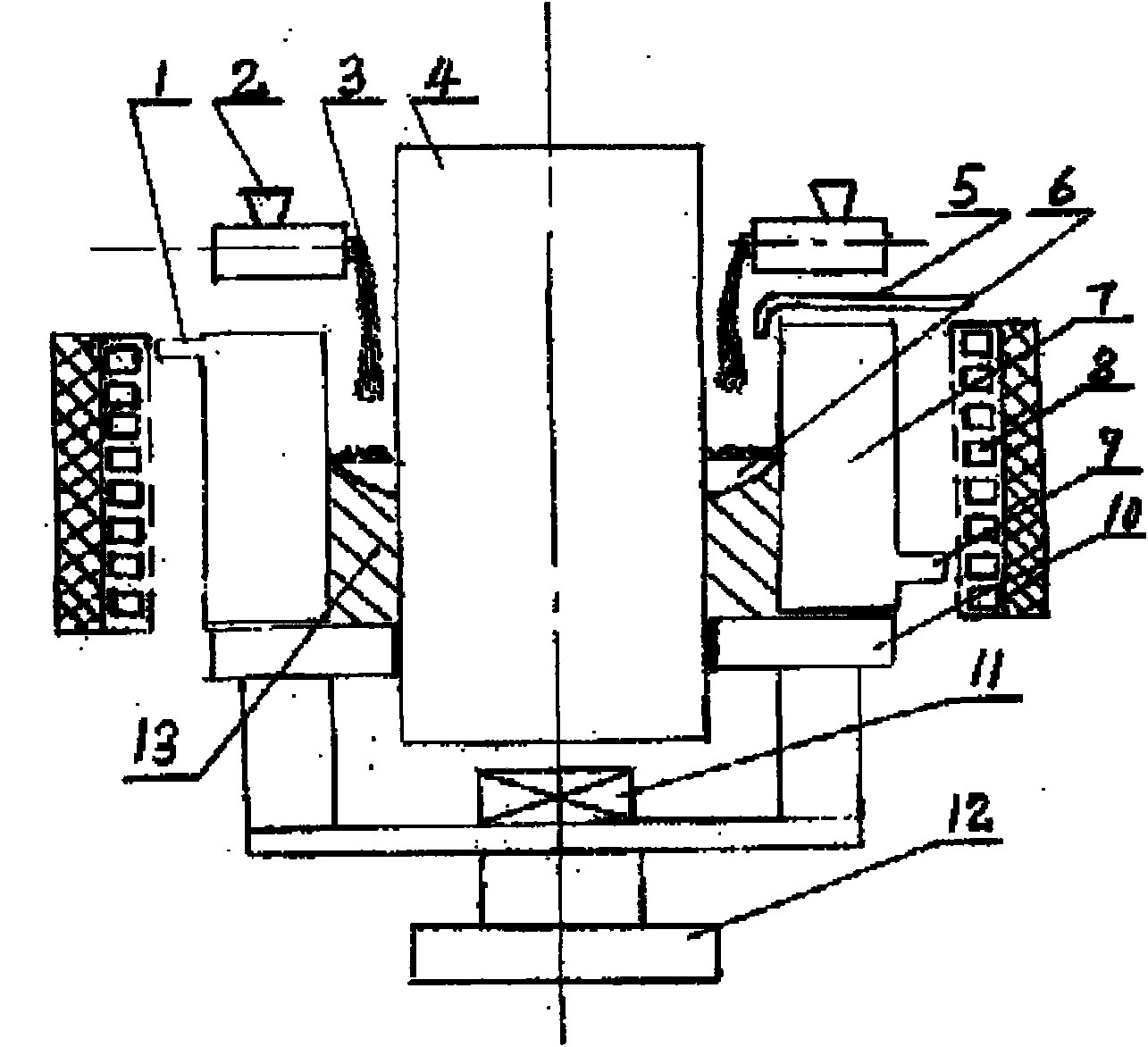

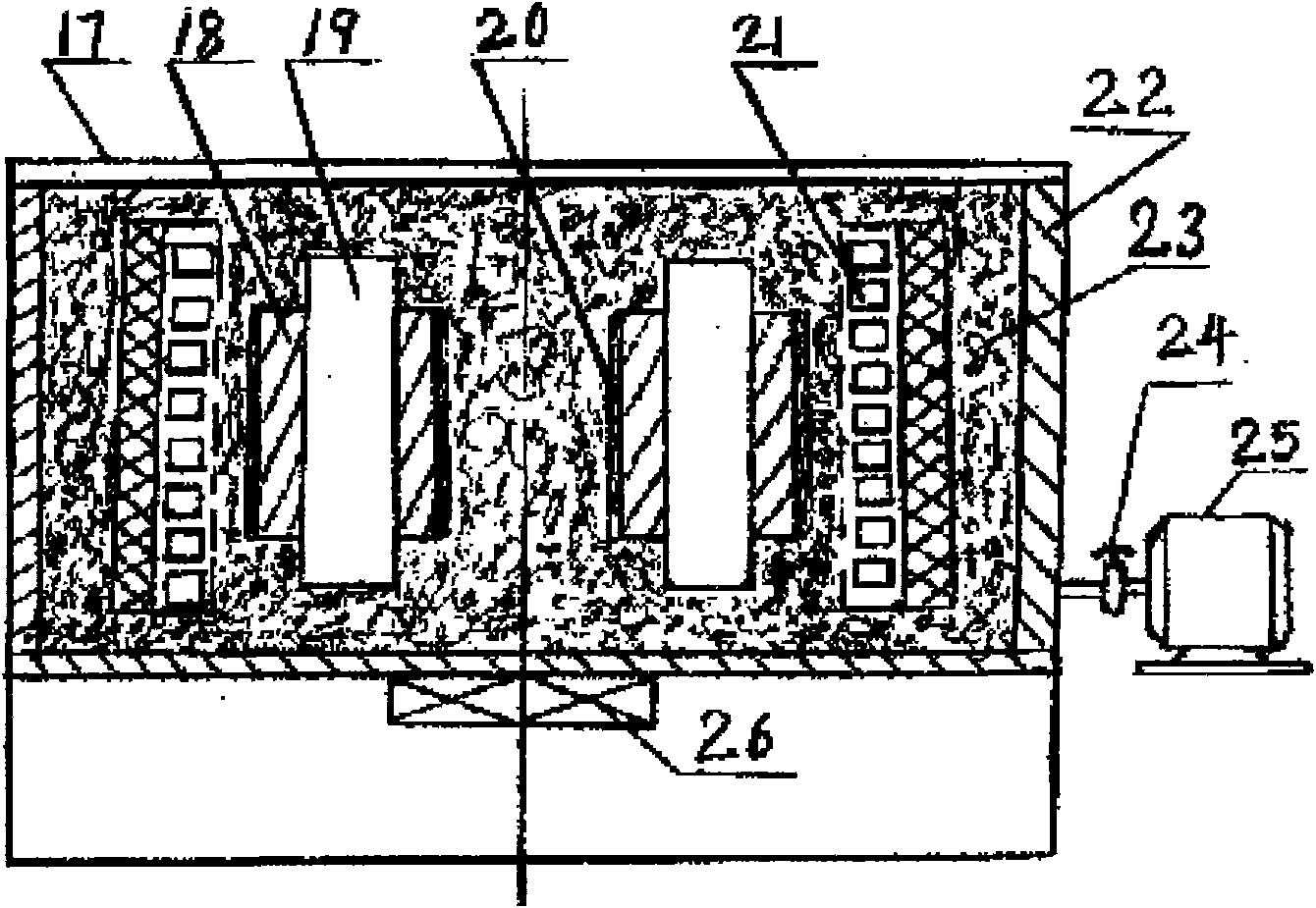

Micro-nano-alloy bimetal composite material preparation technique and device thereof

The invention relates to a micro-nano-alloy bimetal composite material preparation technique and a device thereof; one of wear-resistant and corrosion-resistant ferrous metal material, non-ferrous metal material and various self-fluxing alloy is prepared into power; then, the powder is added with less than or equal to 0.8% of one or combination in CeO2, Y2O3 and La2O3, 0.3-1.5% of MgO, 0.3-1.8% of CaF2, 0.0-1.5% of B, 0.1-0.8% of Nb, 0.1-1.0% of Ti, 0.1-2.0% of grain refining and recrystallization inhibitor according to the mass percent; or the powder is added with 1-40% of carbide, nitride, micro-nano or nano particles of boride; and the mixture is put into a high-energy stirring ball grinding mill for grinding and ball milling, so that the micro-nano or nano alloy powder can be prepared. A variable frequency induction heating device is adopted for cladding and melting vacuum or inert gas, so that a workpiece can be melted and coated with a micro-nano or nano scale alloy cladding layer which has the grain size of 0.1-35mm and is wear-resistant and corrosion-resistant, and the bimetal composite material can be prepared. The invention overcomes the defects in various coating techniques in China at present, can complete the preparation of the workpiece with the cladding layer having high thickness for once, does not need repeated coating and sintering, has high material utilization rate, low machining allowance and preparation cost, simple preparation technique and high production efficiency.

Owner:泰州海天机械配件有限公司

Wear-resistant hard composite material using graphene as filler and preparation method thereof

The invention belongs to the field of macromolecular composite materials and in particular relates to a wear-resistant hard composite material using a novel nanocarbon material graphene as a filler and a preparation method thereof. The composite material is a hard composite material plate formed by blending and hot-pressing a polymer matrix and the graphene, and is prepared through the following steps: mixing the graphene, the polymer matrix and a rare earth stabilizing agent uniformly; melting and blending by using a torque rheometer to obtain a block-shaped composite; hot-pressing by using a flat vulcanizing machine to obtain the hard composite plate, wherein the composite material comprises 0.1-3wt% of two-dimensional graphene nanocarbon material. The polymer-based composite material using the carbon material as the filler has the characteristics of light weight, easiness in processing, corrosion resistance, friction resistance and the like, and is widely applied in the fields of national defense industry and automobiles. The composite material can meet the increasingly higher tribological performance requirements of the fields of aviation, aerospace, automobiles, machinery and the like on the existing high-performance polymer composite materials; the preparation process of the composite material is simple; industrial production is realized easily.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

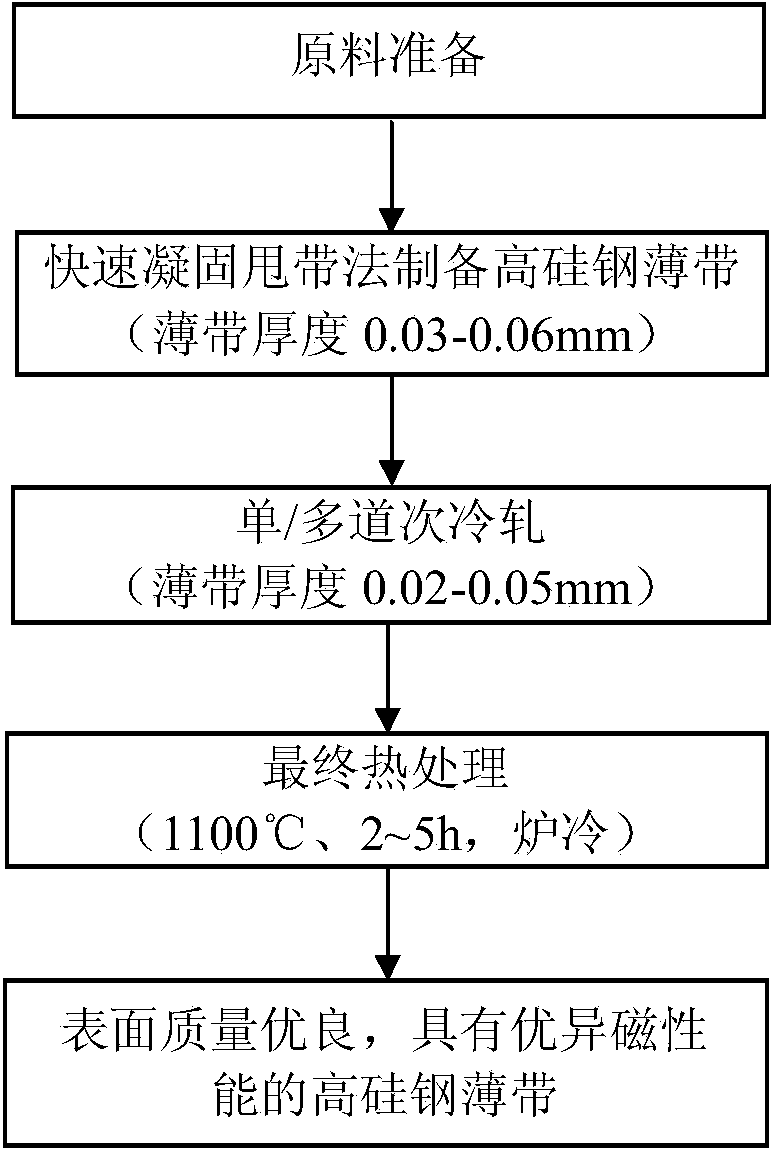

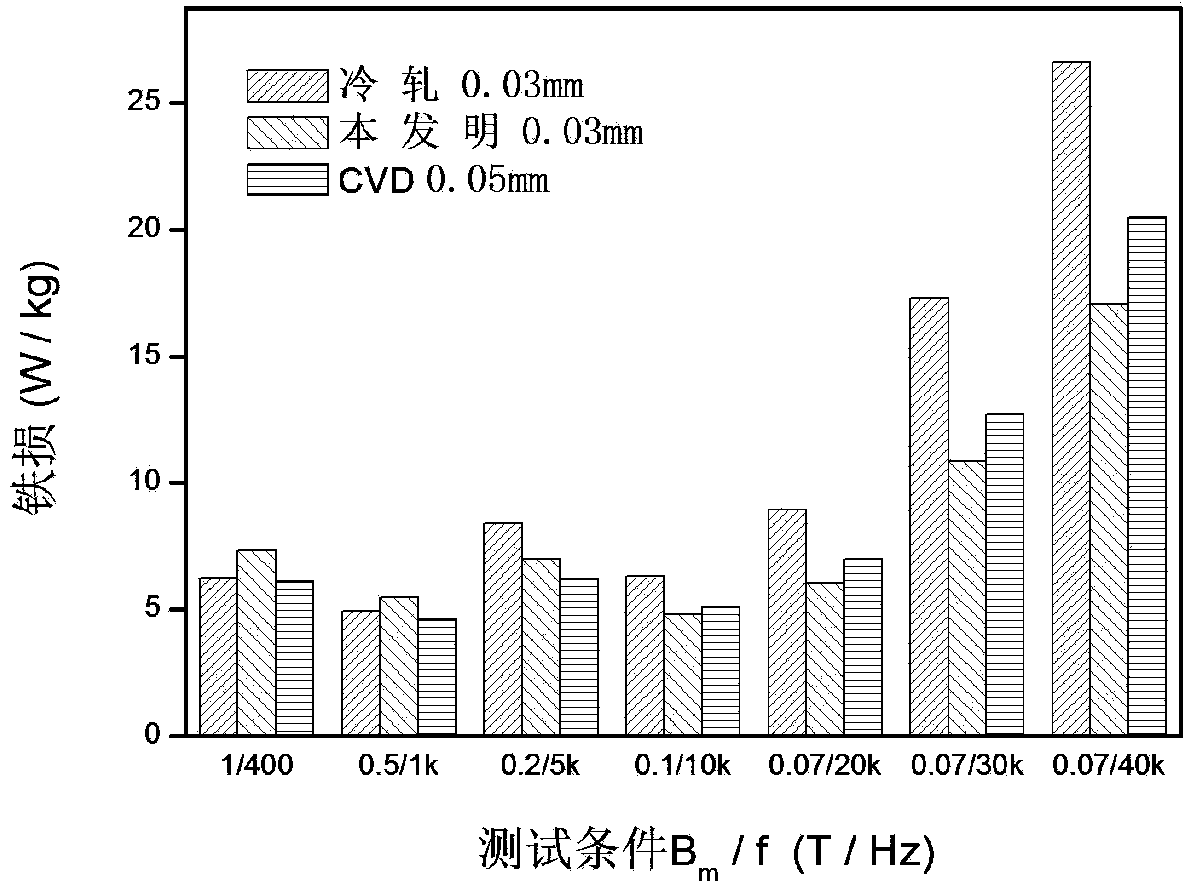

Short-process efficient cold-rolling preparation method of high-silicon steel thin strip

The invention aims at providing a short-process efficient cold-rolling preparation method of a high-silicon steel thin strip. The preparation method is characterized in that the high-silicon steel thin strip is prepared by using a rapid solidification method, and the thickness of the high-silicon steel thin strip is reduced by using a cold rolling method, the surface quality is improved, and the high-frequency magnetic performance is improved; due to rapid solidification, the plasticity of high-silicon steel can be improved, and the thin strip with certain plasticity is obtained and can be wound into a coil; then, cold rolling is carried out, so that the degree of order of the high-silicon steel is further lowered, the plasticity of the high-silicon steel is improved, and a high-silicon steel thin strip coil is obtained; the thin strip obtained through rapid solidification has the advantages that the crystal grain size is obviously reduced, the degree of order is obviously lowered, and the microhardness change is not great, so that next-step cold rolling is facilitated; during cold rolling, the rolling reduction of first-time rolling is controlled, and then, the plasticity is further improved, so that the thin strip with the thinnest thickness of 0.02mm can be obtained. According to the preparation method, the production efficiency of the prepared high-silicon steel thin strip is high, and the product quality of the prepared high-silicon steel thin strip is good, so that the method can be widely implemented industrially and accordingly has a broad application prospect.

Owner:UNIV OF SCI & TECH BEIJING

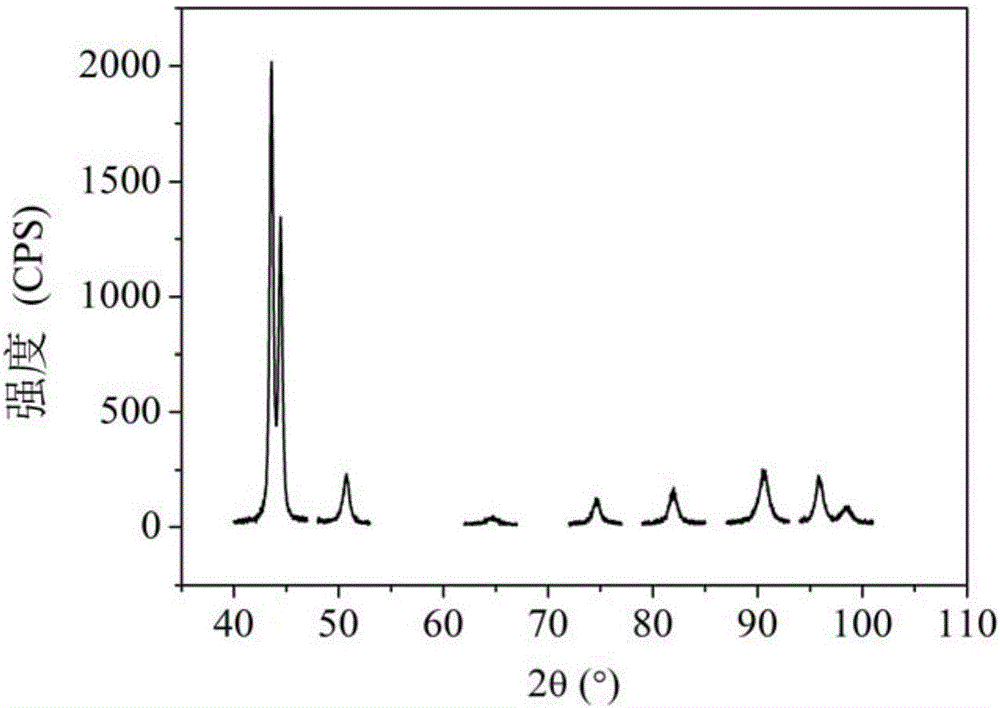

WC-Co-cBN composite hard alloy and preparation method thereof

ActiveCN107739950AGood thermal stabilityGood effect of coating modification and wetting agentTransportation and packagingMetal-working apparatusCemented carbideChemical composition

The invention belongs to the technical field of superhard cutting tools, and relates to a WC-Co-cBN composite hard alloy and a preparation method thereof. The WC-Co-cBN composite hard alloy comprisesthe following chemical components of, by weight, 70%-90% of ultrafine / nano WC powder, 3%-15% of Co powder, 0.35%-0.75% of a grain inhibitor, 1%-10.75% of cBN micro powder with a surface plated with aMo, Ni and Ti metal film with excellent high-temperature and chemical stability, and 0.25%-5% of spherical mixed powder selected from Al, Ni, Cr, Y or other combinations; and the components are prepared into the composite hard alloy through spark plasma sintering. According to the WC-Co-cBN composite hard alloy and the preparation method thereof, the grain size of the prepared alloy is small, hardness, strength and toughness is high, wear resistance is good, the difficulty that heat stability of dry cutting is low can be overcome, machining cost is reduced, and the WC-Co-cBN composite hard alloy and the preparation method thereof are particularly suitable for high-performance machining cutting tools.

Owner:GRIMAT ENG INST CO LTD

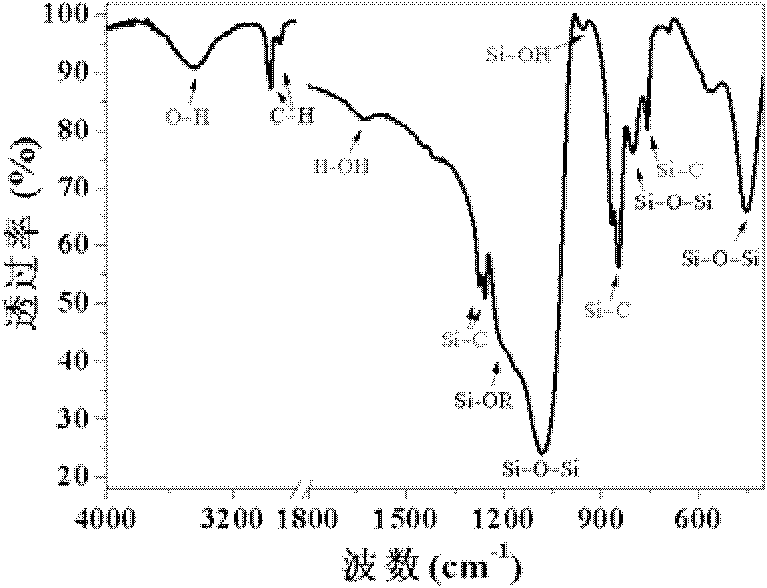

Sandstone stone cultural relic protection material, preparation method and application method

A disclosed sandstone stone cultural relic protection material is a sol with uniform transparent appearance, and is prepared by performing mixing and reacting on 100 parts by weight of tetraethyl orthosilicate, 0.5-10 parts by weight of poly(dimethylsiloxane), 0.05-5 parts by weight of nano-hydroxyapatite, 0.1-3 parts by weight of an organic metallic tin catalyst and 0.002-0.5 part by weight of a silicane coupling agent. When the material is used, the material can be diluted with an organic solvent for 0-10 times, the stone cultural relic subjected to surface cleaning processing is brushed, sprayed or immersed with the diluent until no protection material is absorbed, and then the stone cultural relic is placed in natural environment and aged for one month or more. By employing the protection material to process the substrate surface of sandstone stone cultural relics, the to-be-protected stone cultural relic can be substantially improved in hydrophobic performance and compressive strength; and the protection material provided by the invention is capable of resisting exterior environment influence caused by acid rain, salt, humiture variation and the like, also is simple and practical in operation technology, mild in reaction conditions and low in cost, and is suitable for industrial scale production and application.

Owner:SICHUAN UNIV

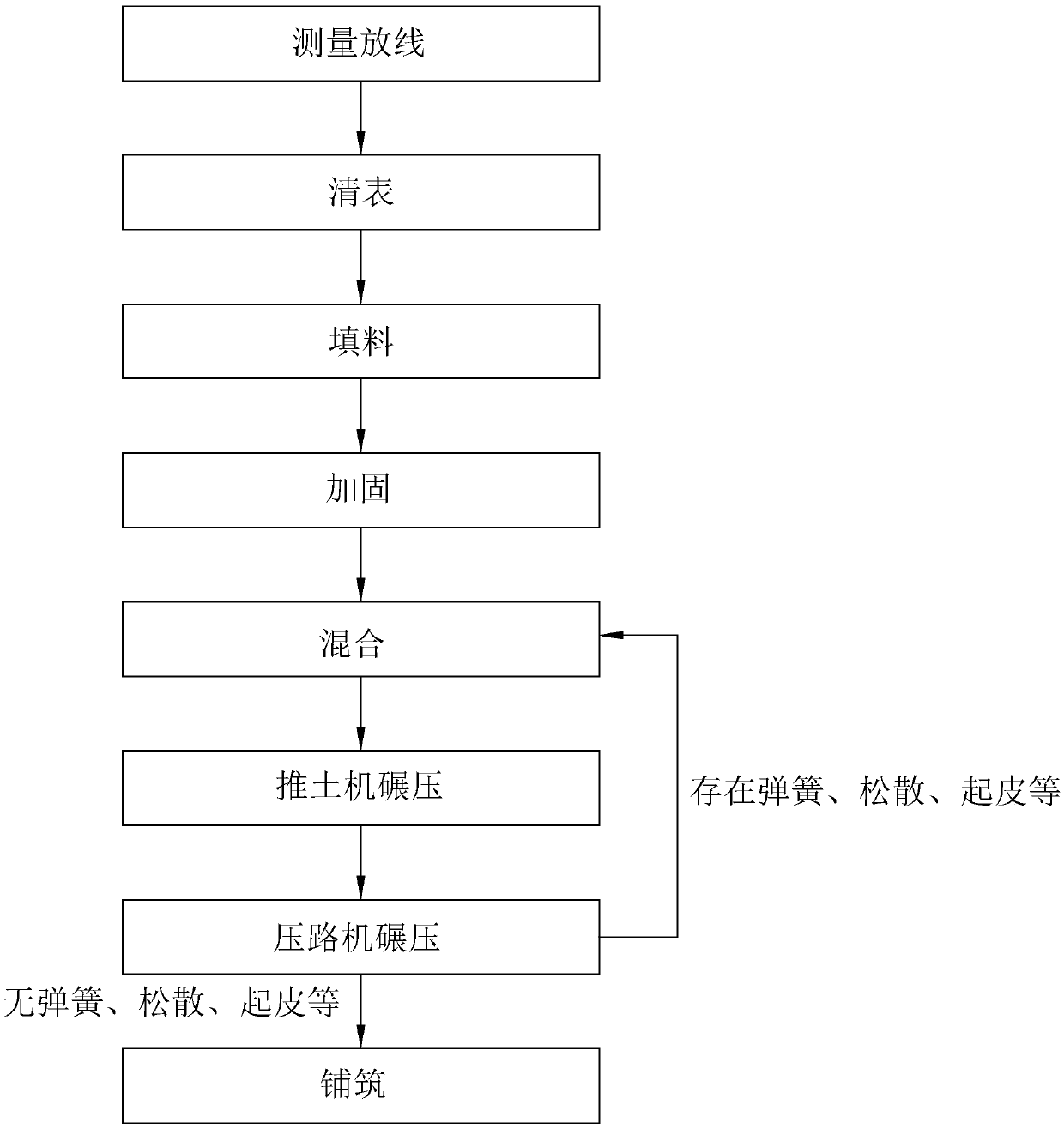

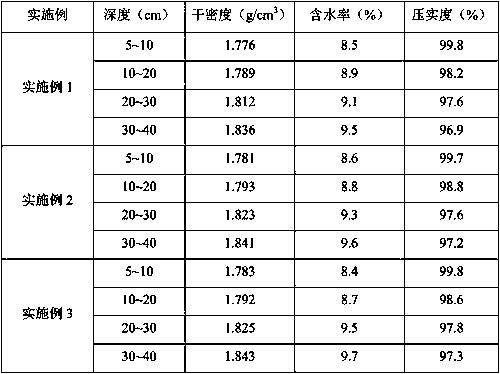

Method for constructing roadbed

InactiveCN109629361AImprove reinforcementImprove corrosion resistanceRoadwaysEngineeringRoad construction

The invention discloses a method for constructing a roadbed through sand filling, and belongs to the field of traffic construction. In the technical scheme, the method is characterized by including the steps of surveying and setting out, surface clearing, filling, reinforcing, mixing, rolling compaction of a bulldozer, rolling compaction of a road roller and paving. The method solves the technicalproblem that in the prior art, the roadbed is prone to losing stability and deforming, and is applied to road construction to enhance the effect of roadbed stability.

Owner:鼎固建安集团有限公司

Welding repair process suitable for cast nickel-base superalloy casting

InactiveCN106425021ADoes not affect machineryPerformance is not affectedArc welding apparatusMelt temperatureMelting temperature

The invention relates to a welding repair process suitable for a cast nickel-base superalloy casting. The process is suitable for welding repair of the cast nickel-base superalloy casting of which the mass percent of Ti does not exceed 5.2% and the mass percent of Al does not exceed 6.5%. Before welding repair, homogenization heat treatment is performed on the casting of which defective parts are removed, the holding temperature of the homogenization heat treatment is not lower than 1205 DEG C and is not greater than 93% of melting temperature of the casting, and the holding time is not less than 10 hours, so that the casting generates high-temperature tissues; the cooling speed of the casting after the homogenization heat treatment is not less than 30 DEG C per minute, so that the high-temperature tissues of the alloy are reserved, cracks are prevented during welding repair, the welding repair for many times is avoided, and the welding repair efficiency is effectively improved.

Owner:上海万泽精密铸造有限公司

3,3',5,5'-tetramethyl-4,4'-biphenyldiglycid ether preparation method

InactiveCN1733745AReduce processing viscosityImprove solubilityOrganic chemistryPolymer scienceEther

The invention relates to a process for preparing 3,3',5,5'-tetramethyl-4,4'-biphenyl didycidyl ether, wherein the 3,3',5,5'-tetramethyl-4,4'-biphenol is reacted with excess epichlorohydrin under the action of phase transition catalyst. The prepared has low epoxy equivalent weight, high yield, and simple reaction steps.

Owner:GUANGZHOU INST OF GEOCHEMISTRY - CHINESE ACAD OF SCI

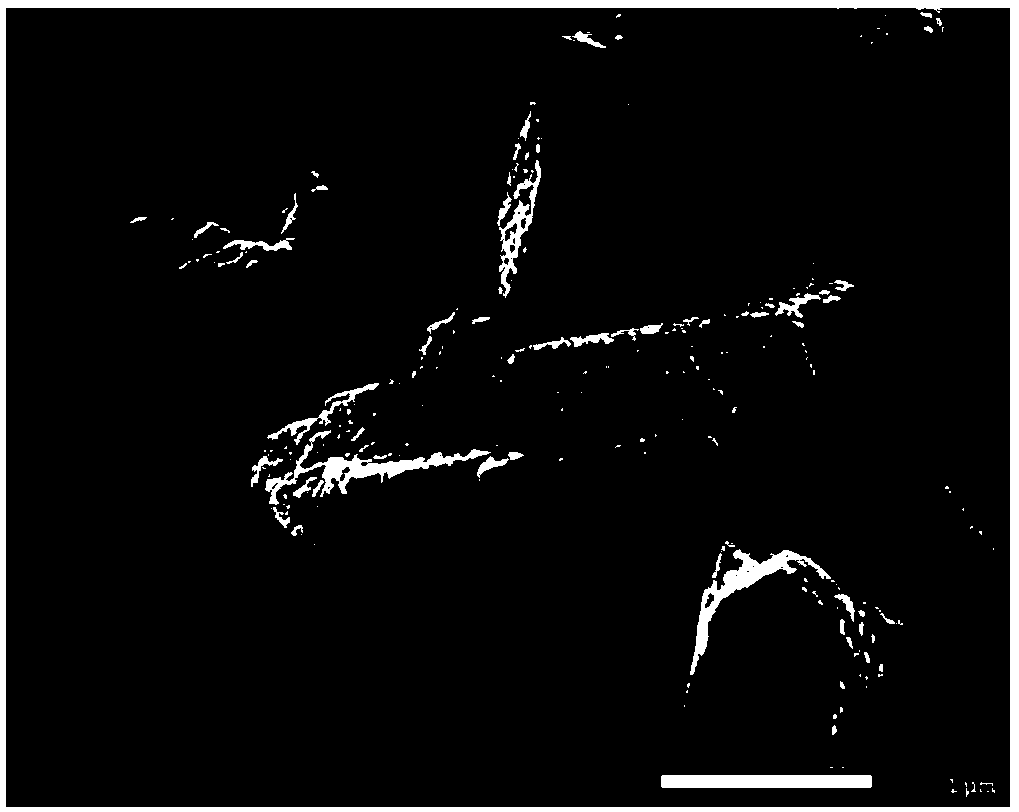

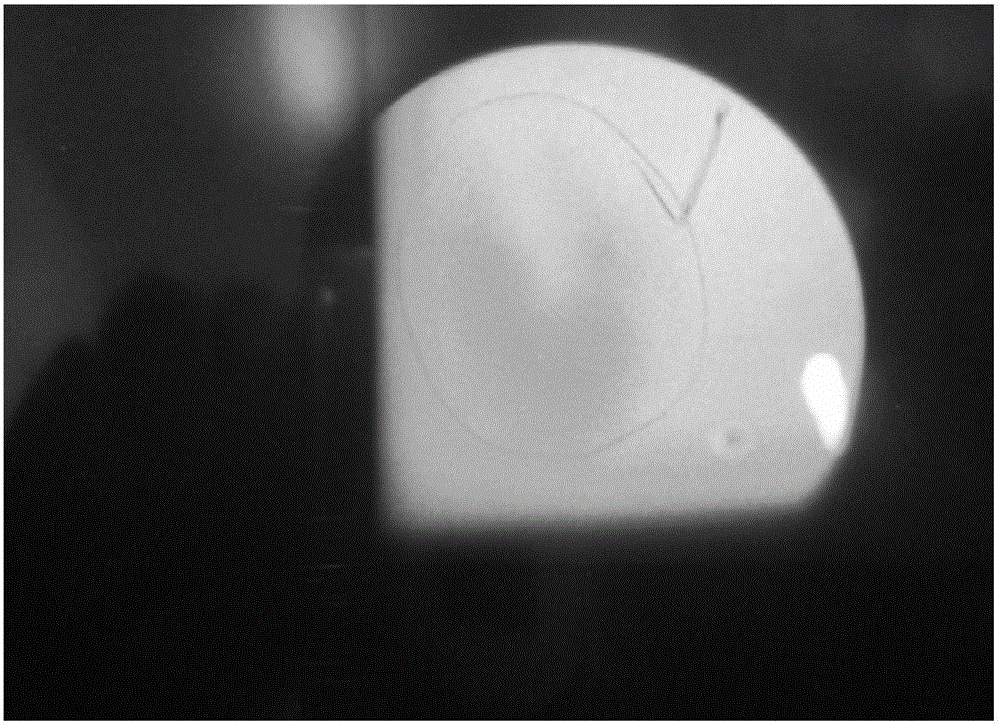

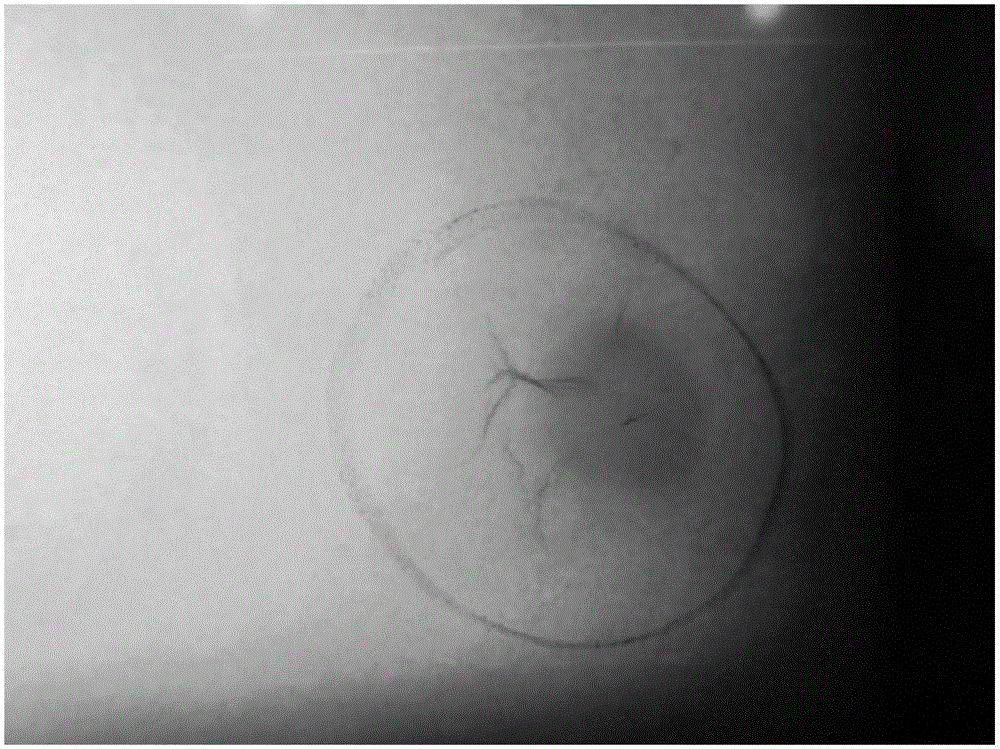

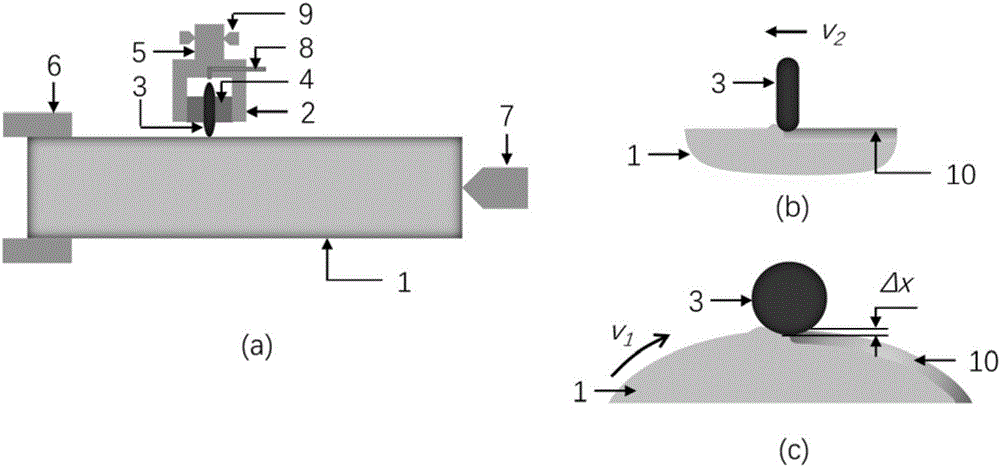

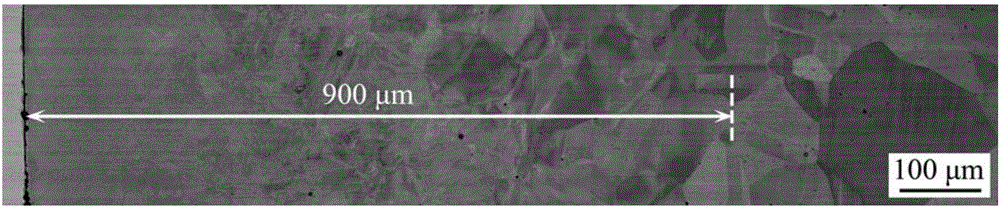

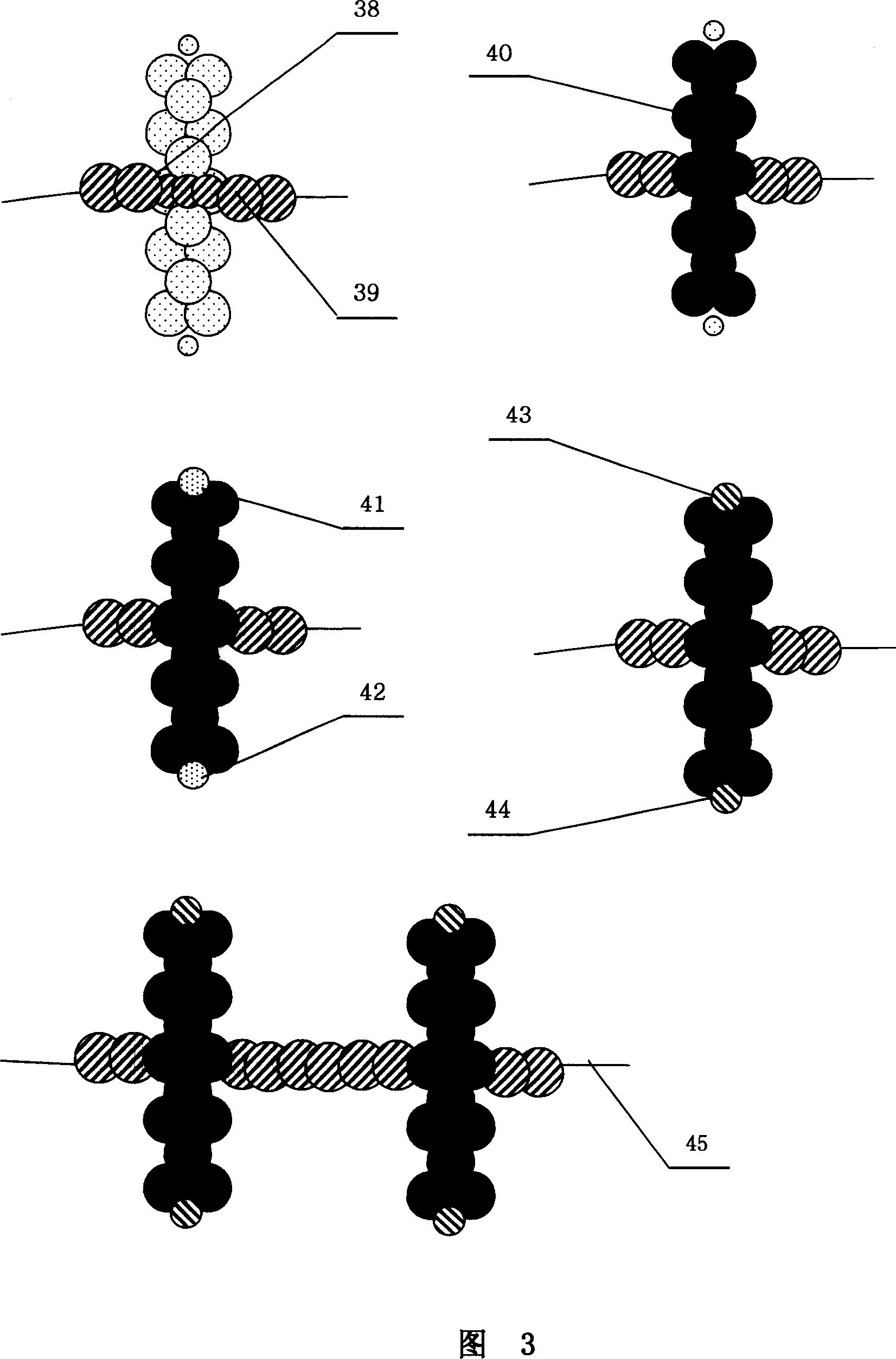

Metal material idler wheel type surface nanocrystallization method

The invention discloses a metal material idler wheel type surface nanocrystallization method and belongs to the technical field of metal material surface nanocrystallization. According to the method, an idler wheel type surface nanocrystallization processing system is adopted to treat a metal material rotating member, and the surface of a metal material generates gradient plastic deformation under the controllable rolling action of an idler wheel, so that a gradient structure refinement layer is generated on the surface of the material; the depth of the gradient structure refinement layer can reach 800 mum to the maximum; an organizational structure on the upmost surface layer is converted into a nanocrystalline structure from a coarse-grain structure. Through idler wheel type surface nanocrystallization treatment, the surface smoothness of the metal material is improved to different extents, the harness of the surface layer changes in a gradient manner from the exterior to interior, and the surface hardness value is remarkably increased compared with the matrix hardness value.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

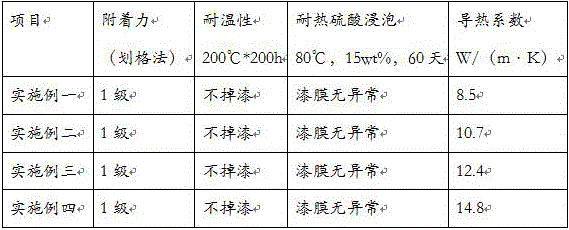

Graphene coating for corrosion prevention of thermal power plant desulfurization chimney, and preparation method of graphene coating

ActiveCN106366928AImprove toughnessImprove thermal stabilityFireproof paintsAnti-corrosive paintsFiberMetallurgy

The invention discloses graphene coating for corrosion prevention of a thermal power plant desulfurization chimney. The graphene coating consists of the following raw materials in parts by weight: 90 to 100 parts of film-forming resin, 0.5 to 3 parts of graphene, 0.5 to 2 parts of reinforced fibers, 10 to 20 parts of fillers, 10 to 20 parts of a curing agent, 15 to 30 parts of a diluents, 1 to 5 parts of polyacrylic acid, 1 to 5 parts of a polyethylenimin crosslinking agent, 1 to 3 parts of stearate and 2 to 6 parts of aids. By the mode of adding the raw materials, such as the reinforced fibers, the fillers, the polyethylenimin crosslinking agent and the polyacrylic acid, the defect that the existing corrosion-resistant coating has low durability and heat stability is overcome, the problem that the corrosion-resistant coating layer is easy to pollute and difficult to clean is solved, the developed graphene corrosion-resistant coating can completely adapt to the high-temperature strong-acid environment, the manufacturing process is simple, the practicability is high and the graphene coating is particularly suitable for thermal power plant desulfurization chimneys and flues.

Owner:CHENGDU LONGZHIQUAN SCI & TECH

Magnesium aluminate spinel-silicon carbide-aluminum composite refractory material

ActiveCN111662090AImprove high temperature mechanical propertiesHigh temperature and mechanical strengthCarbide siliconMetallic aluminum

The invention belongs to the field of refractory materials, and relates to a magnesium aluminate spinel-silicon carbide-aluminum composite refractory material. The magnesium aluminate spinel-silicon carbide-aluminum composite refractory material comprises aggregate and a matrix, wherein the aggregate comprises fused magnesia-alumina spinel particles and sintered magnesia-alumina spinel particles,and the addition amount of the fused magnesia-alumina spinel particles and the sintered magnesia-alumina spinel particles is 50-70% of the total amount of the raw materials; the matrix is silicon carbide, aluminum oxide and magnesium oxide; metal aluminum powder subjected to coating treatment is further added into the matrix, and the adding proportion is 2-8% of the total mass of the raw materials; and the aggregate, the matrix and a binding agent are uniformly mixed, undergo mechanical pressing molding, are dried, and then are sintered in a carbon-buried atmosphere to obtain the magnesium aluminate spinel-silicon carbide-aluminum composite refractory material. The high-temperature mechanical strength, the thermal shock stability and the coal cinder erosion resistance of the product are improved.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

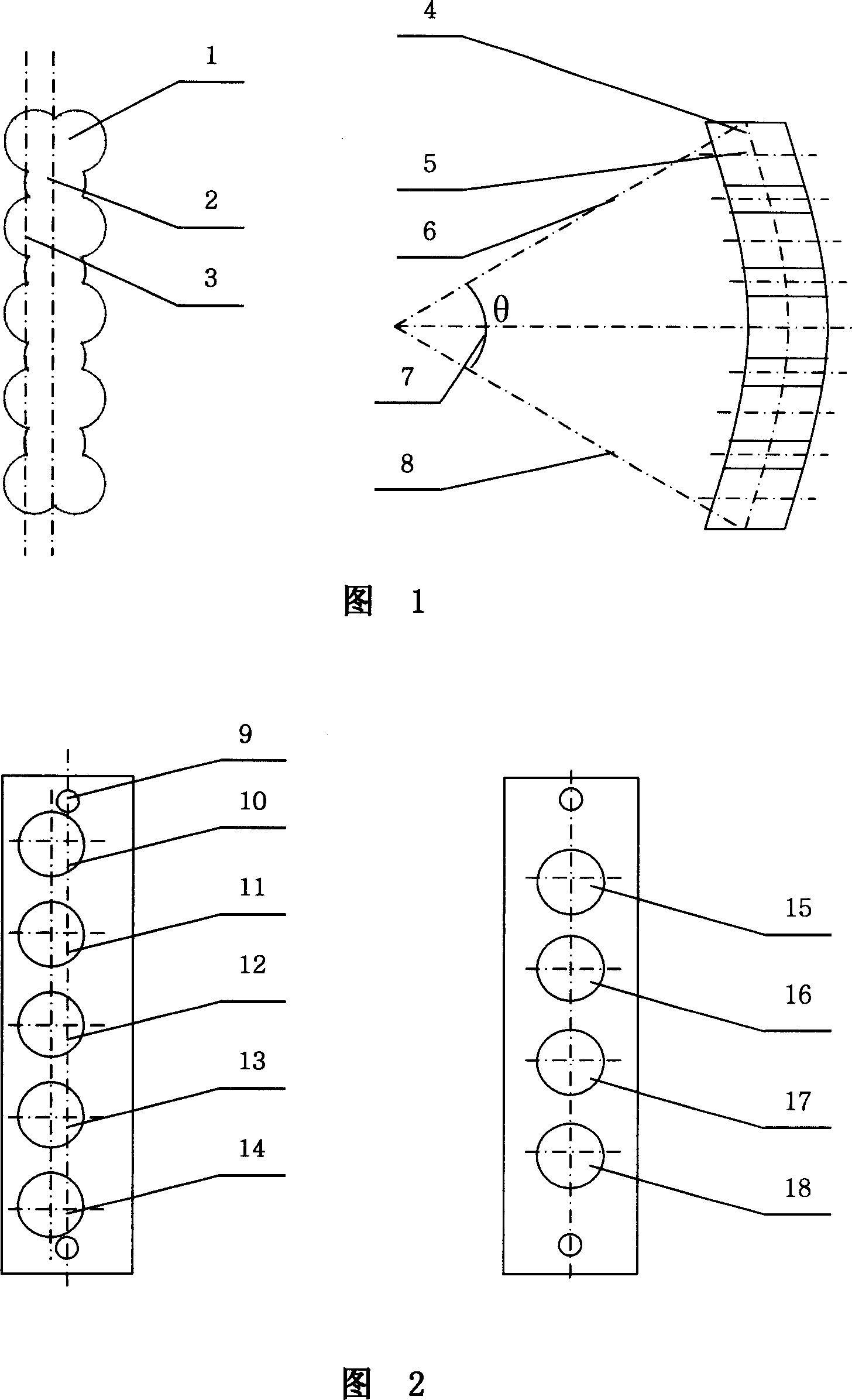

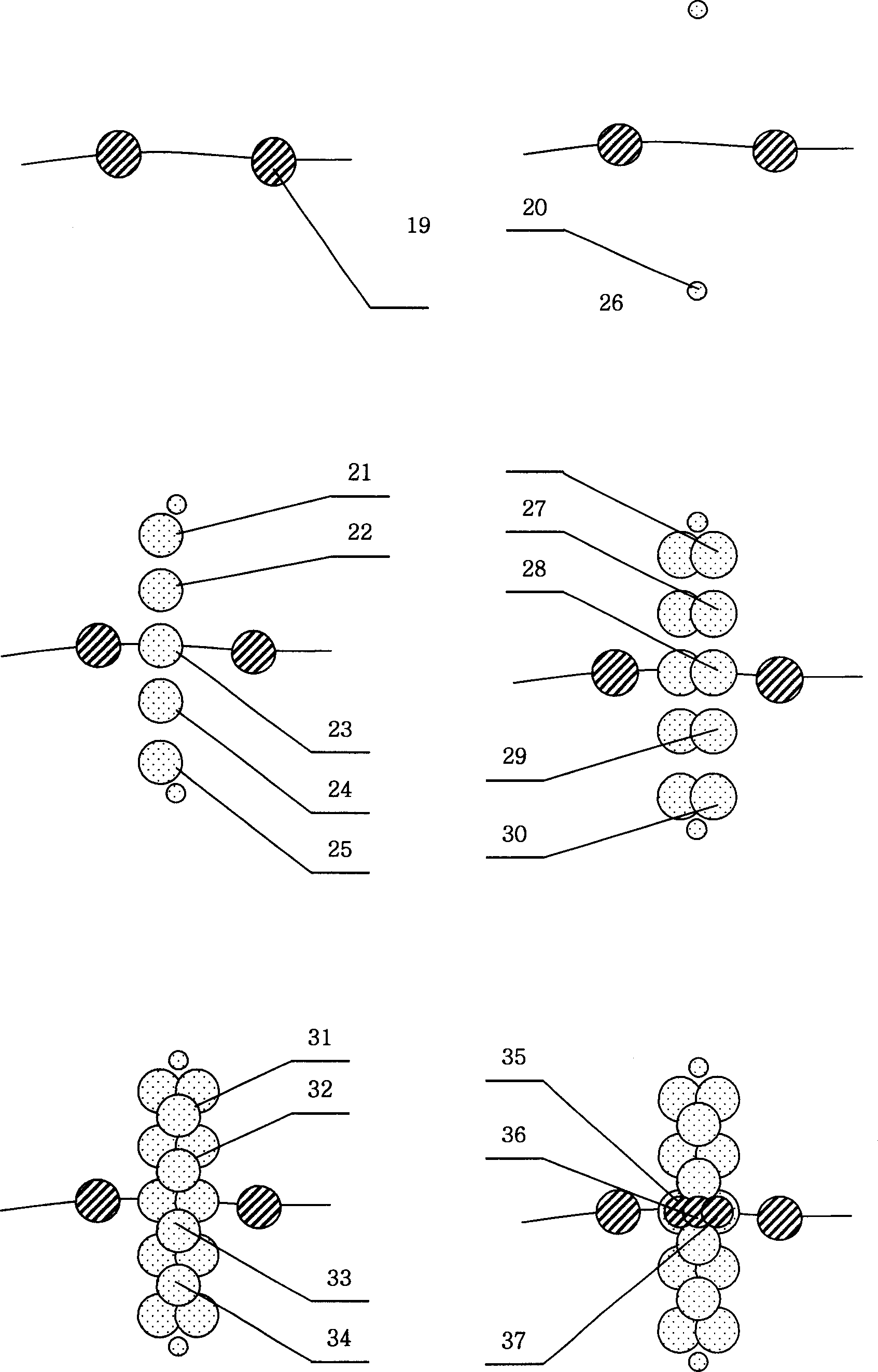

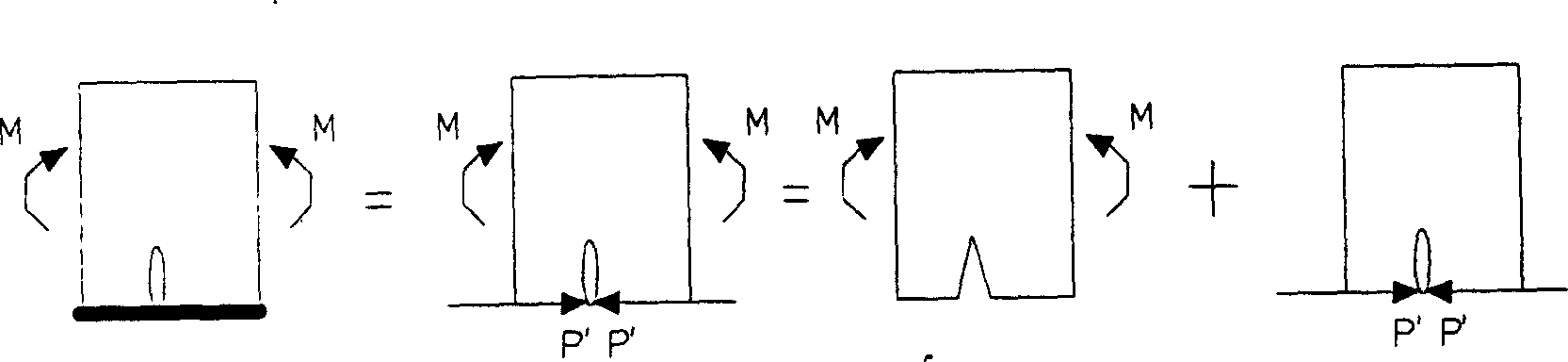

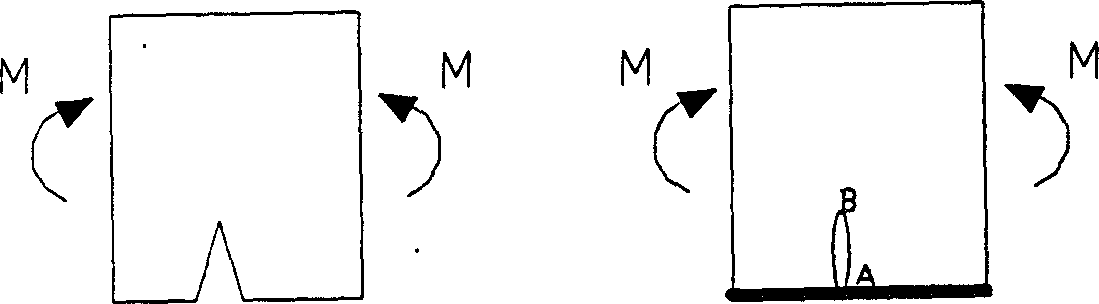

Parts for repairing crack of metal surface and method therefore

The invention relates to a device used to repair the surface crack of metal object and relative method. Wherein, it is characterized in that: it uses the arc embed element with same arc degree as crack surface; based on the condition of arc surface, preparing mould, marking crack line on the mould, and setting special bolts at two ends of crack line, to limit the crack; and drilling two mounting holes for positioning the mould at two ends of crack; and mounting the arc mould via said positioning holes on the arc surface; processing the arc embedded element mounting holes, and layering mounting the bolts on the crack part inside the mounting holes, to eliminate the crack; mounting special bolts at the joint between mounting hole and the crack, to be layered with the inner bolt of mounting holes; and processing the embedded element mounting hole.

Owner:李 昌勋 +1

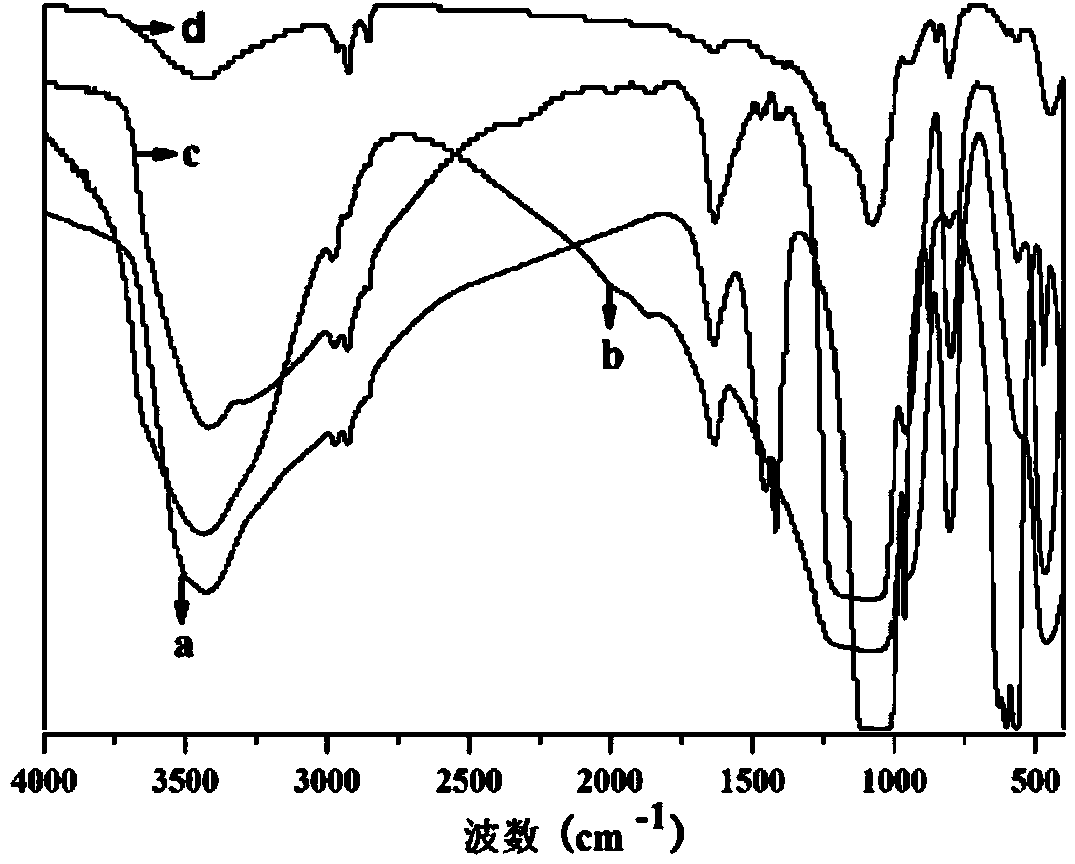

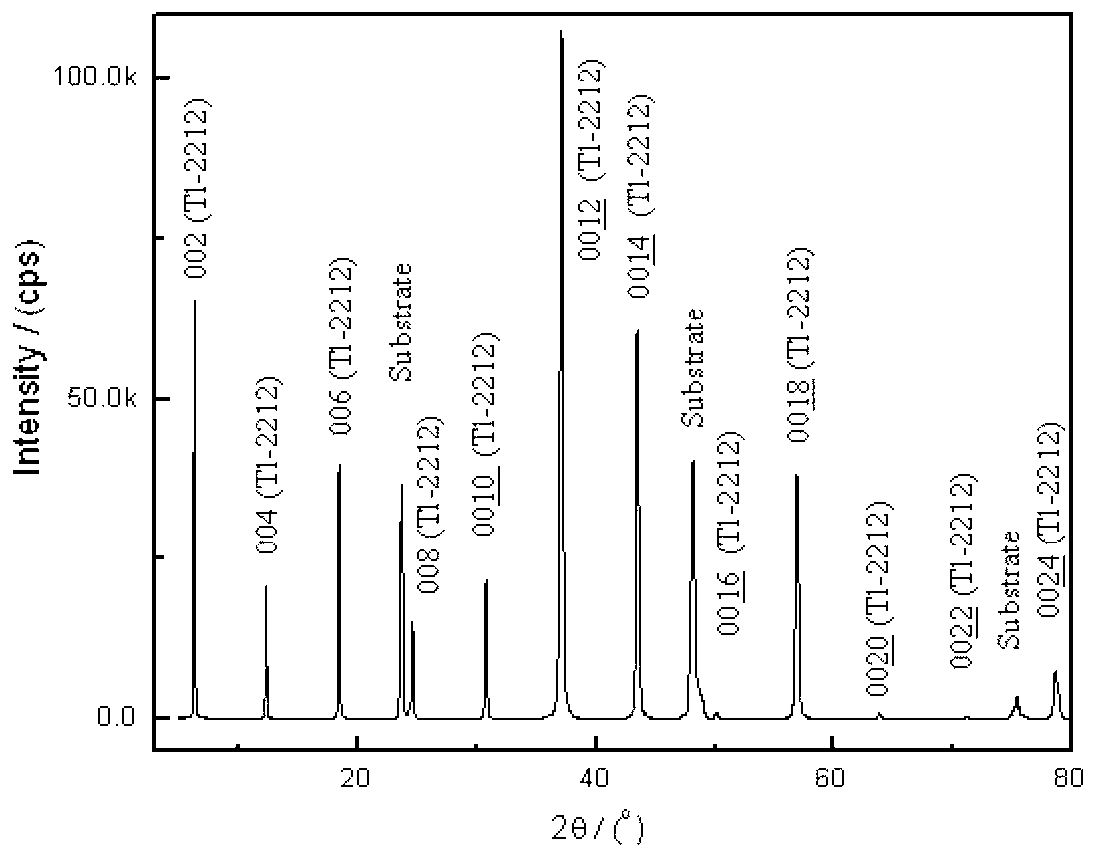

Preparation method for synthesizing T1-2212 superconducting thin film by employing sol-gel method

InactiveCN103304232ASimple processReduce manufacturing costSuperconductor elements usageDiethylenetriamineSolvent

The invention discloses a preparation method for synthesizing a T1-2212 superconducting thin film by employing a sol-gel method. The method comprises the following steps: by taking thallium acetate, barium acetate, calcium acetate and copper acetate as initial raw materials, by taking lactic acid, alpha-methacrylic acid, diethylenetriamine, triethylene tetramine and methanol as complexing agents and solvents, and preparing the sol with proper viscosity. The sol has the characteristics of fewer materials, simple preparation process and easily and accurately controlled components; the T1-2212 superconducting thin film prepared by employing the sol has flat surface topography and good superconducting characteristics.

Owner:GUANGXI TEACHERS EDUCATION UNIV

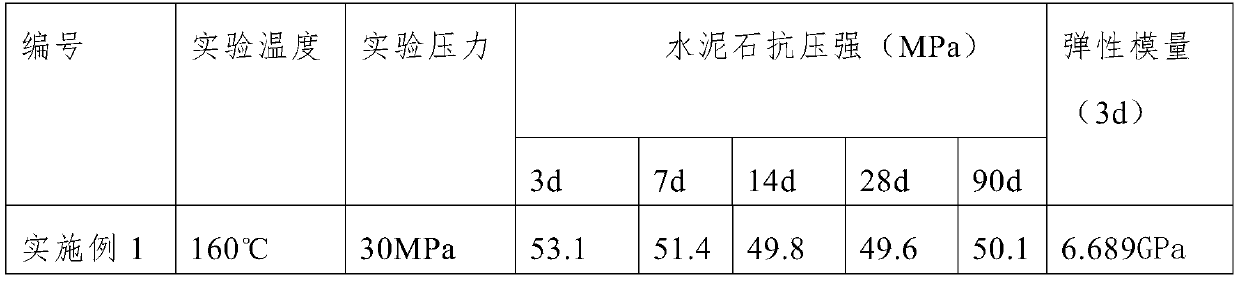

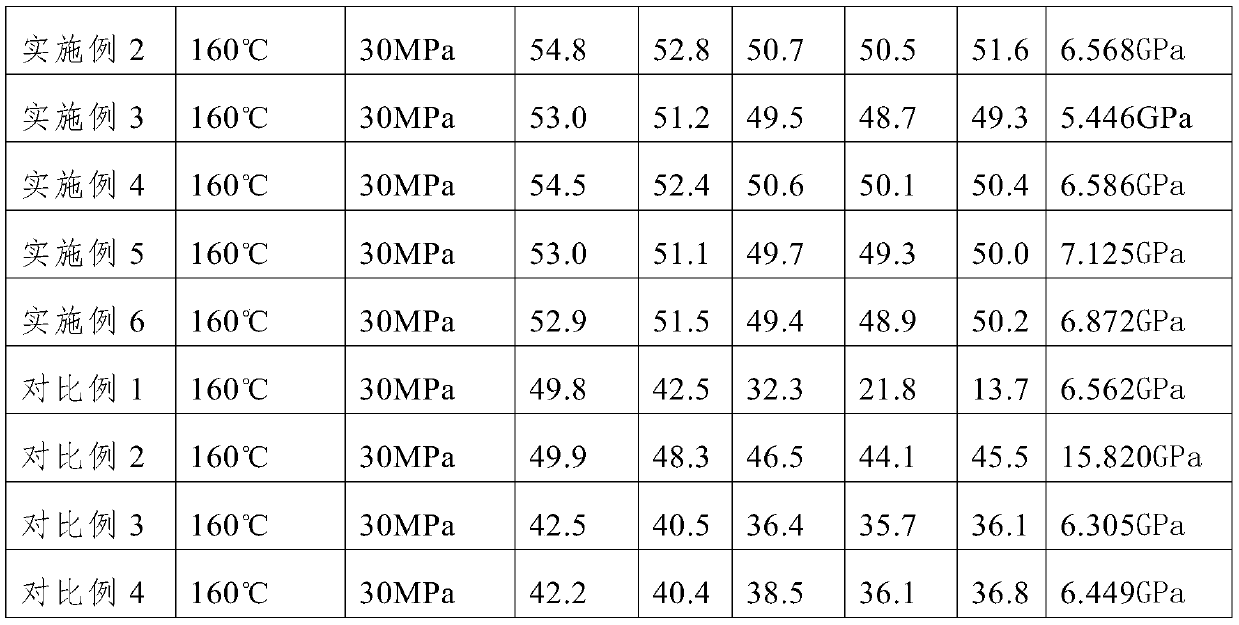

Well cementation oil well cement composition and preparation method thereof

ActiveCN111362656AGood comprehensive performance indexGood practical engineering application effectSolid waste managementCarbon fibersFirming agent

The invention relates to a well cementation oil well cement composition. The oil well cement composition comprises the following components in parts by mass: 50-60 parts of clinker, 5-10 parts of an anti-strength declining agent, 4-8 parts of a brittleness-reducing toughening agent, 2-5 parts of a high-temperature reinforcing agent, 10-20 parts of BFS and 0.5-4 parts of a dispersing agent. The anti-strength declining agent is prepared by mixing wollastonite micro-powder and metakaolin according to a ratio of 1: 4, the brittleness-reducing toughening agent is one or more of high-elastic-modulusPVA fibers, low-elastic-modulus polypropylene fibers, calcium sulfate whiskers, carbon fibers and waterborne epoxy resin containing a curing agent, the high-temperature reinforcing agent is nano SiO2sol, and the dispersing agent is an APC dispersing agent. The invention is used for solving the problem that the strength of the well cementation cement paste is easy to quickly decline and age in ahigh-temperature hydrothermal environment, and can obviously enhance the impact resistance of the cement, enhance the toughness, reduce the brittleness and improve the rheological property of the cement paste.

Owner:BAODING BAOXING OIL FIELD CEMENTING MATERIAL MFG

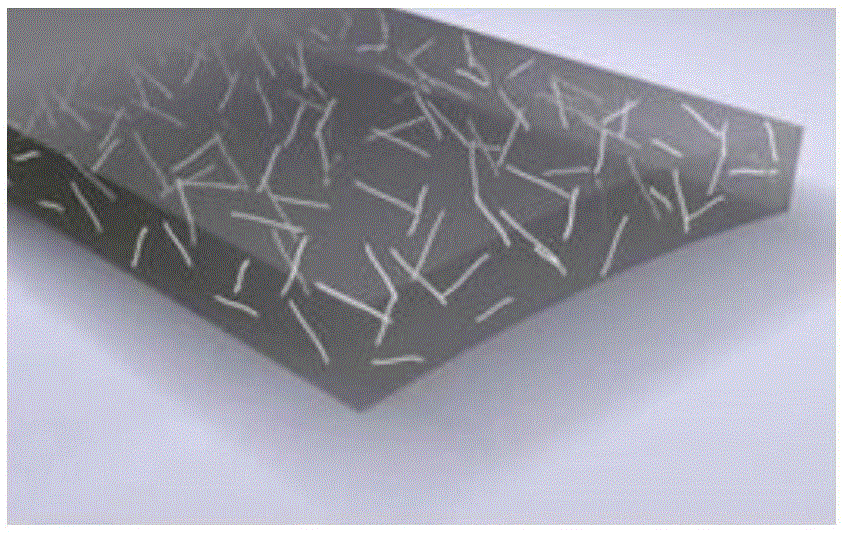

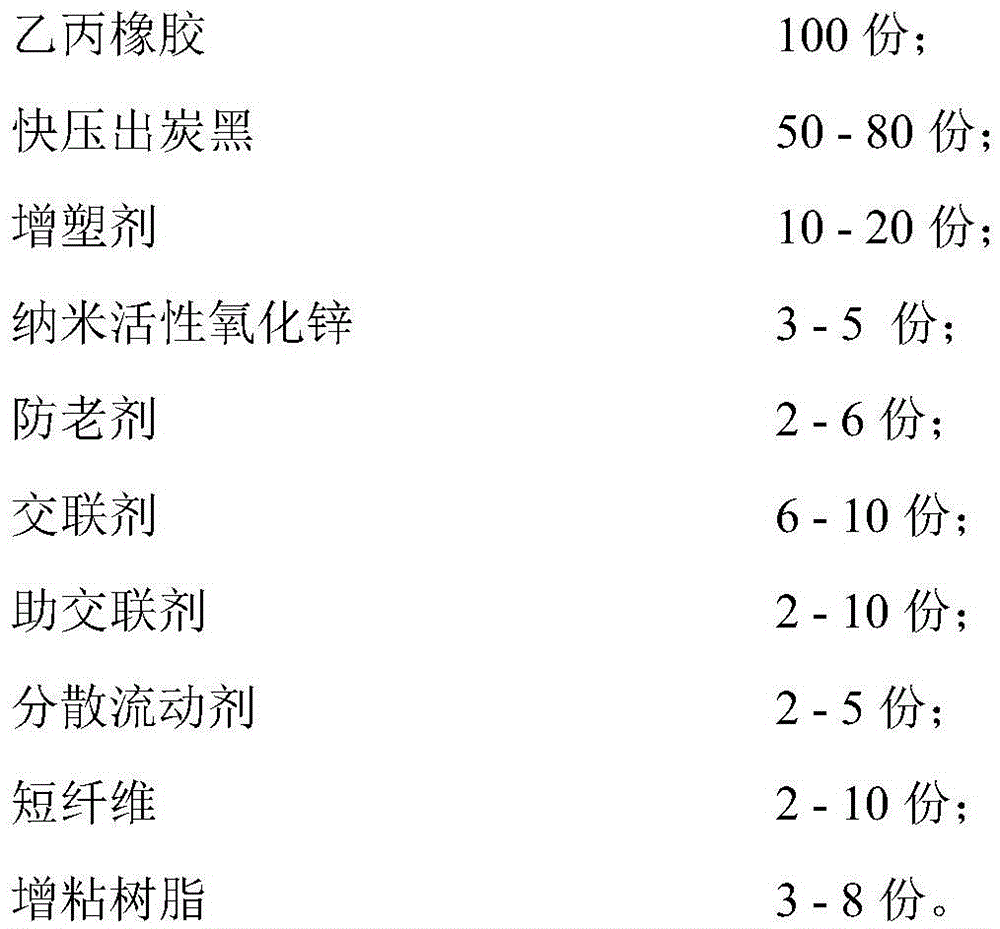

Short fiber-reinforced high temperature-resistant rubber roll, rubber roll rubber material and preparation methods thereof

The invention discloses a short fiber-reinforced high temperature-resistant rubber roll, a rubber roll rubber material and preparation methods thereof, and belongs to the technical field of rubber rolls. The rubber roll rubber material comprises the following components in parts by weight: 100 parts of ethylene propylene rubber, 50-80 parts of rapidly-extruded carbon black, 10-20 parts of a plasticizer, 3-5 parts of nanometer active zinc oxide, 2-6 parts of an anti-aging agent, 6-10 parts of a crosslinking agent, 2-10 parts of an assistant crosslinking agent, 3-8 parts of tackifying resin, 2-5 parts of a dispersing flowable agent and 2-10 parts of short fiber. The preparation method of the rubber roll comprises the following steps: preparing the rubber material, wrapping with the rubber material, vulcanizing in a vulcanizing tank, and turning. The rubber material is high in strength, rebound resilience, and resistance to high temperature and low in permanent compression deformation; the rubber roll made of the rubber material is high in resistance to high temperature and acid and alkali corrosion; the rubber roll is highly consistent in inside and outside hardness and material distribution and high in roller surface machining precision; the service life of the rubber roll is twice of or longer than that of the conventional high temperature-resistant rubber roll, so that the service life of the rubber roll is greatly prolonged.

Owner:南京金三力橡塑有限公司

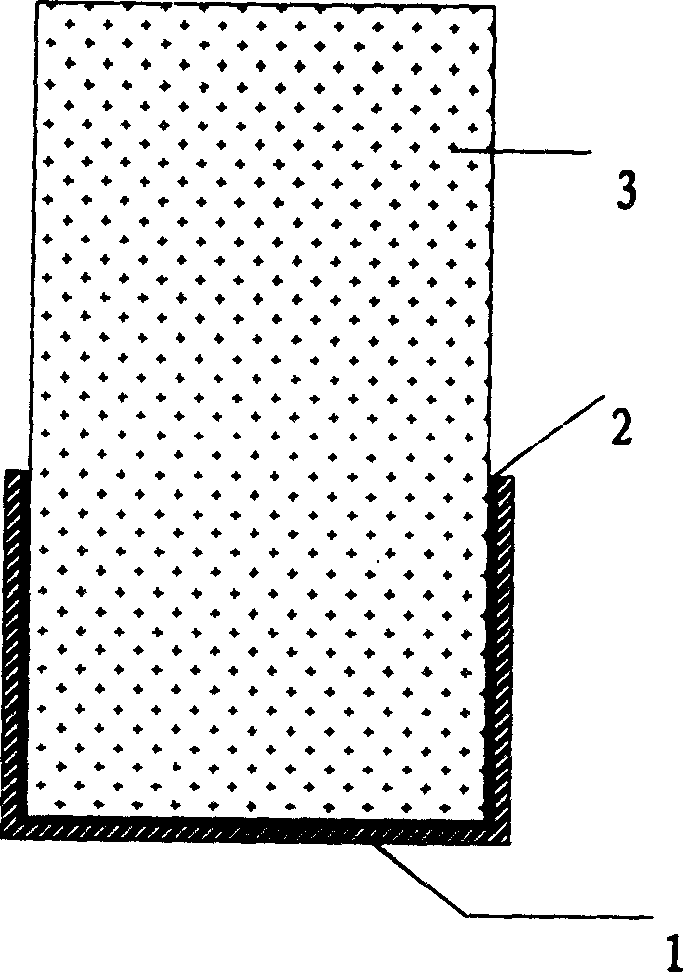

Composite reinforced concrete beam containing crack resistant reinforcement layer and method for making same

InactiveCN1523177AGuaranteed StrengthGuaranteed deformabilityMouldsGirdersReinforced concreteMaterial Crack

The present invention relates to a composite reinforced concrete beam containing crack-resisting reinforcing layer, and it is characterized by that a composite material crack-resisting reinforcing layer can be stuck on the partial or whole tensile area of reinforced concrete beam, and its making method mainly includes the following steps: firstly, making reinforced concrete structure; then brushing a layer of interfacial adhesive glue on the treated undersurface of reinforced concrete structure and its partial side surface below contral line, then sticking composite material crack-resisting reinforcing layer on the surface of the above-mentioned interfacial adhesive glue. Said composite reinforced concrete beam has good crack-resisting property and large structure rigidity.

Owner:CHONGQING JIAOTONG UNIVERSITY

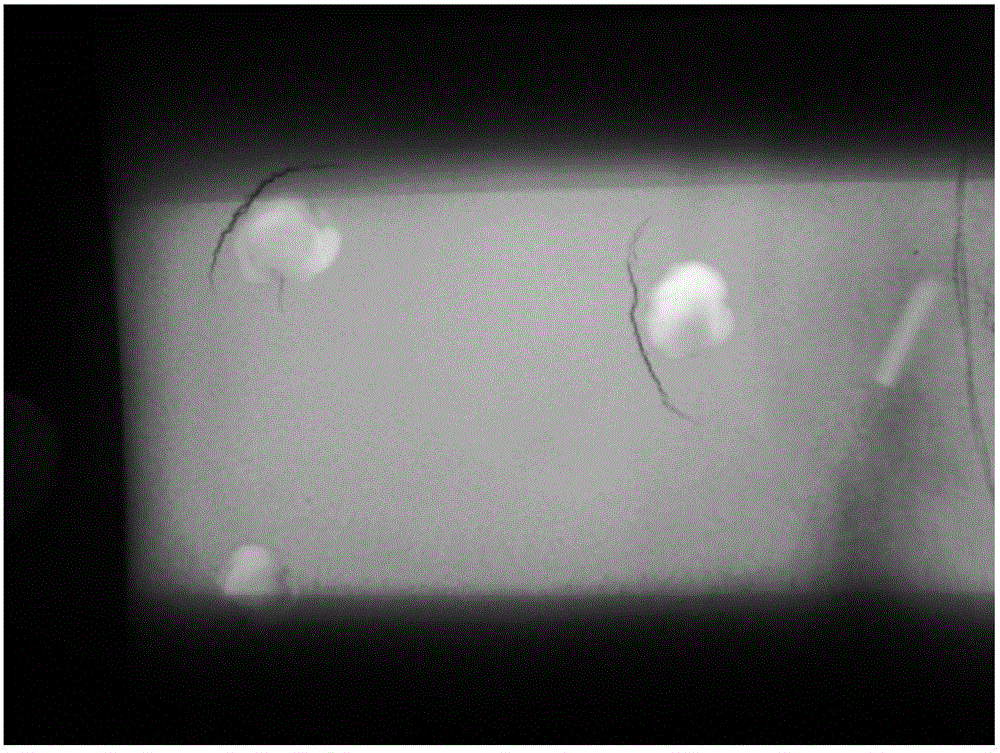

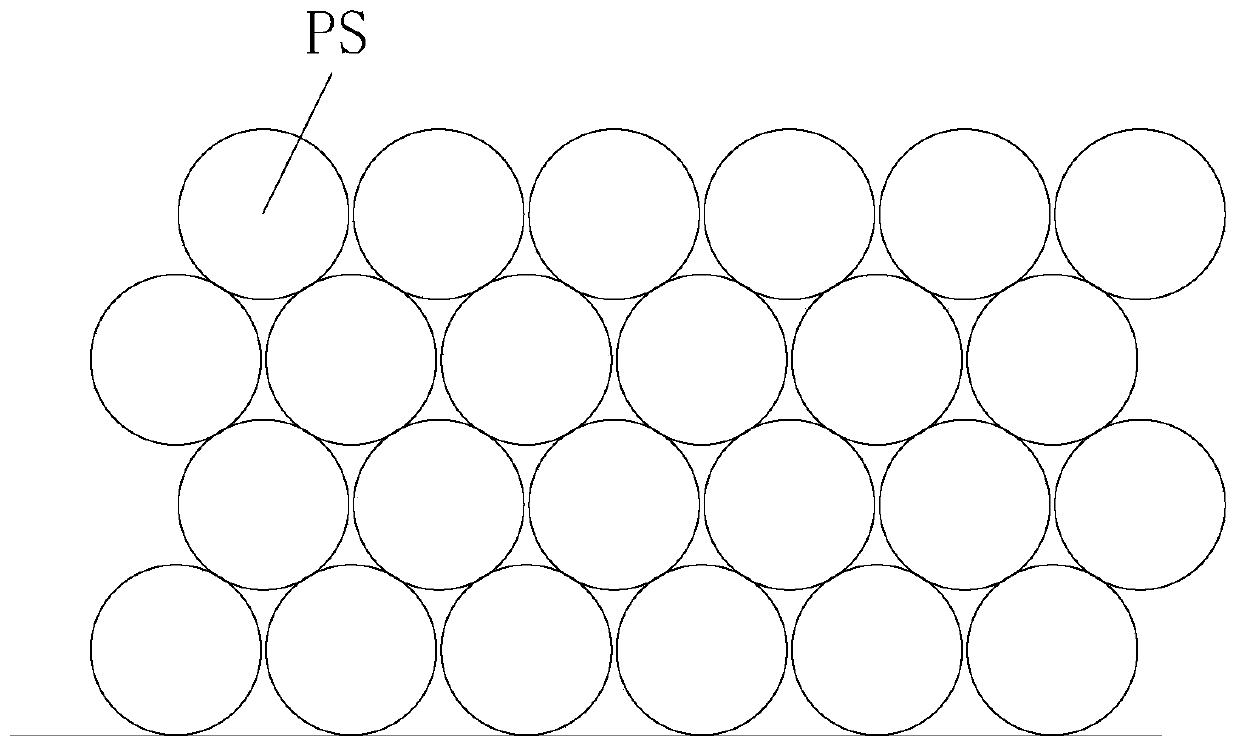

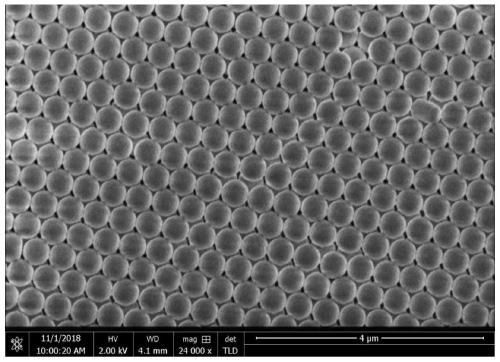

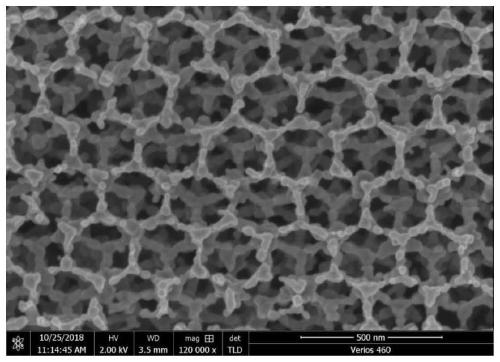

VO2 film with three-dimensional ordered porous network structure, and preparation method and application thereof

ActiveCN110092591AThe ingredients are simple and clearUniform compositionVanadium oxidesCoatingsMicrospherePolystyrene microsphere

The invention discloses a VO2 film with a three-dimensional ordered porous network structure, and a preparation method and application thereof. The method stacks polystyrene microspheres on a glass substrate through a vertical immersion method, so that a die plate preparing a VO2 film can be formed; the die plate is immersed into a VO2 precursor solution, so that the slit between the polystyrene microspheres can be fully filled with V2O5 in the precursor solution; the V2O5 is converted into VO2 through follow-up drying and annealing process; the polystyrene microspheres are heated to evaporate, and the VO2 can form a three-dimensional ordered porous network shape; and the film has a complete three-dimensional ordered porous network structure. As the whole structure has holes, the holes canseparate fractures generated between VO2 particles on some frame, so that fracture force can be separated, and phase transition stress can be diluted.

Owner:西安艾斯达特新材料科技有限公司

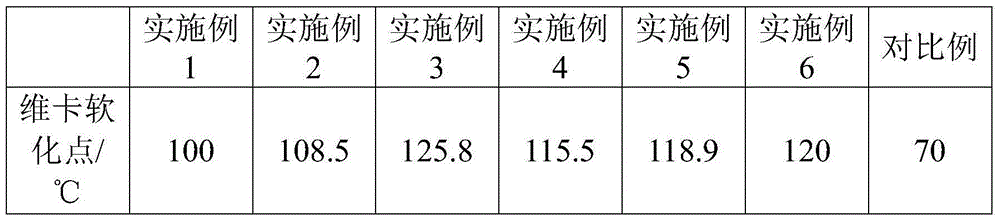

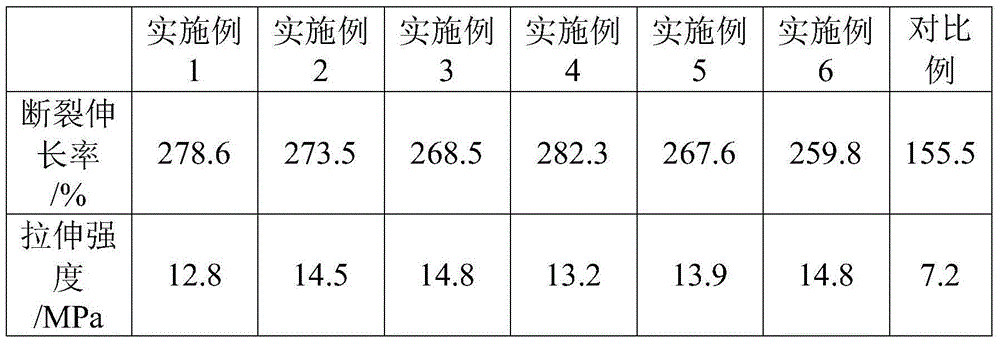

Heat-resistant PVC shoe material and preparation method thereof

InactiveCN104672718AImprove heat resistanceImproved impact resistanceFootwearCalcium carbonatePlasticizer

The invention discloses a heat-resistant PVC shoe material which comprises components in parts by weight as follows: 10-20 parts of PVC resin, 5-10 parts of light calcium carbonate, 6-8 parts of nano titanium oxide, 1-5 parts of MBS, 2-3 parts of SMA, 3-8 parts of a plasticizer and 2-10 parts of a stabilizer. The invention further discloses a preparation method of the heat-resistant PVC shoe material. The heat-resistant PVC shoe material has excellent heat resistance, cannot be degraded at the high temperature, and is free of mechanical property loss, good in low-temperature flexibility, non-toxic and beneficial to environmental protection.

Owner:SUZHOU JINGRO TECH

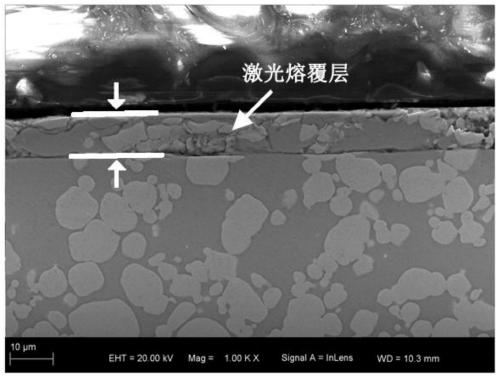

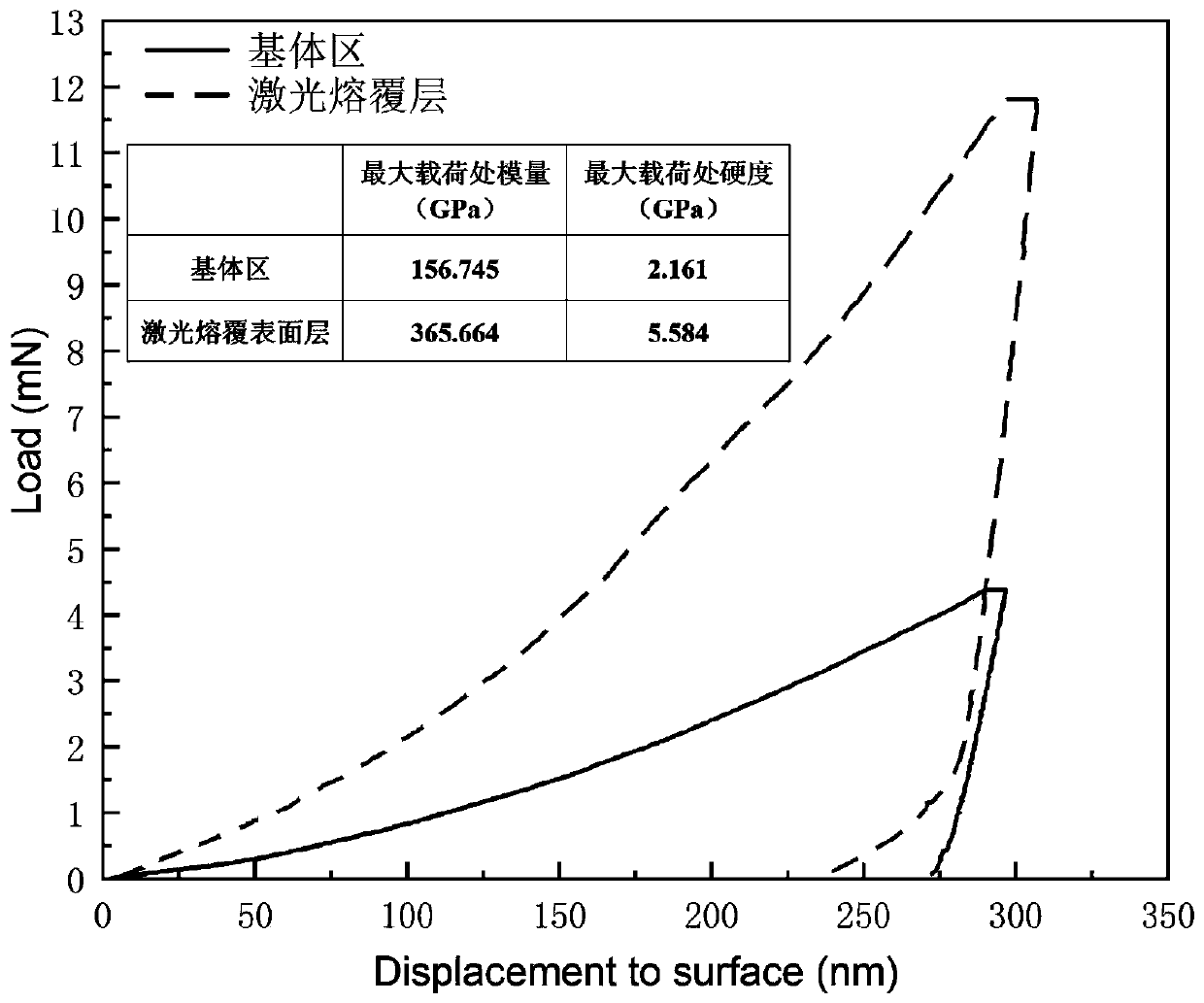

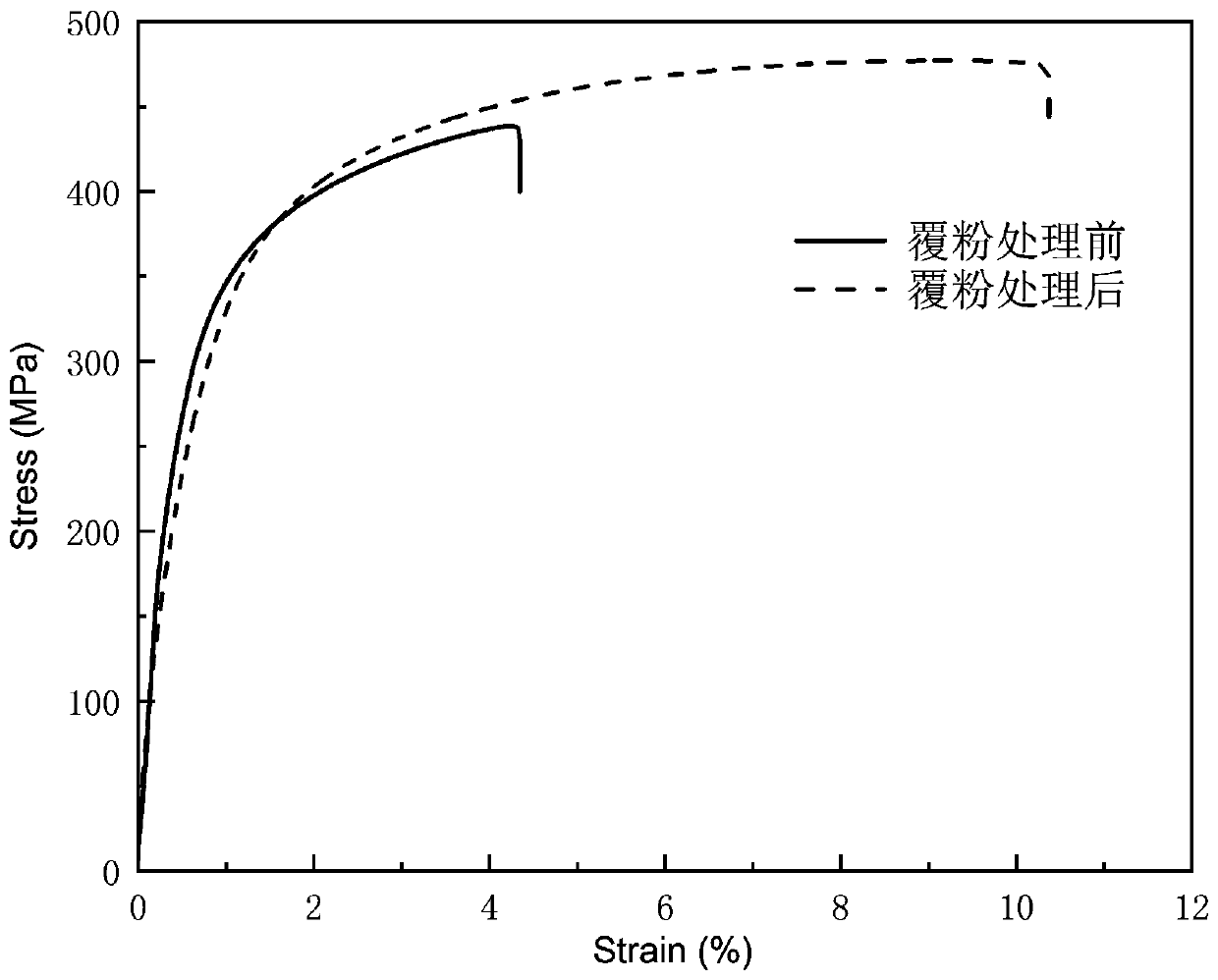

Surface powder coating and laser treatment method for improving mechanical performance of tungsten-copper alloy

ActiveCN110343925ALow costPrevent crack initiation and propagationAdditive manufacturingIncreasing energy efficiencyTungstenUltra fine

A surface powder coating and laser treatment method for improving the mechanical performance of a tungsten-copper alloy comprises the following steps that firstly, after ultra-fine crystal or nanometer crystal tungsten powder and ultra-fine crystal or nanometer crystal copper powder are mixed, ultra-fine crystal or nanometer crystal tungsten-copper powder is obtained; secondly, the tungsten-copperalloy is arranged on a base plate of a workbench of a selective laser melting device, the ultra-fine crystal or nanometer crystal tungsten-copper powder obtained in the step 1 covers the surface of the tungsten-copper alloy for a layer, and after a cabin door is closed and vacuumizing is conducted, argon or nitrogen or other inert gas is fed; thirdly, the ultra-fine crystal or nanometer crystal tungsten-copper powder coated in the step 2 is scanned by a laser beam of the selective laser melting device, the powder laser sintering or melting process is completed, after the alloy is cooled, theneeded material can be obtained after being taken out from a work chamber of the selective laser melting device. The surface powder coating and laser treatment method significantly improves the mechanical performance of the tungsten-copper alloy.

Owner:XIAN UNIV OF TECH

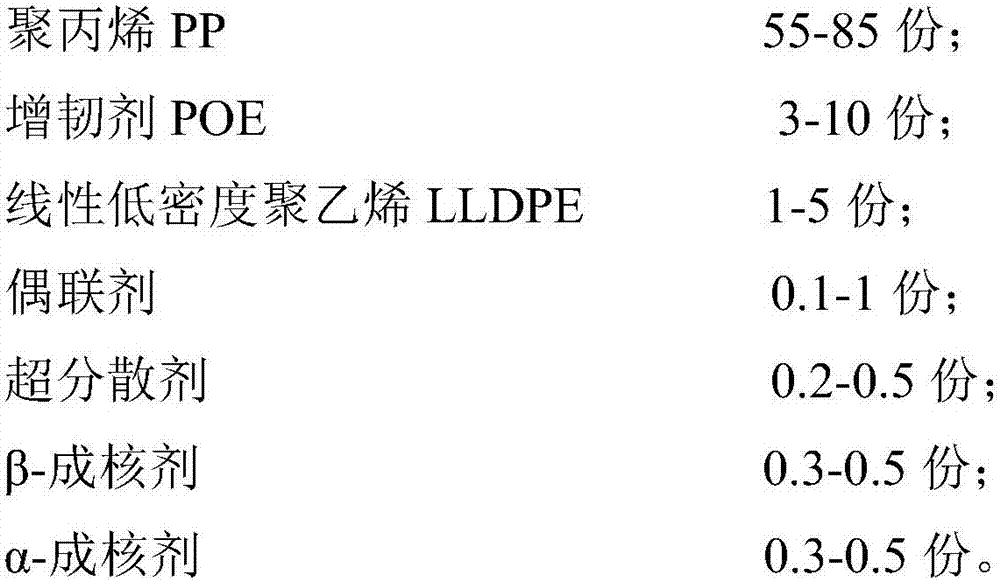

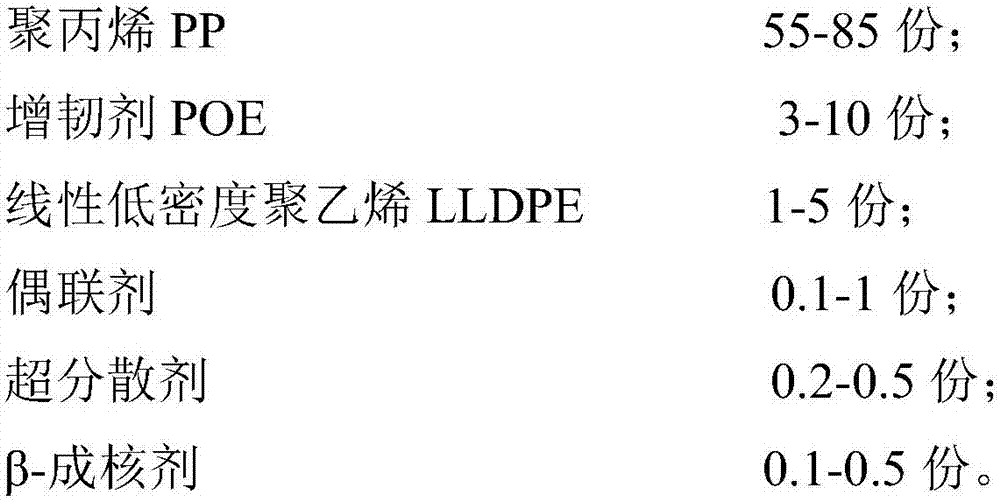

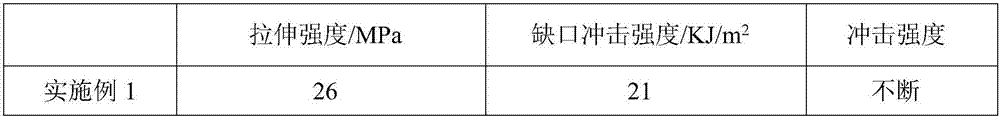

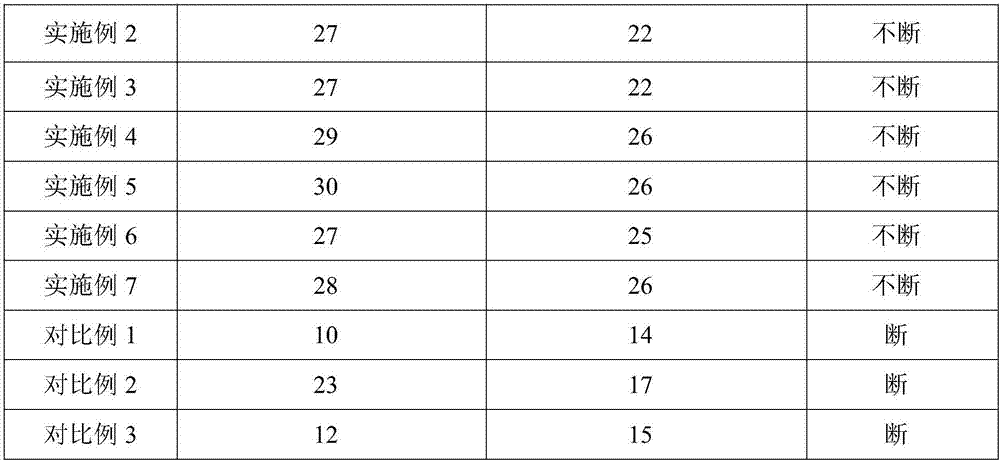

Modified polypropylene for handles of ceilings of automobiles

InactiveCN107254101ARaise the crystallization temperatureHigh crystallinityElastomerLinear low-density polyethylene

The invention discloses modified polypropylene for handles of ceilings of automobiles. The modified polypropylene which is a composite material comprises, by weight, 55-85 parts of polypropylene (PP), 3-10 parts of toughening agents POE (polyolefin elastomers), 1-5 parts of linear low-density polyethylene (LLDPE), 0.1-1 part of coupling agents, 0.2-0.5 part of hyper-dispersants, 0.1-0.5 part of beta-nucleating agents and 0.1-0.5 part of alpha-nucleating agents. The modified polypropylene has the advantages of high rigidity and toughness and wide application range.

Owner:SUZHOU SUNWAY POLYMER

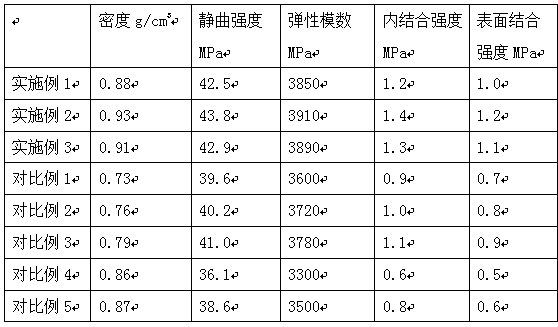

Preparing method for ultra-thin high-density fiberboard

PendingCN110154198AHigh strengthAvoid deformationDomestic articlesFlat articlesFiberAntimony trioxide

The invention discloses a preparing method for an ultra-thin high-density fiberboard. The preparing method comprises the specific steps that (1) after a log material is digested and softened, nanometer antimonous oxide / PP composite fiber is added for hot grinding, heat treatment is carried out after drying, and pulverizing and accurate grinding are carried out to obtain wood powder fiber; (2) thewood powder fiber is placed in a glue blender, a glue material is sprayed onto the surface of the wood powder fiber, then montmorillonite / zirconium dioxide nano composite particles and a maleic anhydride grafted coupling reagent are added, and mixing and blending are carried out to obtain a material; and (3) the material is paved with a paving machine to form a plate blank, hot pressing treatmentis performed after pre-pressing is carried out, and the ultra-thin high-density fiberboard is obtained. According to the preparing method, the log material is adopted as the raw material of the fiberboard, the glue material and all functional auxiliary agents are sufficiently combined with the wood fiber through process machining, and therefore the preparation process is more efficient and environment-friendly; and the high-density fiberboard has the characteristics of being high in strength, high in density, ultra-thin, not easy to be deform, low in carbon, environment-friendly and durable.

Owner:阜阳大可新材料股份有限公司

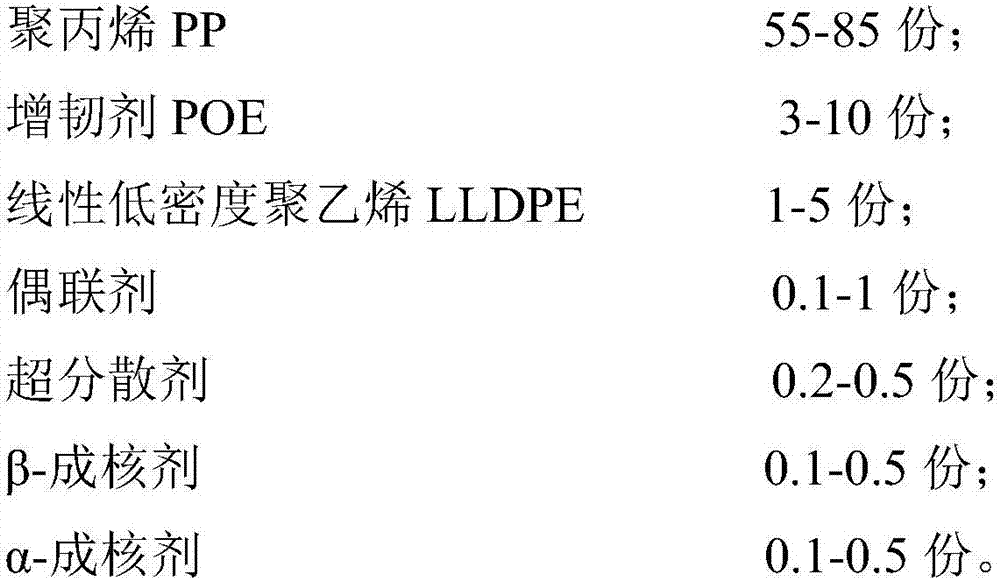

Low-temperature-impact-resistant modified polypropylene

InactiveCN107163391AImprove low temperature impact performanceGood compatibilityLinear low-density polyethylenePolymer science

The invention discloses low-temperature-impact-resistant modified polypropylene composed of, by weight, 55-85 parts of polypropylene PP, 3-10 parts of a toughening agent POE, 1-5 parts of linear low density polyethylene (LLDPE), 0.1-1 part of a coupling agent, 0.2-0.5 parts of a super-dispersant, and 0.1-0.5 parts of a beta-nucleating agent. The low-temperature-impact-resistant modified polypropylene has good low-temperature-impact resistance and has a larger application range.

Owner:SUZHOU SUNWAY POLYMER

Full-biodegradable bionic bait and preparation method thereof

PendingCN113429716AImprove mechanical propertiesImprove water resistanceBaitCalcium carbonatePolyvinyl alcohol

The invention discloses a full-biodegradable bionic bait and a preparation method thereof.The preparation method comprises the following steps: uniformly mixing modified polyvinyl alcohol, modified nano calcium carbonate, a phagostimulant, a pigment, an antioxidant, citrate and a lubricant in a high-speed mixer to obtain a blended material, adding the obtained blended material into a hopper of a double-screw extruder, and carrying out melt extrusion, drawing, cooling, pelletizing and drying to obtain modified polyvinyl alcohol particles. The addition of the starch can accelerate the degradation of the polyvinyl alcohol on one hand, and can reduce the cost of the bionic bait on the other hand, and the addition of the fibers can improve the water resistance, biodegradability and environment-friendly degree of the material, thereby achieving the purposes of improving the degradation speed of the bionic bait and protecting the environment.

Owner:安徽宏飞钓具有限公司

Plastic metal composite pipe and preparation method thereof

InactiveCN109370001AChange in structural regularityNo pollution in the processPolyureas/polyurethane adhesivesMacromolecular adhesive additivesTriethoxysilaneNylon 66

The invention discloses a plastic metal composite pipe and a preparation method thereof, and belongs to the field of pipeline processing. According to the preparation method, alpha, omega-dihydroxyl polyphenylmethyl siloxane is added into a dealcoholizing crosslinker methoxyl triethoxysilane and a catalyst dibutyltin dilaurate to form an additive of a silicon rubber type plastic pipe base material, so that the low temperature resistance can be improved, and the low temperature resistance of a plastic-metal composite pipe can be increased; fumed silica and kaolin are added and modified throughgamma-(methacryloxy), and crazing is prevented from further developing and forming cracking, the impact resistance of the material and toughness and mechanical property of plastics can be improved; nylon-66 salt and decyldiamine sebacate are added to serve as a nylon mixture, the blend low-temperature initial property is effectively improved, and the low-temperature impact is strong, so that plastics cannot be embrittled under a low-temperature condition and have relatively good toughness, and the low-temperature resistance of a composite pipe can be reinforced. The plastic metal composite pipe can solve the problems of poor low temperature endurance and poor mechanical performance of an existing aluminum plastic composite pipe.

Owner:俞小峰

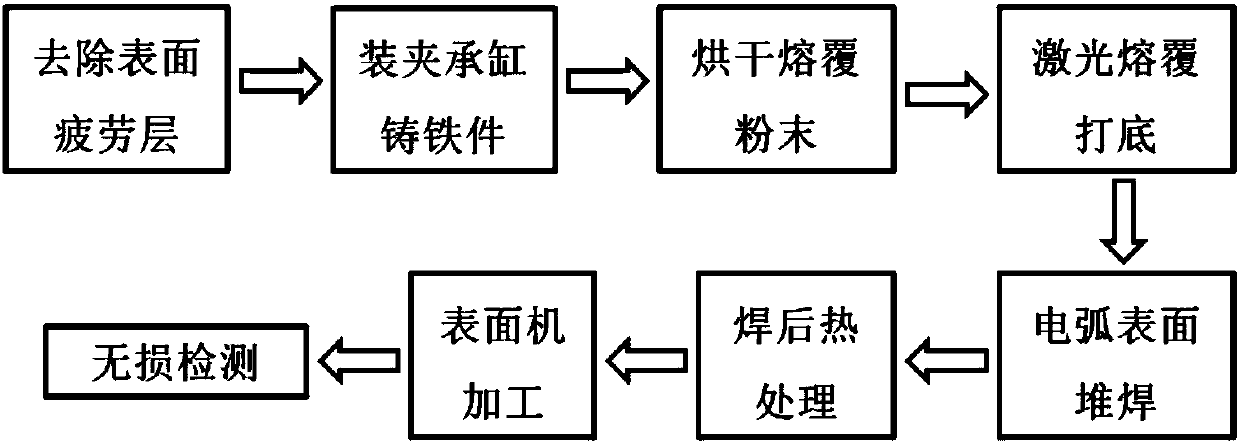

Laser-arc compound remanufacturing method for TRT bearing cylinder iron castings

ActiveCN108015424ADiffusion barrierLow Thermal Expansion PropertiesWelding/cutting media/materialsSoldering mediaAlloyUltimate tensile strength

The invention relates to a laser-arc compound remanufacturing method for TRT bearing cylinder iron castings. Alloy powder comprises the following components in percentage by weight: 0.01-0.03% of C, 2.5-3.5% of Si, 0.5-1.5% of B, 0.2-0.5% of Fe, 10-15% of Cu, and the balance of Ni. Self-melting alloy powder is adopted to perform the laser cladding-arc welding compound remanufacturing repair on theTRT bearing cylinder iron castings; and cladding layers are lower in heat expansion characteristic, and brittle phases in repair layer and basal body interface areas can be prominently reduced, so that the interface area strength is improved, interface area cracks are prevented, and the repair quality is improved.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY +1

High-hardness low-compression-deformation rubber nano composite material and preparation method thereof

PendingCN114685997ACompromise with low compression set performanceTaking into account high hardness performanceRubber materialAl powder

The invention discloses a high-hardness low-compression-deformation rubber nano composite material and a preparation method thereof, raw materials of the high-hardness low-compression-deformation rubber nano composite material comprise a component A and a component B, and the crosslinking weight ratio of the component A to the component B is 1: 1-1.5: 1; the component A is prepared from the following raw materials in parts by weight: 100 parts of methyl vinyl silicone oil, 3 to 8 parts of polytetraethoxysilane, 2 to 5 parts of tetramethyl orthosilicate cross-linking agent, 0.5 to 1.2 parts of anti-aging agent, 1 to 1.3 parts of platinum catalyst and 3 to 8 parts of agarose; the component B is prepared from the following raw materials in parts by weight: 100 parts of organic nano montmorillonite, 40 to 60 parts of vulcanizing agent, 9 to 17 parts of nanoscale aluminum nitride powder, 3 to 6 parts of hydrogen-containing silicone oil, 3 to 8 parts of divinyl benzene cross-linking agent, 0.5 to 4 parts of silane coupling agent and 1 to 5 parts of matting agent. In this way, the refractive index, yellowing resistance and air tightness of the rubber material can be improved, and the long-term reliability of packaged components is effectively improved.

Owner:昆山市昆力鸿橡塑制品有限公司

Method for preparing foam material reinforced silica aerogel composite material

The invention discloses a method for preparing a foam material reinforced silica aerogel composite material and relates to silica aerogel. The method comprises the following steps of: preparing silica plural gel and aging the silica plural gel, modifying and drying. Through test, porosity is 80 t o 95 percent, density is 0.15 to 0.5g / cm<3>, the Brunauer-Emmett-Teller (BET) specific surface area is 600 to 1,100m<2> / g, and a water contact angle is 130 to 160 degrees; the foam material reinforced silica aerogel composite material is super hydrophobic; aerogel pore size distribution is relativelycentralized and the pore size of the aerogel is 2 to 50nm; and coefficient of heat conductivity is 0.01 to 0.035 W / (m.K), compression strength is 0.3 to 2Mpa (2 percent deformation), and elastic modulus is 1 to 5 Mpa. Meanwhile, the foam material reinforced silica aerogel composite material has good heat insulation performance, and adsorption performance, environment-friendliness and the other excellent performance. The method is simple, is short in a cycle, low in cost, and high in safety, and contributes to large-scale production; and by the method, excellent performance of the aerogel can be kept and the mechanical property of aerogel can be improved.

Owner:ZHONGKE RUNZI (CHONGQING) ENERGY SAVING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com