Method for preparing foam material reinforced silica aerogel composite material

A technology for silica and foam materials, which is applied in the field of preparing silica aerogel composite materials, can solve the problem that polymer materials are rarely used as reinforcements, etc., and achieves high operability, strong adsorption, and excellent product performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 10ml of tetraethyl orthosilicate, 25ml of absolute ethanol, 5ml of methyltriethoxysilane, and 6ml of distilled water into the container and stir to mix. After 15 minutes, slowly add 1ml of hydrochloric acid alcohol solution and continue to mix and stir . After 16 hours, slowly add 5ml of ammonia-water-alcohol solution dropwise, stop stirring after 5 minutes, pour the gel into a mold of a suitable size with polyurethane foam, seal it and let it stand until it gels. After the gel was aged in ethanol at 50°C for 2 days, the composite gel was immersed in a mixed solution containing 8mlTMCS and 50ml n-hexane, and modified at room temperature for 2 days; the composite wet gel was aged in n-hexane solution for 1 day, and finally often press and dry to obtain polyurethane foam reinforced silica composite airgel. The drying process is as follows: the sample is kept at 55°C for 3 hours, at 80°C for 5 hours, and then at 130°C for 3 hours. The heating rate of the drying proces...

Embodiment 2

[0032] Take 10ml, 25ml, 4ml, and 7.5ml of tetraethyl orthosilicate: absolute ethanol: methyltriethoxysilane: water in a molar ratio of 1:12:0.4:8, mix them, and slowly mix 1ml of hydrochloric acid alcohol solution Add it into the solution, adjust the pH of the solution to between 2 and 3, stir and hydrolyze for 12 hours, add ammonia water and alcohol solution to adjust the pH to about 8, stir to make the solution fully mixed, stop stirring after 5 minutes, pour the gel into a certain shape The phenolic resin foam material mold, seal and let stand, to be gel. Then aged in ethanol at 55°C for 2 days. Then soak the sample in a mixed solution of 8ml trimethylchlorosilane, 5ml absolute ethanol, and 50ml n-hexane to modify at room temperature for 2 days. Afterwards, it was aged with n-hexane for 1 day, and finally the sample was heated and dried under normal pressure to obtain a silica airgel composite material. The drying process was consistent with that of Example 1.

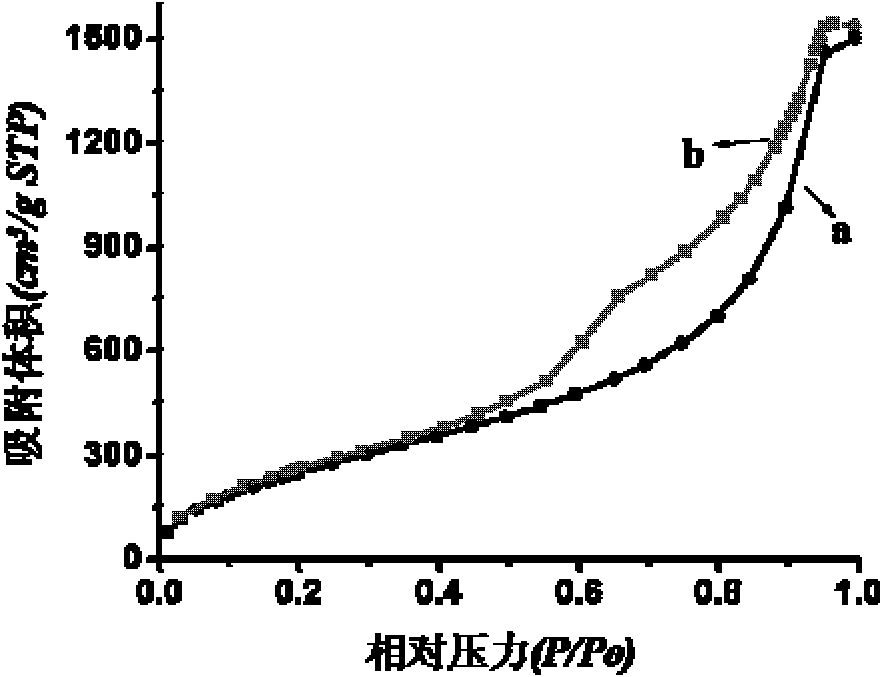

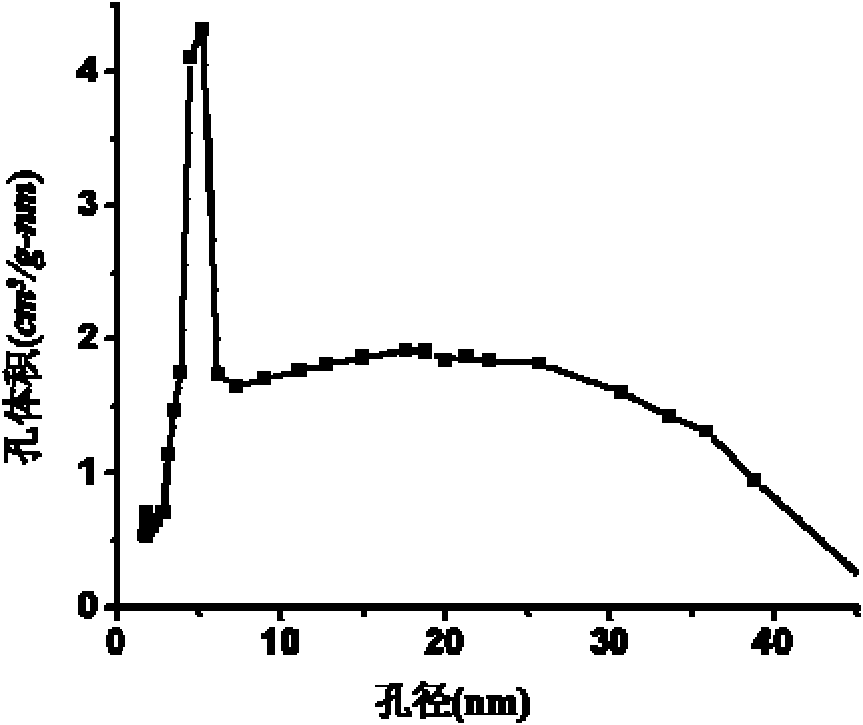

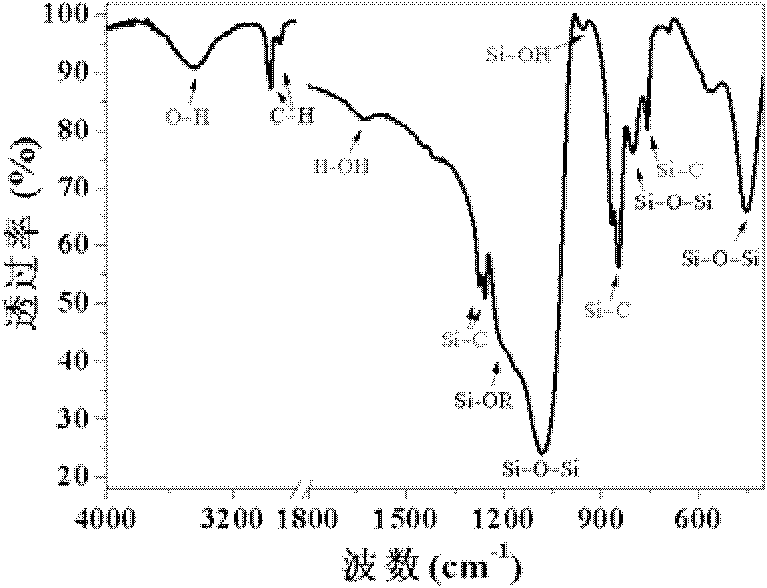

[0033] Th...

Embodiment 3

[0035] Add 10ml of tetraethyl orthosilicate, 25ml of absolute ethanol, and 6ml of distilled water into the container and stir to mix. After 15 minutes, slowly add hydrochloric acid alcohol solution to adjust the pH value between 2 and 3, and continue to mix and stir. After 12 hours, slowly add a certain amount of ammonia water alcohol solution drop by drop, adjust the pH value to about 8, stop stirring after 10 minutes, pour the gel into a polyurethane foam mold with a suitable size, seal it and let it stand until it gels. Then soak the sample in a mixed solution of 8ml trimethylchlorosilane, 5ml absolute ethanol, and 50ml n-hexane for modification at 35°C for 2 days. Afterwards, it was aged with n-hexane for 1 day, and finally the sample was heated and dried under normal pressure to obtain a silica airgel composite material. The drying process was the same as in Example 1. The prepared silica composite airgel has a density of 0.3-0.4 g / cm 3 , the porosity is 83-90%, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com