Metal material idler wheel type surface nanocrystallization method

A metal material and nanotechnology, which is applied in the field of metal material roller-type surface nanotechnology, can solve the problems of increased surface roughness, limited SMAT processing efficiency, and restrictions on the application field of SMAT surface nanotechnology technology, and achieves low cost and high realization method simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, 316L austenitic stainless steel is selected as the object, and its chemical composition is (wt.%): C 0.03%, Si0.03%, Mn 1.01%, S 0.016%, P 0.042%, Cr 16.72%, Mo 2.12% , Ni 10.7%, Fe balance. The supply state of 316L austenitic stainless steel is annealed state, and the diameter of the test rod is 10mm. The surface of the test bar is in the state of turning processing.

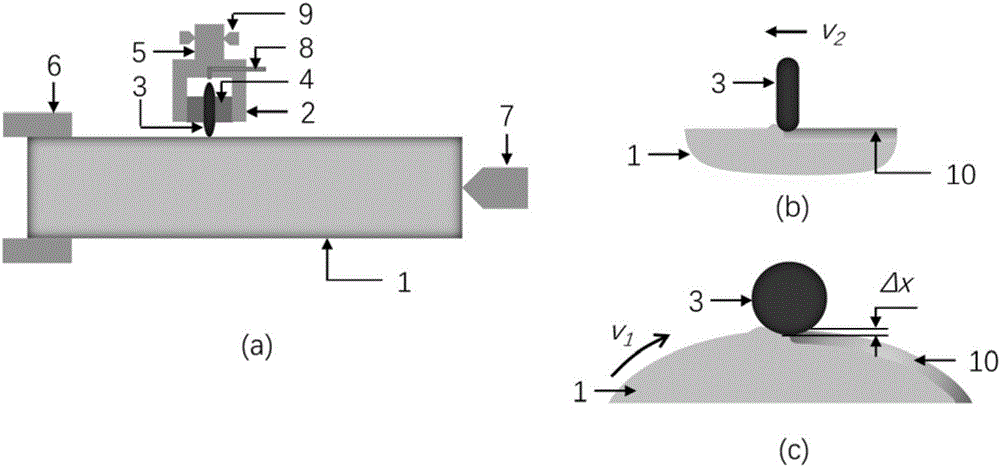

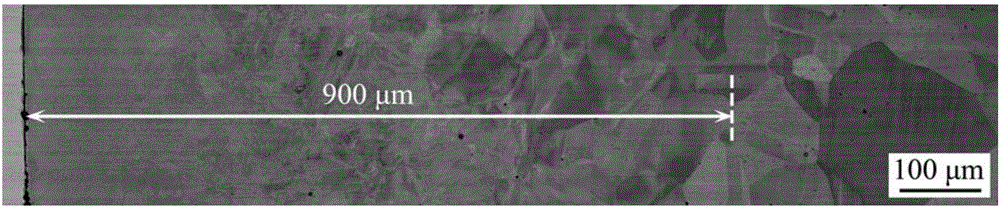

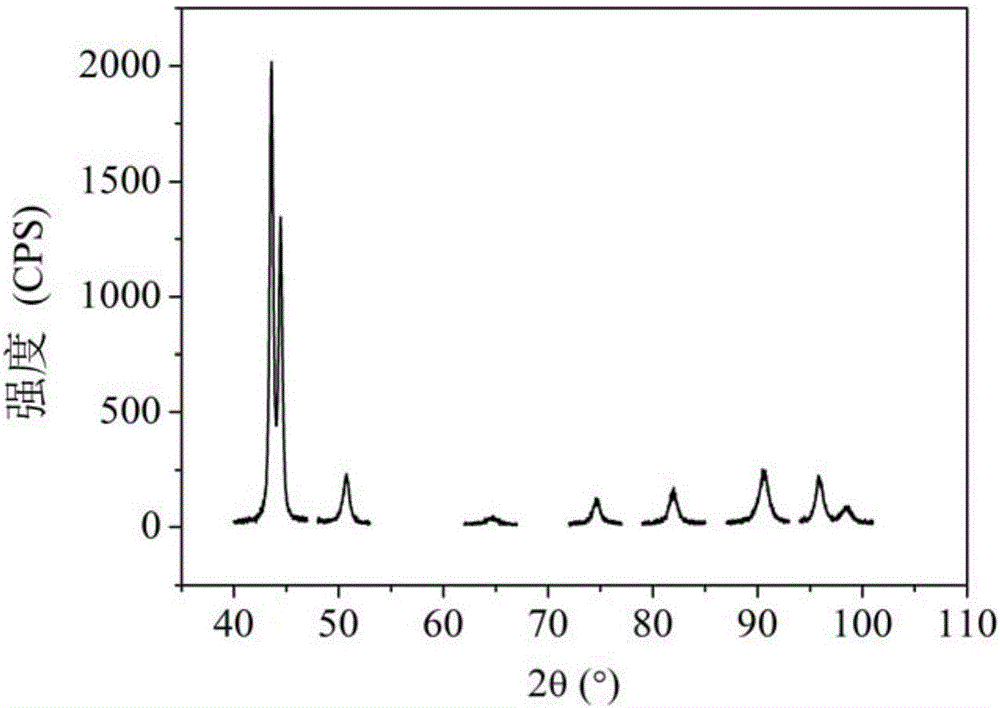

[0036] The surface nanometerization processing of 316L austenitic stainless steel is carried out by adopting the roller type surface nanometerization method of the present invention. The roller material of the roller-type surface nano-processing tool is GCr15, the diameter of the roller is 30mm, and the diameter of the end surface of the roller 3 is 10mm. 316L austenitic stainless steel test rod rotation speed v 1 =1.7×10 4 mm / min; tool feed speed v for roller-type surface nano-processing 2 =5×10 -3 mm / r; the depth Δx of the end of the roller pressed into the surface of 316L aus...

Embodiment 2

[0039] This embodiment selects IF steel as the object, and its chemical composition is (wt.%): C 0.04%, Si 0.04%, Mn0.29%, S 0.003%, P 0.04%, Ti 0.01%, Ni 0.02%, Cu 0.03 %, Al 0.03%, Fe balance. The supply state of IF steel is annealed state, and the diameter of the test rod is 20mm. The surface of the test bar is in the state of turning processing.

[0040] The surface nanometerization process of the IF steel is carried out by adopting the roller type surface nanometerization method of the present invention. The roller material of the roller-type surface nano-processing tool is GCr15, the diameter of the roller is 30mm, and the diameter of the end surface of the roller 3 is 10mm. IF steel test rod rotation speed v 1 =1.7×10 4 mm / min; tool feed speed v for roller-type surface nano-processing 2 =7×10 -3 mm / r; the depth Δx of the end of the roller pressed into the IF steel surface 1 =25μm, Δx 2 =25μm, Δx 3 = 50 μm.

[0041] The experimental results show that after the ...

Embodiment 3

[0043] This embodiment selects 42CrMoA quenched and tempered steel as the object, and its chemical composition is (wt.%): C 0.41%, Si0.23%, Mn 0.75%, S 0.024%, P 0.015%, Cr 1.12%, Mo 0.22%, Cu 0.02%, Fe balance. The supply state of 42CrMoA quenched and tempered steel is the quenched and tempered state (quenching, high temperature tempering treatment and aging treatment in sequence), and the diameter of the test rod is 20mm. The surface of the test bar is in the state of turning processing.

[0044] The surface nanometerization process of 42CrMoA quenched and tempered steel is carried out by adopting the roller type surface nanometerization method of the present invention. The roller material of the roller-type surface nano-processing tool is GCr15, the diameter of the roller is 30mm, and the diameter of the end surface of the roller 3 is 10mm. 42CrMoA quenched and tempered steel test rod rotation speed v 1 =1.9×10 4 mm / min; tool feed speed v for roller-type surface nano-pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com