Preparing method for ultra-thin high-density fiberboard

A technology of high-density fiberboard and its manufacturing method, which is applied in the field of fiberboard processing, can solve problems such as unstable chemical properties, large pores, and poor adsorption, and achieve the effects of small size, large specific surface area, and improved binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

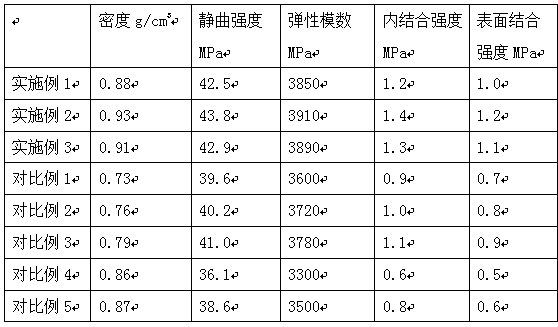

Examples

Embodiment 1

[0026] A manufacturing method of ultra-thin high-density fiberboard, the specific manufacturing method is as follows:

[0027] 1) After slicing the log material, cook and soften it, add nano antimony trioxide / PP composite fiber to it, place it in a heat refiner for heat grinding, obtain wood fiber pulp, and then dry naturally to obtain wood fiber, and wood fiber Put it into an electric constant temperature blower box, heat-treat at 80°C for 5 hours, then crush and finely grind through a 50-mesh sieve to obtain wood flour fibers;

[0028]2) Put the wood flour fiber in the glue mixing machine, and spray the glue on the surface of the wood flour fiber, then add montmorillonite / zirconia nanocomposite particles and maleic anhydride graft coupling agent, stir , so that the glue is evenly mixed and the material is obtained;

[0029] 3) Pave the material with a paving machine to form a slab belt, and then pre-press the slab belt under a pressure of 5MPa to obtain a slab with a thickn...

Embodiment 2

[0040] A manufacturing method of ultra-thin high-density fiberboard, the specific manufacturing method is as follows:

[0041] 1) After slicing the log material, cook and soften it, add nano antimony trioxide / PP composite fiber to it, place it in a heat refiner for heat grinding, obtain wood fiber pulp, and then dry naturally to obtain wood fiber, and wood fiber Put it into an electric constant temperature blower box, heat-treat at 110°C for 4 hours, then crush and finely grind through an 80-mesh sieve to obtain wood flour fibers;

[0042] 2) Put the wood flour fiber in the glue mixing machine, and spray the glue on the surface of the wood flour fiber, then add montmorillonite / zirconia nanocomposite particles and maleic anhydride graft coupling agent, stir , so that the glue is evenly mixed and the material is obtained;

[0043] 3) Pave the material with a paving machine to form a slab belt, and then pre-press the slab belt under a pressure of 6MPa to obtain a slab with a thi...

Embodiment 3

[0054] A manufacturing method of ultra-thin high-density fiberboard, the specific manufacturing method is as follows:

[0055] 1) After slicing the log material, cook and soften it, add nano antimony trioxide / PP composite fiber to it, place it in a heat refiner for heat grinding, obtain wood fiber pulp, and then dry naturally to obtain wood fiber, and wood fiber Put it into an electric constant temperature blower box, heat-treat at 140°C for 3 hours, then crush and finely grind through a 100-mesh sieve to obtain wood flour fibers;

[0056] 2) Put the wood flour fiber in the glue mixing machine, and spray the glue on the surface of the wood flour fiber, then add montmorillonite / zirconia nanocomposite particles and maleic anhydride graft coupling agent, stir , so that the glue is evenly mixed and the material is obtained;

[0057] 3) Pave the material with a paving machine to form a slab belt, and then pre-press the slab belt under a pressure of 7MPa to obtain a slab with a thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com