Preparation method for synthesizing T1-2212 superconducting thin film by employing sol-gel method

A technology of tl-2212 and superconducting thin film, which is applied in the usage of superconducting elements, etc., can solve the problems of difficulty in preparing high-quality Tl-2212 thin film and lack of Tl-2212 thin film, and achieve good superconducting characteristics and low production cost , good chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

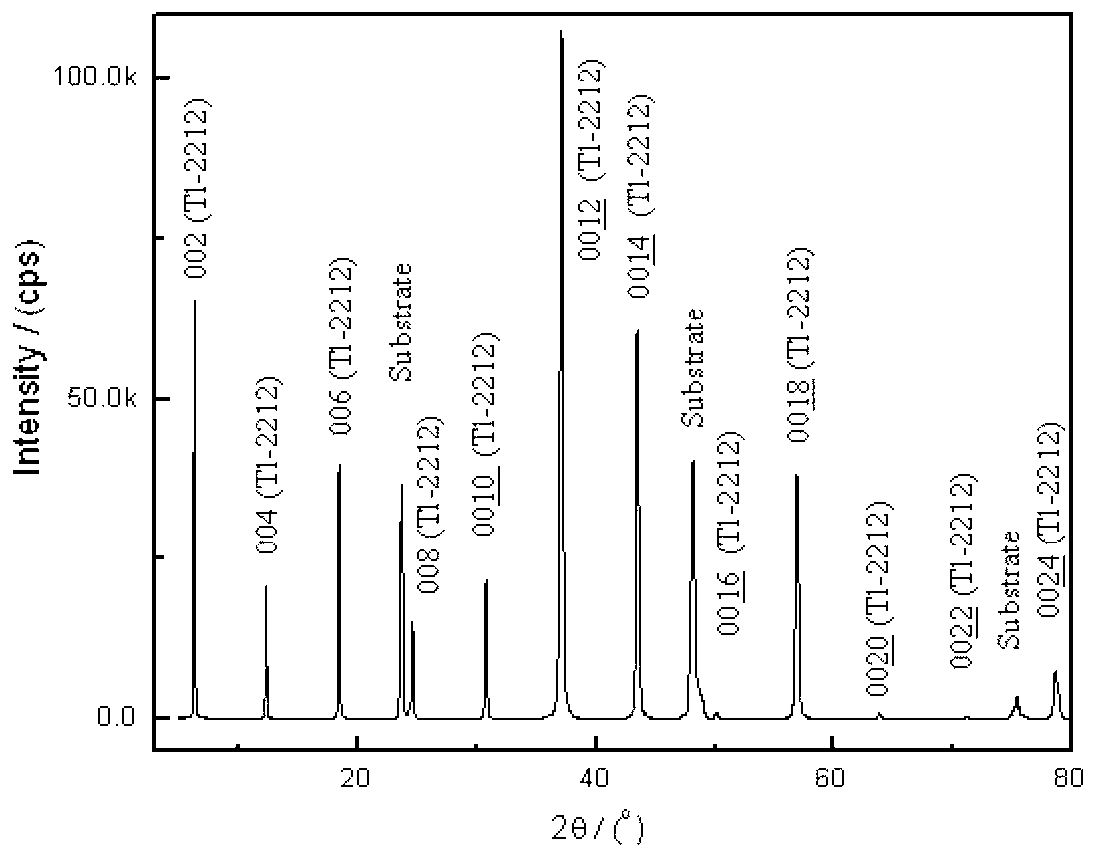

Image

Examples

Embodiment 1

[0033] Preparation of 104K Tl-2212 Superconducting Thin Film

[0034] 1. Sol preparation process

[0035] 1. Using thallium acetate, barium acetate, calcium acetate, and copper acetate as starting materials, lactic acid, α-methacrylic acid, diethylenetriamine, triethylenetetramine, and methanol as complexing agents and solvents to prepare sols. The active ingredients and molar ratio of the metal compound are: Thallium acetate: Barium acetate: Calcium acetate: Copper acetate=2.6:2:1:2.5.

[0036] 2. Add lactic acid, diethylenetriamine and methanol to thallium acetate, the molar ratio of each component is thallium acetate: lactic acid: diethylenetriamine: methanol = 1:2.5:2.5:70, and stir at 70°C to obtain solution A.

[0037] 3. Add lactic acid and methanol to barium acetate, the molar ratio of each component is barium acetate: lactic acid: methanol = 1:3:40, and stir at 80°C to obtain solution B.

[0038] 4. Add lactic acid and methanol to calcium acetate, the molar ratio of...

Embodiment 2

[0048] Preparation of 106K Tl-2212 Superconducting Thin Film

[0049] 1. Sol preparation process

[0050] 1. Using thallium acetate, barium acetate, calcium acetate, and copper acetate as starting materials, lactic acid, α-methacrylic acid, diethylenetriamine, triethylenetetramine, and methanol as complexing agents and solvents to prepare sols. The active ingredients and molar ratio of the metal compound are: Thallium acetate: Barium acetate: Calcium acetate: Copper acetate=3:2:1:2.7.

[0051] 2. Add lactic acid, diethylenetriamine and methanol to thallium acetate, the molar ratio of each component is thallium acetate: lactic acid: diethylenetriamine: methanol = 1:3.5:3.5:85, and stir at 70°C to obtain solution A.

[0052] 3. Add lactic acid and methanol to barium acetate, the molar ratio of each component is barium acetate: lactic acid: methanol = 1:2.5:50, and stir at 80°C to obtain solution B.

[0053] 4. Add lactic acid and methanol to calcium acetate, the molar ratio of...

Embodiment 3

[0063] Preparation of 103K Tl-2212 Superconducting Thin Film

[0064] 1. Sol preparation process

[0065] 1. Using thallium acetate, barium acetate, calcium acetate, and copper acetate as starting materials, lactic acid, α-methacrylic acid, diethylenetriamine, triethylenetetramine, and methanol as complexing agents and solvents to prepare sols. The active ingredients and molar ratio of the metal compound are: Thallium acetate: Barium acetate: Calcium acetate: Copper acetate=3.5:2:1:2.5.

[0066] 2. Add lactic acid, diethylenetriamine and methanol to thallium acetate, the molar ratio of each component is thallium acetate: lactic acid: diethylenetriamine: methanol = 1:3.5:3.5:80, and stir at 70°C to obtain solution A.

[0067] 3. Add lactic acid and methanol to barium acetate, the molar ratio of each component is barium acetate: lactic acid: methanol = 1:3.5:60, and stir at 80°C to obtain solution B.

[0068] 4. Add lactic acid and methanol to calcium acetate, the molar ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com