Composite reinforced concrete beam containing crack resistant reinforcement layer and method for making same

A reinforced concrete beam and reinforced concrete technology, applied in joists, girders, trusses, etc., can solve the problems of early crack development, limited spanning ability, low stiffness, etc., and achieve the effect of delaying cracks and improving structural performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

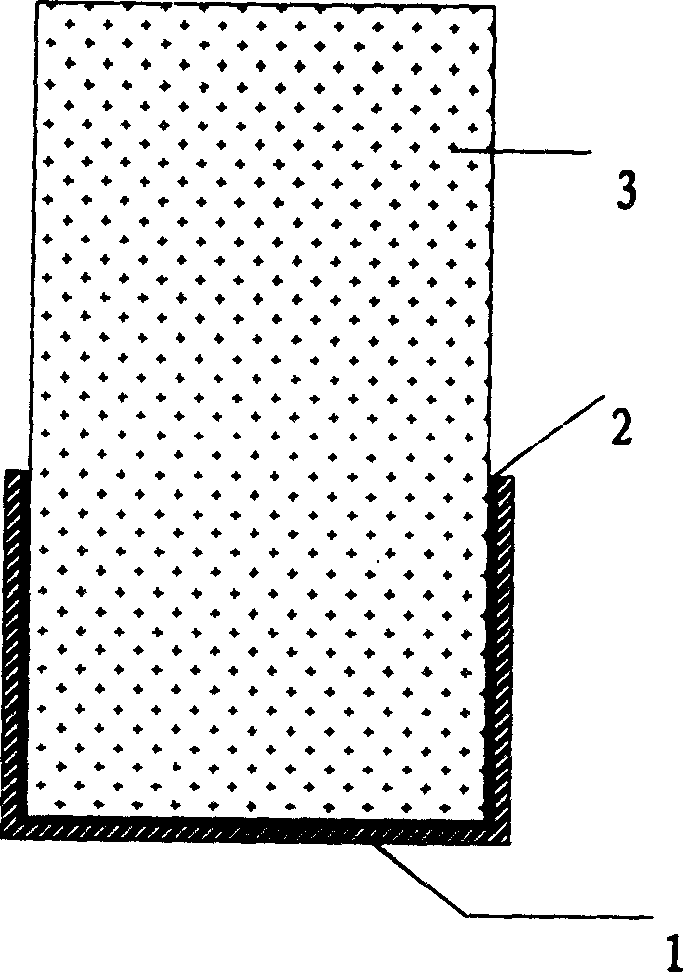

[0034] The composite reinforced concrete beam containing the anti-crack reinforcement layer and the construction method provided by the present invention are as follows: firstly, the reinforced concrete structure 3 is made, and then the treated bottom surface and the side of the part below the midline of the reinforced concrete structure 3 are the pulling surface, and then one layer is applied. The interface adhesive 2 is bonded to the surface of the interface adhesive 2 to bond the crack-resistant reinforcement layer 1 of composite material.

[0035] The crack-resistant reinforced layer 1 of composite material can be bonded to the interface adhesive 2 layer by layer; or the crack-resistant reinforced layer 1 of composite material can be made first and bonded to the interface adhesive 2 as a whole.

[0036] It is also possible to make the composite material crack-resistant reinforcing layer 1 first, and use it as the outer mold when it is not cured or after it is cured, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield stress | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com