Plastic metal composite pipe and preparation method thereof

A technology of plastic metal and composite pipes, applied in the direction of pipes, rigid pipes, mechanical equipment, etc., can solve the problems of poor mechanical properties and low temperature tolerance, and achieve improved toughness and mechanical properties, improved heat resistance, and increased low temperature resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

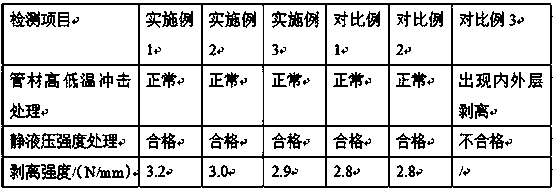

Examples

preparation example Construction

[0024] The preparation method of toughening additive is:

[0025] A. Take fumed silica and mix it with kaolin at a mass ratio of 2~6:1~4:2~5, and dry it at 100~110°C for 1~3h to obtain a dried product. Take the dried product at a mass ratio of 1~4:10 ~15 Add absolute ethanol, then add γ-(methacryloyloxy)propyltrimethoxysilane with 2~5% of dry matter, stir and mix at 60~65°C for 1~3h, filter with suction, and take the filter residue Grind and crush through a 200-400 mesh sieve, and collect the sieved particles;

[0026] B. Take sodium lauryl sulfate and add deionized water according to the mass ratio of 1~4:10~20, heat up to 50~60°C and stir and mix for 20~30min to obtain a mixed solution, adjust the pH to 8~9, and press the mass ratio Count, take 30~60 parts of sieved particles, 15~20 parts of mixed solution, 6~9 parts of methyl methacrylate, 4~7 parts of butyl acrylate, mix them, and ultrasonicate for 20~30min to obtain ultrasonic liquid, heat up to 40 ~50°C, add potassium ...

Embodiment 1

[0036] The preparation method of toughening additive is:

[0037] A. Take fumed silica and add kaolin at a mass ratio of 2:1:2 to mix, and dry at 100°C for 1 hour to obtain a dry product. Take the dry product and add absolute ethanol at a mass ratio of 1:10, and then add 2% of the dry product. γ-(Methacryloyloxy)propyltrimethoxysilane, stirred and mixed at 60°C for 1 hour, suction filtered, and the suction filter residue was ground and pulverized through a 200-mesh sieve, and the sieved particles were collected;

[0038] B. Take sodium lauryl sulfate and add deionized water at a mass ratio of 1:10, heat up to 50°C and stir and mix for 20 minutes to obtain a mixed solution, adjust the pH to 8, and take 30 parts of sieved particles, Mix 15 parts of the mixed solution, 6 parts of methyl methacrylate, and 4 parts of butyl acrylate, and ultrasonicate for 20 minutes to obtain an ultrasonic solution, raise the temperature to 40°C, add potassium persulfate with a mass of 1% of the ult...

Embodiment 2

[0048] The preparation method of toughening additive is:

[0049] A. Take fumed silica and add kaolin at a mass ratio of 6:4:5 to mix, dry at 110°C for 3 hours to obtain a dry product, take the dry product and add absolute ethanol at a mass ratio of 4:15, and then add 5% of the dry product γ-(methacryloyloxy)propyltrimethoxysilane, stirred and mixed at 65°C for 3 hours, filtered with suction, took the suction filter residue, ground and pulverized it through a 400 mesh sieve, and collected the sieved particles;

[0050] B. Take sodium lauryl sulfate and add deionized water at a mass ratio of 4:20, heat up to 60°C and stir and mix for 30 minutes to obtain a mixed solution, adjust the pH to 9, and take 60 parts of sieved particles, Mix 20 parts of the mixed solution, 9 parts of methyl methacrylate, and 7 parts of butyl acrylate, and ultrasonicate for 30 minutes to obtain an ultrasonic solution, raise the temperature to 50°C, add potassium persulfate with a mass of 3% of the ultra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com