Laser-arc compound remanufacturing method for TRT bearing cylinder iron castings

A casting and remanufacturing technology, which is applied in the field of repairing TRT iron castings, can solve the problems of increasing the width of the interface brittle zone and whitening tendency, large heat input of arc welding, and obvious diffusion of carbon elements, etc., and achieves low thermal expansion characteristics, The effect of reducing the tendency of cracking and improving the repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

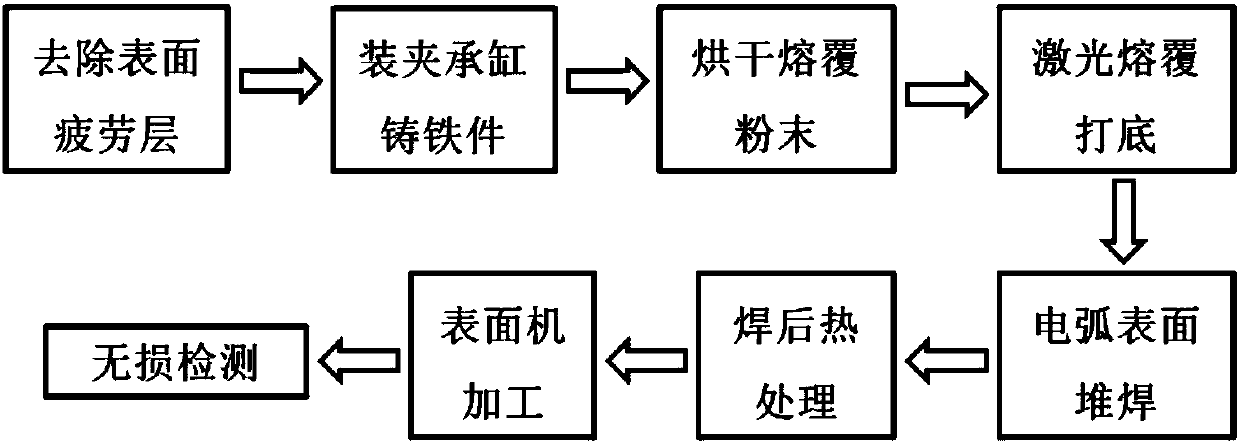

[0027] There is a lot of corrosion and wear on the surface of the TRT bearing cylinder casting iron, the wear thickness reaches 30mm, and there are a lot of cracks on the surface, and the preliminary detection determines that the crack depth reaches 15mm. The remanufacturing repair steps are as follows:

[0028] (1) Removal of the fatigue layer of TRT bearing cylinder iron castings: use an angle grinder or a grinding wheel to remove the fatigue layer on the surface to be repaired, expose the fresh matrix, and smooth the surface;

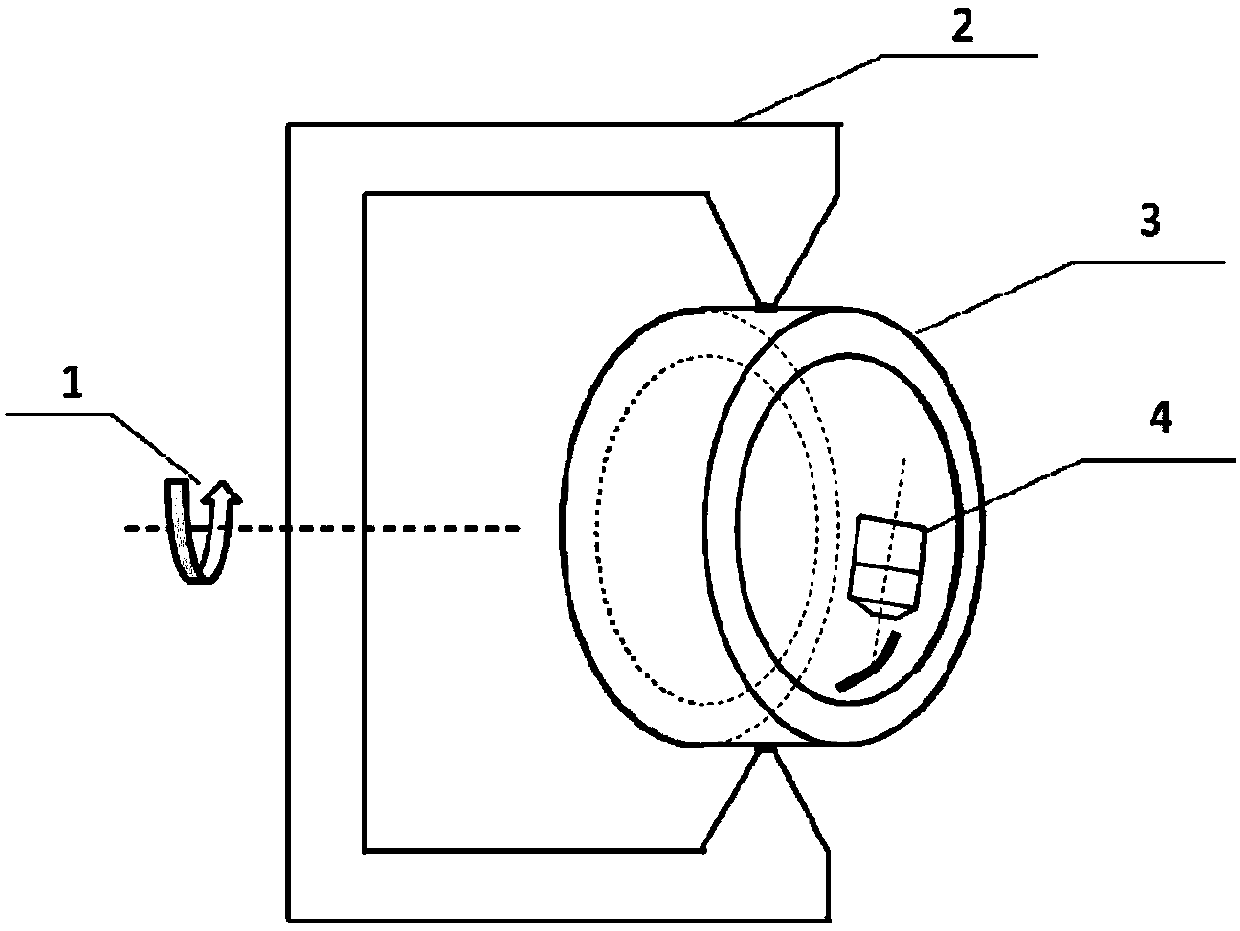

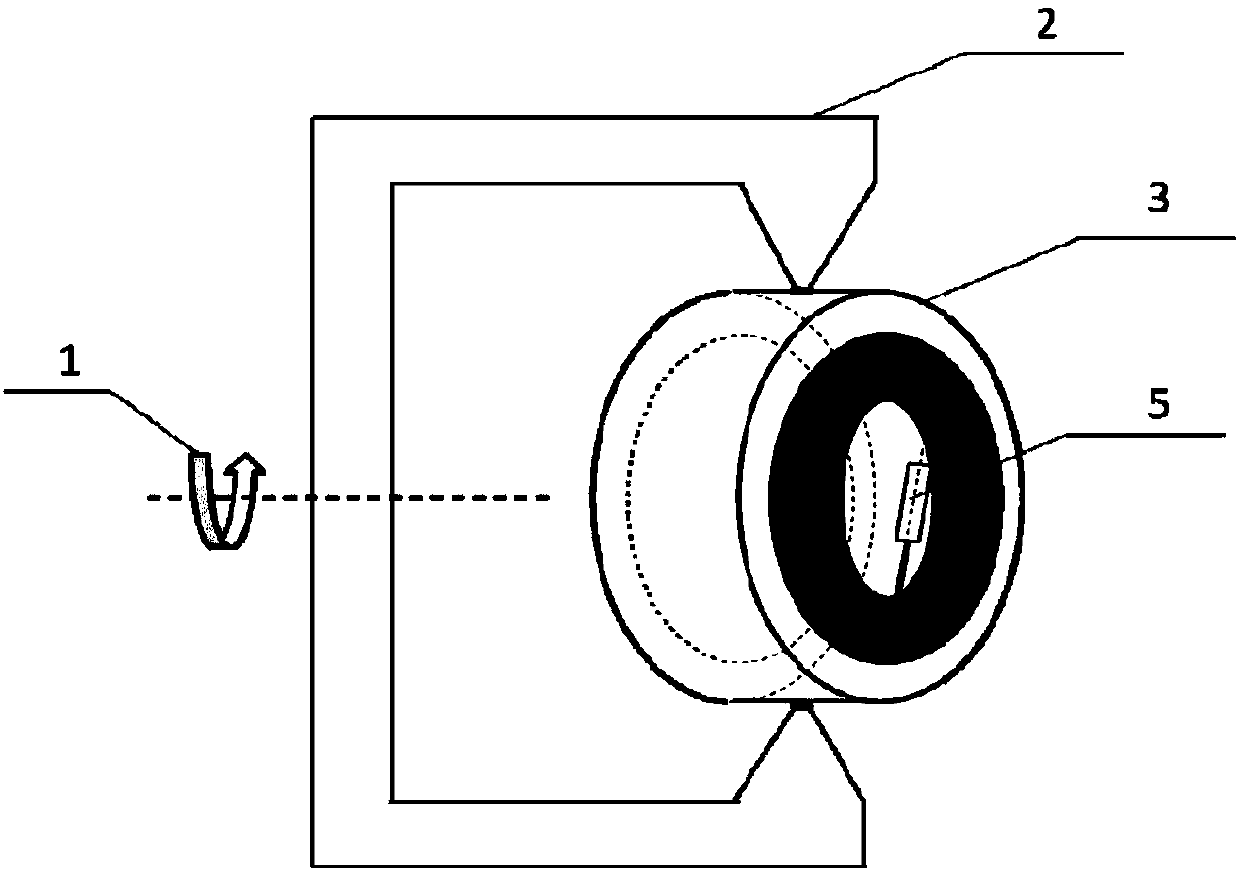

[0029] (2) Clamping of cylinder-bearing cast iron parts: fix the cylinder-bearing cast iron parts on the working turntable, the axis of the cylinder-bearing cast iron parts coincides with the axis of the turntable, and the laser head is offset in the direction perpendicular to the cladding direction every time the cylinder is rotated once 2mm;

[0030] (3) Powder drying: Put the self-fluxing alloy powder into a vacuum oven, evacuate to below 0.1MPa,...

Embodiment 2

[0036] There are uneven corrosion and wear phenomena on the surface of TRT bearing cylinder castings. The maximum wear pit depth reaches 40mm, and there are a large number of cracks on the surface. The preliminary detection determines that the crack depth reaches 12mm. The remanufacturing repair steps are as follows:

[0037] (1) Removal of the fatigue layer of TRT bearing cylinder iron castings: use an angle grinder or a grinding wheel to remove the fatigue layer on the surface to be repaired, expose the fresh matrix, and smooth the surface;

[0038] (2) Clamping of cylinder-bearing cast iron parts: fix the cylinder-bearing cast iron parts on the working turntable, the axis of the cylinder-bearing cast iron parts coincides with the axis of the turntable, and the laser head is offset in the direction perpendicular to the cladding direction every time the cylinder is rotated once 1.8mm;

[0039] (3) Powder drying: Put the self-fluxing alloy powder into a vacuum oven, evacuate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com