Flame retardant electroplating PC/ABS alloy material for automobile and preparation method of flame retardant electroplating PC/ABS alloy material

A technology for alloy materials and automobiles, which is applied in the field of flame-retardant electroplating PC/ABS alloy materials and preparations for automobiles. Focus on the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

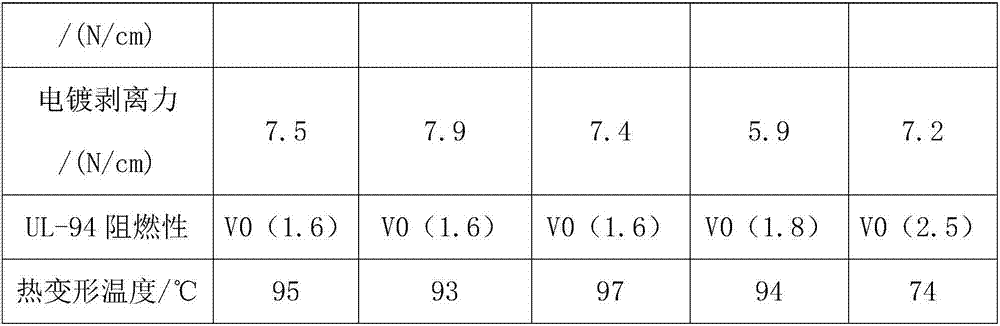

Examples

Embodiment 1

[0024] A flame-retardant electroplating PC / ABS alloy material for automobiles, its raw materials include by weight: 35 parts of low-flow PC resin, 35 parts of high-flow PC resin, 15 parts of ABS resin, 15 parts of modified mineral fiber, 10 parts of nickel-plated carbon fiber 1 part, 5 parts of compatibilizer, 10 parts of composite flame retardant, 1 part of processing aid;

[0025] Among them, the melt index of low flow PC resin (300°C, 1.2kg) is 3g / 10min, and the melt index of high flow PC resin (300°C, 1.2kg) is 20g / 10min.

Embodiment 2

[0027] A flame-retardant electroplating PC / ABS alloy material for automobiles, its raw materials include by weight: 45 parts of low-flow PC resin, 25 parts of high-flow PC resin, 8 parts of ABS resin, 25 parts of modified mineral fiber, 15 parts of nickel-plated carbon fiber 2 parts, 2 parts of compatibilizer, 15 parts of composite flame retardant, 3 parts of processing aid;

[0028] Among them, the melt index (300°C, 1.2kg) of low-flow PC resin is 9g / 10min, and the melt index (300°C, 1.2kg) of high-flow PC resin is 40g / 10min;

[0029] The modified mineral fiber is acid-etched and treated with a coupling agent, wherein the mineral fiber is basalt fiber.

Embodiment 3

[0031] A flame-retardant electroplating PC / ABS alloy material for automobiles, its raw materials include by weight: 40 parts of low-flow PC resin, 30 parts of high-flow PC resin, 10 parts of ABS resin, 20 parts of modified mineral fiber, 12 parts of nickel-plated carbon fiber 8 parts, 8 parts of compatibilizer, 12 parts of composite flame retardant, 2 parts of processing aid;

[0032] Among them, the melt index (300°C, 1.2kg) of low-flow PC resin is 5g / 10min, and the melt index (300°C, 1.2kg) of high-flow PC resin is 30g / 10min;

[0033] The modified mineral fiber is acid-etched and treated with a coupling agent, wherein the mineral fiber is basalt fiber and brucite fiber. The preparation process of the modified mineral fiber includes: placing the mineral fiber in 1mol / L acid solution , react at 70°C for 2h, suction filter, wash and dry to obtain acid etching material; disperse silane coupling agent in 25wt% ethanol aqueous solution to obtain silane coupling agent ethanol solut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com