Anti-oxidation treatment technology before steel structure material heat treatment

A processing technology and steel structure technology, applied in the direction of metal material coating technology, coating, melting spray plating, etc., can solve the problems of high equipment cost, high technical difficulty, increased heat treatment cost, etc., to improve roughness, widely used Prospects, the effect of improving corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

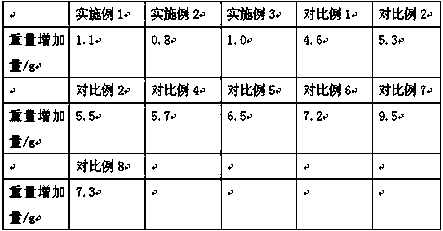

Examples

Embodiment 1

[0027] An anti-oxidation treatment process for steel structure materials before heat treatment, the specific process steps are as follows:

[0028] 1) Pretreatment of steel structure materials

[0029] Melt the raw material of the steel structure material to obtain a steel solution, cast it into a mold, preheat the ultrasonic vibrating tool head at 1000°C for 15 minutes, then place the ultrasonic vibrating tool head in the middle of the casting mold, and immerse it into the steel solution to a depth of 1 / 3 place, vibrated at 900W for 30 minutes, then increased the vibration power to 1800W, continued to vibrate until the surface of the casting was basically solidified, took out the ultrasonic vibrating tool head, and waited until the steel melt was air-cooled until it was completely solidified. Pretreated steel structure materials;

[0030] 2) Roughening treatment of steel structure materials

[0031] When the temperature of the steel structure material drops to 1050°C, keep it...

Embodiment 2

[0045] An anti-oxidation treatment process for steel structure materials before heat treatment, the specific process steps are as follows:

[0046] 1) Pretreatment of steel structure materials

[0047] Melt the raw material of the steel structure material to obtain a steel solution, cast it into a mold, preheat the ultrasonic vibrating tool head at 1100°C for 12 minutes, then place the ultrasonic vibrating tool head in the middle of the casting mold, and immerse it into the steel solution at a depth of 1 / 3 place, vibrate at 1000W for 25 minutes, then increase the vibration power to 2000W, continue to vibrate until the surface of the casting is basically solidified, take out the ultrasonic vibrating tool head, and wait for the steel solution to be air-cooled until it is completely solidified. Pretreated steel structure materials;

[0048] 2) Roughening treatment of steel structure materials

[0049] When the temperature of the steel structure material drops to 1100°C, keep it...

Embodiment 3

[0063] An anti-oxidation treatment process for steel structure materials before heat treatment, the specific process steps are as follows:

[0064] 1) Pretreatment of steel structure materials

[0065] Melt the raw material of the steel structure material to obtain a steel solution, cast it into a mold, preheat the ultrasonic vibrating tool head at 1200°C for 10 minutes, then put the ultrasonic vibrating tool head in the middle of the casting mold, and immerse it into the steel solution to a depth of At 1 / 2 place, vibrate at 1200W for 20 minutes, then increase the vibration power to 2100W, continue to vibrate until the surface of the casting is basically solidified, take out the ultrasonic vibrating tool head, and wait until the steel solution is air-cooled until it is completely solidified. Pretreated steel structure materials;

[0066] 2) Roughening treatment of steel structure materials

[0067] When the temperature of the steel structure material drops to 1150°C, keep it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com