Welding repair process suitable for cast nickel-base superalloy casting

A technology for superalloys and castings, applied in the field of welding repair technology, can solve the problems of poor welding performance of nickel-based superalloys and have not been effectively improved, so as to improve the welding repair efficiency, prevent the occurrence of cracks, and avoid multiple welding repairs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

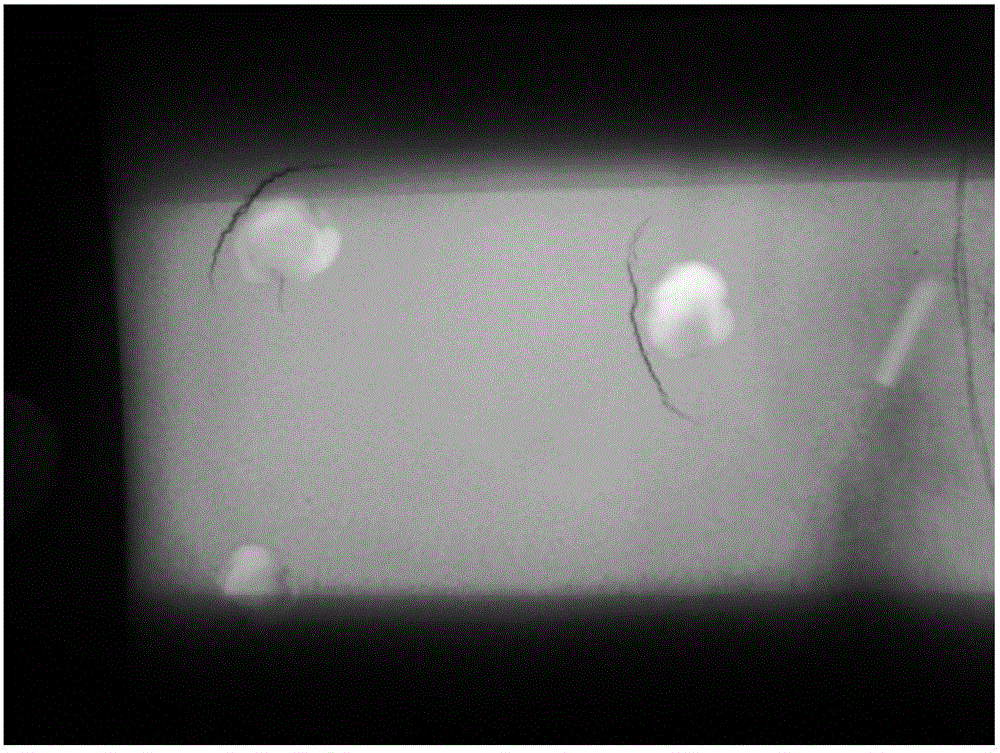

[0023] Microscopic shrinkage was found in guide vanes cast with material brand CM939 superalloy after casting. The mass percentages of the main elements of this brand superalloy were Cr 22.0~22.8%, Co 18.5~19.5%, Ti3.6~3.8%, Al 1.8~ 2.0%, W1.8~2.2%, a small amount of impurity elements that cannot be completely removed during the smelting process, and the rest is Ni; the welding repair process of the above-mentioned defective guide vanes includes the following steps: digging out the shrinkage part and processing it out Groove, the groove angle is 60-70° without blunt edge; use stainless steel wire brush and acetone to clean the groove and the surface around the groove; this can prevent the groove surface from overheating and carburizing the groove surface; After cleaning, use penetrant testing, if there is no crack on the surface, it is qualified; put the casting in 1250 o C heat preservation 14 hours, control furnace temperature with 55 o C / min average rate of cooling to room...

Embodiment 2

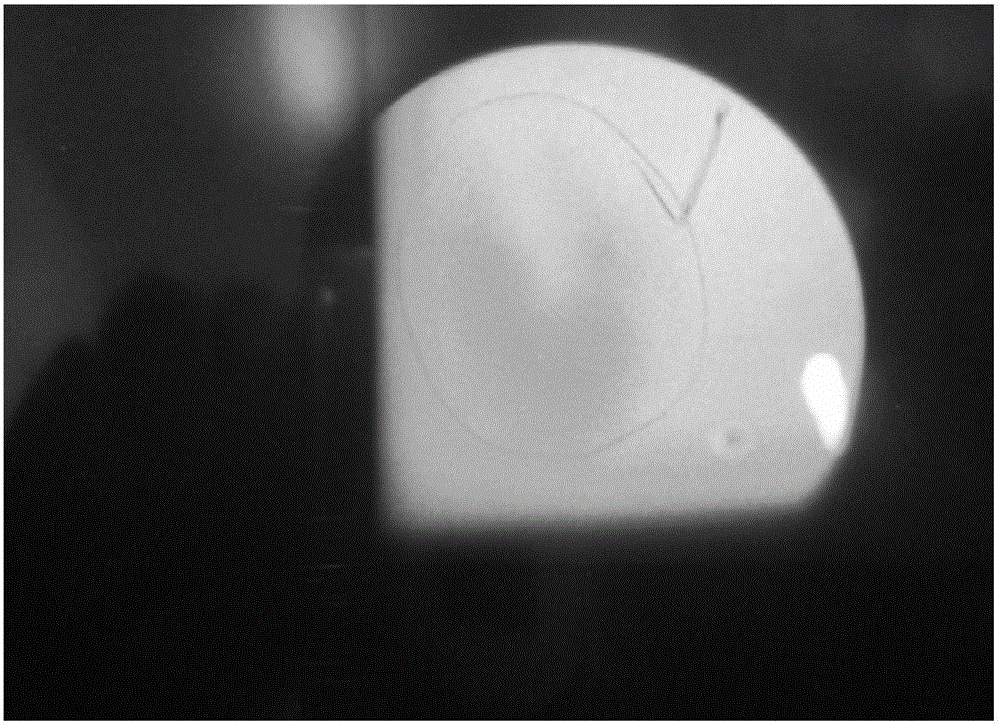

[0025] The guide vane cast with the material grade GTD222 superalloy has holes with a diameter of about 10mm that need to be repaired. The mass percentages of the main elements of this grade of superalloy are Cr 22.2~22.8%, Co 18.5~19.5%, Ti2.20~2.40% , Al 1.10~1.30%, W 1.80~2.20%, a small amount of impurity elements that cannot be completely removed during the smelting process, and the rest is Ni.

[0026] The welding repair process for the above-mentioned defective guide vanes includes the following steps: clean the surface around the hole with a stainless steel wire brush and acetone before welding repair; 1205 o C heat preservation 12 hours, control furnace temperature with 62 o C / min average rate of cooling to room temperature. Argon arc welding was used for surfacing repair, and after welding, grinding and solution treatment were carried out. No welding cracks were found in the welding repair area by visual observation and X-ray non-destructive testing (see Figure 4 ...

Embodiment 3

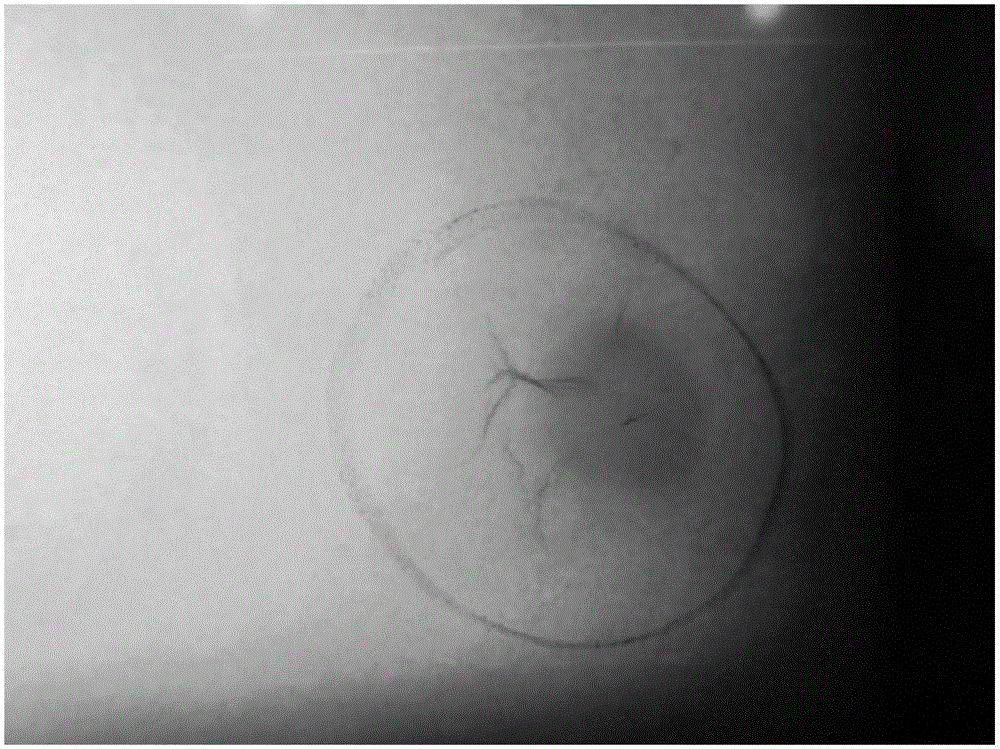

[0028] Use the nozzle liner set cast by the superalloy of material grade K4648. The mass percentage of the main elements of the superalloy of this grade is Cr32.0~35.0%, Mo 2.30~3.50%, Ti0.70~1.30%, Al 0.70~1.30% , W 4.30~5.50%, Nb0.70~1.30%, a small amount of impurity elements that cannot be completely removed during the smelting process, and the rest is Ni.

[0029] Microscopic porosity with a diameter of about 30 mm occurs in the flange after casting. Before welding repair, dig out the loose part and process the groove, the groove angle is 60-70° without blunt edge; use stainless steel wire brush and acetone to clean the groove and the surface around the groove; this can prevent the groove surface from Overheating and carburizing of the groove surface; after the groove and its surroundings are cleaned, the penetration test is used, and it is qualified if there is no crack on the surface; the casting is placed in 1290 o C heat preservation 12 hours, control furnace temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com