The installation method of the spun yarn broken detection control circuit board on the angle steel

A technology for controlling circuit boards and yarn break detection, which is applied in textiles and papermaking, can solve problems such as complicated wiring and difficult installation, and achieves the effects of easy processing, convenient installation and disassembly, and low installation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

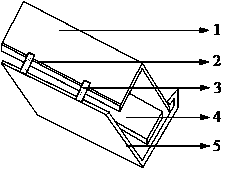

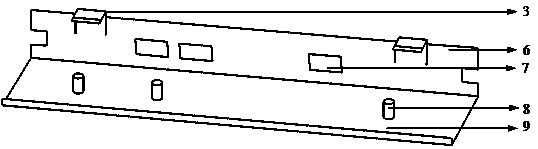

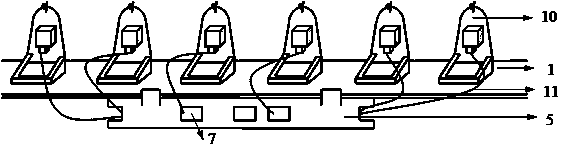

[0024] Such as figure 1 Shown includes fender angle steel 1 , control circuit board angle steel 5 and broken yarn detection control circuit board 4 . The angle steel of the control circuit board is installed under the angle steel of the fender plate, and the two bayonets 3 on one side of the angle steel of the control circuit board are stuck on one side with a convex edge 2 of the angle steel of the fender plate, and are fixed on the angle steel of the fender plate by elastic force. The two form a rectangular space, and the yarn break detection control circuit board is installed in the above-mentioned rectangular space. Such as figure 2 As shown, there is a rectangular hole 7 on one side 6 of the angle steel of the detection control circuit board, which is used for wiring of the yarn breakage detection control circuit board. The other side 9 has a stud hole 8 for installing a broken yarn detection control circuit board. Such as image 3 As shown, the wiring 11 of the dete...

Embodiment 2

[0026] Such as figure 1 Shown are fender angles, control circuit board angles and yarn break detection control circuit board. The angle steel of the control circuit board is installed under the angle steel of the fender plate, and the two bayonets on one side of the angle steel of the control circuit board are stuck on one side with a convex edge of the angle steel of the fender plate, and are fixed on the angle steel of the fender plate by elastic force. A rectangular space is formed, and the yarn break detection control circuit board is installed in the above-mentioned rectangular space. Such as Figure 4 As shown, there is a round hole 12 on one side of the angle steel of the detection control circuit board, which is used for wiring of the yarn breakage detection control circuit board. The other side has stud holes for installing the yarn break detection control circuit board. Such as image 3 As shown, the wiring of the detection control circuit board is connected to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com