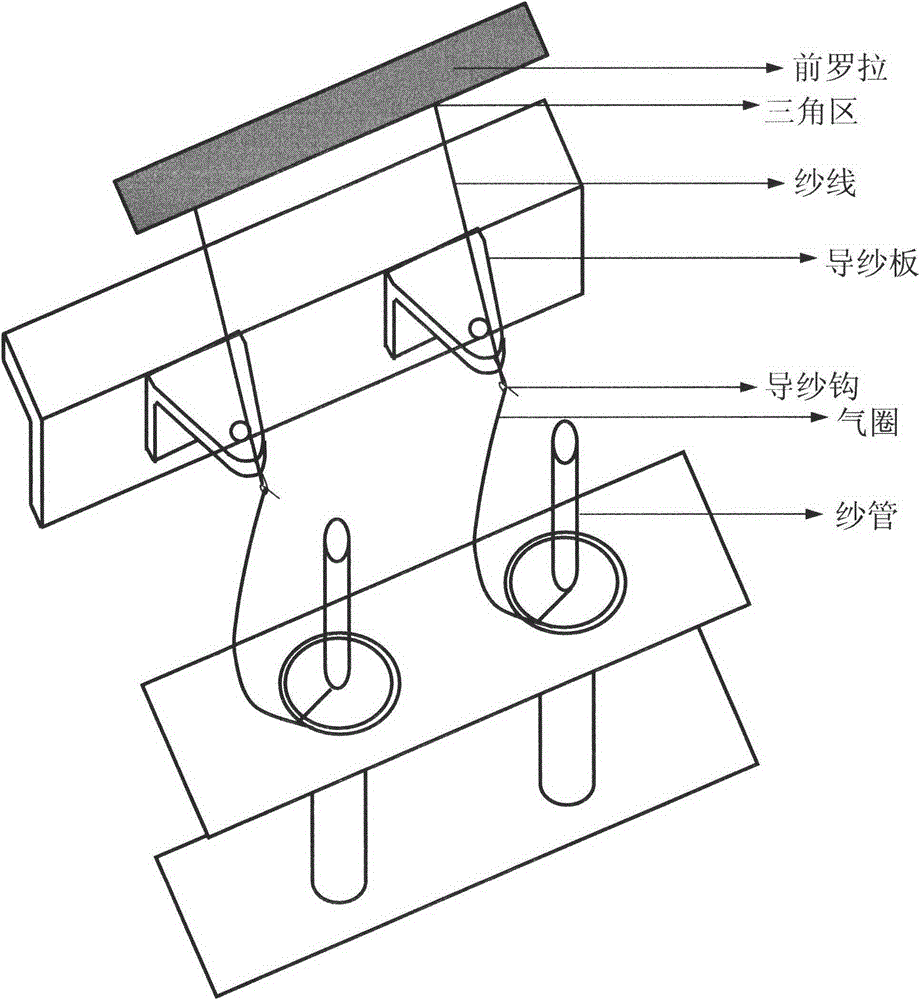

Special infrared reflection type yarn guide device for yarn breakage monitoring

An infrared light and reflective technology, applied in textiles and papermaking, etc., can solve the problems of needing air source, difficult maintenance, high investment cost, etc., and achieve the effect of improving discrimination accuracy and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

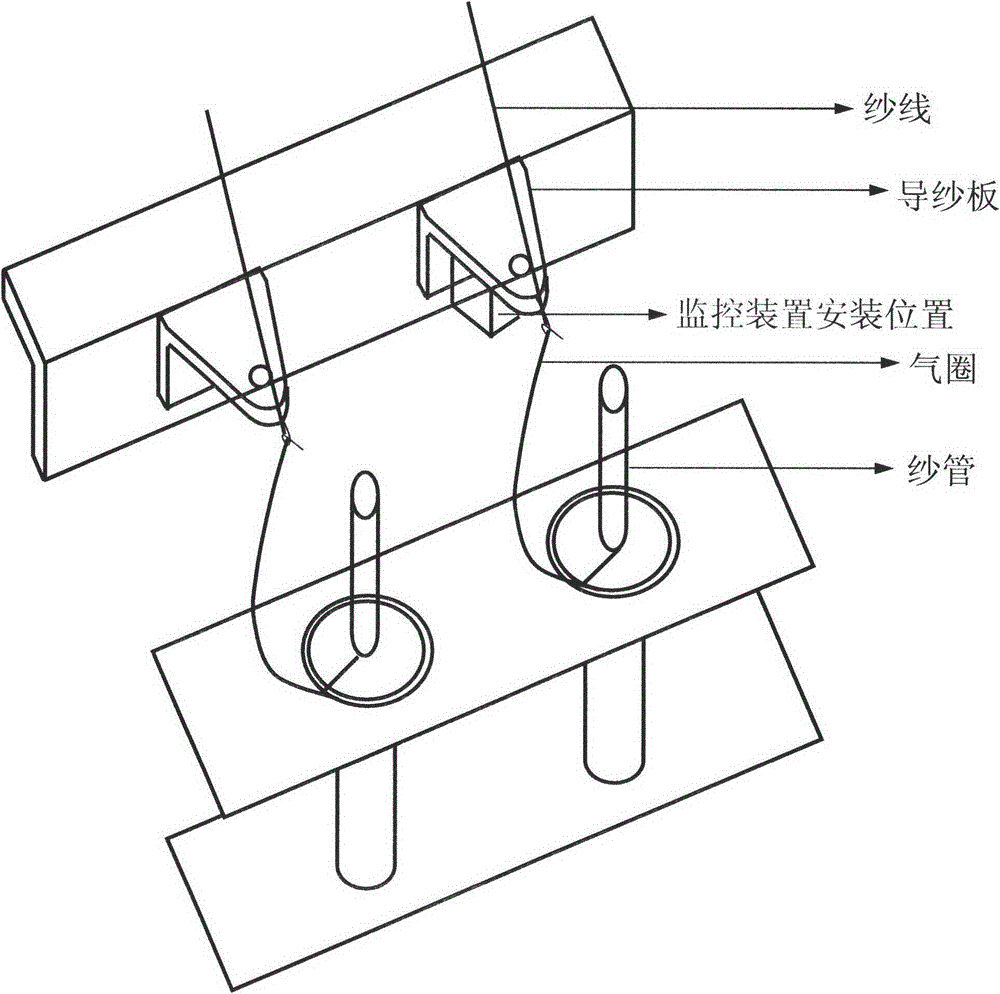

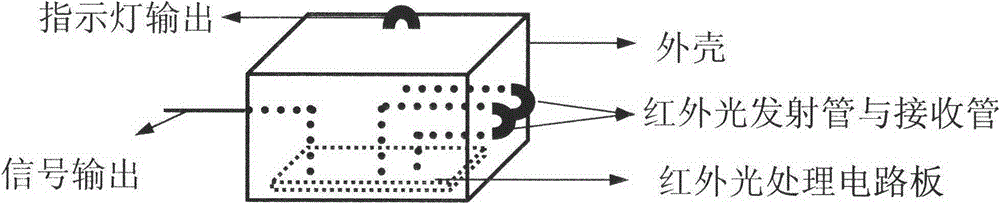

[0040] Such as figure 2 will be shown as image 3 The modified part shown in the device is installed on the lower side of the yarn guide plate, and the modified part is composed of an infrared light emitting tube and an infrared light receiving tube. The infrared light processing circuit board drives the infrared light-emitting tube to emit infrared light. In the normal spinning process, the yarn passes in front of the infrared light-emitting tube. At this time, the infrared light reflected by the surface of the yarn is reflected to the surface of the infrared light receiving tube. After processing and analyzing the changed analog signal on the infrared light processing circuit board, a digital signal output is generated, and the result is "1". After yarn breakage occurs, no yarn passes in front of the infrared light-emitting tube, and the non-reflected infrared light is reflected to the surface of the infrared light-receiving tube, and the analog signal of this change is pr...

Embodiment 2

[0042] Such as Figure 4 will be shown as image 3 The modified part shown in the device is installed on the upper side of the yarn guide plate, and the modified part is composed of an infrared light emitting tube and an infrared light receiving tube. Its signal processing principle is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com