Parts for repairing crack of metal surface and method therefore

A crack and metal technology, applied in the field of mechanical maintenance, can solve problems such as difficult to ensure repair quality and effective working life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

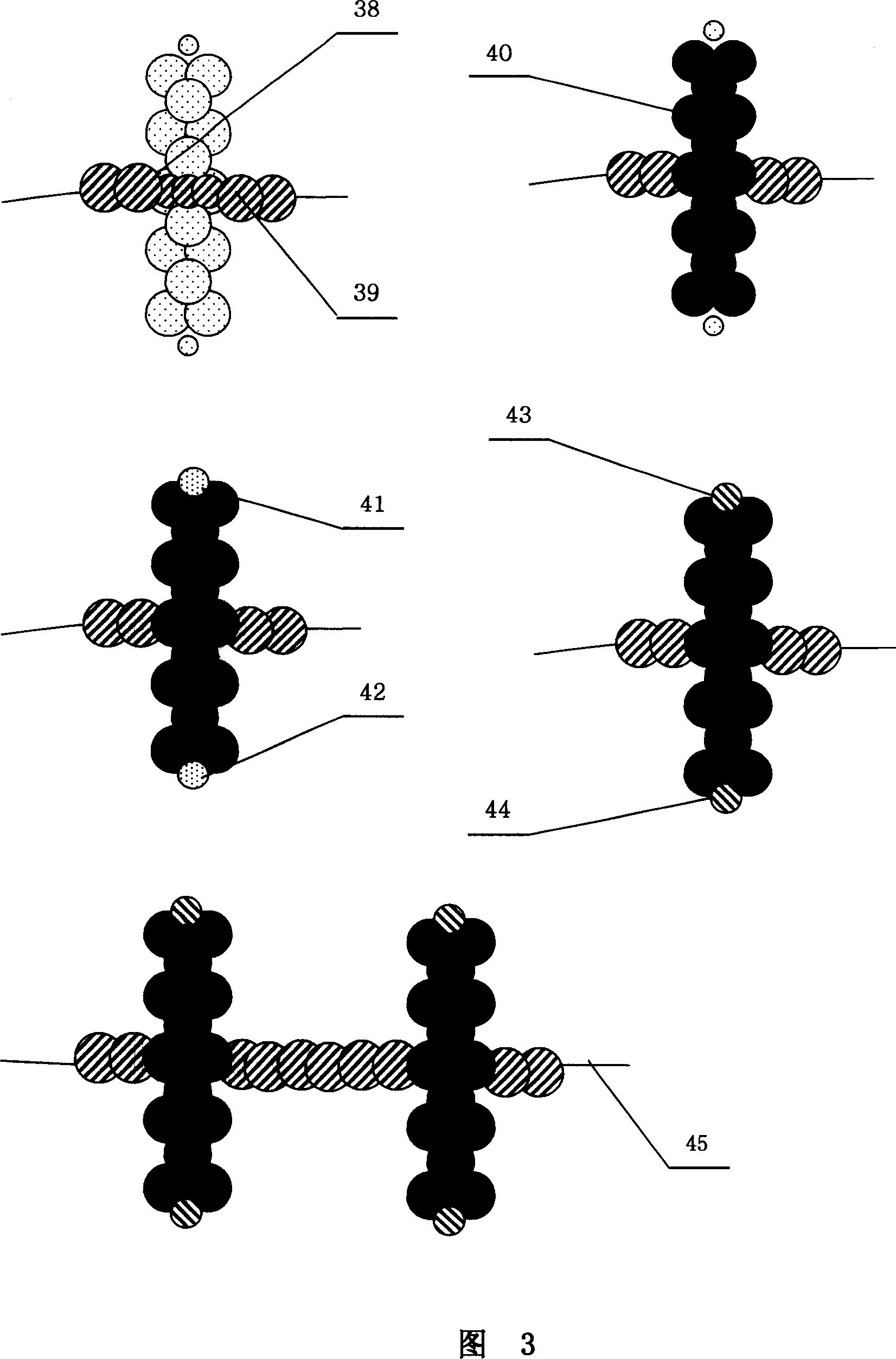

[0022] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

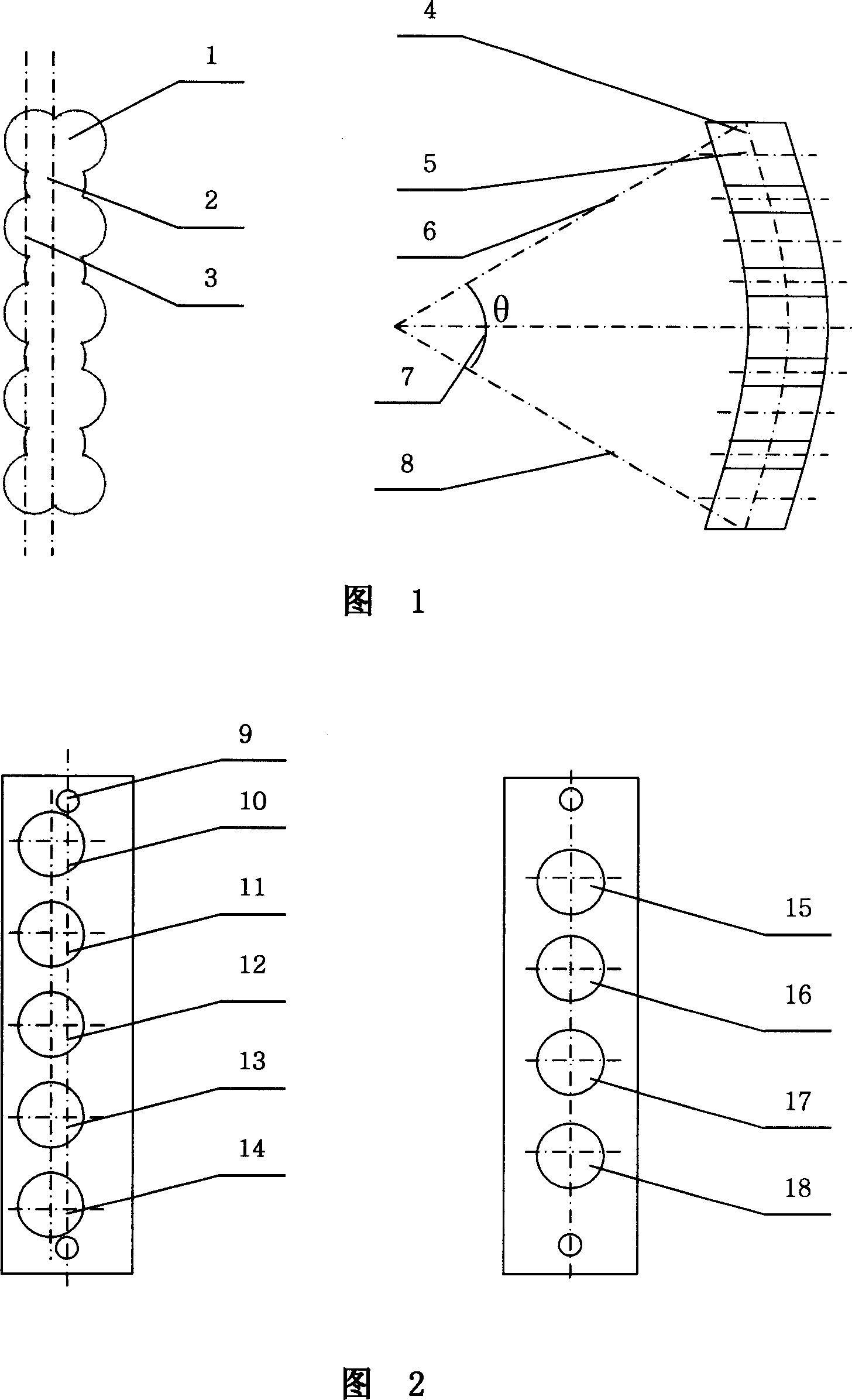

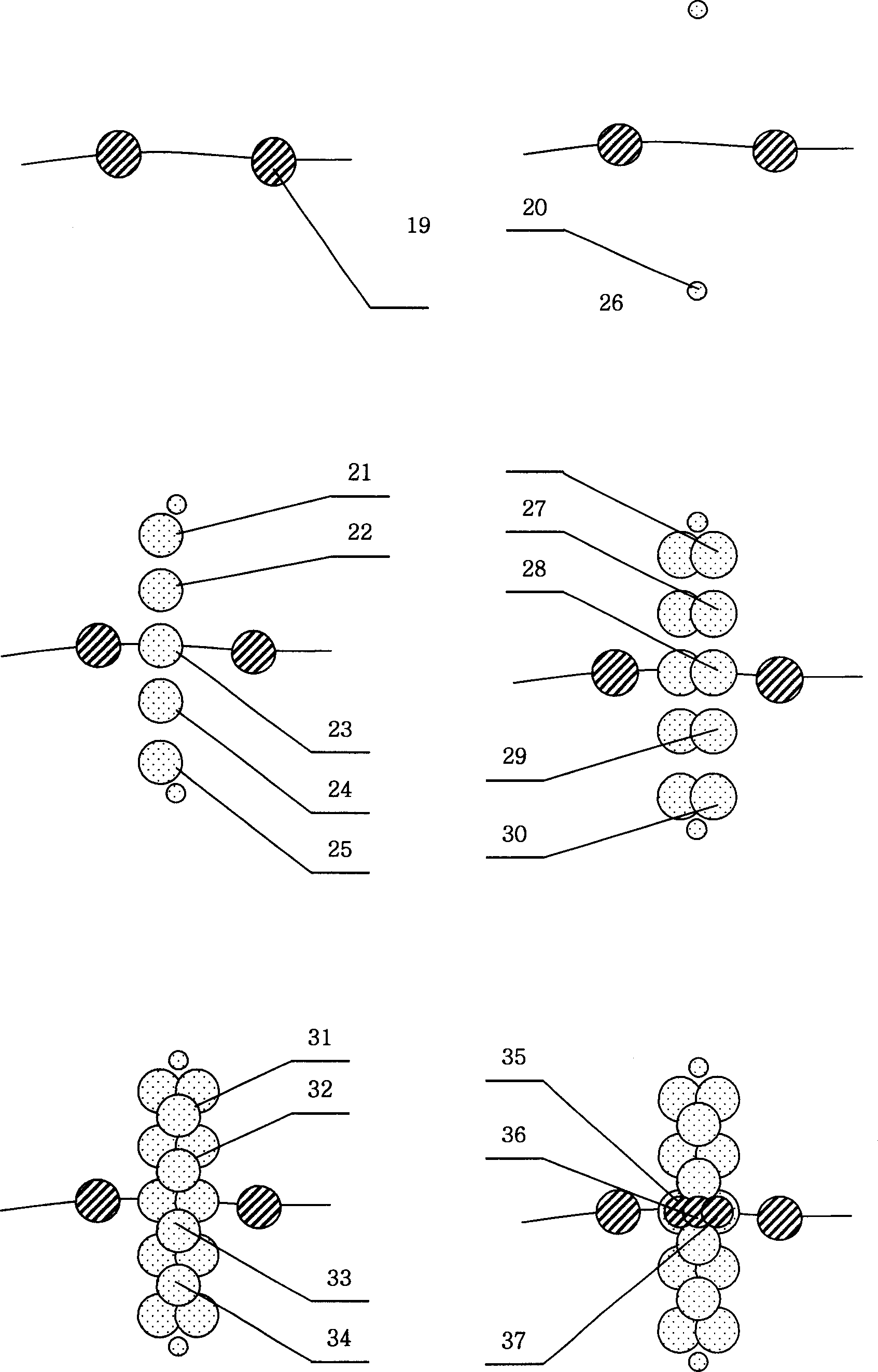

[0023] In Fig. 1, the curved inlay of the present invention consists of four circles above the main body (1), the central axis (2), five circles above the left axis of symmetry (3), and five circles above the right axis of symmetry (3). Five circles overlap each other. From the side view, it can be seen that the axis of symmetry (4), its own axis (5), the radius (6) and the radius (8) should be the same, and the arc (7) of the arc-shaped inlay is the angle θ, and the range of the arc is based on the needs of the site Should satisfy 0°<θ<180°.

[0024] The mold used when installing the arc-shaped insert in Figure 2 is divided into two modes, one of which consists of the mold positioning hole 9 and the 5 limit holes on the left, namely the limit hole 1-1 (10), the limit hole 1- 2 (11), spacer hole 1-3 (12), spacer hole 1-4 (13), spacer hole 1-5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com