Heat-resistant PVC shoe material and preparation method thereof

A technology for PVC resin and shoe materials, applied in the field of plastic processing, can solve the problems of large loss of mechanical properties, difficult to control conditions, poor heat resistance, etc., and achieve the effects of improving impact resistance, promoting gelation, and improving heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

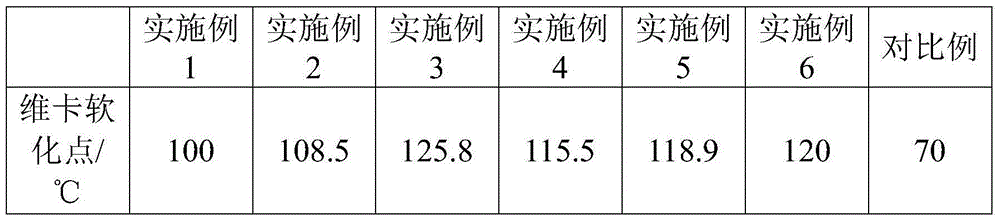

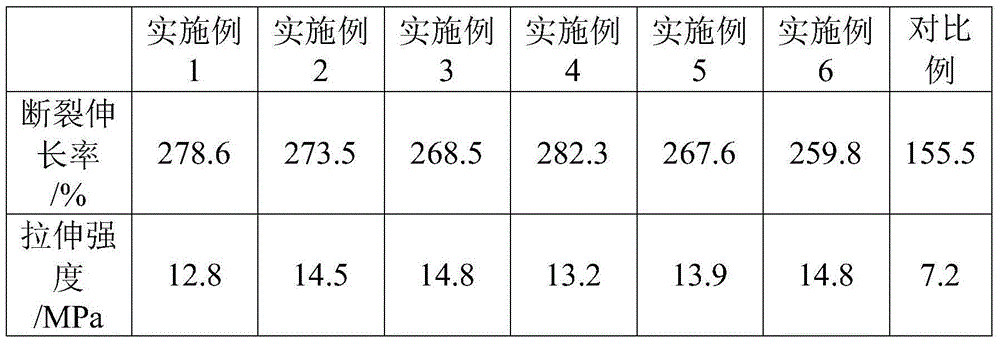

Examples

Embodiment 1

[0032] A heat-resistant PVC shoe material, in parts by weight, comprises the following components:

[0033] 10 parts of PVC resin, 5 parts of light calcium carbonate,

[0034] 6 parts of nano-titanium oxide, 1 part of MBS,

[0035] 2 parts of SMA, 3 parts of plasticizer,

[0036] Stabilizer 2 parts.

[0037] Its preparation method comprises the following steps:

[0038] (1) Add 10 parts of PVC resin, 5 parts of light calcium carbonate, and 6 parts of nano-titanium oxide into the mixer, and knead for 10 minutes at 100°C; add 1 part of MBS, 2 parts of SMA, and 3 parts of plasticizer , 2 parts of stabilizer, continue mixing for 5 minutes;

[0039] (2) The material after mixing is extruded and granulated by a single-screw extruder. Injection molding at 170°C to obtain heat-resistant PVC shoe materials.

Embodiment 2

[0041] A heat-resistant PVC shoe material, in parts by weight, comprises the following components:

[0042] 20 parts of PVC resin, 10 parts of light calcium carbonate,

[0043] 8 parts of nano-titanium oxide, 5 parts of MBS,

[0044] 3 parts of SMA, 8 parts of plasticizer,

[0045] 10 parts of stabilizer.

[0046] Its preparation method comprises the following steps:

[0047] (1) Add 20 parts of PVC resin, 10 parts of light calcium carbonate, and 8 parts of nano-titanium oxide into the mixer, and knead for 15 minutes at 120°C; add 5 parts of MBS, 3 parts of SMA, and 8 parts of plasticizer , 10 parts of stabilizer, continue mixing for 10 minutes;

[0048] (2) The material after mixing is extruded and granulated by a single-screw extruder. The process conditions are body temperature 180°C, die temperature 170°C, single-screw speed 40r / min, and then by the injection molding machine. Injection molding at 180°C to obtain heat-resistant PVC shoe materials.

Embodiment 3

[0050] A heat-resistant PVC shoe material, in parts by weight, comprises the following components:

[0051] 12 parts of PVC resin, 6 parts of light calcium carbonate,

[0052] 7 parts of nano-titanium oxide, 2 parts of MBS,

[0053] 2 parts of SMA, 4 parts of plasticizer,

[0054] 4 parts of stabilizer.

[0055] Its preparation method comprises the following steps:

[0056] (1) Add 12 parts of PVC resin, 6 parts of light calcium carbonate, and 7 parts of nano-titanium oxide into the mixer, and knead for 11 minutes at 105°C; add 2 parts of MBS, 2 parts of SMA, and 4 parts of plasticizer , 4 parts of stabilizer, continue mixing for 6 minutes;

[0057] (2) The material after mixing is extruded and granulated by a single-screw extruder. The process conditions are that the body temperature is 130°C, the die temperature is 155°C, and the single-screw speed is 25r / min, and then by the injection molding machine. Injection molding at 172°C to obtain heat-resistant PVC shoe materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com