Micro-nano-alloy bimetal composite material preparation technique and device thereof

A composite material and preparation process technology, which is applied in the field of metal composite materials to achieve the effects of increased reaction driving force, increased contact area and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

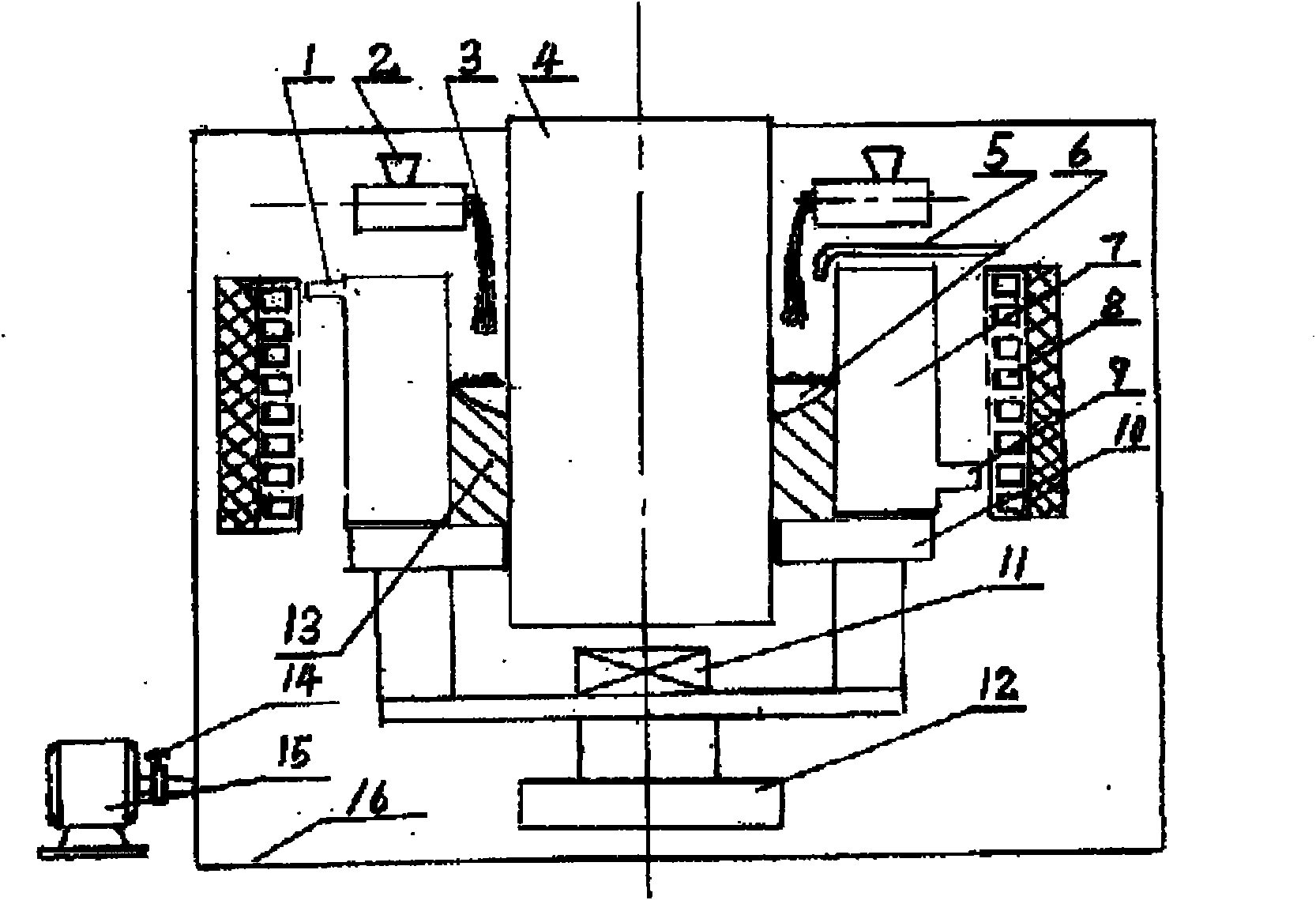

[0032] Example 1: figure 1 It is a vacuum induction cladding equipment. The equipment consists of water outlet pipe 1, particle feeder 2, alloy powder 3, workpiece 4, inert gas delivery pipe 5, molten pool 6, forming mold 7, frequency conversion induction heater 8, water inlet pipe 9, base 10, high-energy ultrasonic Vibrator 11, lifting and ingot drawing equipment 12, cladding layer 13, vacuum pump valve 14, vacuum motor 15, and vacuum sealing cover 16; 1 to 6 particle feeders 2 are installed on the upper part of the forming mold 7, and the A variable frequency induction heater 8 is installed on the outside of the molding die 7, a base 10 and a lifting ingot device 12 are installed on the bottom of the molding die 7, a high-energy ultrasonic vibrator 11 is installed on the bottom or upper part or side of the molding die 7, and an inert gas The conveying pipe 5 is installed on the top of the forming mold 7, and the vacuum sealing cover 11 seals the forming mold 7 equipment. Th...

Embodiment 2

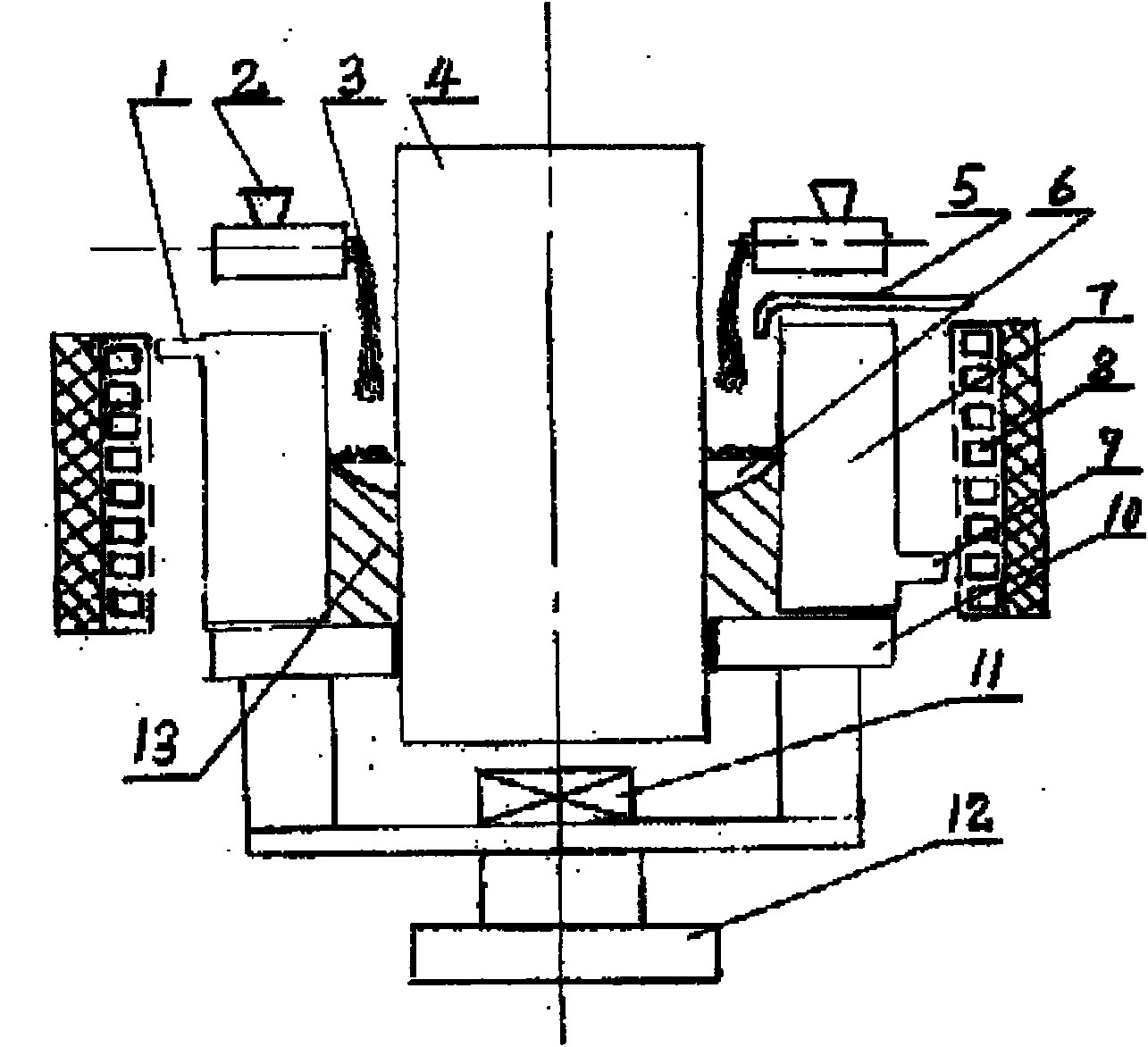

[0034] Example 2: In figure 2 in, with figure 1 The difference is that the induction cladding equipment is not installed in a vacuum sealed enclosure.

[0035] When work starts, first put Cr 12 MoV cold work die steel is prepared into powder, or metal and alloy powder according to Cr 12 The alloy composition of MoV cold work die steel material is prepared, and then 0.4% Y is added in it according to the mass percentage 3 o 2 , 0.6% MgO, 0.5% CaF 2 , 0.25% Nb, 0.30% TiB, 0.15% TiN, 0.25% VN, and the rest is Fe. After proportioning its component raw materials, put them into a high-energy stirring ball mill for stirring ball milling to prepare micro-nano or nano-alloy powders; then Add 8% rosin oil binder to the above alloy powder, make it into granules or powder after mixing, dry it in the air or dry it at a temperature of 80 degrees, add it to the granule feeder, and clean the surface The processed workpiece 4 is placed in the forming mold 7, the forming mold 7 is fixed ...

Embodiment 3

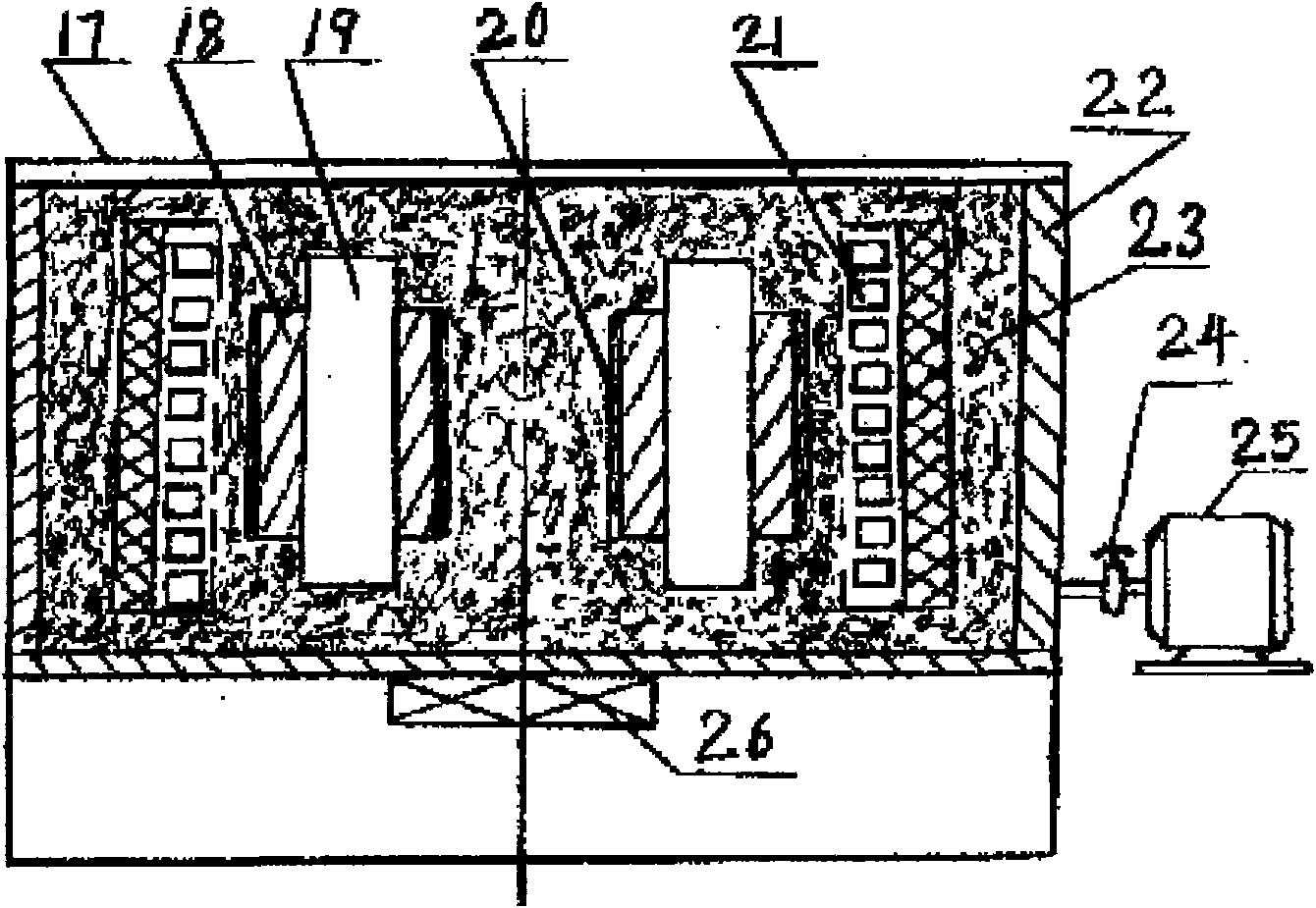

[0037] Example 3: image 3 It is a vacuum induction melting equipment. The equipment consists of box cover 17, cladding layer 18, workpiece 19, protective coating 20, frequency conversion induction heater 21, box body 22, manufacturing sand 23, vacuum pump valve 24, vacuum pump motor 25, vibrator 26, frequency conversion induction heater 21 is installed inside the box body 22, and the vibrator 26 is installed on the bottom or side of the box body 22. The vibrator 22 is mechanical vibration or ultrasonic vibration. The frequency of the frequency conversion induction heater 21 can be divided into steps from 200Hz to 500kHz. To adjust, the vacuum pump is installed on either side of the casing 22, and is connected with the vacuum pump valve 24 and the vacuum pump through a pipeline.

[0038] At the beginning of the work, the high chromium cast iron is first prepared into powder, or metal and alloy powder are used according to Cr 12 The alloy composition of MoV cold work die stee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com