Surface powder coating and laser treatment method for improving mechanical performance of tungsten-copper alloy

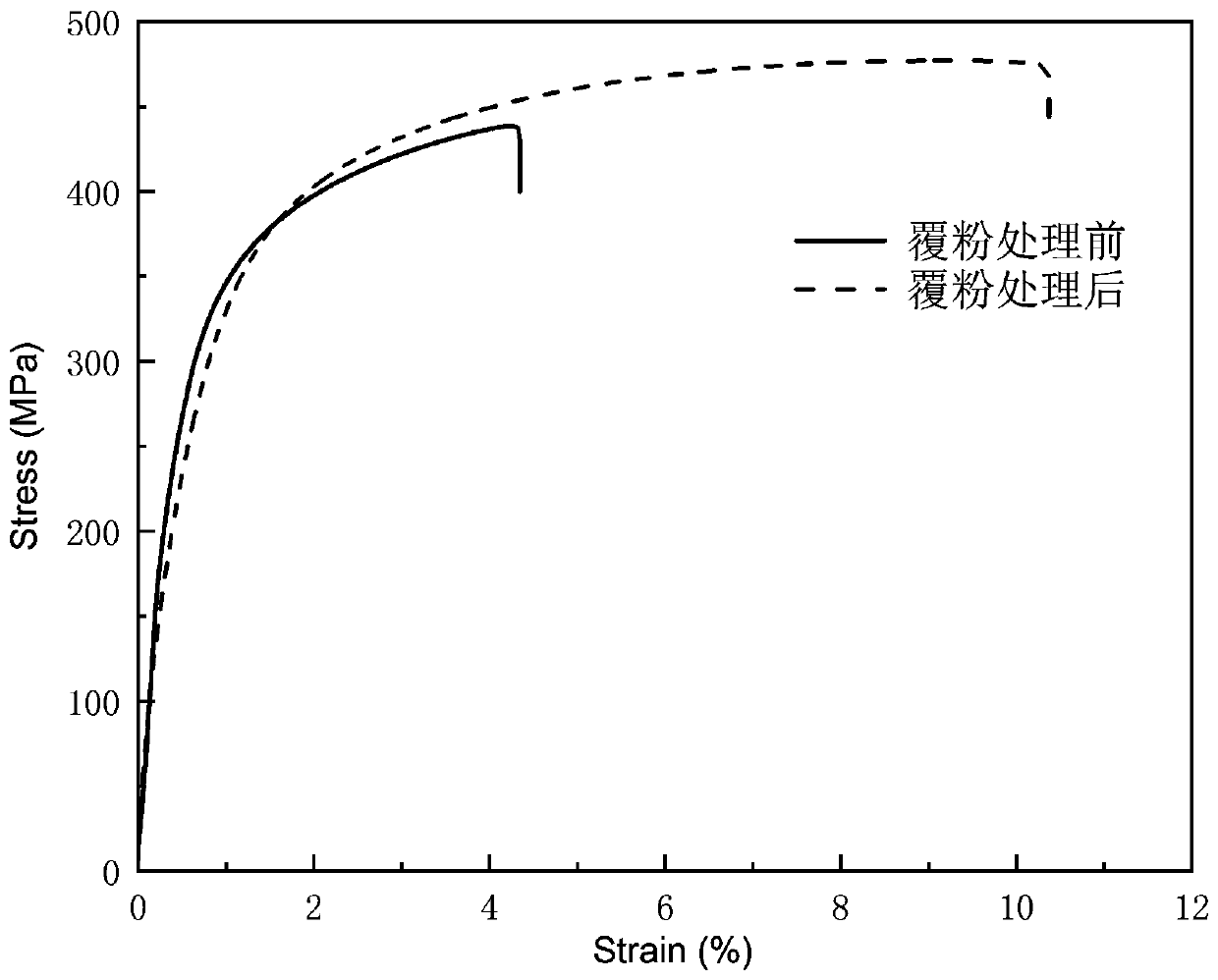

A tungsten-copper alloy and laser processing technology are applied in the direction of improving energy efficiency, process efficiency, and additive manufacturing. Cost, improvement of strength and plastic deformation ability, effect of preventing crack initiation and propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1, mixing ultrafine / nanocrystalline powder

[0030] The ultrafine crystal or nanocrystalline tungsten powder is mixed with copper powder to obtain ultrafine crystal / nanocrystalline tungsten copper powder; the above mixed powder is composed of 30% tungsten and 70% copper respectively by mass percentage;

[0031] Step 2, powder the surface

[0032] Place the tungsten-copper alloy on the substrate of the selective laser melting equipment workbench, then cover the surface of the tungsten-copper alloy with the ultra-fine crystal / nanocrystalline tungsten-copper powder obtained in step 1, with a thickness of 10nm, close the hatch and vacuumize After filling with argon;

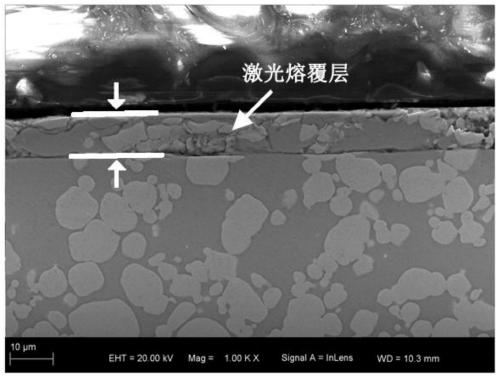

[0033] Step 3, Laser Treatment

[0034] Scan the ultra-fine crystal / nanocrystalline tungsten copper powder coated in step 2 by the laser beam of the selective laser melting equipment. The specific laser surface treatment parameters are: laser power 20W, scanning speed 50mm / s, scanning distance 0.01mm, a...

Embodiment 2

[0036] Step 1, mixing ultrafine / nanocrystalline powder

[0037] Ultrafine crystal or nanocrystalline tungsten powder is mixed with copper powder to obtain ultrafine crystal / nanocrystalline tungsten copper powder; the above mixed powder is composed of 95% tungsten and 5% copper respectively by mass percentage.

[0038] Step 2, powder the surface

[0039] Place the tungsten-copper alloy on the substrate of the selective laser melting equipment workbench, and then cover the surface of the tungsten-copper alloy with the ultra-fine crystal / nanocrystalline tungsten-copper powder obtained in step 1, with a thickness of 500 μm, close the hatch and vacuumize Then fill with nitrogen.

[0040] Step 3, Laser Treatment

[0041] Scan the ultra-fine crystal / nanocrystalline tungsten copper powder coated in step 2 through the laser beam of the selective laser melting equipment. The specific laser surface treatment parameters are: laser power 1000W, scanning speed 1500mm / s, scanning distance ...

Embodiment 3

[0043] Step 1, mixing ultrafine / nanocrystalline powder

[0044] Ultrafine crystal or nanocrystalline tungsten powder is mixed with copper powder to obtain ultrafine crystal / nanocrystalline tungsten copper powder; the above mixed powder is composed of 50% tungsten and 50% copper respectively by mass percentage.

[0045] Step 2, powder the surface

[0046] Place the tungsten-copper alloy on the substrate of the workbench of the selective laser melting equipment, and then cover the surface of the tungsten-copper alloy with the ultra-fine crystal / nanocrystalline tungsten-copper powder obtained in step 1, with a thickness of 100 μm, close the hatch and vacuumize Then filled with argon.

[0047] Step 3, Laser Treatment

[0048] Scan the ultra-fine crystal / nanocrystalline tungsten copper powder coated in step 2 by the laser beam of the selective laser melting equipment. The specific laser surface treatment parameters are: laser power 500W, scanning speed 1000mm / s, scanning distance...

PUM

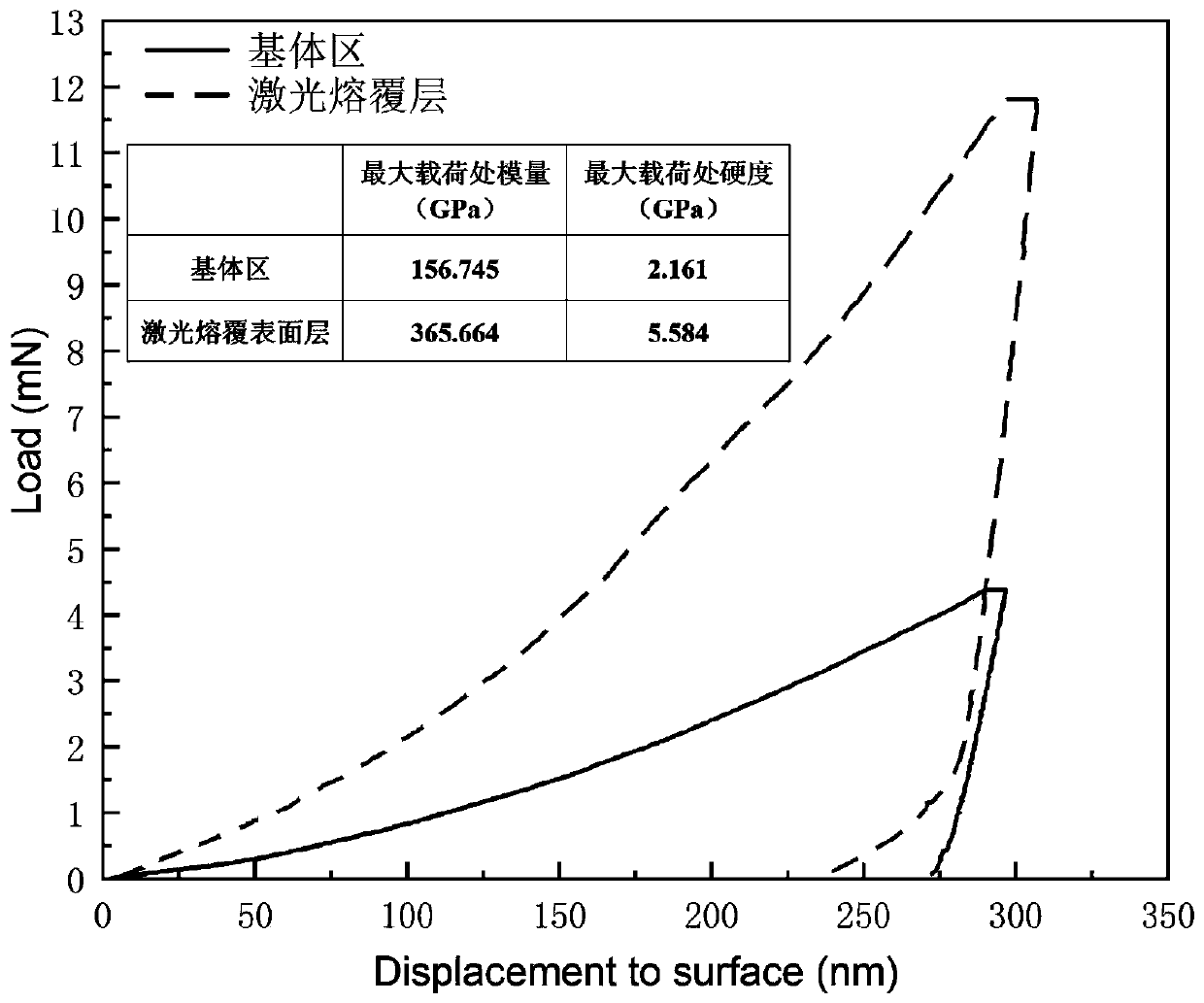

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com