Well cementation oil well cement composition and preparation method thereof

A technology of oil well cement and composition, which is applied in the field of oil well cement composition and its preparation, can solve the problems of easy and rapid decline and aging of cement cement strength, and achieve the effect of enhancing mechanical properties, preventing occurrence and expansion, and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

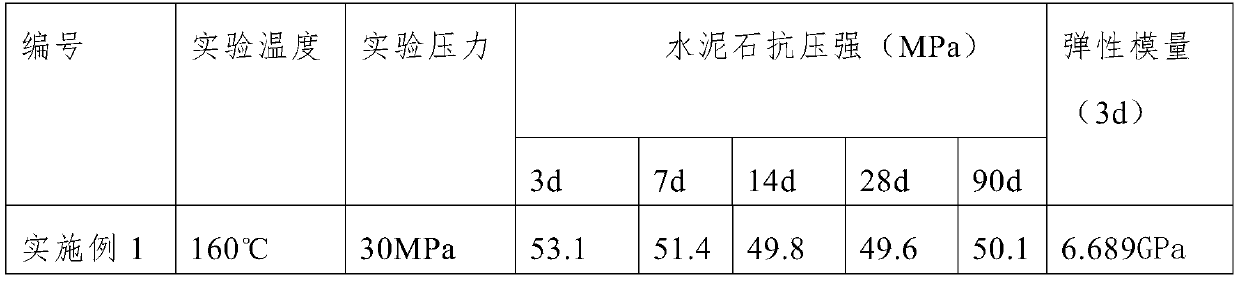

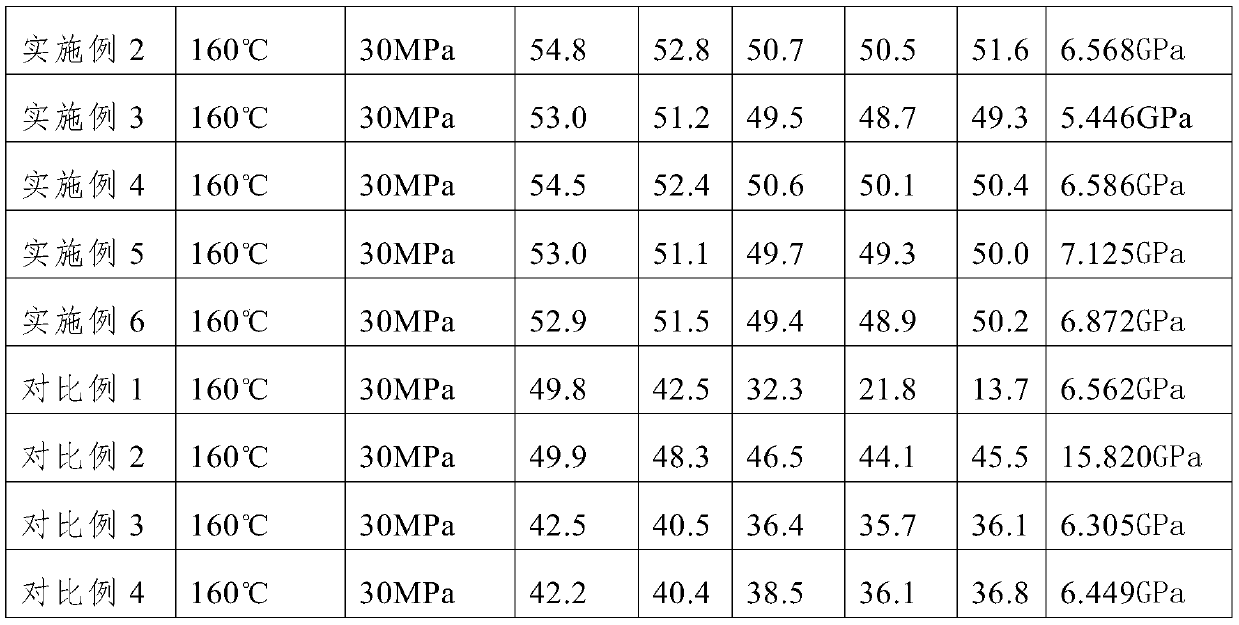

Examples

Embodiment 1

[0062] This embodiment provides an oil well cement composition for well cementing, including parts by mass: 60 parts of clinker, 8 parts of anti-strength recession agent, 4 parts of brittleness reducing and toughening agent, 4 parts of high temperature strengthening agent, 20 parts of BFS, 1.5 parts of dispersant. BFS is composed of the following raw materials by weight percentage: CaO35-45%, SiO 2 30-40%, Al 2 O 3 10-18%, MgO 5-12%, Fe 2 O 3 0.2-1%, MnO 0.2-1%, SO 3 1-5%. The anti-strength decay agent is wollastonite powder, and the brittleness reducing and toughening agent is high elastic modulus PVA fiber, low elastic modulus polypropylene fiber, and calcium sulfate whiskers mixed in a ratio of 1:1:10; the high temperature reinforcing agent is nano SiO 2 Sol (size range 1-100nm); dispersant is APC. Preparation method: ball mill BFS and clinker, and grind it to a specific surface area of about 3000cm 2 / g, after adding other components, mixing again to obtain the oil wel...

Embodiment 2

[0064] In this example, on the basis of example 1, the strength-reducing agent is changed to wollastonite powder and metakaolin mixed in a mass ratio of 1:4. Others are the same as in Example 1.

Embodiment 3

[0066] This embodiment is on the basis of embodiment 1, the brittleness reducing and toughening agent is changed to a composition composed of carbon fiber and waterborne epoxy resin containing curing agent, wherein the mass ratio of carbon fiber and waterborne epoxy resin containing curing agent is 1:5 , And control the content of carbon fiber in the oil well cement composition to 0.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com